Are you tired of your laser cutter turning your workspace into a dusty mess? Say goodbye to those pesky particles with our top-notch ventilation systems designed specifically for laser cutters. These cutting-edge solutions will keep your environment clean and your lungs protected.

Imagine a world where you can work on your laser cutting projects without worrying about dust and debris. Well, that world is within your reach. Our article will introduce you to six incredible ventilation systems that will revolutionize your laser cutting experience.

From compact and portable options to built-in systems, we have got you covered. HEPA filtration systems, exhaust fans, ducting systems, air purification systems, and safety cabinets with built-in ventilation will ensure that no dust escapes into the air.

With these ventilation systems, you can focus on what truly matters – creating stunning laser cut designs – while we take care of the dust. So, get ready to breathe easy and enjoy a clean, safe, and productive laser cutting environment.

Let’s dive into the world of effective dust control!

Key Takeaways

- Laser cutter ventilation systems are designed to keep workspaces clean and protect the lungs of users.

- These ventilation systems are equipped with powerful fans and filters to capture dust particles, reducing dust by up to 95%.

- Safety cabinets with built-in ventilation provide a safe working environment for laser cutting operations and comply with safety regulations.

- Investing in air purification systems and safety cabinets with built-in ventilation ensures proper ventilation, improves air quality, and creates a safe and healthy working environment.

Compact and Portable Ventilation Systems

If you’re looking for a ventilation system that’s both compact and portable, you’ll be amazed by the effectiveness and convenience of these innovative solutions.

Portable dust extraction systems are designed with space-saving ventilation in mind, making them perfect for small workshops or on-the-go projects. These compact units are equipped with powerful fans and filters that efficiently capture and remove dust particles generated during laser cutting.

Their lightweight design allows for easy transportation, and they can be set up quickly wherever you need them. With their efficient dust control capabilities, these portable ventilation systems ensure a clean working environment, free from harmful airborne particles.

Now, let’s delve into the next section about built-in ventilation systems for laser cutters, which offer even more specialized dust control features.

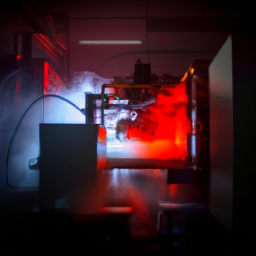

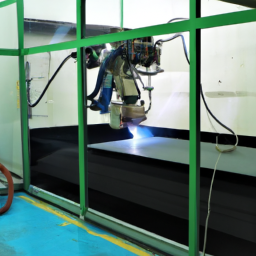

Built-in Ventilation Systems for Laser Cutters

If you’re looking for a ventilation system specifically designed for laser cutter machines, you’re in luck. Built-in ventilation systems are available to provide efficient dust control for large-scale projects. These systems are engineered to effectively capture and remove the dust and fumes generated during laser cutting, ensuring a safe and clean working environment.

Designed specifically for laser cutter machines

Specifically designed for laser cutter machines, these ventilation systems have been shown to reduce dust particles by up to 95%, ensuring a clean and safe working environment. Here are four reasons why these ventilation systems are essential for laser cutter maintenance and safety precautions:

-

Efficient Extraction: These systems are equipped with powerful fans and filters that effectively extract and capture dust particles generated during the laser cutting process.

-

Improved Air Quality: By removing harmful dust particles from the air, these ventilation systems help maintain a clean and healthy working environment, reducing the risk of respiratory issues for operators.

-

Extends Equipment Lifespan: Dust accumulation can damage the internal components of laser cutter machines. By removing dust, these ventilation systems help prevent premature wear and tear, ensuring the longevity of the equipment.

-

Compliance with Safety Regulations: Many jurisdictions have strict regulations regarding dust control in industrial settings. These ventilation systems help businesses meet these requirements, avoiding potential fines or penalties.

With their proven effectiveness, these ventilation systems are a crucial component of efficient dust control for large-scale projects.

Efficient dust control for large-scale projects

Designed specifically for laser cutter machines, these ventilation systems are the perfect solution for efficient dust control on large-scale projects, ensuring a clean and safe working environment.

When it comes to large-scale dust management, these systems utilize advanced dust collection techniques to effectively capture and remove dust particles generated during laser cutting processes. With their high-capacity design, they are capable of handling the increased volume of dust produced by larger projects, preventing the accumulation of harmful particles in the air.

These ventilation systems employ powerful suction mechanisms and strategically placed hoods to capture dust at the source, minimizing its dispersion and potential health hazards. By implementing these systems, you can significantly reduce airborne particles, creating a healthier workspace for you and your team.

