Are you an artist or maker who loves working with a laser cutter? It’s an incredible tool that allows you to bring your creative visions to life. However, it’s important to remember that working with a laser cutter can be dangerous if not done properly. That’s why we’ve compiled a list of 6 laser cutter safety tips to help keep you safe while you unleash your artistic genius.

These tips will guide you through understanding the machine’s operation and safety features, wearing appropriate personal protective equipment (PPE), creating a well-ventilated workspace, regularly inspecting and maintaining the laser cutter, following proper material handling and preparation procedures, and educating yourself on emergency procedures and first aid.

By following these tips, you can ensure that your laser cutting adventures are not only exciting but also safe. Let’s dive in and learn how to protect yourself while creating masterpieces with a laser cutter.

Key Takeaways

- Understand the machine’s operation and safety features.

- Wear appropriate personal protective equipment (PPE) and regularly inspect and maintain it.

- Create a well-ventilated workspace to prevent exposure to harmful fumes and particles.

- Follow proper material handling and preparation procedures to minimize risks.

Understand the Machine’s Operation and Safety Features

To ensure your safety and the proper functioning of the machine, it’s crucial that you familiarize yourself with its operation and the various safety features it possesses.

Laser cutters are complex machines that require regular maintenance to ensure optimal performance and longevity. Understanding the machine’s operation involves knowing how to power it on and off, how to adjust the settings for different materials, and how to load and unload materials safely.

Additionally, it’s important to be aware of the safety protocols in place, such as emergency stop buttons and interlock systems that prevent the laser from firing when the machine is open. By familiarizing yourself with these aspects, you can minimize the risk of accidents and ensure a smooth workflow.

Now, let’s move on to the next section about wearing appropriate personal protective equipment (PPE).

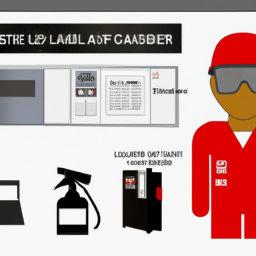

Wear Appropriate Personal Protective Equipment (PPE)

Make sure you’re properly equipped with the right gear to protect yourself while working with the laser cutting machine. Proper personal protective equipment (PPE) selection is crucial to ensure your safety. Here are some essential PPE items and their functions:

| PPE Item | Function |

|---|---|

| Safety glasses | Protect your eyes from laser radiation and flying debris. |

| Respirator | Filter out harmful fumes and particles from the air you breathe. |

| Gloves | Shield your hands from burns and cuts while handling materials. |

| Apron | Prevent sparks, hot materials, and chemicals from contacting your body. |

| Closed-toe shoes | Protect your feet from falling objects and hot surfaces. |

Remember to regularly inspect and maintain your PPE to ensure its effectiveness. Clean or replace dirty or damaged equipment promptly. Now that you have the right gear, let’s move on to creating a well-ventilated workspace.

Create a Well-ventilated Workspace

Ensure that you have proper ventilation in your workspace to prevent exposure to harmful fumes and particles, which can lead to respiratory issues and long-term health problems.

Did you know that according to a study, poor indoor air quality can cause up to 50% of all illnesses? This highlights the importance of air quality and the need for effective ventilation systems in your laser cutting workspace.

A well-ventilated area helps to remove airborne contaminants, such as smoke and volatile organic compounds, ensuring a healthier environment for you to work in. Consider installing an exhaust system or using a fume extractor to efficiently remove these pollutants.

Additionally, make sure your workspace has adequate fresh air circulation to maintain a safe atmosphere. By prioritizing proper ventilation, you can create a safer and healthier environment for your laser cutting projects.

Moving on to the next section, it’s crucial to regularly inspect and maintain the laser cutter to ensure optimal performance and safety.

Regularly Inspect and Maintain the Laser Cutter

Don’t neglect the importance of regular inspection and maintenance for optimal performance and safety of your laser cutting equipment. Laser cutters are complex machines that require routine checks and upkeep to ensure they’re operating efficiently and safely. To keep your equipment in top shape, follow these maintenance procedures:

- Inspect the laser tube for any signs of damage or wear.

- Clean the lens and mirrors regularly to remove any dust or residue that can affect the quality of the laser beam.

- Check the alignment of the mirrors to ensure accurate cutting and engraving.

- Verify the cooling system is functioning properly and the water is clean and at the correct temperature.

- Keep the workspace clean and free from debris that can interfere with the laser cutter’s operation.

By regularly inspecting your equipment and performing necessary maintenance, you can prevent potential issues and keep your laser cutter running smoothly.

