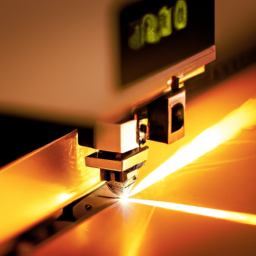

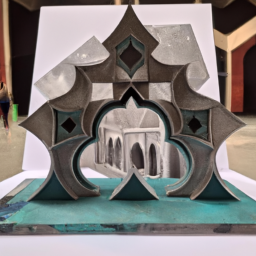

In the world of laser cut model making, where precision and creativity intertwine, you are the master of transforming ideas into tangible works of art. But as with any business, there are always ways to improve and optimize your operations. Just as a laser beam cuts through materials with precision, you too can cut through inefficiencies and enhance your business.

By implementing these five strategic measures, you can take your laser cut model making business to new heights. Streamline your design process to bring your ideas to life faster. Maximize efficiency in production to meet growing demands. Improve communication and collaboration to ensure seamless teamwork. Enhance the customer experience to build brand loyalty. And finally, implement quality control measures to deliver flawless creations.

By staying updated with industry trends, you can remain at the forefront of innovation and cater to the evolving needs of your customers. It’s time to take your laser cut model making business to the next level.

Key Takeaways

- Streamlining the design process with advanced software for creating and modifying 3D models

- Maximizing efficiency in production through time-saving techniques and advanced machinery

- Improving communication and collaboration with clients and suppliers through project management tools

- Enhancing customer experience by focusing on their needs, providing personalized service, and implementing quality control measures

Streamline Your Design Process

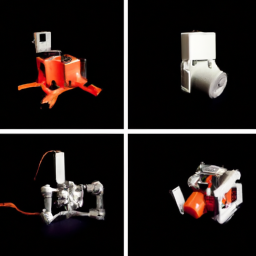

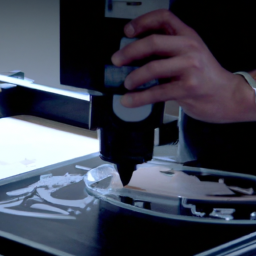

You can speed up your design process by using software that allows you to easily create and modify 3D models. This results in a smoother and more efficient workflow. By utilizing advanced design software, you can improve productivity and reduce costs in your laser cut model making business.

This software enables you to quickly generate intricate designs, make modifications on the fly, and visualize the end product before even starting production. It also allows for easy collaboration with team members, reducing the time spent on back-and-forth communication.

Additionally, the software provides tools for optimizing material usage, minimizing waste, and accurately estimating costs. By streamlining your design process with the right software, you can maximize efficiency in production and seamlessly transition to the next section about how to further enhance your laser cut model making business.

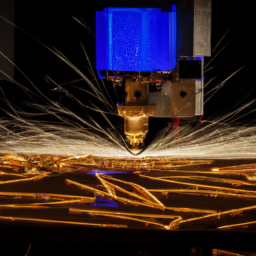

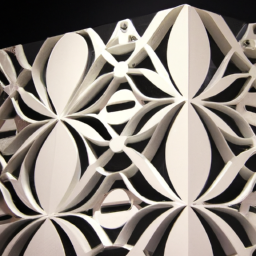

Maximize Efficiency in Production

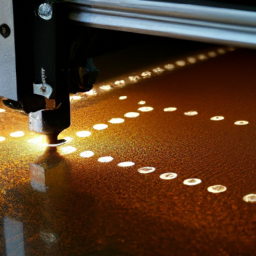

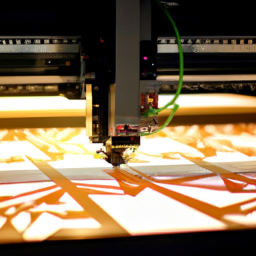

Streamline the production process by implementing time-saving techniques and utilizing advanced machinery for maximum efficiency. To automate operations, consider investing in machinery that can handle multiple tasks simultaneously, reducing the need for manual intervention and saving time.

Additionally, optimize material usage to reduce waste and lower production costs. Implementing nesting software can help maximize material utilization by arranging parts more efficiently on a sheet, minimizing scrap.

