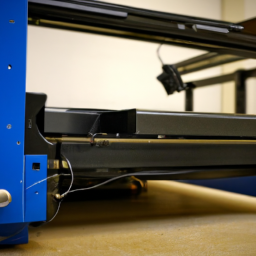

Are you looking to maximize the lifespan of your laser cutter and ensure its peak performance for years to come? If so, then you’re in luck. We have compiled a list of six essential accessories that will not only extend the lifespan of your laser cutter but also enhance its efficiency and effectiveness.

From protective covers and cases to cooling systems, air assist systems, exhaust systems, lens cleaning kits, and spare parts and maintenance kits, these accessories are designed to address the common wear and tear issues that laser cutters face over time.

By investing in these accessories, you can protect your machine from dust, debris, and other potential hazards, while also maintaining optimal temperature levels and ensuring clean and precise cuts.

By taking proactive steps to maintain and care for your laser cutter, you can save on costly repairs and replacements down the line.

So, let’s dive into the world of laser cutter accessories and discover how they can help you extend the lifespan of your valuable machine.

Key Takeaways

- Protective covers and cases are essential to prevent damage from dust, debris, spills, and scratches, and regular maintenance of these covers is important for their effectiveness.

- Cooling systems play a crucial role in optimal performance and preventing damage to the laser cutter. Regular cleaning, coolant level monitoring, temperature monitoring, and proper ventilation are important for cooling system maintenance.

- Air assist systems improve cutting efficiency by blowing away debris and smoke and help troubleshoot issues like excessive charring or burning of materials. They offer benefits such as improved cutting precision, reduced material damage, and extended lifespan of the laser cutter.

- Efficient exhaust systems are necessary for a safe work environment, as they whisk away harmful fumes and smoke. Proper installation, maintenance, and troubleshooting are important for optimal performance.

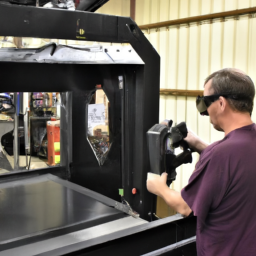

Protective Covers and Cases

You’ll want to invest in protective covers and cases to ensure your laser cutter stays safe and protected, prolonging its lifespan and keeping it in pristine condition for years to come.

Protective covers provide a barrier against dust, debris, and other potential hazards that can damage the delicate components of your laser cutter. They also prevent accidental spills or scratches during transportation or storage.

Regular maintenance of the protective cover is essential to ensure its effectiveness. Clean it regularly with a soft cloth and mild detergent to remove any dust or dirt buildup.

Additionally, consider laser cutter storage solutions such as hard cases or custom-built enclosures to provide maximum protection when the cutter is not in use. By implementing these protective measures, you can safeguard your investment and minimize the risk of damage.

Now let’s move on to discussing cooling systems for your laser cutter.

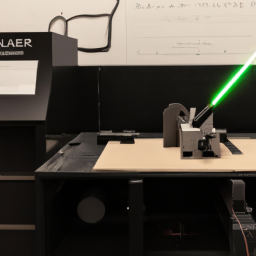

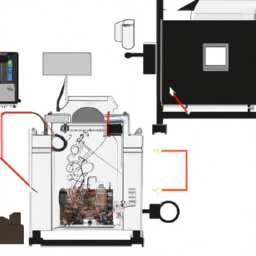

Cooling Systems

To ensure optimal performance and prevent any potential damage, it’s crucial to have a reliable cooling system for your laser cutter. Proper cooling system maintenance is essential to ensure that your machine operates at its best and prolong its lifespan. Here are four important considerations for cooling system maintenance:

-

Regular cleaning: Dust and debris can accumulate in the cooling system, obstructing the flow of coolant. Regularly clean the radiator, fans, and filters to prevent clogs and ensure efficient cooling.

-

Coolant level monitoring: Check the coolant level regularly and top it up as needed. Low coolant levels can lead to overheating and damage the laser tube.

-

Temperature monitoring: Keep an eye on the temperature of the cooling system. If it exceeds the recommended range, troubleshoot the issue immediately to prevent any potential damage.

-

Proper ventilation: Ensure that your laser cutter is placed in a well-ventilated area to allow for effective heat dissipation.

By following these maintenance practices, you can troubleshoot cooling system issues and extend the lifespan of your laser cutter.

