Did you know that the average lifespan of a laser cutter is only around 5 to 7 years? That’s a relatively short amount of time considering the investment you’ve made in your machine. But fear not! There are ways to extend the lifespan of your laser cutter and ensure it continues to perform at its best for years to come.

In this article, we’ll introduce you to the top 5 products that can help you achieve just that.

First up, protective covers. These shields are designed to keep dust, debris, and other contaminants away from your machine, preventing any potential damage.

Next, cleaning solutions specifically formulated for laser cutters are essential for maintaining optimal performance. They effectively remove residue and grime, ensuring your machine operates at peak efficiency.

A lens cleaning kit is another must-have. Regularly cleaning the lens not only improves the quality of your cuts but also extends the lifespan of your laser cutter.

Additionally, an air assist nozzle helps to clear away debris and improve the cutting process.

Lastly, don’t forget about maintaining the cooling system. A cooling system maintenance kit ensures that your machine stays cool, preventing overheating and potential damage.

By utilizing these top 5 products, you can significantly prolong the lifespan of your laser cutter, saving you time, money, and the frustration of unexpected breakdowns. Let’s dive into the details and explore how each product can benefit your machine.

Key Takeaways

- Regular maintenance and cleaning practices are essential for extending the lifespan of a laser cutter.

- Using protective covers and cleaning solutions can prevent dust, debris, and damage to delicate components.

- Investing in high-quality lenses and laser tubes can improve precision, speed, and overall performance.

- Promptly replacing worn-out or damaged components and conducting regular inspections and preventive maintenance are crucial for minimizing downtime and maximizing productivity.

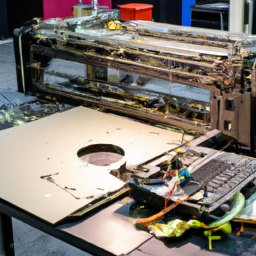

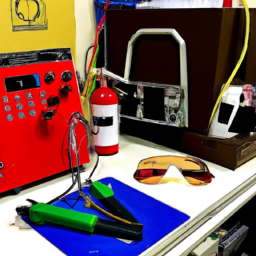

Protective Covers

Don’t let your laser cutter suffer from wear and tear – protect it with these top-notch covers!

Protective covers are essential for keeping your machine safe from dust, debris, and accidental damage. These covers are made from high-quality materials that provide a barrier against scratches and impacts. They’re designed to fit snugly over your laser cutter, ensuring a secure and reliable fit.

Additionally, some covers come with a lens cleaning kit, which includes all the necessary tools for keeping your cutter’s lens clean and free from dirt or smudges. Proper maintenance and protection will significantly extend the lifespan of your laser cutter and ensure optimal performance.

Now, let’s move on to the next section about cleaning solutions, which will help you keep your machine in pristine condition.

Cleaning Solutions

To maintain the cleanliness of your laser cutter, it’s crucial to use appropriate cleaning solutions. These solutions effectively remove residue and buildup, ensuring optimal performance of your machine. By regularly cleaning your laser cutter, you can prevent damage to delicate components. This prolongs the lifespan of your equipment and ensures consistent and precise laser cutting results.

Maintain the cleanliness of your laser cutter

Ensure you regularly clean the lenses, mirrors, and debris tray of your laser cutter to keep it running smoothly and efficiently. Cleaning these components is crucial to maintaining the cleanliness of your machine and preventing any buildup that can lead to decreased performance or damage. Use a lint-free cloth and a mild cleaning solution specifically designed for laser cutters to gently wipe the lenses and mirrors. Make sure to follow the manufacturer’s instructions for cleaning techniques and frequency. Additionally, empty and clean the debris tray regularly to remove any dust, debris, or residue that may have accumulated during operation. By incorporating a regular maintenance schedule and proper cleaning techniques, you can extend the lifespan of your laser cutter and ensure optimal performance. Transitioning into the next section, removing residue and buildup is essential for maintaining the machine’s efficiency.

Remove residue and buildup for optimal performance

Keep your laser cutter running at its best by regularly removing residue and buildup for optimal performance. Residue and buildup can accumulate on the lens, mirrors, and other components of your laser cutter, diminishing its efficiency and affecting the quality of the cuts and engravings.

To remove residue, use a lint-free cloth or cotton swab dampened with isopropyl alcohol. Gently wipe the affected areas, ensuring that you don’t scratch or damage any delicate components. For stubborn residue, you can use a specialized cleaning solution recommended by the laser cutter manufacturer.

