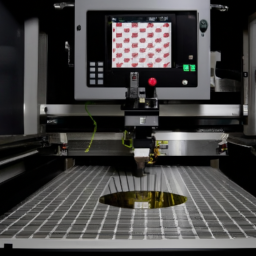

Imagine stepping into a workshop, the air filled with the scent of freshly cut wood and the hum of machinery. In the corner, a laser cutter sits, its powerful beam slicing through materials with precision and ease. But to keep this magnificent tool running at its best, proper maintenance is essential.

In this article, we will explore six expert tips for maintaining your laser cutter, ensuring its longevity and optimal performance. From regular cleaning to lubricating moving parts, checking laser alignment, monitoring temperature and humidity, inspecting and replacing consumables, to following the manufacturer’s maintenance schedule, we will delve into the nitty-gritty details of laser cutter maintenance.

So, whether you’re a seasoned professional or just starting out in the world of laser cutting, these tips will help you keep your machine in top shape, allowing you to continue creating with precision and efficiency.

Key Takeaways

- Regular cleaning is crucial for preventing dust and debris buildup.

- Use the recommended lubricant for lubricating the moving parts.

- Regularly check and adjust the laser alignment for accuracy and precision.

- Proper focus adjustment is essential for clean cuts and precise engraving.

Clean the Laser Cutter Regularly

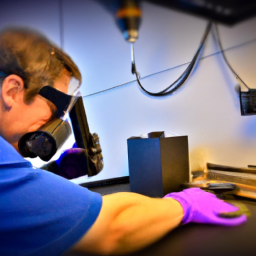

To keep your laser cutter in top shape, make sure to regularly clean it and remove any debris that may be compromising its performance. Regular cleaning is essential to prevent the buildup of dust, dirt, and residue on the various components of the laser cutter.

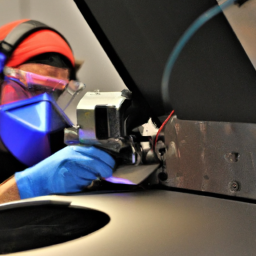

Begin by turning off the machine and unplugging it for safety. Use a soft brush or compressed air to gently remove any loose debris from the laser head, lens, and mirrors. Be careful not to scratch or damage these delicate parts.

Additionally, wipe down the exterior surfaces with a clean, lint-free cloth. Taking these preventive measures will not only ensure optimal performance but also extend the lifespan of your laser cutter.

Moving on to the next section, it’s equally important to lubricate the moving parts to maintain smooth operation.

Lubricate Moving Parts

When it comes to lubricating the moving parts of your laser cutter, it’s crucial to use the right lubricant. Using the wrong lubricant can lead to damage and reduce the effectiveness of the machine.

Make sure to follow the manufacturer’s recommendations regarding the type of lubricant to use and how often to apply it. By doing so, you can ensure that your laser cutter operates smoothly and efficiently, minimizing the risk of breakdowns and extending its lifespan.

Use the Right Lubricant

Using the proper lubricant for your laser cutter is like giving it a refreshing drink of water on a hot summer day. Choosing the right lubricant is crucial to ensure the smooth operation and longevity of your machine. Not all lubricants are created equal, and using the wrong one can lead to costly repairs and downtime.

When selecting a lubricant for your laser cutter, consider the following:

-

Compatibility: Ensure that the lubricant is compatible with the materials used in your machine to prevent any adverse reactions.

-

Temperature resistance: Laser cutters generate high levels of heat, so the lubricant should be able to withstand these temperatures without breaking down.

-

Anti-rust properties: Laser cutters are susceptible to rust and corrosion, so choose a lubricant that offers excellent protection against these elements.

-

Long-lasting: Opt for a lubricant that provides long-lasting lubrication to minimize the frequency of application.

By following these guidelines, you can prevent rust and corrosion while maintaining optimal performance.

Now, let’s move on to the next section and explore the importance of following the manufacturer’s recommendations.

