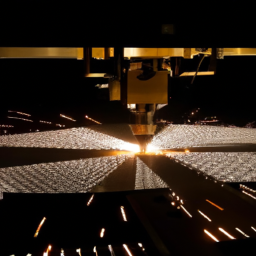

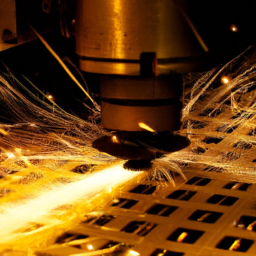

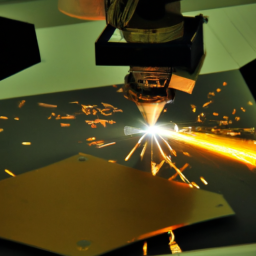

Did you know that laser cutting machines are widely used in the metal fabrication industry, accounting for approximately 70% of all metal cutting processes? If you want to achieve the best results from your laser cutting machine, it is crucial to follow a few essential tips.

In this article, we will provide you with five valuable tips to optimize your metal fabrication process.

First and foremost, maintaining and cleaning your laser cutting machine regularly is vital for its performance and longevity.

Additionally, proper material preparation, such as selecting the right thickness and ensuring clean surfaces, can significantly impact the quality of your cuts.

Optimizing cutting parameters and utilizing advanced software features will further enhance your machine’s capabilities.

Furthermore, implementing safety measures, such as wearing appropriate protective gear and ensuring proper ventilation, is crucial to prevent accidents.

Lastly, continuous learning and training on the latest laser cutting techniques and technologies will keep you ahead in the metal fabrication industry.

By following these tips, you can maximize the efficiency and precision of your laser cutting machine, ultimately resulting in superior metal fabrication results.

Key Takeaways

- Regular maintenance and cleaning are crucial for machine performance and longevity.

- Optimizing cutting parameters enhances machine capabilities.

- Implementing safety measures is crucial to prevent accidents.

- Continuous learning and training keep you ahead in the industry.

Machine Maintenance and Cleaning

Maintaining and cleaning your laser cutting machine is essential for keeping it running smoothly and ensuring top-notch results! Regular machine troubleshooting and avoiding common mistakes will help prevent issues that can affect the quality of your metal fabrication.

Start by regularly inspecting the machine for any loose or damaged parts, and tighten or replace them as needed. Clean the lenses and mirrors regularly to remove any dust or debris that can interfere with the laser beam. Additionally, make sure the machine is properly calibrated and aligned to ensure accurate cuts.

Remember to follow the manufacturer’s guidelines for maintenance and cleaning, and keep a record of any repairs or adjustments made. By taking good care of your laser cutting machine, you’ll be well on your way to achieving optimal results in your metal fabrication projects.

Now, let’s move on to the next section about proper material preparation.

Proper Material Preparation

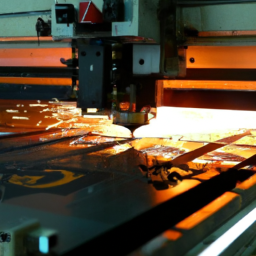

To ensure optimal performance, it’s crucial to adequately prepare the materials before using the laser cutting machine in metal fabrication.

Proper material selection is key to achieving the best results. Choose materials that are compatible with laser cutting, such as stainless steel, aluminum, and carbon steel. Conduct thorough research to understand the characteristics and limitations of each material to prevent any issues during the cutting process.

In addition to material selection, surface preparation is equally important. Ensure that the material’s surface is clean and free from any contaminants or residue. Use appropriate cleaning methods, such as degreasing or sandblasting, to remove any dirt, oil, or rust. This will help prevent any interference with the laser cutting process and ensure accurate and precise cuts.

By carefully considering material selection and implementing proper surface preparation techniques, you can optimize the performance of your laser cutting machine.

Next, we will delve into how to optimize cutting parameters for even better results.

