Are you tired of your laser cutting equipment constantly breaking down and causing delays in your business operations? Well, fear not! We have the ultimate solution for you.

In this article, we will explore 5 ways to optimize maintenance for your laser cutting business. These strategies will not only ensure that your equipment is running smoothly, but also increase its lifespan and efficiency.

From regularly cleaning and maintaining your equipment to implementing preventive maintenance procedures, we have got you covered.

Additionally, we will discuss the importance of training your staff on proper equipment handling and maintenance, as well as monitoring and analyzing equipment performance.

Lastly, we will explore the benefits of developing a spare parts inventory system and seeking professional assistance for complex maintenance tasks.

So, get ready to revolutionize your laser cutting business and experience a whole new level of productivity and success!

Key Takeaways

- Regular cleaning and maintenance of equipment is crucial for performance and longevity

- Implement preventive maintenance procedures to address potential issues before they become major problems

- Maintain a comprehensive spare parts inventory to minimize downtime

- Seek professional assistance and troubleshooting to quickly resolve complex problems.

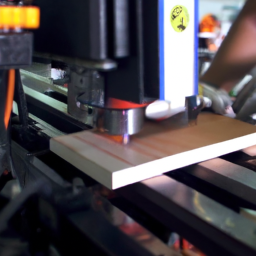

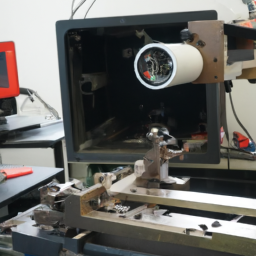

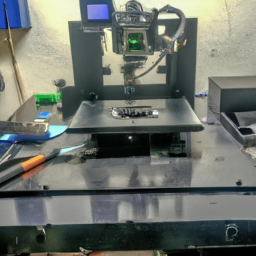

Regularly Clean and Maintain Your Laser Cutting Equipment

Make sure you regularly clean and maintain your laser cutting equipment to keep it running smoothly and efficiently. Regular maintenance is crucial to ensure optimal performance and longevity of your equipment.

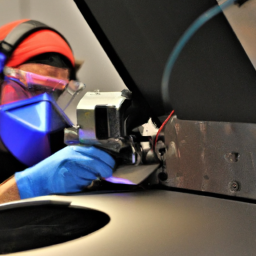

Start by implementing a cleaning schedule to remove dust, debris, and residue from the machine. Use a soft cloth or brush to clean the exterior and interior components, paying close attention to the lenses, mirrors, and cutting bed.

Additionally, check for any loose or damaged parts and tighten or replace them as needed. Keeping your equipment clean not only improves its efficiency but also prevents potential issues that can arise from dirt buildup.

With regular maintenance and equipment cleanliness, you can minimize downtime and maximize productivity.

Now, let’s move on to the next section and discuss how to implement preventive maintenance procedures.

Implement Preventive Maintenance Procedures

To optimize maintenance for your laser cutting business, it’s important to implement preventive maintenance procedures.

Start by creating a maintenance schedule to ensure regular upkeep of your equipment. Conduct regular inspections to identify and address any potential issues before they become major problems.

Lastly, keep detailed maintenance records to track the history of your equipment and identify any recurring issues.

By following these key points, you can ensure that your laser cutting equipment is operating at its best and minimize downtime.

Create a Maintenance Schedule

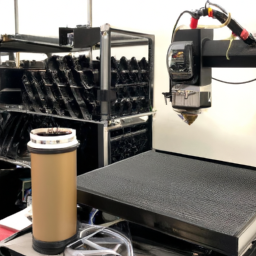

Ensure your laser cutting business operates smoothly by creating a maintenance schedule that keeps your equipment running efficiently. Start by developing a maintenance checklist that covers all the essential tasks needed to maintain your laser cutting machines.

This checklist should include regular cleaning, lubrication, and calibration procedures to ensure optimal performance. Additionally, consider outsourcing some maintenance tasks to professionals who specialize in laser cutting equipment. This can help ensure that all maintenance is done correctly and in a timely manner.

By creating a maintenance schedule and following it consistently, you can avoid unexpected breakdowns and costly repairs. With a well-maintained laser cutting business, you can focus on meeting customer demands and growing your business.

Now, let’s move on to the next section about conducting regular inspections to further optimize your maintenance efforts.

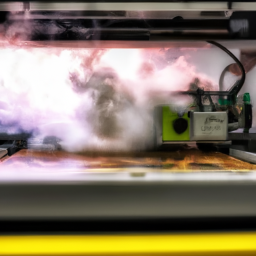

Conduct Regular Inspections

Regular inspections are essential for keeping your laser cutting machines in top condition and preventing unexpected breakdowns or performance issues. Did you know that 80% of equipment failures can be prevented by conducting regular inspections?

