Imagine the laser cutter software as the conductor of an intricate symphony, orchestrating your designs with precision and efficiency. To ensure a harmonious workflow and seamless integration, you need to master the art of using this software effectively.

In this article, we will share six expert tips that will elevate your laser cutting game to new heights. By understanding the software interface, customizing settings, and utilizing design templates and libraries, you will be able to streamline your workflow and maximize productivity.

Additionally, we will explore how to optimize material usage and cutting speed, as well as implement workflow automation tools for a smoother operation. Lastly, we will emphasize the importance of regularly updating and maintaining the software to stay at the forefront of laser cutting technology.

Get ready to fine-tune your laser cutter software skills and unlock its full potential. Let’s dive in!

Key Takeaways

- Understand the software interface, including layout, navigation, and troubleshooting, to master laser cutter software.

- Customize settings for efficiency, such as material selection, cutting parameters, and user interface customization.

- Utilize design templates and libraries to enhance efficiency and creativity in laser cutting projects.

- Regularly update and maintain the software to access new features, bug fixes, and security patches, ensuring smooth operation and compatibility.

Understand the Software Interface

To understand the software interface, you’ll need to familiarize yourself with its layout and navigation, allowing you to easily access and utilize the various tools and features available. Navigating menus is a crucial step in mastering laser cutter software. Take the time to explore each menu and submenu to understand the organization of options and functions. This will enable you to quickly locate the tools you need for your projects.

Additionally, troubleshooting common issues is essential to ensure a smooth workflow. Familiarize yourself with common error messages and their solutions to minimize downtime and maximize productivity. Understanding the software interface and its troubleshooting capabilities will set a solid foundation for efficient laser cutting.

Transitioning into the subsequent section about customizing settings for efficiency, it’s important to optimize the software to suit your specific workflow needs.

Customize Settings for Efficiency

For maximum productivity, tweaking the preferences is like fine-tuning a musical instrument to create the perfect harmony. To maximize productivity, reduce production costs, and streamline your workflow with laser cutter software, consider customizing the settings for efficiency.

Here are two key areas to focus on:

-

Material and Cutting Parameters:

- Adjust the speed, power, and frequency settings based on the material you’re working with, ensuring optimal results and minimizing waste.

- Fine-tune the cutting parameters to achieve the desired level of precision, balance, and speed.

-

User Interface Customization:

- Customize the software interface layout, toolbars, and shortcuts to suit your specific workflow, allowing for quick access to frequently used commands.

- Personalize the software preferences to match your working style, enabling a seamless and efficient laser cutting experience.

By customizing settings to maximize productivity and reduce production costs, you can enhance your laser cutting process.

In the next section, we’ll explore how to utilize design templates and libraries to further optimize your workflow.

Utilize Design Templates and Libraries

Enhance your efficiency and creativity by taking advantage of design templates and libraries. Design templates provide pre-made layouts and elements that can be customized to fit your specific project. They serve as a great starting point, saving you time and effort in creating designs from scratch.

Libraries, on the other hand, offer a collection of pre-designed graphics, shapes, and patterns that you can easily incorporate into your projects. These resources not only provide design inspiration but also help streamline your workflow.

When utilizing design templates and libraries, it’s important to ensure compatibility with your laser cutter software. Troubleshooting tips should be readily available to address any issues that may arise during the design process.

By optimizing material usage and cutting speed in the subsequent section, you can further enhance the efficiency of your laser cutting workflow.

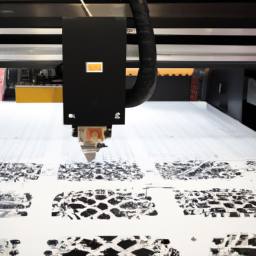

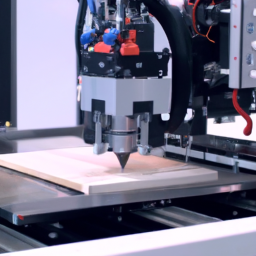

Optimize Material Usage and Cutting Speed

Maximize the efficiency of your laser cutting process by optimizing how you use materials and adjusting the cutting speed. A study found that when these factors are optimized, there can be a 20% reduction in production time. To maximize productivity and reduce production costs, it is important to carefully plan and utilize your materials. By nesting your designs efficiently, you can minimize waste and make the most out of your materials. Additionally, adjusting the cutting speed can help save time and increase throughput. It is important to find the right balance between speed and quality to ensure accurate and clean cuts. Consider using the following table as a guide to help optimize your material usage and cutting speed:

| Factor | Recommendation |

|---|---|

| Material utilization | Nest designs efficiently to minimize waste |

| Cutting speed | Find the right balance between speed and quality |

By implementing these strategies, you can maximize productivity and reduce production costs. In the next section, we will discuss how implementing workflow automation tools can further streamline your laser cutting process.