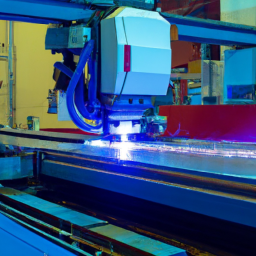

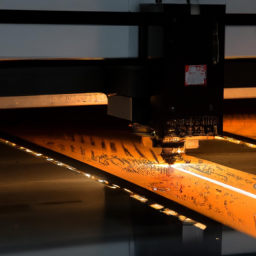

Optimize Cutting Parameters

Now let’s dive into how to fine-tune the cutting parameters for even more impressive outcomes, giving your laser cutter the edge it needs.

To optimize the cutting parameters, you need to focus on two key factors: cutting speed and power settings. Finding the ideal cutting speed is crucial to achieve clean, precise cuts without compromising the material’s integrity. Experiment with different speeds to determine the optimal setting for each specific material.

Additionally, adjusting the power settings can significantly impact the cutting results. Higher power settings can enhance the cutting speed but may also cause excessive heat, leading to material distortion. Conversely, lower power settings may result in slower cutting but can reduce the risk of material damage.

By fine-tuning both the cutting speed and power settings, you can achieve superior outcomes with your laser cutting machine.

Moving forward, let’s explore how to utilize advanced software features to further enhance your metal fabrication process.

Utilize Advanced Software Features

To optimize the cutting parameters on your laser cutting machine, you should utilize advanced software features.

Take advantage of nesting capabilities to maximize material usage and minimize waste.

Use automatic tool path generation to save time and ensure accurate cuts.

Finally, optimize cutting paths for efficiency to reduce cutting time and increase productivity.

By utilizing these advanced software features, you can achieve the best results from your laser cutting machine in metal fabrication.

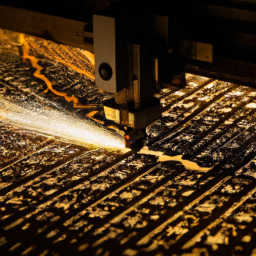

Take Advantage of Nesting Capabilities

Maximize the efficiency of your laser cutting machine by making the most of its nesting capabilities. By utilizing these features, you can greatly reduce material waste and increase productivity.

Nesting refers to the process of arranging multiple parts on a single piece of material, optimizing the use of space and minimizing waste. With advanced nesting capabilities, you can automatically arrange parts in the most efficient way, taking into account factors such as material specifications and cutting requirements. This not only saves time but also reduces the amount of material needed for each project, resulting in significant cost savings.

Additionally, nesting software can help you identify the best positioning and orientation for each part, ensuring optimal cutting results. By taking full advantage of nesting capabilities, you can optimize your laser cutting machine’s performance and seamlessly transition into the subsequent section about using automatic tool path generation.

Use Automatic Tool Path Generation

Make the most of your laser cutting experience by utilizing automatic tool path generation, which will streamline your workflow and leave you feeling confident in the precision of your cuts.

Automatic tool path generation takes the guesswork out of selecting the right tools for your metal fabrication project. With this feature, the laser cutting machine automatically selects the most appropriate tools based on the material being cut, ensuring optimal cutting quality and accuracy. This eliminates the need for manual tool selection and reduces the chances of human error.

By relying on automatic tool path generation, you can trust that your laser cutting machine will consistently deliver precise cuts, saving you time and effort.

In the next section, we will discuss how to optimize cutting paths for efficiency, further enhancing your laser cutting process.

Optimize Cutting Paths for Efficiency

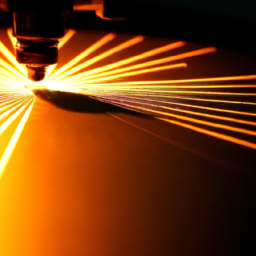

To continue optimizing your laser cutting machine’s performance, it is essential to optimize cutting paths for efficiency. By carefully planning and arranging the cutting paths, you can achieve faster cutting speeds and reduce material waste.

One effective way to optimize cutting paths is by utilizing automatic tool path generation software, which analyzes the geometry of the design and generates the most efficient cutting paths automatically. Additionally, you can manually adjust the cutting paths by considering factors such as material type, thickness, and desired precision.