Regularly cleaning your laser cutter will enhance its performance and extend its lifespan. By removing residue and buildup, you can prevent damage to delicate components and ensure that your laser cutter operates at its full potential, producing precise and high-quality results.

Prevent damage to delicate components

Avoiding damage to delicate components is like safeguarding the heart of your laser cutter. To prevent overheating, it’s crucial to ensure proper ventilation within the machine. Make sure the cooling fans and vents are clean and free from any obstructions that may impede the airflow. Regularly check for dust accumulation and clean it to maintain optimal performance.

Additionally, consider installing a temperature monitoring system that alerts you if the machine exceeds safe operating temperatures. Properly managing the heat generated by the laser cutter will prolong the lifespan of its delicate components.

Now that you understand the importance of preventing damage, let’s explore the next section about the ‘lens cleaning kit’ for maintaining clear and precise laser cuts.

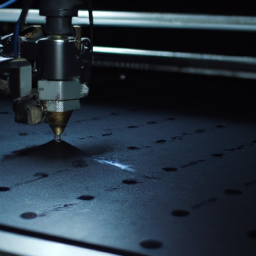

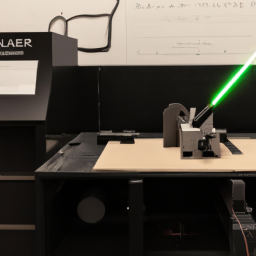

Lens Cleaning Kit

To maximize the lifespan of your laser cutter, you’ll want to regularly clean the lens using a specialized cleaning kit. Proper lens cleaning techniques are essential for preventing lens damage and ensuring optimal performance.

The lens cleaning kit contains all the necessary tools to effectively remove dust, debris, and residue that can accumulate on the lens surface over time. Start by gently blowing off any loose particles with compressed air. Then, use the provided lens cleaning solution and a soft, lint-free cloth to carefully wipe the lens in a circular motion. Avoid applying excessive pressure or using abrasive materials, as this can scratch or damage the lens.

After cleaning, ensure the lens is completely dry before reinstalling it. By following these lens cleaning techniques, you can maintain the clarity and efficiency of your laser cutter.

Now, let’s move on to the next section about the air assist nozzle.

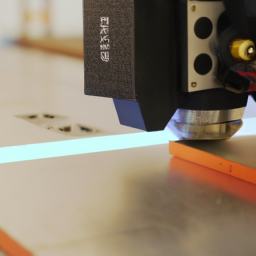

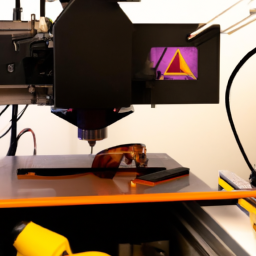

Air Assist Nozzle

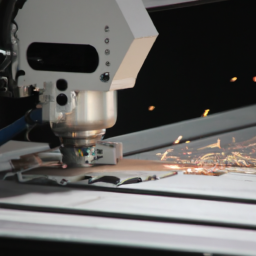

The Air Assist Nozzle is an essential accessory that can greatly enhance the cutting and engraving process of your laser cutter. It helps to blow away debris and particles from the work area, resulting in cleaner and more precise cuts. Additionally, this nozzle also plays a crucial role in reducing the risk of flare-ups and scorch marks, as it helps to prevent the accumulation of smoke and residue on the material being processed.

Overall, incorporating an Air Assist Nozzle into your laser cutter setup can significantly improve its efficiency, allowing for faster production and better quality results.

Enhance the cutting and engraving process

Maximize the potential of your laser cutter with these must-have products that will take your cutting and engraving process to the next level, leaving you in awe of the jaw-dropping results! Enhancing the precision and accuracy of your laser cutter is essential for achieving intricate designs and flawless cuts.

One product that can greatly enhance this aspect is a high-quality lens. By choosing a lens with excellent clarity and focusing capabilities, you can optimize the speed and performance of your laser cutter, ensuring clean and precise cuts every time.

Additionally, investing in a high-powered laser tube can also enhance the cutting and engraving process by providing a more powerful beam, allowing for faster and deeper cuts.

These products will not only enhance your laser cutter’s capabilities but also reduce the risk of flare-ups and scorch marks, providing you with the best possible results.