Regularly analyze production data to identify bottlenecks and areas for improvement, allowing you to optimize workflows and allocate resources effectively.

By streamlining production and reducing material waste, you can increase productivity and profitability for your laser cut model making business.

Next, improve communication and collaboration to further enhance the efficiency of your operations.

Improve Communication and Collaboration

To improve communication and collaboration in your laser cut model making business, it’s crucial to foster strong relationships with both clients and suppliers. By building trust and open lines of communication, you can ensure that everyone is on the same page and working towards a common goal.

Additionally, utilizing project management tools can greatly enhance team collaboration and efficiency. These tools provide a centralized platform for task management, file sharing, and real-time communication. They allow for effective project planning, tracking, and collaboration, ultimately leading to improved productivity and customer satisfaction.

Foster Strong Relationships with Clients and Suppliers

Building strong relationships with clients and suppliers is essential for the success of your laser cut model making business – after all, ‘a friend in need is a friend indeed’.

To optimize your business, focus on client retention and cultivating strong supplier partnerships. Here are four strategies to foster these relationships:

-

Provide exceptional customer service: Go above and beyond to meet your clients’ needs and exceed their expectations. Promptly address any issues or concerns they may have.

-

Build trust and loyalty: Establish a reputation for reliability and consistency. Be transparent in your communication and deliver on your promises.

-

Regularly communicate and engage: Stay in touch with your clients and suppliers to keep them informed about new projects, updates, and opportunities for collaboration. Show genuine interest in their success.

-

Seek feedback and act on it: Encourage open dialogue with your clients and suppliers. Actively listen to their suggestions and implement changes that align with their needs.

By fostering strong relationships with clients and suppliers, you’ll create a solid foundation for your business’s growth and success.

Moving forward, it’s important to utilize project management tools for effective team collaboration.

Utilize Project Management Tools for Effective Team Collaboration

Maximize your team’s efficiency and productivity by utilizing project management tools for seamless collaboration.

In today’s fast-paced business environment, it’s crucial to have effective team collaboration, especially when working remotely. Project management tools provide a centralized platform for team members to communicate, share files, track progress, and assign tasks.

These tools increase team productivity by ensuring everyone’s on the same page and working towards a common goal. With features like real-time updates and notifications, project management tools enable teams to stay organized and meet deadlines.

Additionally, these tools allow for easy delegation of responsibilities, ensuring that each team member knows their role and can contribute effectively. By using project management tools, your team can streamline processes, improve communication, and ultimately enhance the customer experience.

Enhance Customer Experience

Improve your customer’s experience by focusing on their needs and providing a personalized touch to every laser cut model you create.

Customer satisfaction is crucial in building a successful business, and offering personalized service is a surefire way to achieve it.

Take the time to understand your customer’s requirements and preferences, and tailor your designs accordingly.

Communication plays a vital role in this process, so make sure to keep your customers informed about the progress of their projects and address any concerns promptly.

Additionally, consider offering customization options to give your customers the opportunity to make the model truly their own.

By prioritizing their needs and delivering a personalized experience, you can ensure that your customers are not only satisfied but also become loyal advocates for your business.

To further enhance your reputation for quality, it’s essential to implement quality control measures.

Implement Quality Control Measures

To enhance customer experience, you’ve implemented various strategies, such as personalized consultations and quick turnaround times. Now, let’s delve into the next step to optimize your laser cut model making business: implementing quality control measures.

By establishing robust inspection procedures, you can ensure that every product leaving your workshop meets the highest standards. This will not only prevent errors from reaching your customers but also enhance your reputation as a reliable and professional service provider.

Your quality control measures should include a thorough examination of each model for accuracy and precision, as well as a final inspection for any imperfections or inconsistencies. Additionally, consider implementing error prevention techniques, such as regular maintenance of your equipment and continuous training for your staff.

By prioritizing quality, you can differentiate yourself from competitors and attract loyal customers.

Now, let’s explore how staying updated with industry trends can further propel your business forward.