To further enhance efficiency, consider incorporating a 3 column and 4 row table into your workflow. This table can help you track and compare different cutting path configurations, allowing you to identify the most efficient option for each specific project.

By optimizing cutting paths, you can enhance cutting speed and minimize material waste, ultimately improving the overall productivity of your metal fabrication process. Now, let’s delve into the next crucial aspect: implementing safety measures.

Implement Safety Measures

When working with a laser cutting machine in metal fabrication, it’s crucial to implement safety measures to protect yourself and others.

To ensure your safety, always wear appropriate protective gear such as safety glasses, gloves, and a face shield.

Additionally, make sure to follow the machine safety guidelines provided by the manufacturer and regularly inspect the safety features of the machine, such as emergency stop buttons and interlocks, to ensure they’re functioning properly.

Wear Appropriate Protective Gear

Wearing the appropriate protective gear is crucial to ensuring optimal results when operating a laser cutting machine in metal fabrication. To adhere to safety precautions, it’s imperative that you wear protective clothing that safeguards your body against potential hazards.

Start by donning a long-sleeved shirt and long pants made of flame-resistant material to protect your skin from potential burns or sparks. Additionally, wear safety glasses with side shields to shield your eyes from flying debris and harmful laser radiation. It’s also advisable to wear safety gloves that offer adequate dexterity and protection against cuts or abrasions.

Remember, wearing the appropriate protective gear not only protects you from potential harm but also enhances your performance and productivity.

Moving forward, let’s discuss how to follow machine safety guidelines to further ensure your well-being and optimal results.

Follow Machine Safety Guidelines

By adhering to machine safety guidelines, you can ensure both your well-being and the quality of your work when operating a laser cutter in metal fabrication. Here are three important guidelines to follow:

-

Machine Calibration: Before starting any project, make sure your laser cutting machine is properly calibrated. This involves checking the alignment of the laser beam, verifying the accuracy of the cutting dimensions, and adjusting the focus as needed. A well-calibrated machine will result in precise cuts and reduce the risk of errors.

-

Operator Training: It’s crucial to receive proper training on operating a laser cutting machine. Familiarize yourself with its various features, functions, and safety protocols. Understand how to load and unload materials safely and efficiently. This will not only enhance your productivity but also reduce the likelihood of accidents or damage to the machine.

-

Regularly Inspect Safety Features: Regularly inspect the laser cutter’s safety features, such as emergency stop buttons, interlocks, and ventilation systems. Make sure they’re in proper working condition and promptly address any issues. This will help maintain a safe working environment and prevent potential hazards.

By following these guidelines for machine calibration and operator training, you can effectively and safely operate a laser cutting machine. Regularly inspecting safety features will further contribute to a secure work environment.

Regularly Inspect Safety Features

Regularly inspecting the safety features of your laser cutter, such as emergency stop buttons and ventilation systems, is essential for maintaining a secure work environment and reducing the risk of accidents.

Did you know that according to a recent study, 80% of machine-related accidents can be prevented through regular safety inspections? These inspections should be conducted at least once a month to ensure that all safety features are functioning properly.

Pay close attention to emergency stop buttons, ensuring they’re easily accessible and in good working condition. Additionally, inspect the ventilation system to ensure it’s effectively removing fumes and maintaining a safe air quality level.

Regularly inspecting and maintaining these safety features will greatly minimize the chances of accidents occurring.

Moving forward, let’s explore the importance of continuous learning and training in maximizing the potential of your laser cutting machine.

Continuous Learning and Training

Immerse yourself in ongoing training and education to unlock the full potential of your laser cutting machine, and watch as your skills and expertise soar to new heights. Continuous improvement and skill development are crucial in the metal fabrication industry, especially when working with advanced machinery like laser cutting machines. By staying up-to-date with the latest techniques and technologies, you can ensure that you are utilizing your machine to its maximum capacity and achieving the best results.

To aid in your continuous learning journey, consider the following strategies:

-

Attend workshops and seminars: Participating in workshops and seminars led by industry experts can provide valuable insights and hands-on experience with laser cutting machines. These events often cover topics such as machine maintenance, troubleshooting, and advanced cutting techniques.