Reduce the risk of flare-ups and scorch marks

By opting for a lens and laser tube of superior quality, you can effectively minimize the occurrence of flare-ups and scorch marks during the cutting and engraving process. A high-quality lens ensures that the laser beam remains focused and precise, reducing the chances of flare-ups and unwanted burning. Additionally, a superior laser tube provides consistent and stable power output, preventing scorch marks caused by fluctuations in intensity.

It is essential to choose lenses and laser tubes that are specifically designed for your laser cutter model to achieve optimal performance. By reducing flare-ups and preventing scorch marks, you can improve the overall efficiency of your laser cutter and achieve cleaner and more precise cuts and engravings. This will result in higher quality products and a more satisfying user experience.

Now let’s explore how to improve the overall efficiency of your laser cutter.

Improve the overall efficiency of your laser cutter

To enhance your laser cutting experience, you can optimize the overall efficiency of your machine by implementing various techniques and strategies. Improving efficiency is crucial to increase productivity and reduce downtime.

One effective way to achieve this is by regularly cleaning the optics and mirrors of your laser cutter. Dust and debris can accumulate on these surfaces, reducing the quality and accuracy of your cuts.

Additionally, adjusting the focus of the laser beam ensures precise and efficient cutting. Another technique is to properly align the laser beam with the cutting path, which reduces the chance of misalignment and improves overall efficiency.

By implementing these strategies, you can significantly improve the efficiency of your laser cutter and achieve higher productivity.

Now, let’s move on to the subsequent section about the ‘cooling system maintenance kit’.

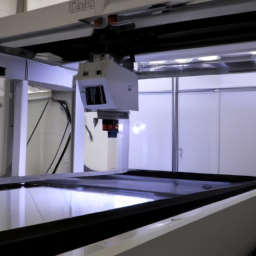

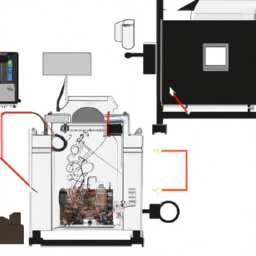

Cooling System Maintenance Kit

Make sure you get yourself a cooling system maintenance kit to keep your laser cutter running smoothly and extend its lifespan. Here are four essential items included in the kit:

-

Cooling system troubleshooting guide: This guide will help you identify and resolve any issues with your laser cutter’s cooling system, ensuring optimal performance.

-

Pump cleaning solution: Regular cleaning of the water pump is crucial for maintaining proper water flow and preventing clogs or blockages.

-

Filter replacement: The cooling system filter should be replaced regularly to ensure clean water circulation and prevent contamination.

-

Water quality testing kit: This kit allows you to test the quality of the water in your laser cutter’s cooling system, ensuring it meets the necessary requirements for efficient operation.

By regularly maintaining and optimizing your laser cutter’s cooling system, you can prevent potential issues and maximize its lifespan.

Now, let’s move on to discussing the importance of replacement parts.

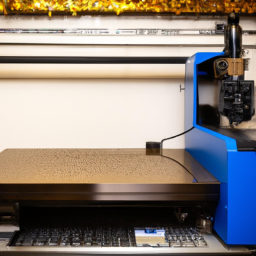

Replacement Parts

To ensure the smooth operation and longevity of your laser cutter, it’s crucial to have essential spare parts on hand. By having these spare parts readily available, you can quickly replace any worn-out or damaged components. This will minimize downtime and maximize productivity. Promptly replacing these components will not only keep your laser cutter running smoothly but also extend its overall lifespan. It will save you time and money in the long run.

Have essential spare parts on hand

Ensure you always have essential spare parts readily available for your laser cutter to keep it running smoothly and prevent any unexpected downtime. The importance of spare parts can’t be overstated, as they’re crucial for emergency repair strategies. When a component fails unexpectedly, having spare parts on hand allows you to quickly replace the faulty part and get your laser cutter back up and running without delay.

This minimizes any potential loss of productivity and ensures that your laser cutter remains in optimal condition. In addition, it’s essential to replace worn-out or damaged components promptly to maintain the overall performance and longevity of your laser cutter.

By staying proactive and keeping spare parts readily available, you can effectively extend the lifespan of your laser cutter and avoid any unnecessary disruptions in your workflow.

Replace worn-out or damaged components promptly

When worn-out or damaged components of your laser cutter are promptly replaced, you can reduce the risk of unexpected downtime by up to 80%. Regular inspection and preventive maintenance are crucial to ensure the longevity of your machine.