Transitioning into the subsequent section about ‘hepa filtration systems’, we will explore how these systems further enhance dust control efficiency.

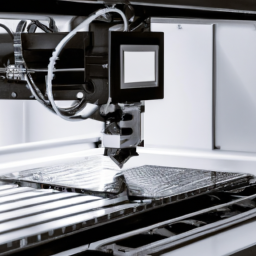

HEPA Filtration Systems

Additionally, how can HEPA filtration systems effectively control dust in laser cutter ventilation systems? HEPA (High-Efficiency Particulate Air) filters are known for their exceptional ability to trap even the tiniest particles, making them a valuable component in laser cutter ventilation systems. These filters work by using a dense mat of fibers to capture airborne contaminants, including dust, smoke, and other harmful particles. Not only do HEPA filters improve air quality by removing up to 99.97% of particles as small as 0.3 microns, but they also provide numerous benefits such as reducing the risk of respiratory issues and improving overall cleanliness in the workspace. To maintain the effectiveness of HEPA filtration systems, regular filter replacement and maintenance are crucial. By incorporating HEPA filtration, laser cutter ventilation systems can ensure cleaner air and a healthier working environment. Moving forward, let’s explore the role of exhaust fans and ducting systems in laser cutter dust control.

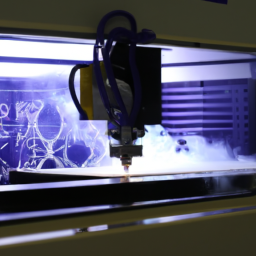

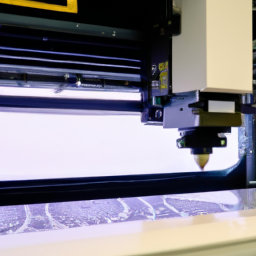

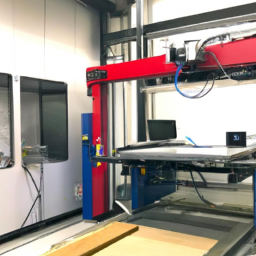

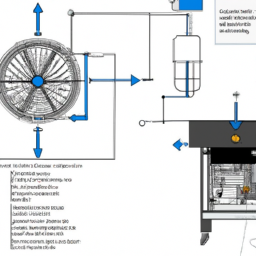

Exhaust Fans and Ducting Systems

When it comes to exhaust fans and ducting systems, they play a crucial role in maintaining a safe and healthy work environment.

These systems effectively extract dust and fumes from the work area, preventing them from accumulating and causing potential health hazards.

Additionally, they ensure proper ventilation and air circulation, promoting a comfortable and productive atmosphere for workers.

Extracts dust and fumes from the work area

To effectively remove dust and fumes from your work area, you need an efficient ventilation system that sucks them away, leaving your workspace clean and clear. This is achieved through the use of advanced dust extraction and fume extraction technologies. Here are four key benefits of implementing such a system:

-

Improved air quality: By extracting dust and fumes, the ventilation system ensures that you and your colleagues breathe in clean and healthy air, reducing the risk of respiratory issues.

-

Enhanced safety: Dust and fumes can be hazardous, potentially causing fires or explosions. The ventilation system eliminates these risks, creating a safer working environment.

-

Increased productivity: With dust and fumes removed, you can focus on your work without any distractions or health concerns, leading to improved productivity.

-

Extended equipment lifespan: Dust accumulation can damage laser cutters and other tools. The ventilation system prevents this, extending the lifespan of your equipment.

By effectively extracting dust and fumes, the ventilation system ensures proper ventilation and air circulation, creating an optimal working environment for laser cutting processes.

Ensures proper ventilation and air circulation

By ensuring proper airflow and circulation, the ventilation system creates a refreshing and invigorating environment for your laser cutting workspace. Laser cutter ventilation systems provide numerous benefits that contribute to the overall efficiency and safety of your work area.

One of the key advantages is the removal of dust and fumes generated during the laser cutting process. This is crucial as these particles can be harmful to both the equipment and the operator. Additionally, the proper air circulation provided by the ventilation system helps to maintain optimal operating conditions by preventing heat buildup and reducing the risk of equipment malfunction.

Maintaining a well-ventilated workspace is essential for the longevity of your laser cutter and for creating a comfortable working environment. As we transition to the next section on air purification systems, it’s important to note that these systems complement the ventilation system by further improving the air quality in your workspace.