Now, let’s move on to the next section about following proper material handling and preparation procedures.

Follow Proper Material Handling and Preparation Procedures

When handling and preparing materials for laser cutting, it’s crucial to adopt proper procedures for optimal results and to avoid any mishaps. Start by ensuring proper material storage to maintain their integrity and prevent any damage or contamination.

Store materials in a clean and dry area, away from direct sunlight or extreme temperatures. Keep flammable materials, such as wood or paper, in a separate designated area to minimize fire risks.

Additionally, always check the material’s compatibility with the laser cutter to prevent any chemical reactions or harmful emissions. Prioritize fire prevention by removing any flammable debris from the cutting area and ensuring the laser cutter is equipped with a fire suppression system.

Proper material handling and preparation procedures are essential for a safe and successful laser cutting experience.

Transitioning into the next section, it’s equally important to educate yourself on emergency procedures and first aid to handle any unforeseen situations.

Educate Yourself on Emergency Procedures and First Aid

Be prepared for any unforeseen situations by educating yourself on emergency procedures and first aid, because you never know when accidents may happen. When working with a laser cutter, it’s crucial to have a thorough understanding of emergency response protocols and basic first aid training. Here are four key points to keep in mind:

-

Familiarize yourself with the laser cutter’s emergency shut-off procedures. Know the location of the shut-off switch and how to activate it quickly in case of an emergency.

-

Ensure you have a well-stocked first aid kit nearby. Familiarize yourself with its contents and know how to use them effectively to provide immediate assistance if needed.

-

Take a first aid training course to gain the necessary skills to handle common injuries associated with laser cutter accidents, such as burns or cuts.

-

Communicate emergency procedures and first aid knowledge with your team or colleagues who may also be working with the laser cutter. This will help create a safer environment and enable everyone to respond appropriately in case of an emergency.

Frequently Asked Questions

Can laser cutters be used on any type of material?

Laser cutters are compatible with a wide range of materials, but not all. The best materials for laser cutting include wood, acrylic, leather, paper, and fabric. These materials have properties that allow the laser to cut them with precision and accuracy. However, laser cutters are not suitable for cutting metals or materials that contain chlorine, such as PVC. It’s important to check the compatibility of the material with the laser cutter before attempting to cut it.

How often should the laser cutter be inspected and maintained?

To ensure the longevity and efficiency of your laser cutter, it’s crucial to adhere to a strict maintenance schedule. Think of your laser cutter as a well-oiled machine, requiring regular check-ups and inspections.

Laser cutter maintenance frequency depends on usage. For heavy usage, inspections should occur monthly, while lighter usage may only require inspections every three months.

By following a laser cutter inspection schedule, you can catch any potential issues early on and maintain optimal performance.

Is it necessary to have a fire extinguisher nearby while operating a laser cutter?

It’s absolutely necessary to have a fire extinguisher nearby while operating a laser cutter. Laser cutters involve the use of intense heat and highly flammable materials, which can easily lead to fires. As part of laser cutter safety measures, having a fire extinguisher within reach ensures that any potential fires can be quickly and effectively extinguished, minimizing the risk of injury or damage to the equipment. It’s crucial to prioritize safety and be prepared for any emergencies that may arise.

What are the potential health risks associated with laser cutting?

Laser cutting can be a dangerous endeavor if proper precautions aren’t taken. When it comes to your health, eye protection is absolutely vital. The intense laser beam can cause severe damage to your eyes if not shielded properly.

Additionally, the fumes released during the cutting process can be harmful if inhaled. Adequate ventilation is crucial to ensure these fumes are safely dispersed.

Take these health risks seriously and prioritize safety measures while laser cutting.

Are there any specific regulations or certifications required for operating a laser cutter?

To operate a laser cutter, there are specific regulations and certifications that must be met. These ensure the safety of both the operator and those in the surrounding area.

Regulations typically include guidelines for ventilation, fire safety, and proper training. Additionally, certifications may be required to demonstrate competency in operating the equipment.

It is important to adhere to these regulations and obtain the necessary certifications to ensure a safe working environment when using a laser cutter.

Conclusion

In conclusion, by following these laser cutter safety tips, you can ensure a safe and productive work environment. Remember to always take the time to understand the machine’s operation and safety features, wear the appropriate PPE, and create a well-ventilated workspace.

Regularly inspect and maintain the laser cutter to prevent any potential hazards. Additionally, be sure to follow proper material handling and preparation procedures to minimize risks.

Lastly, educate yourself on emergency procedures and first aid, so you can respond quickly and effectively if an accident occurs. Stay safe and keep creating!