Here are three key reasons why replacing worn-out or damaged components promptly is essential:

-

Preventive Maintenance: Timely replacement of worn-out components helps prevent further damage to the laser cutter and avoids potential breakdowns during operation.

-

Optimal Performance: By promptly replacing damaged components, you can ensure that your laser cutter operates at its peak performance, delivering accurate cuts and reducing material waste.

-

Extended Lifespan: Regularly replacing worn-out parts helps extend the overall lifespan of your laser cutter, maximizing your return on investment and minimizing the need for costly repairs or replacements.

By addressing component wear and damage in a timely manner, you can minimize downtime and extend the overall lifespan of your laser cutter, ensuring continuous productivity and efficiency.

Minimize downtime and extend the overall lifespan of your laser cutter

To ensure your laser cutter operates at its peak performance and prolong its lifespan, it is crucial to minimize downtime and address any issues promptly. By doing so, you can maximize its performance and minimize the risk of major breakdowns. One effective way to achieve this is by regularly maintaining and cleaning your laser cutter. This involves cleaning the optics, checking and replacing filters, and lubricating moving parts. Additionally, it is essential to implement a preventive maintenance schedule and adhere to it religiously. This means regularly inspecting and replacing worn-out or damaged components, such as belts, bearings, and mirrors. By implementing these practices, you can significantly extend the overall lifespan of your laser cutter and ensure smooth and efficient operation.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Clean optics | Monthly | High |

| Check and replace filters | Quarterly | Medium |

| Lubricate moving parts | Bi-annually | Medium |

| Inspect and replace components | Annually | High |

Frequently Asked Questions

Are protective covers necessary for laser cutters, or are they just an optional accessory?

Protective covers for laser cutters aren’t just optional accessories, but they’re essential for ensuring their longevity. The pros of using protective covers include shielding the machine from dust, debris, and moisture, preventing damage to sensitive components.

However, there are cons too, such as limited visibility and potential overheating. If you don’t use protective covers, it’s crucial to maintain cleanliness by regularly cleaning the machine, using air compressors, and ensuring proper ventilation to minimize the risk of damage.

How often should I clean my laser cutter using cleaning solutions?

To maintain optimal performance, you must clean your laser cutter regularly. But how often should you clean it? Cleaning frequency depends on usage, but a general guideline is to clean it at least once a week. However, if you use your laser cutter heavily, it’s recommended to clean it every few days.

As for cleaning solutions, the most effective ones for laser cutters are isopropyl alcohol and specialized lens cleaning solutions. They ensure thorough cleaning without damaging delicate components.

Can I use regular cleaning solutions or do I need to buy specific ones for laser cutters?

Using regular cleaning solutions for your laser cutter may not be the best idea. Laser cutters require specific cleaning solutions that are designed to effectively remove debris and residue without damaging the delicate components. Using regular cleaning solutions can potentially harm the laser cutter and shorten its lifespan.

On the other hand, using protective covers for your laser cutter has numerous benefits. They shield the machine from dust, debris, and other contaminants, preventing damage and extending its lifespan.

What is included in a lens cleaning kit and how often should I use it?

To keep your laser cutter in top shape, it’s crucial to clean the lens regularly with a lens cleaning kit. This kit typically includes a soft brush, lens cleaning solution, and lint-free wipes.

The frequency of lens cleaning depends on your usage, but it’s recommended to clean it at least once a week. Using proper cleaning techniques is vital as any residue or smudges can negatively impact the laser’s performance.

Remember, a clean lens is the key to a long-lasting laser cutter.

Is it possible to use an air assist nozzle with any type of laser cutter, or are there specific models that are compatible?

To improve the lifespan of your laser cutter, you may consider using an air assist nozzle. Not all laser cutter models are compatible with this feature, so it’s important to check the specifications of your machine.

The air assist nozzle helps to blow away debris and smoke, reducing the chances of damage to the lens and other components. If your laser cutter is not compatible with an air assist nozzle, there are alternative methods such as regular maintenance, cleaning, and using quality materials to extend its lifespan.

Conclusion

In conclusion, by investing in the top products mentioned, you can significantly prolong the lifespan of your laser cutter.

These include protective covers to shield your machine from dust and debris, cleaning solutions to maintain its performance, a lens cleaning kit for crystal-clear precision, an air assist nozzle for enhanced cutting capabilities, and a cooling system maintenance kit to prevent overheating.

Don’t wait until it’s too late; equip yourself with these anachronistic tools and ensure your laser cutter stands the test of time.