Stay Updated with Industry Trends

Staying updated with industry trends can be crucial for the success and growth of your laser cut model making business. By conducting industry research and competitor analysis, you can gain valuable insights into the latest developments and emerging trends in the market.

This information allows you to stay ahead of the competition and make informed strategic decisions. Industry research helps you identify new materials, techniques, and designs that can enhance the quality and appeal of your laser cut models.

By analyzing your competitors, you can identify their strengths and weaknesses, enabling you to differentiate your business and offer unique value to your customers. Keeping up with industry trends ensures that your laser cut model making business remains relevant and innovative, helping you attract new customers and retain existing ones.

Frequently Asked Questions

How can I effectively manage inventory and material resources in my laser cut model making business?

To effectively manage inventory and optimize material resources in your laser cut model making business, you need a systematic approach.

Start by implementing inventory management software to track stock levels and streamline ordering processes.

Analyze sales data to identify popular items and adjust your inventory accordingly.

Utilize lean manufacturing techniques to minimize waste and maximize resource utilization.

Regularly review and update your supplier relationships to ensure timely delivery and cost-effective pricing.

By implementing these strategies, you can enhance efficiency and profitability in your business.

What strategies can I implement to attract new customers and expand my client base?

To attract new customers and expand your client base, you should focus on implementing customer retention strategies and targeting niche markets.

Customer retention strategies such as offering loyalty programs, personalized customer experiences, and excellent customer service can help you retain existing customers and attract new ones through word-of-mouth referrals.

Additionally, targeting niche markets allows you to tailor your products and marketing efforts to a specific audience, increasing your chances of attracting customers who’re more likely to be interested in your laser cut model making business.

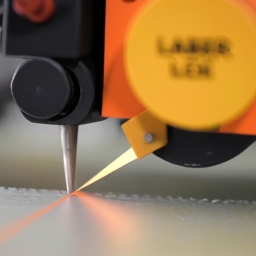

Are there any emerging technologies or techniques in the laser cutting industry that I should be aware of?

In the world of laser cutting, it’s crucial to stay ahead of the curve and embrace emerging laser cutting techniques. The latest advancements in laser cutting technology are revolutionizing the industry, allowing for more precise and intricate designs.

By keeping yourself informed about these breakthroughs, you can offer your clients cutting-edge solutions and stay ahead of the competition.

Stay updated on the latest trends and incorporate these techniques into your business to optimize your laser cut model making business.

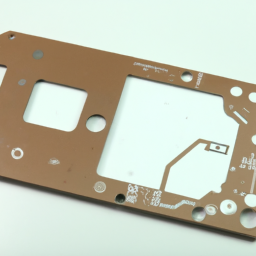

How can I ensure consistent quality and accuracy in my laser cut models?

To ensure consistent quality and accurate laser cutting in your models, there are a few key strategies you can employ.

First, invest in high-quality laser cutting machines that offer precise control and accuracy.

Second, implement a rigorous quality control process to identify and rectify any issues before the final product is delivered.

Additionally, regularly calibrate and maintain your machines to ensure optimal performance.

Lastly, provide comprehensive training to your staff to ensure they have the necessary skills to consistently produce top-notch results.

What are some effective marketing and promotional strategies specifically tailored for a laser cut model making business?

Looking to maximize your laser cut model making business’s exposure? Wondering how to effectively promote your unique creations?

Well, have you considered the power of social media advertising? With its wide reach and targeting capabilities, platforms like Facebook and Instagram can help you showcase your work to a larger audience.

Additionally, collaborating with influencers in the crafting or DIY niche can further boost your brand’s visibility.

By strategically leveraging these marketing strategies, you can generate buzz and attract more customers to your laser cut model making business.

Conclusion

In conclusion, optimizing your laser cut model making business requires a strategic approach. By streamlining your design process and maximizing production efficiency, you can enhance customer experience and ensure success in this competitive industry.

Improving communication and implementing quality control measures are also essential. Stay updated with industry trends like a surfer riding the waves, and watch your business soar to new heights.

With these tactics in place, you’ll be able to navigate the market like a skilled captain steering their ship to success.