Are you looking to achieve the best results from your subtractive laser cutting machine? Wondering how to optimize your designs for flawless cuts? Look no further! In this article, we will provide you with five expert tips that will help you get the most out of your laser cutting machine.

Have you ever wondered what makes subtractive laser cutting so effective? It’s all about understanding the basics. By familiarizing yourself with the principles behind this cutting technique, you’ll be able to make informed decisions and maximize your machine’s potential.

Selecting the right laser cutting machine is crucial. With so many options available, it’s essential to choose one that aligns with your specific needs and requirements. We’ll guide you through the selection process, helping you find the perfect machine for your projects.

But that’s not all! We’ll also share strategies for optimizing your design files, preparing materials, and testing and fine-tuning your settings. Plus, we’ll provide maintenance tips to keep your machine running smoothly.

So, if you’re ready to take your subtractive laser cutting to the next level, let’s dive right in!

Key Takeaways

- Understand the basics of subtractive laser cutting and the different types of laser cutting techniques.

- Choose the right laser cutting machine by considering factors such as machine power, size and thickness of materials, and reliable suppliers for compatible materials.

- Optimize design files for laser cutting by using vector-based design software and simplifying designs for improved accuracy and reduced production time.

- Maintain and clean the laser cutting machine regularly to ensure optimal performance, prevent breakdowns, and prolong its lifespan.

Understand the Basics of Subtractive Laser Cutting

Before diving into the world of subtractive laser cutting, it’s crucial to grasp the basics and unleash your inner creative genius! Understanding the fundamentals will help you make the most of your machine and achieve the best results.

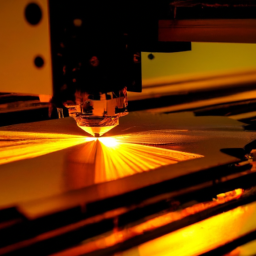

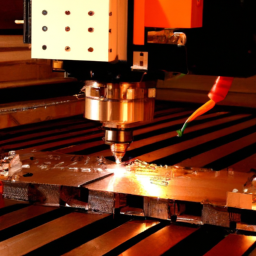

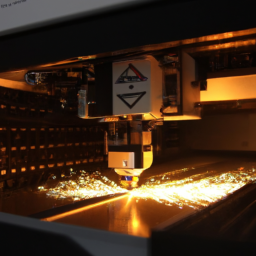

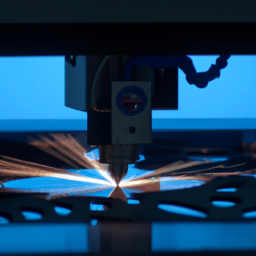

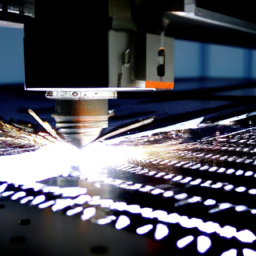

Subtractive laser cutting offers numerous advantages over additive manufacturing, such as precision, speed, and versatility. By removing material instead of adding it, you can create intricate designs with fine details.

There are different types of laser cutting techniques available, including CO2 laser cutting and fiber laser cutting, each with its own strengths and applications.

As you delve into the world of subtractive laser cutting, remember to choose the right laser cutting machine for your needs. This will ensure that you can bring your ideas to life with ease and efficiency.

Choose the Right Laser Cutting Machine for Your Needs

When choosing the right laser cutting machine for your needs, consider the power and capabilities of different machines.

Determine the size and thickness of materials you’ll be working with to ensure the machine can handle them effectively.

Research and compare different brands and models to find the best fit for your requirements.

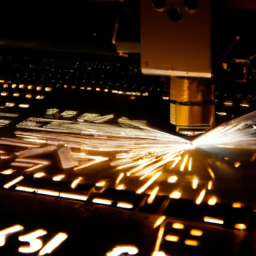

Consider the power and capabilities of different machines

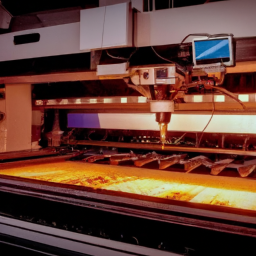

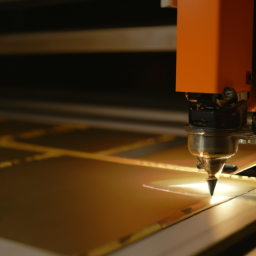

One important factor to consider is the power and capabilities of different laser cutting machines. This will greatly impact the quality and precision of your cuts. For instance, a high-powered machine with a CO2 laser can easily cut through thick materials like acrylic or wood. It allows for intricate designs and detailed engravings. However, it’s important to note that with increased power comes increased safety precautions. Make sure to follow all recommended safety guidelines, such as wearing protective eyewear and ensuring proper ventilation in your workspace. Taking these precautions will ensure that you can work with the power and precision of the machine without compromising your safety.