By regularly inspecting your machines, you can identify any potential issues before they become major problems. This allows you to take proactive measures, such as cleaning or replacing worn-out parts, to ensure optimal performance. Regular inspections also help extend the lifespan of your equipment, saving you money in the long run.

Additionally, these inspections provide an opportunity to identify any safety hazards and address them promptly. By prioritizing regular inspections, you can maximize the efficiency and productivity of your laser cutting business.

Moving forward, it’s crucial to keep detailed maintenance records to track the results of your inspections and monitor the overall health of your machines.

Keep Detailed Maintenance Records

By keeping detailed maintenance records, you’ll have a clear picture of the health and longevity of your machines, giving you peace of mind and confidence in the reliability of your equipment.

To achieve this, consider using tracking software that allows you to easily record and monitor all maintenance activities. This will help you track the frequency of inspections, identify patterns of wear and tear, and schedule preventive maintenance tasks more effectively.

Additionally, maintaining a comprehensive spare parts inventory is crucial. By documenting the parts used for repairs and replacements, you can ensure you always have the necessary components on hand, minimizing downtime and maximizing productivity.

With detailed maintenance records and a well-managed spare parts inventory, you can optimize the efficiency of your laser cutting business.

Transitioning to the next section, it’s essential to train your staff on proper equipment handling and maintenance.

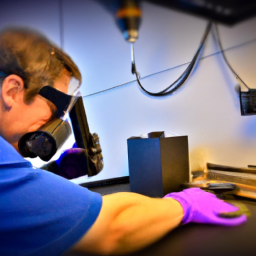

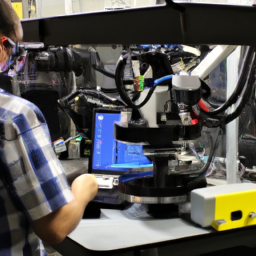

Train Your Staff on Proper Equipment Handling and Maintenance

To maximize efficiency and minimize downtime in your laser cutting business, make sure you train your staff on how to handle and maintain the equipment properly, ensuring smooth operations and extending the lifespan of your machines. By providing comprehensive equipment training, your staff will gain the necessary knowledge and skills to operate the laser cutting machines safely and effectively. This includes understanding the different maintenance techniques required for optimal machine performance.

To convey a deeper meaning for your audience, consider using a table to outline the key training topics and maintenance techniques. Here’s an example:

| Training Topics | Maintenance Techniques |

|---|---|

| Machine operation | Regular cleaning |

| Safety protocols | Lubrication |

| Troubleshooting | Inspection |

| Emergency procedures | Calibration |

By incorporating these training topics and maintenance techniques, your staff will be well-equipped to handle any issues that may arise and ensure the smooth operation of your laser cutting business. In the next section, we will discuss how to monitor and analyze equipment performance, further optimizing your maintenance efforts.

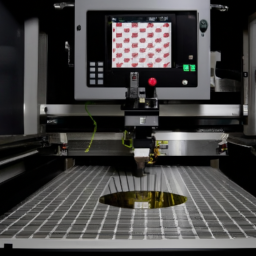

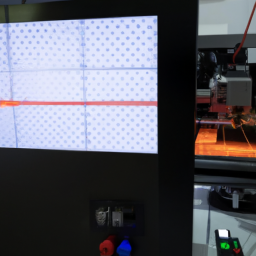

Monitor and Analyze Equipment Performance

To optimize the maintenance of your laser cutting business, it’s crucial to monitor and analyze the performance of your equipment. By utilizing performance tracking software, you can easily track and analyze key metrics such as cutting speed and accuracy. This will allow you to identify any issues or areas for improvement and make necessary adjustments to enhance overall performance.

Additionally, analyzing maintenance trends and patterns will help you identify recurring problems and develop preventive measures to minimize downtime and maximize productivity.

Use Performance Tracking Software

Investing in performance tracking software is a game-changer for your laser cutting business. It allows you to streamline maintenance and maximize efficiency. With performance tracking software, you can easily monitor and analyze equipment performance. This helps you identify any issues or inefficiencies and take proactive measures to address them.

This software provides real-time data on various metrics like cutting speed, accuracy, and downtime. It gives you valuable insights into your machine’s performance. By tracking these metrics, you can identify patterns and trends. This enables you to make informed decisions regarding maintenance schedules and adjustments.

Furthermore, performance tracking software helps you set performance goals, measure progress, and identify areas for improvement. By leveraging this technology, you can optimize maintenance processes, reduce downtime, and improve overall efficiency.

Transitioning to the next section, monitoring cutting speed and accuracy will further enhance your laser cutting business’s performance.