Implement Workflow Automation Tools

Implementing workflow automation tools can significantly streamline the laser cutting process, increasing productivity and reducing production costs. By automating repetitive tasks such as file preparation, job scheduling, and machine setup, these tools eliminate the need for manual intervention, saving valuable time and effort.

Moreover, they ensure consistent and accurate execution of the cutting process, minimizing errors and material waste. Streamlining production processes through automation allows for faster turnaround times and higher throughput, ultimately boosting overall productivity.

Additionally, automation enables operators to focus on more value-added tasks, such as design optimization and quality control.

As we move into the next section on regularly updating and maintaining the software, it’s important to understand how these automation tools integrate seamlessly with the latest advancements and features.

Regularly Update and Maintain the Software

Neglecting to keep the software regularly updated and maintained would be a brilliant move if you want to experience constant glitches and frustration in your laser cutting process. To avoid such headaches, it’s crucial to prioritize software troubleshooting and maintenance.

Regular updates ensure that you have access to the latest features, bug fixes, and security patches. By staying up to date, you can optimize your workflow and enhance the compatibility of your laser cutter software with other tools and devices.

Additionally, maintaining the software helps to prevent system crashes and ensures smooth operation. It’s essential to regularly check for updates, install them promptly, and address any compatibility issues that may arise.

Taking these steps will maximize the efficiency and reliability of your laser cutting workflow.

Frequently Asked Questions

Can laser cutter software be used with any type of laser cutter machine?

Laser cutter software is compatible with various types of laser cutter machines. It allows for seamless integration and enhances workflow efficiency. By using laser cutter software, you can streamline the design process, optimize material usage, and improve cutting precision.

The software provides advanced features such as nesting, which arranges multiple designs on a single sheet to maximize material utilization. Additionally, it offers precise control over laser settings, resulting in accurate and consistent cuts.

How do I import my own designs into the software?

To import your own designs into laser cutter software, follow these best practices to ensure a smooth process.

First, make sure your designs are in compatible file formats like DXF or SVG. Then, open the software and locate the import function.

If you encounter any issues, check the design’s dimensions, layers, and file integrity. Troubleshoot by re-saving the file or using different software versions.

By following these steps, you’ll be able to seamlessly import your designs into the laser cutter software.

Are there any limitations on the size of the designs that can be processed by the software?

There are limitations on the size of designs that can be processed by the software. The software is compatible with different laser cutter models, but each model has its own maximum file size limit.

It’s important to check the specifications of your specific laser cutter to ensure that your designs fall within the acceptable file size range. Exceeding the file size limit may result in errors or incomplete cutting.

Can the software simulate the cutting process before actually starting the job?

Yes, the software features a simulation mode that allows you to visualize the cutting process before initiating the job. This feature offers several benefits.

Firstly, it helps you identify any potential issues or errors in the design, saving you time and materials.

Additionally, it allows you to make necessary adjustments to optimize the cutting process, ensuring precise and accurate results.

Overall, simulating the cutting process with this software is a valuable tool for enhancing workflow efficiency and achieving high-quality outcomes.

Is it possible to integrate the laser cutter software with other design software programs?

Are you wondering if the laser cutter software can be seamlessly integrated with other design software programs? The answer is yes, and it comes with several benefits.

Integration allows for a streamlined workflow, saving you time and effort. It also enables you to transfer designs easily and accurately between different software, increasing productivity. However, it’s important to note that challenges may arise, such as compatibility issues or the need for additional configuration.

Overall, integration enhances your laser cutting process, providing a more efficient and effective experience.

Conclusion

In conclusion, by following these expert tips, you can enhance your workflow and integration with laser cutter software. Understanding the software interface allows you to navigate with ease and efficiency. Customizing settings according to your needs will maximize productivity.

Design templates and libraries save time and effort, while optimizing material usage and cutting speed ensures cost-effectiveness. Implementing workflow automation tools streamlines processes and increases efficiency.

Lastly, regularly updating and maintaining the software guarantees smooth operations. By incorporating these strategies, you’ll become a laser cutting pro in no time.