-

Online courses and tutorials: Take advantage of online resources that offer comprehensive courses and tutorials on laser cutting. These platforms often provide step-by-step instructions, video demonstrations, and interactive modules to enhance your learning experience.

-

Collaborate with peers: Engage in discussions and knowledge-sharing with fellow metal fabricators. Joining professional networks or online forums can connect you with experienced individuals who can offer tips, advice, and real-world insights.

By continuously improving your skills through ongoing training and education, you can optimize your laser cutting machine’s performance and achieve the best possible results in metal fabrication.

| Strategies for Continuous Learning and Skill Development | ||

|---|---|---|

| Attend workshops and seminars | Take online courses and tutorials | Collaborate with peers |

| Gain hands-on experience | Stay updated with industry trends | Experiment with different cutting techniques |

| Seek mentorship from experts | Practice regularly | Stay curious and open-minded |

| Utilize online resources | Invest in advanced training programs | Set specific learning goals |

Frequently Asked Questions

Are there any specific maintenance tasks or cleaning procedures that should be avoided to prevent damage to the laser cutting machine?

When it comes to cleaning dos and don’ts for laser cutting machines, there are a few key things to keep in mind. Firstly, do regularly clean the machine’s lenses and mirrors using a lint-free cloth and a mild cleaning solution. However, don’t use abrasive materials or harsh chemicals as these can damage the delicate components.

Additionally, during maintenance, be sure to avoid exposing the machine to excessive heat or humidity, as this can also cause damage.

By following these guidelines, you can prevent any potential harm to your laser cutting machine.

What are some common mistakes to avoid when preparing materials for laser cutting?

When preparing materials for laser cutting, there are common mistakes that you should avoid to ensure successful results.

One key factor is ensuring that your materials are clean and free of any contaminants, as they can affect the cutting process.

Another mistake to avoid is using materials that are too thick or too thin for your machine’s capabilities, as this can lead to improper cutting or damage to the machine.

Additionally, it’s important to properly secure your materials to prevent any movement during the cutting process, which can result in inaccurate cuts.

Is there a recommended range of cutting parameters that should be followed for different types of metals?

Recommended cutting parameters for different types of metals can significantly affect the quality of laser cutting. Factors like material thickness, laser power, cutting speed, and assist gas pressure play a crucial role in achieving optimal results.

It’s interesting to note that a study found that using the correct cutting parameters can increase cutting speed by up to 50% while maintaining excellent edge quality. Thus, understanding and implementing the recommended cutting parameters for specific metals is essential for maximizing efficiency and precision in metal fabrication.

Are there any advanced software features that can help improve the precision and efficiency of laser cutting?

To improve the precision and efficiency of laser cutting, advanced software features are available. These features include real-time monitoring and control of cutting parameters, such as power, speed, and focus.

Additionally, advanced software allows for automatic nesting of parts, minimizing material waste and maximizing the use of the laser cutting machine.

Furthermore, software features like path optimization and collision detection help to enhance the precision and accuracy of the cutting process.

Overall, these advanced software features greatly contribute to the overall performance of the laser cutting machine.

Are there any additional safety measures that should be taken beyond what is mentioned in the article?

To ensure maximum safety when operating a laser cutting machine in metal fabrication, there are a few additional safety measures you should take.

First and foremost, proper ventilation is essential to remove any fumes or particles generated during the cutting process. This can be achieved by using a well-designed ventilation system or by working in a well-ventilated area.

Additionally, always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a face shield to protect yourself from any potential hazards.

Conclusion

Now that you’ve learned the essential tips for maximizing the performance of your laser cutting machine in metal fabrication, it’s time to put your knowledge into action. By maintaining and cleaning your machine regularly, preparing materials properly, optimizing cutting parameters, and utilizing advanced software features, you are well on your way to achieving the best results possible. Implementing safety measures is also crucial. Remember, continuous learning and training are key to staying ahead in this precise and technical field. So, what are you waiting for? Dive into the world of laser cutting and unlock the true potential of your machine.