Monitor Cutting Speed and Accuracy

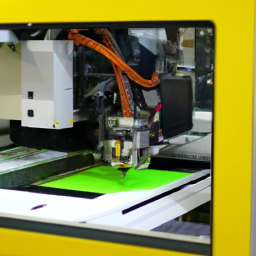

By closely monitoring the cutting speed and accuracy of your laser machine, you can ensure that each project is completed efficiently and with precision, leading to satisfied customers and potential referrals.

For example, a signage company that regularly monitors the cutting speed and accuracy of their laser cutter was able to consistently produce intricate and flawless designs, resulting in increased customer satisfaction and a growing client base.

To improve cutting efficiency, it’s important to regularly assess and adjust the cutting speed of your machine. By optimizing cutting speed, you can reduce production time and increase throughput without compromising the quality of the final product.

Additionally, monitoring the accuracy of your laser cutter ensures that each cut is precise and eliminates the need for rework or adjustments. By maintaining a high level of cutting speed and accuracy, you can maximize productivity and minimize waste.

This leads us to the next section, where we’ll discuss how to analyze maintenance trends and patterns.

Analyze Maintenance Trends and Patterns

One key aspect to consider is the importance of regularly analyzing maintenance trends and patterns in order to maximize efficiency and minimize downtime. By tracking maintenance activities and analyzing the data, you can identify common issues, predict potential problems, and develop proactive maintenance strategies. A maintenance tracking system allows you to record and monitor all maintenance activities, including repairs, replacements, and inspections. This data can then be analyzed to identify trends and patterns, such as recurring issues or equipment that requires frequent maintenance. By understanding these trends, you can implement preventive measures to address potential problems before they occur, reducing unplanned downtime and increasing overall productivity. Additionally, predictive maintenance techniques, such as condition monitoring and predictive analytics, can help predict equipment failure and schedule maintenance in advance. By analyzing maintenance trends and patterns, you can optimize your maintenance operations and ensure the smooth functioning of your laser cutting business.

| Maintenance Activity | Frequency | Downtime (hours) |

|---|---|---|

| Lubrication | Weekly | 1 |

| Calibration | Monthly | 2 |

| Cleaning | Daily | 0.5 |

| Blade Replacement | Quarterly | 4 |

| Inspection | Bi-annually | 3 |

To further enhance your maintenance strategy, it is crucial to develop a spare parts inventory system that will be discussed in the next section.

Develop a Spare Parts Inventory System

To effectively manage maintenance for your laser cutting business, it’s crucial to implement a spare parts inventory system that combines organization and efficiency.

Spare parts management is an essential aspect of optimizing maintenance operations. By having a well-organized inventory of spare parts, you can ensure that you have the necessary components readily available when equipment breakdowns occur. This helps minimize downtime and keeps your laser cutting machines running smoothly.

Inventory optimization is another key benefit of a spare parts inventory system. By tracking usage patterns and analyzing maintenance trends, you can identify which spare parts are frequently needed and adjust your inventory levels accordingly. This prevents overstocking or understocking, saving you time and money.

As you develop your spare parts inventory system, it is important to seek professional assistance for complex maintenance tasks. This ensures that repairs and replacements are done correctly and efficiently, helping your business maintain optimal productivity.

Seek Professional Assistance for Complex Maintenance Tasks

When it comes to complex maintenance tasks for your laser cutting business, it’s highly recommended to seek professional assistance. Hiring certified technicians for major repairs ensures that the job is done efficiently and correctly.

Consulting with experts for troubleshooting can help you identify and resolve any issues that may arise. Additionally, staying updated on industry best practices and innovations ensures that your maintenance processes are optimized and up to date.

Hire Certified Technicians for Major Repairs

Hiring certified technicians for major repairs ensures that you have skilled professionals who can efficiently handle any issues that may arise with your laser cutting equipment. These technicians have undergone certification requirements and possess the necessary qualifications to effectively troubleshoot and repair complex problems.

By hiring certified technicians, you can be confident that they have the expertise and knowledge to diagnose and resolve any issues with your laser cutting machines. They can identify the root cause of the problem and implement the appropriate solutions in a timely manner.

Additionally, certified technicians are familiar with the specific maintenance and repair procedures recommended by the manufacturer, ensuring that the repairs are done correctly and in accordance with industry standards. By entrusting major repairs to certified technicians, you can minimize downtime and keep your laser cutting business running smoothly.

Now, let’s discuss how you can consult with experts for troubleshooting.

Consult with Experts for Troubleshooting

Consulting with experts for troubleshooting can greatly help in resolving complex issues with your laser cutting equipment. When you encounter problems that you cannot solve on your own, seeking expert advice can save you time and money. These professionals have extensive knowledge and experience in troubleshooting techniques specific to laser cutting machines. They can quickly identify the root cause of the problem and provide you with effective solutions.