Now that you understand the importance of machine power, it’s time to determine the size and thickness of materials you will be working with.

Determine the size and thickness of materials you will be working with

To ensure optimal performance and avoid any limitations, assess the size and thickness of materials you’ll be working with. Determining suitable materials is crucial in getting the best results from your subtractive laser cutting machine.

Consider the maximum size and thickness that your machine can handle, and then find reliable suppliers who can provide you with the appropriate materials. Look for suppliers who have a good reputation for delivering high-quality materials that meet your specifications. It’s important to have a consistent supply of materials that are compatible with your machine’s capabilities.

Once you have determined the suitable materials and found reliable suppliers, you can move on to the next step, which is to research and compare different brands and models to find the best fit for your requirements.

Research and compare different brands and models to find the best fit for your requirements

Researching and comparing different brands and models can help you discover the perfect laser cutting machine that meets all your requirements. Here are some tips to make your research process easier and more effective:

-

Pricing comparison: Look for machines within your budget range and compare the features they offer.

-

Customer reviews and satisfaction rankings: Read reviews from other users to get insights into the performance and reliability of different machines.

-

Machine specifications: Consider factors like cutting speed, power, precision, and ease of use when comparing different models.

-

Software compatibility: Check if the machine is compatible with the design software you use to ensure seamless integration.

-

After-sales support: Look for brands that offer good customer support and warranty options.

By researching and comparing different brands and models, you can find a laser cutting machine that fits your budget and meets your specific needs. Once you’ve chosen the right machine, you can proceed to optimize your design files for laser cutting.

Optimize Your Design Files for Laser Cutting

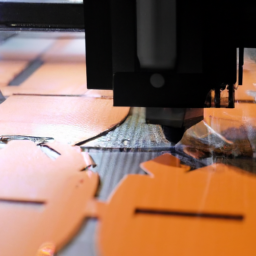

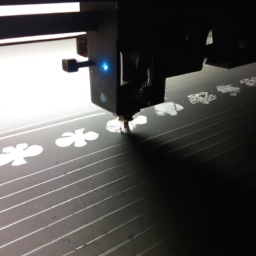

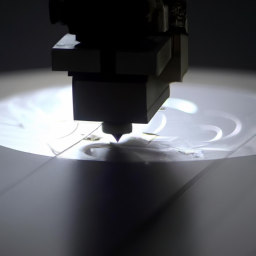

Get the most out of your laser cutting machine by optimizing your design files to ensure the best results possible. Design optimization is crucial when it comes to laser cutting techniques.

Start by using vector-based design software, such as Adobe Illustrator or CorelDRAW, to create your design files. This will allow for precise lines and shapes that can be easily interpreted by the laser cutting machine. Make sure to convert all text to outlines to avoid any font compatibility issues.

Additionally, simplify your design by removing unnecessary elements and combining shapes whenever possible. This will not only improve cutting accuracy but also reduce production time. By optimizing your design files, you’ll be able to achieve cleaner cuts and more intricate designs.

Now, let’s transition into the next section about how to prepare your materials for cutting.

Prepare Your Materials for Cutting

Ensure that you properly prepare your materials before cutting to achieve optimal results with your laser cutter. Here are some laser cutting techniques to help you troubleshoot common cutting issues:

-

Clean your materials: Dust and debris can interfere with the cutting process, so make sure to clean your materials thoroughly before cutting.

-

Secure your materials: Use clamps or adhesive tape to secure your materials in place to prevent them from moving during the cutting process.

-

Choose the right settings: Adjust the power, speed, and focus of your laser cutter based on the material you’re cutting to ensure clean and precise cuts.

-

Test and fine-tune: Before cutting your final design, it’s always a good idea to test your settings on a small scrap piece of material. This’ll allow you to make any necessary adjustments and ensure that you’re getting the best results.

Now that you’ve prepared your materials, let’s move on to the next step of testing and fine-tuning your settings.

