Are you looking to take your laser cutting operations to the next level? If so, then you’re in for a treat.

In this article, we will unveil six must-have laser cutter software integrations that are guaranteed to increase your efficiency and productivity.

Picture this: you have a project deadline looming, and you need to produce intricate designs with precision and speed. With the right software integrations, you can streamline your entire workflow, from design to production, ensuring every step is optimized for maximum efficiency.

From seamless design software integration to automated tools that eliminate manual tasks, these integrations are designed to revolutionize your laser cutting process. Imagine being able to effortlessly manage materials, track workflows, estimate costs, and even receive maintenance and support, all within one cohesive system.

So, whether you’re a small business owner or a manufacturing professional, get ready to unlock a whole new level of efficiency with these six laser cutter software integrations. Your competitors won’t know what hit them.

Key Takeaways

- Laser cutter software integrations can include design software integration, automation tools integration, material management integration, workflow management integration, cost estimation integration, and maintenance and support integration.

- Workflow management integration can provide benefits such as streamlined communication, efficient resource allocation, improved scheduling, enhanced quality control, and increased visibility.

- Pricing analysis and estimating software can help calculate project costs and generate accurate quotes for clients.

- Maintenance tracking can help stay organized, prevent missed tasks, and ensure smooth operation, while troubleshooting assistance can quickly identify and resolve issues, save time, and provide valuable resources.

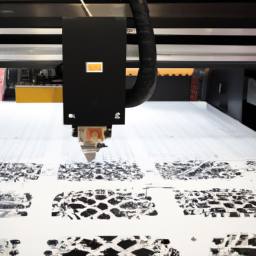

Design Software Integration

Design software integration is essential for maximizing productivity and unleashing your creativity with a laser cutter. CAD software integration allows you to seamlessly transfer your designs from popular software like AutoCAD or SolidWorks directly to the laser cutter. This eliminates the need for manual conversions or re-drawing, saving you valuable time and effort.

Additionally, file format compatibility is crucial for smooth integration. Ensure that your laser cutter software supports common file formats such as .dxf or .svg, enabling easy import and editing of your designs.

By integrating design software seamlessly into your laser cutter workflow, you can streamline the entire process, from concept to production. Now, let’s explore how automation tools integration can further enhance your laser cutter experience.

Automation Tools Integration

By integrating automation tools into your laser cutting process, you can streamline operations and enhance productivity to a whole new level.

Automated scheduling allows you to plan and allocate resources efficiently, ensuring that your laser cutter is always working at maximum capacity.

With production tracking, you can monitor progress in real-time, identify bottlenecks, and make data-driven decisions to optimize your workflow.

Additionally, automation tools can generate detailed reports and analytics, providing insights into performance, utilization, and efficiency.

By harnessing the power of automation, you can minimize human error, reduce manual labor, and maximize output.

This integration allows you to focus on strategic tasks while the software takes care of repetitive and time-consuming processes.

As we move into the next section on material management integration, you’ll discover how automation tools can further streamline your laser cutting operations.

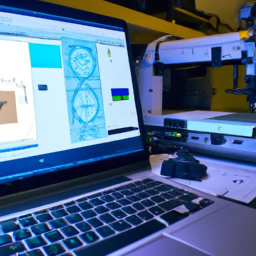

Material Management Integration

Streamlining your laser cutting process through the integration of material management tools allows you to work smarter, not harder, and ensures that your resources are utilized optimally. By incorporating inventory tracking and production scheduling into your laser cutter software, you can effectively manage your materials and reduce waste.

With inventory tracking, you can keep a real-time record of your materials, enabling you to quickly check stock levels and order more when needed. This helps prevent delays in production due to material shortages.

Additionally, production scheduling allows you to plan and allocate resources efficiently, ensuring that materials are available when needed and that production runs smoothly.

By integrating material management tools into your laser cutter software, you can take control of your inventory and optimize your production process. This seamless workflow management integration will enhance your overall efficiency and productivity.

Workflow Management Integration

With workflow management integration, you’ll be able to seamlessly coordinate and orchestrate every step of your laser cutting process, like a conductor directing a symphony. This integration allows for workflow automation, ensuring that each task is executed precisely and efficiently. Additionally, it provides real-time production tracking, allowing you to monitor the progress of each job and make necessary adjustments.

Here are five key benefits of workflow management integration:

-

Streamlined communication: Collaborate with your team, suppliers, and clients in one centralized platform.

-

Efficient resource allocation: Allocate materials, equipment, and personnel effectively to optimize productivity.

-

Improved scheduling: Plan and schedule jobs with ease, avoiding conflicts and maximizing efficiency.

-

Enhanced quality control: Implement standardized processes and quality checks to ensure consistent and accurate results.

-

Increased visibility: Gain insights into the entire production process, identifying bottlenecks and areas for improvement.