To give you an idea of the benefits of consulting with experts, here is a table showcasing some common issues and the corresponding troubleshooting techniques they may recommend:

| Common Issue | Troubleshooting Technique |

|---|---|

| Poor cutting quality | Adjusting focal length |

| Excessive smoke | Checking gas pressure |

| Machine not powering on | Inspecting power supply |

By leveraging their expertise, you can efficiently address issues and get your laser cutting business back on track. Once you have resolved any problems, it is important to stay updated on industry best practices and innovations to maintain optimal performance.

Stay Updated on Industry Best Practices and Innovations

To stay ahead of the game in the laser cutting industry, make sure you keep your finger on the pulse of industry best practices and innovations, like a savvy business owner with their ear to the ground.

Staying updated on industry best practices and innovations is crucial for optimizing maintenance in your laser cutting business. Here are three ways to ensure you stay in the loop:

-

Attend industry conferences and trade shows: These events are great opportunities to learn about the latest innovative technologies and advancements in laser cutting. Network with industry experts and gain valuable insights that can help you improve your maintenance practices.

-

Subscribe to industry publications and newsletters: Stay informed by subscribing to magazines, blogs, and newsletters that focus on laser cutting. These publications often provide updates on the latest industry trends, new technologies, and maintenance tips.

-

Join industry forums and online communities: Engage with fellow laser cutting professionals in online forums and communities. These platforms provide a space to ask questions, share experiences, and stay updated on industry news and developments.

By staying updated on industry best practices and innovations, you can optimize maintenance in your laser cutting business and stay ahead of the competition.

Frequently Asked Questions

What safety measures should be taken while cleaning and maintaining laser cutting equipment?

When cleaning and maintaining laser cutting equipment, it’s crucial to prioritize safety measures. Firstly, always wear personal protective equipment such as gloves and safety glasses to prevent injuries.

Secondly, ensure that the equipment is turned off and unplugged before starting the cleaning process. Use approved cleaning solutions and follow the manufacturer’s guidelines for proper cleaning techniques.

Regularly inspect and replace worn-out parts to avoid accidents. Lastly, provide proper training to employees on safe cleaning procedures to minimize risks.

How often should preventive maintenance procedures be conducted on laser cutting machines?

To ensure optimal performance and longevity of your laser cutting machines, it’s crucial to conduct preventive maintenance procedures regularly. Regular inspections are essential in identifying and addressing any potential issues before they escalate into costly problems. The frequency of maintenance depends on several factors, including machine usage and manufacturer recommendations. By adhering to a consistent maintenance schedule, you can minimize downtime, enhance efficiency, and extend the lifespan of your equipment.

What are some common mistakes to avoid when handling and maintaining laser cutting equipment?

Avoiding common mistakes is crucial when handling and maintaining laser cutting equipment. Just like a tightrope walker without a safety net, neglecting safety measures can lead to disastrous consequences.

Some common mistakes to steer clear of include:

- Improper cleaning techniques

- Neglecting regular maintenance schedules

- Ignoring warning signs

- Using incorrect settings

- Failing to train operators properly

By avoiding these mistakes and prioritizing safety, you can ensure the longevity and efficiency of your laser cutting equipment.

What key performance indicators should be monitored and analyzed to ensure optimal equipment performance?

To ensure optimal equipment performance, it’s crucial to monitor and analyze key performance indicators (KPIs). By regularly conducting equipment monitoring and performance analysis, you can identify any issues or inefficiencies and take proactive measures to address them.

Some important KPIs to consider include machine uptime, productivity rates, error rates, and maintenance costs. By tracking these metrics, you can make data-driven decisions and implement strategies to maximize your laser cutting business’s efficiency and profitability.

How can a spare parts inventory system help in minimizing downtime and maximizing productivity in a laser cutting business?

A spare parts inventory system acts as a shield, protecting your laser cutting business from the deadly blows of downtime. By carefully managing and organizing your spare parts, you ensure that your equipment stays reliable and efficient.

When a breakdown occurs, you can swiftly replace the faulty part and minimize the downtime, allowing your business to continue operating smoothly. This proactive approach not only maximizes productivity but also saves you from the frustration and financial burden of extended equipment downtime.

Conclusion

In conclusion, by following these five strategies, you can optimize the maintenance for your laser cutting business.

Regularly cleaning and maintaining your equipment will ensure its longevity and efficiency.

Implementing preventive maintenance procedures will help identify and address potential issues before they become major problems.

Training your staff on proper equipment handling and maintenance will minimize the risk of damage.

Monitoring and analyzing equipment performance will allow you to make necessary adjustments for optimal results.

Finally, developing a spare parts inventory system will ensure you have what you need when you need it.

Remember, by taking these steps, you’ll be on the fast track to success, like a rocket soaring through the sky!