Now, let’s move on to the next section about air assist systems.

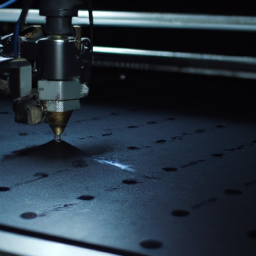

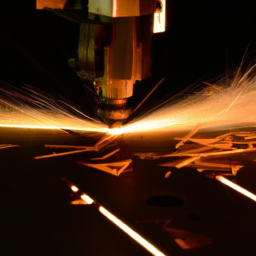

Air Assist Systems

Make sure your laser cutting process is precise and efficient with the help of air assist systems. These systems play a crucial role in improving cutting efficiency by providing a constant stream of compressed air to blow away debris and smoke from the cutting area. This prevents the buildup of debris on the laser lens, ensuring optimal beam quality and reducing the need for frequent cleanings. Additionally, air assist systems help in troubleshooting common issues such as excessive charring or burning of materials by assisting in the removal of heat generated during the cutting process.

To give you a clearer picture, imagine a table where the first column represents the laser cutting process without air assist, the second column represents the laser cutting process with air assist, and the third column represents the benefits of using air assist.

| Without Air Assist | With Air Assist | Benefits |

|---|---|---|

| Debris and smoke buildup on lens | Clear lens, optimal beam quality | Improved cutting precision |

| Excessive charring or burning | Heat removal, reduced material damage | Enhanced cutting efficiency |

| More frequent lens cleanings required | Reduced maintenance, increased productivity | Extended lifespan of laser cutter |

By incorporating an air assist system into your laser cutter setup, you can ensure improved cutting efficiency and troubleshoot common issues. Now, let’s move on to the next section about exhaust systems.

Exhaust Systems

With an efficient exhaust system, the harmful fumes and smoke produced during the laser cutting process are whisked away like a gust of wind, ensuring a safe and clean work environment.

Proper exhaust system installation, maintenance, and troubleshooting are crucial for optimal laser cutter performance. During installation, it’s important to position the exhaust outlet away from the laser cutter to prevent recirculation of fumes.

Regular maintenance includes inspecting and cleaning the exhaust fan, replacing filters, and checking for any leaks. Troubleshooting involves identifying and resolving any issues with the exhaust system, such as clogs or inadequate airflow.

By optimizing exhaust flow, you can achieve improved laser cutting performance, as a steady and efficient removal of fumes prevents interference with the laser beam.

Now, let’s move on to discussing lens cleaning kits.

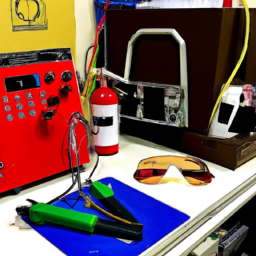

Lens Cleaning Kits

To ensure precise and accurate cuts with your laser cutter, it’s crucial to keep the lens clean. A dirty lens can lead to distorted laser beams and result in imprecise cuts. By regularly cleaning the lens using a lens cleaning kit, you can prevent damage to the lens and maintain optimal performance of your laser cutter.

Keep your laser cutter’s lens clean for precise and accurate cuts

Ensure your laser cutter’s lens stays crystal clear for those perfectly precise and accurate cuts by regularly cleaning it with a soft cloth. Regular maintenance is crucial to ensure the longevity and optimal performance of your laser cutter lens.

Here are some tips for cleaning your laser cutter lens effectively:

-

Use a soft, lint-free cloth: Avoid using abrasive materials that could scratch the lens. A microfiber cloth is ideal for gently removing dust and debris.

-

Use a cleaning solution: For stubborn dirt or smudges, you can use a specialized lens cleaning solution. Apply a small amount to the cloth and gently wipe the lens in a circular motion.

-

Avoid touching the lens with your fingers: Oils and residues from your fingers can negatively affect the lens. Always handle the lens with clean, dry hands or use gloves.

By following these cleaning tips, you can prevent damage to the lens and maintain optimal performance.

Prevent damage to the lens and maintain optimal performance

To ensure the longevity and optimal performance of your laser cutter, it’s crucial to prevent any damage to the lens. The lens is a vital component that directly affects the accuracy and precision of the cuts. Therefore, it’s essential to implement lens protection measures and follow regular maintenance routines.