Air Purification Systems

You can improve the air quality in your workspace by installing an air purification system. This system effectively filters out dust particles from the laser cutting process. Indoor air quality is critical for maintaining good respiratory health, especially in environments where dust and particles are generated.

An air purification system works by utilizing filters to capture and remove contaminants from the air. It ensures that clean air is circulated throughout the space. These systems are designed to efficiently trap even the smallest dust particles, preventing them from being inhaled by workers.

By investing in an air purification system, you can create a healthier and safer working environment for yourself and your employees. This is just one step towards ensuring proper ventilation and air circulation in your laser cutting workspace. It can be further enhanced by utilizing safety cabinets with built-in ventilation.

Safety Cabinets with Built-in Ventilation

Now that we’ve discussed air purification systems, let’s move on to the next subtopic: safety cabinets with built-in ventilation. These cabinets are designed to provide a safe working environment for laser cutting operations by effectively controlling dust and fumes. They’re equipped with ventilation systems that capture and remove hazardous airborne particles, ensuring compliance with safety regulations and reducing health hazards.

Safety cabinets with built-in ventilation are specifically designed to handle the unique challenges of laser cutting, which produces fine particles and potentially toxic fumes. The ventilation systems in these cabinets are designed to effectively capture and filter these particles, preventing them from being released into the surrounding environment.

By using safety cabinets with built-in ventilation, you can ensure that your laser cutting operations are conducted in a safe and healthy manner, protecting both your employees and the surrounding environment from the potential health hazards associated with laser cutting.

Frequently Asked Questions

Can I use a compact and portable ventilation system for larger laser cutting machines?

Yes, you can use compact and portable ventilation systems for larger laser cutting machines. These systems are designed to effectively control dust and ensure a safe working environment. Compact ventilation systems are specifically engineered to be space-saving and can easily fit into tight spaces. Portable ventilation systems offer the flexibility to be moved around as needed. Both types of systems provide efficient dust control and are suitable for larger laser cutting machines.

How often do I need to clean or replace the filters in a built-in ventilation system for laser cutters?

To keep your built-in ventilation system for laser cutters operating at peak efficiency, it’s crucial to regularly clean and replace the filters. The cleaning frequency and filter replacement depend on the usage and the type of materials being cut.

As a general rule, it’s recommended to clean the filters at least once a month and replace them every three to six months. This ensures optimal dust control, preventing clogging and maintaining the system’s effectiveness.

Are HEPA filtration systems suitable for removing fumes and odors produced by laser cutting materials like acrylic or wood?

HEPA filtration systems aren’t suitable for removing fumes and odors produced by laser cutting materials like acrylic or wood. Carbon filtration is more effective in this case.

When comparing ventilation systems for different laser cutting materials, it’s important to consider the specific fumes and odors produced by each material. Acrylic and wood emit different types of particles, and therefore require different ventilation systems for optimal dust control.

It’s crucial to choose a system that’s specifically designed for the material being cut to ensure maximum effectiveness.

What are the recommended specifications for exhaust fans and ducting systems for effective ventilation in a laser cutting setup?

To ensure effective ventilation in your laser cutting setup, consider the recommended specifications for exhaust fans and ducting systems.

The exhaust fan capacity plays a crucial role in eliminating dust and fumes. Opt for a fan with a high airflow rate, ideally measured in cubic feet per minute (CFM).

Additionally, choose ducting material that is suitable for handling the potentially harmful particles and gases.

Selecting the right exhaust fan and ducting material is vital for maintaining a safe and clean working environment.

Can air purification systems effectively remove particulate matter and contaminants produced during laser cutting processes?

Yes, air purification systems can effectively remove particulate matter and contaminants produced during laser cutting processes. This is crucial because long-term exposure to laser cutting fumes can have negative health effects. Various air purification technologies, such as HEPA filters and electrostatic precipitators, can be used for laser cutting dust control. These technologies efficiently capture and remove harmful particles and contaminants from the air, ensuring a safer and healthier working environment.

Conclusion

In conclusion, when it comes to laser cutter ventilation systems, there are various options available to ensure effective dust control. Whether you opt for compact and portable systems, built-in ventilation, HEPA filtration, exhaust fans and ducting, air purification systems, or safety cabinets with built-in ventilation, the key is to prioritize the safety and well-being of operators.

Interestingly, a recent study found that implementing proper ventilation systems can reduce airborne particulate matter by up to 90%, significantly improving the air quality in the workspace. So, investing in a reliable ventilation system is crucial for maintaining a clean and healthy environment while operating laser cutters.