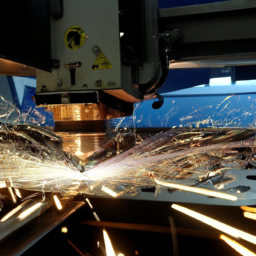

Test and Fine-Tune Your Settings

Now that you have prepared your materials for cutting, it’s time to move on to the next crucial step: testing and fine-tuning your settings. This is an essential part of ensuring that you get the best results from your subtractive laser cutting machine. By conducting tests and calibration, you can troubleshoot any issues and solve problems that may arise during the cutting process. It allows you to fine-tune the power, speed, and focus settings to achieve optimal results for different materials. To help you understand the importance of this step, here is a visual representation of the key ideas:

| Test and Calibration | Troubleshooting and Problem Solving |

|---|---|

| Fine-tune settings | Identify and fix issues |

| Optimize power, speed, and focus | Ensure optimal cutting results |

By investing time in testing and fine-tuning, you can ensure that your subtractive laser cutting machine performs at its best. This will lead to high-quality cuts and minimize any potential problems. Now, let’s move on to the next section to learn how to maintain and clean your laser cutting machine.

Maintain and Clean Your Laser Cutting Machine

Take some time to properly maintain and clean your laser cutting machine to ensure its longevity and optimal performance. Here are three essential maintenance tasks to help maintain machine performance and prevent laser cutting machine breakdowns:

-

Regularly clean the lens: Use a soft cloth and lens cleaning solution to gently wipe the lens of your laser cutting machine. This will remove any dust or debris that may have accumulated, ensuring the laser can pass through cleanly and accurately.

-

Check and clean the exhaust system: The exhaust system plays a crucial role in removing smoke, fumes, and debris from the cutting area. Regularly inspect and clean the exhaust system, removing any clogs or blockages to maintain proper ventilation and prevent overheating.

-

Lubricate moving parts: Proper lubrication of the moving parts is vital to prevent friction and ensure smooth operation. Keep an eye on the belts, gears, and bearings, and apply lubricant as recommended by the manufacturer to keep everything running smoothly.

By following these maintenance tasks, you can prolong the lifespan of your laser cutting machine and avoid costly breakdowns or performance issues.

Frequently Asked Questions

How much does a subtractive laser cutting machine cost?

The cost of a subtractive laser cutting machine can vary depending on several factors. These factors include the size and power of the machine, the type of materials it can cut, and any additional features or accessories it may have.

Additionally, you should consider the maintenance requirements of the machine, such as regular cleaning and replacing consumable parts. It’s important to factor in these costs when budgeting for a subtractive laser cutting machine.

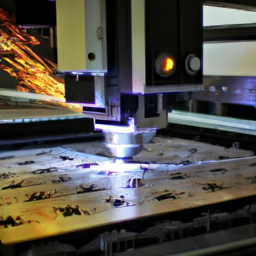

Can a subtractive laser cutting machine cut through metal?

Yes, a subtractive laser cutting machine can cut through metal, which is one of its many advantages. These machines utilize a high-powered laser beam to remove material and create precise cuts.

In addition to metal, they can also cut through materials like wood, acrylic, fabric, and more. This versatility makes them a popular choice for various industries, such as manufacturing, automotive, and jewelry.

The ability to cut through different materials efficiently is a significant benefit of using a subtractive laser cutting machine.

What safety precautions should be taken while operating a laser cutting machine?

When operating a laser cutting machine, it’s crucial to prioritize safety precautions. First, ensure proper ventilation to prevent the accumulation of harmful fumes.

Regular laser cutting machine maintenance is also essential for optimal performance and to minimize the risk of accidents. This includes cleaning the machine and checking for any loose parts or damaged components.

By following these precautions, you can ensure a safe and efficient operation of your laser cutting machine.

What is the average lifespan of a laser cutting machine?

The average lifespan of a laser cutting machine depends on various factors. Proper maintenance is key to keeping it running smoothly for as long as possible. Factors such as usage frequency, intensity of laser beams, and regular cleaning all play a role in determining its lifespan. By taking good care of your machine and conducting routine maintenance, you can extend its lifespan and ensure optimal performance.

Can a laser cutting machine be used for engraving purposes as well?

Yes, a laser cutting machine can be used for engraving purposes as well. Laser cutting machines have engraving capabilities that allow you to create intricate and precise designs on various materials.

From wood and acrylic to metal and glass, the applications of a laser cutting machine are vast. With its high-powered laser beam, it can etch detailed patterns, logos, and text onto different surfaces, making it a versatile tool for both cutting and engraving.

Conclusion

So there you have it, my friend! By following these five tips, you’ll surely get the best results from your subtractive laser cutting machine.

Remember to understand the basics and choose the right machine.

Optimize your designs and prepare your materials.

Test and fine-tune your settings.

And don’t forget to maintain and clean your machine regularly to keep it running smoothly.

With these tricks up your sleeve, you’ll be cutting through materials like a hot knife through butter in no time!