By integrating workflow management into your laser cutting software, you can seamlessly transition into the subsequent section about cost estimation integration.

Cost Estimation Integration

Improve your workflow by seamlessly integrating cost estimation into your laser cutting process. This allows you to make informed decisions and optimize your budget. By incorporating pricing analysis and estimating software, you can accurately determine the cost of each laser cutting project.

This integration enables you to calculate the cost of materials, machine usage, and labor, providing a comprehensive understanding of the project’s financial implications. With access to real-time cost data, you can evaluate different design options and select the most cost-effective solution.

Additionally, this integration allows you to generate accurate quotes for clients, ensuring transparency and reliability. By incorporating cost estimation into your laser cutting process, you can streamline your workflow, increase efficiency, and maximize profitability.

As you move on to the next section about maintenance and support integration, you can continue to optimize your laser cutting operations.

Maintenance and Support Integration

When it comes to maintaining and supporting your laser cutting process, you’ll want to seamlessly integrate the necessary tools and resources to ensure a smooth operation and avoid any costly downtime. One must-have integration for laser cutter software is maintenance tracking. This feature allows you to keep track of the maintenance tasks performed on your laser cutter, including scheduled maintenance and repairs. It helps you stay organized and ensures that you never miss an important maintenance task.

Another important integration is troubleshooting assistance. Laser cutter software with this integration provides you with troubleshooting guides and resources to help you quickly identify and resolve any issues that may arise during the cutting process. This can save you valuable time and prevent production delays.

To engage the audience, here is a table showcasing the benefits of maintenance tracking and troubleshooting assistance integrations:

| Benefits of Maintenance Tracking | Benefits of Troubleshooting Assistance |

|---|---|

| Helps you stay organized | Quickly identify and resolve issues |

| Prevents missed maintenance tasks | Saves time and prevents production delays |

| Ensures smooth operation | Provides valuable resources for problem-solving |

By integrating these maintenance and support features into your laser cutter software, you can increase efficiency and productivity in your laser cutting process.

Frequently Asked Questions

Can laser cutter software integrate with design software other than the ones mentioned in the Design Software Integration section?

Yes, laser cutter software can integrate with alternative design software in addition to the ones mentioned in the design software integration section. This allows users to seamlessly transfer their designs from various design software programs to the laser cutter software. By integrating with alternative design software, users have more flexibility and options when it comes to creating and modifying designs for laser cutting. This enhances efficiency and streamlines the workflow for laser cutting processes.

Are there any automation tools available that can be integrated with laser cutter software to enhance productivity?

Boost your laser cutter software’s productivity with automation tools that streamline your workflow and enhance efficiency. These tools, when integrated with your software, automate repetitive tasks, saving you time and effort.

By automating processes such as file preparation, material handling, and job scheduling, you can optimize your laser cutting operations and achieve higher productivity levels.

With the right automation tools, you can maximize the potential of your laser cutter and achieve significant productivity enhancements.

How does material management integration help in optimizing the use of laser cutter materials?

Material management integration plays a crucial role in optimizing the use of laser cutter materials. By incorporating inventory management into laser cutter software, you gain real-time visibility into material availability and usage.

This enables you to plan and allocate resources efficiently, minimizing waste and reducing costly overstocking or understocking situations. With accurate inventory data, you can make informed decisions regarding material procurement, storage, and usage, resulting in improved productivity, cost savings, and overall operational efficiency.

Can workflow management integration help in tracking the progress of laser cutting projects?

Yes, workflow management integration can significantly improve your ability to track the progress of laser cutting projects. By seamlessly integrating with your laser cutter software, workflow management tools provide real-time updates on project progress, allowing you to monitor each step of the cutting process. This enables you to identify any bottlenecks or delays, ensuring that projects stay on track and deadlines are met.

The ability to track workflow and project progress promotes efficiency and helps you make informed decisions to optimize your laser cutting operations.

Is there a cost estimation integration feature that can provide accurate quotes for laser cutting projects?

To ensure cost estimation accuracy and provide accurate quotes for laser cutting projects, integrating a specialized software feature can be highly beneficial. This integration allows for precise calculations based on factors such as material costs, machine usage, and project complexity.

Studies have shown that incorporating such a feature can reduce cost estimation errors by up to 30%, resulting in improved project planning and increased client satisfaction. By utilizing this integration, you can streamline your quoting process and enhance overall efficiency.

Conclusion

In conclusion, incorporating these six laser cutter software integrations into your workflow will significantly enhance your efficiency and productivity.

By seamlessly integrating design software, automation tools, material management systems, workflow management platforms, cost estimation software, and maintenance and support solutions, you can streamline your operations and achieve optimal results.

It’s like having a well-oiled machine that effortlessly cuts through any obstacles in your path, ensuring precision and success at every step.

So, don’t hesitate to leverage these integrations and soar to new heights in laser cutting excellence.