One way to protect the lens is by using a lens cover when the machine isn’t in use, preventing dust and debris from settling on it. Additionally, it’s important to clean the lens regularly using a recommended lens cleaner and a lint-free cloth. This’ll help remove any residue or smudges that can negatively impact the laser’s performance.

By incorporating these lens protection and maintenance routines, you can ensure that your laser cutter operates at its best while extending its lifespan.

In the next section, we’ll discuss the importance of spare parts and maintenance kits.

Spare Parts and Maintenance Kits

Consider investing in spare parts and maintenance kits for your laser cutter, as they can greatly extend its lifespan and help you avoid costly repairs in the future.

Laser cutter troubleshooting and common maintenance issues can be easily addressed with the use of spare parts and maintenance kits. These kits typically include essential components such as lenses, mirrors, belts, and motors, which are prone to wear and tear over time. By having these spare parts readily available, you can quickly replace any damaged or worn-out components, minimizing downtime and maximizing productivity.

Additionally, regular maintenance is crucial in preventing potential issues. Maintenance kits often include cleaning supplies, lubricants, and calibration tools, allowing you to keep your laser cutter in optimal condition. By proactively addressing maintenance needs and having spare parts on hand, you can ensure the longevity and efficiency of your laser cutter.

Frequently Asked Questions

How often should I clean the lens of my laser cutter using a lens cleaning kit?

To ensure optimal performance and extend the lifespan of your laser cutter, it’s recommended to clean the lens regularly using a lens cleaning kit. The cleaning frequency depends on various factors such as usage and environment, but a general guideline is to clean it every couple of weeks.

Failure to clean the lens can result in decreased cutting accuracy and efficiency. Using a specialized lens cleaning kit, like the one from XYZ Company, will effectively remove dust and debris without damaging the lens.

Are there any specific maintenance tasks or procedures I should follow when using spare parts and maintenance kits?

When using spare parts and maintenance kits for your laser cutter, it’s important to follow routine maintenance procedures to ensure its longevity.

Regularly inspect and clean all spare parts before installation, and refer to the manufacturer’s guidelines for proper installation and usage.

Keep a maintenance log to track the replacement of parts and schedule routine maintenance tasks.

Additionally, regularly check and adjust the alignment of spare parts to optimize performance and prevent damage.

Can I use a regular cooling system for my laser cutter, or do I need to invest in a specialized one?

To ensure optimal performance and longevity of your laser cutter, it’s crucial to invest in a specialized cooling system rather than relying on a regular one. Laser cutters generate significant amounts of heat during operation, and a specialized cooling system is designed to efficiently dissipate this heat and maintain the optimal operating temperature.

Regular cooling systems may not have the necessary features to effectively cool the laser cutter, potentially leading to overheating and damage to the equipment.

Are there any specific safety precautions I should take when installing an exhaust system for my laser cutter?

When installing an exhaust system for your laser cutter, there are several safety precautions you should take. First, ensure that the system is properly installed and securely attached to the laser cutter. This will prevent any leaks or potential hazards.

Additionally, make sure the exhaust system is properly sized for your laser cutter to ensure efficient ventilation. Proper ventilation is crucial for removing harmful fumes and particulates, protecting both the machine and the operator.

How frequently should I replace the protective cover or case for my laser cutter to ensure optimal protection?

To ensure optimal protection for your laser cutter, it’s crucial to replace the protective cover or case regularly, just like a knight replacing their armor.

The frequency of replacement depends on the level of wear and tear, but a good rule of thumb is to inspect it monthly and replace it every 6-12 months.

Proper ventilation is equally important in laser cutter maintenance, as it prevents overheating and prolongs the lifespan of the machine.

Conclusion

In conclusion, investing in these six accessories can significantly extend the lifespan of your laser cutter. By using protective covers and cases, you can shield your machine from dust and debris, ensuring its longevity.

Cooling systems are crucial to prevent overheating, which can lead to costly repairs. Air assist systems enhance cutting and engraving efficiency, while exhaust systems remove fumes and keep the work area clean.

Regularly cleaning the lens with lens cleaning kits will maintain optimal performance. Lastly, having spare parts and maintenance kits on hand will allow for quick and easy repairs.

Just like a well-maintained car that can go the extra mile, these accessories will keep your laser cutter running smoothly for years to come.