Follow the Manufacturer’s Recommendations

It is imperative to adhere to the manufacturer’s recommendations for optimal performance and longevity of your laser cutting machine. Following the manufacturer’s recommendations ensures that you are using the machine in a way that is safe and effective. One important aspect of maintenance is cleaning procedures. Regularly cleaning the machine will prevent debris from accumulating and interfering with its functionality. Be sure to use the right cleaning agents and follow the recommended procedures to avoid damaging the machine. Additionally, it is essential to follow safety precautions when performing maintenance tasks. This includes wearing protective gear, such as gloves and goggles, and ensuring the machine is turned off before starting any maintenance procedures. By following these guidelines, you can maintain the machine’s efficiency and extend its lifespan. Moving on to the next section, let’s discuss how to check and adjust the laser alignment.

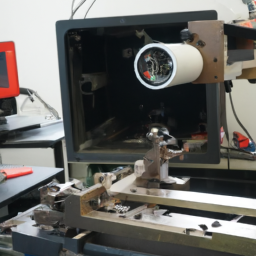

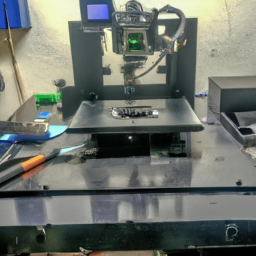

Check and Adjust the Laser Alignment

To ensure proper beam alignment in your laser cutter, it’s crucial to regularly check and adjust the laser alignment. This will help maintain the accuracy and precision of the laser cutting process.

Additionally, it’s important to adjust the focus of the laser to ensure optimal performance and avoid any potential damage to the materials being cut.

Ensure Proper Beam Alignment

Ironically, achieving proper beam alignment on a laser cutter is a task that shouldn’t be taken lightly. Laser beam calibration is crucial to ensure the accuracy and precision of your cuts.

To achieve optimal beam alignment, there are several techniques you can employ. Firstly, you should start by checking the mirrors and lenses for any dirt or debris that could affect the beam’s path. Clean them carefully using a lint-free cloth and lens cleaner.

Next, use a beam alignment tool to adjust the beam’s position and angle. This tool will help you determine if the beam is hitting the target accurately. Additionally, you may need to adjust the mirror mounts to fine-tune the alignment.

Once you have achieved proper beam alignment, you can proceed to the next step of adjusting the focus, which is equally important for achieving high-quality laser cutting results.

Adjust the Focus

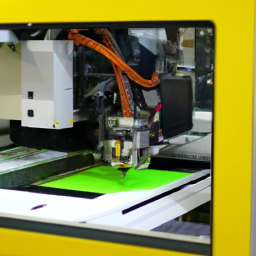

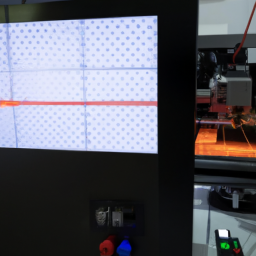

Achieve optimal cutting precision and experience the satisfaction of flawlessly focused laser beams by adjusting the focus using these simple steps.

-

Begin by ensuring that the laser cutter is calibrated properly. Laser cutter calibration is crucial for accurate focus adjustment.

-

Locate the focal length adjustment mechanism on the laser cutter. This mechanism allows you to fine-tune the focus of the laser beam.

-

Use the control panel or software interface to adjust the focal length. Make small incremental changes and test the focus after each adjustment to achieve the desired result.

Properly adjusting the focus of your laser cutter is essential for achieving clean cuts and precise engraving. By following these steps, you can ensure that your laser cutter is operating at its best.

Now, let’s move on to the next section about monitoring and controlling temperature and humidity to further optimize your laser cutter’s performance.

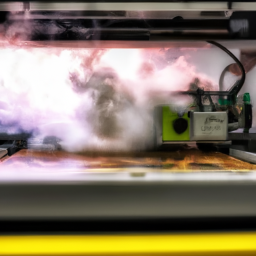

Monitor and Control Temperature and Humidity

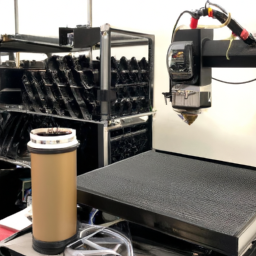

To ensure the optimal performance of your laser cutter, it’s essential to maintain an optimal environment. This can be achieved by monitoring and controlling the temperature and humidity levels in your workspace. Fluctuations in these factors can significantly impact the accuracy and efficiency of the laser cutter. You can use climate control systems like air conditioning or dehumidifiers to regulate the temperature and humidity levels. Creating a stable environment for the machine to operate in can minimize the risk of potential issues and maximize the lifespan of your laser cutter.

Maintain an Optimal Environment

Creating the perfect environment for your laser cutter is like tending to a delicate garden, ensuring the right temperature, humidity, and ventilation for optimal performance. To achieve this, it’s essential to create a maintenance checklist that includes monitoring and controlling temperature and humidity levels.

Additionally, preventing dust buildup is crucial to maintain a clean environment for your laser cutter. Here are three key steps to maintain an optimal environment for your laser cutter:

-

Regularly clean the laser cutter and its surroundings to prevent dust particles from settling on the machine’s components.

-

Use air filters or purifiers to minimize airborne contaminants that can affect the laser cutter’s performance.

-

Implement proper ventilation systems to remove fumes and maintain a steady airflow within the workspace.

By following these maintenance practices, you can ensure a clean and controlled environment that promotes the longevity and efficiency of your laser cutter. To further enhance the environment, consider using climate control systems.

Use Climate Control Systems

To maintain an optimal environment for your laser cutter, it’s crucial to use climate control systems. These systems play a vital role in monitoring humidity levels and controlling the temperature within the workspace. Laser cutters are sensitive machines, and fluctuations in temperature and humidity can significantly impact their performance and accuracy.

By investing in a reliable climate control system, you can ensure that the conditions remain stable and ideal for your laser cutter to operate efficiently.

Monitoring humidity levels is essential because high humidity can lead to condensation on the laser optics, resulting in poor cutting quality and potential damage to the machine. Similarly, extreme temperatures can cause thermal expansion and contraction, affecting the overall precision of the laser cutter. Therefore, it’s crucial to maintain a controlled environment to avoid any potential issues.

Now, let’s delve into the next section where we’ll discuss the importance of regularly inspecting and replacing consumables for proper laser cutter maintenance.

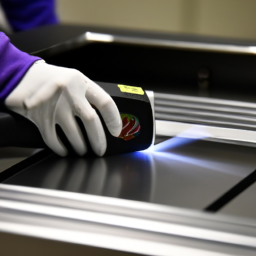

Regularly Inspect and Replace Consumables

Make sure to regularly check and swap out worn-out consumables to keep your laser cutter running smoothly and efficiently. It’s crucial to inspect laser components such as lenses, mirrors, and nozzles for any signs of wear or damage. Over time, these parts can become scratched, pitted, or coated with debris, which can negatively impact the performance of your laser cutter. By replacing worn parts, you can ensure optimal beam quality and prevent any potential damage to your machine.

Additionally, regularly inspecting and replacing consumables will help extend the lifespan of your laser cutter and reduce the need for costly repairs. Following this maintenance routine will help maintain the overall performance of your laser cutter.

Transitioning into the subsequent section, it’s also important to follow the manufacturer’s maintenance schedule to ensure the longevity of your machine.

Follow Manufacturer’s Maintenance Schedule

To ensure optimal performance and longevity of your laser cutter, it’s crucial to adhere to the manufacturer’s maintenance schedule.

Perform routine inspections and maintenance as recommended to identify and address any potential issues before they escalate.

Additionally, schedule professional servicing according to the manufacturer’s guidelines to keep your laser cutter operating at its best and to prevent costly breakdowns.

Perform Routine Inspections and Maintenance

Regularly checking and maintaining your laser cutter is like giving your car a tune-up – it ensures smooth operation and prevents breakdowns. To keep your laser cutter in peak condition, it’s crucial to perform routine inspections and maintenance tasks.

Here are four essential steps to help you troubleshoot common issues and ensure optimal performance:

-

Clean the lens: Dust and debris can accumulate on the laser cutter lens, affecting the quality of your cuts. Regularly clean the lens using a lint-free cloth and a gentle, non-abrasive cleaner.

-

Check the belts and pulleys: Over time, belts and pulleys can become loose or worn out, leading to inaccurate cuts. Inspect them regularly and tighten or replace them as needed.

-

Lubricate moving parts: Proper lubrication of the moving components is vital for smooth operation. Apply a recommended lubricant to the rails, bearings, and other moving parts following the manufacturer’s guidelines.

-

Inspect the cooling system: Ensure that the cooling system is functioning correctly by checking coolant levels, cleaning filters, and ensuring unobstructed airflow.

By performing these maintenance tasks regularly, you can prevent potential issues and extend the lifespan of your laser cutter. Remember, it’s also important to schedule professional servicing as recommended to address more complex maintenance needs and ensure optimal performance.

Schedule Professional Servicing as Recommended

Scheduling professional servicing as recommended ensures that your laser cutter receives expert attention to keep it running smoothly and prevent any potential issues. It is crucial to adhere to the recommended scheduling frequency to maintain the optimal performance of your machine.

Regular servicing not only extends the lifespan of your laser cutter but also ensures that it operates at its peak efficiency. When scheduling professional servicing, it is essential to find reputable service providers who specialize in laser cutters. Look for companies with a proven track record in laser cutter servicing, as they possess the expertise and experience required to handle intricate machinery.

Additionally, reputable service providers should offer comprehensive maintenance plans that include thorough inspections, cleaning, lubrication, and calibration of your laser cutter. By entrusting your machine to reputable professionals, you can rest assured that it will receive the necessary care to continue delivering excellent results.

Frequently Asked Questions

How often should I clean the laser cutter?

You should clean the laser cutter every day, because who has time for dirty machines, right? To prevent laser cutter damage during cleaning, make sure to follow these steps.

First, turn off the power and unplug the machine. Then, use a soft cloth or sponge to gently wipe away any debris or residue. Avoid using harsh chemicals or abrasive materials that could scratch the surface. Finally, be careful not to accidentally touch the laser lens or mirrors.

What type of lubricant should I use for the moving parts?

To ensure optimal performance of your laser cutter, it’s crucial to select the appropriate lubricant for the moving parts.

When choosing a lubricant, consider factors such as viscosity, temperature resistance, and compatibility with the materials being processed. Additionally, regular lubrication is essential to prevent wear and reduce friction.

The lubrication frequency depends on the manufacturer’s recommendations and the intensity of usage. Proper lubrication plays a vital role in maintaining the efficiency and longevity of your laser cutter.

How can I check and adjust the laser alignment?

To check and adjust the laser alignment, start by troubleshooting any issues that may arise. Check if the laser beam is hitting the center of the nozzle. If not, inspect the mirrors and lenses for any dirt or misalignment.

Use a laser alignment tool for precise adjustments. Adjust the mirrors and lenses until the laser beam hits the center of the nozzle accurately.

Regular laser alignment maintenance ensures optimal performance and prevents cutting errors.

What temperature and humidity levels are considered optimal for the laser cutter?

To achieve laser cutting perfection, you must create an environment that is as precise as the laser itself. Symbolizing the laser’s need for harmony, optimal temperature and humidity levels are crucial.

The ideal temperature for laser cutter operation ranges between 18-25°C (64-77°F), while humidity should be maintained at 45-55%. These conditions ensure consistent laser performance and prevent material warping.

Furthermore, proper ventilation is vital in laser cutter maintenance, as it removes harmful fumes and ensures a safe working environment.

Which consumables should I regularly inspect and replace?

To ensure optimal performance, regularly inspect and replace certain consumables in your laser cutter. As part of your laser cutter maintenance checklist, pay close attention to the condition of the laser tube. Look for signs of wear and tear, such as reduced power or irregular beam quality.

Additionally, inspect the lens for scratches or debris that may affect the cutting or engraving quality. Replace these consumables as needed to maintain the efficiency and accuracy of your laser cutter.

Conclusion

In conclusion, maintaining your laser cutter is crucial for its optimal performance and longevity. By regularly cleaning the machine, lubricating its moving parts, and checking the laser alignment, you can ensure accurate and precise cuts.

Additionally, monitoring temperature and humidity levels, inspecting and replacing consumables, and adhering to the manufacturer’s maintenance schedule are essential for the machine’s efficient operation.

Remember, just like a well-oiled machine, a well-maintained laser cutter will cut through any task with precision and ease.