You might be thinking, ‘Ventilation tips for laser cutting? That seems unnecessary.’ But let us assure you, when it comes to laser cutting, ventilation is not only necessary, it is crucial for your safety. Laser cutting involves the use of high-powered lasers that can produce hazardous fumes and particles. Without proper ventilation, these pollutants can accumulate in your workspace, putting your health at risk.

In this article, we will provide you with 6 must-know ventilation tips to ensure safe laser cutting.

First and foremost, we will emphasize the importance of ventilation in laser cutting and debunk any doubts you may have.

Then, we will guide you through choosing a well-ventilated workspace and installing an effective exhaust system.

We will also discuss the use of proper air filtration and the importance of regularly cleaning and maintaining your ventilation system.

Lastly, we will emphasize the need for educating yourself and others on safe ventilation practices.

By following these tips, you can create a safe and healthy environment for laser cutting.

Key Takeaways

- Choose a well-ventilated workspace with natural or mechanical ventilation options.

- Install an effective exhaust system with properly sized ductwork and high-quality exhaust fans.

- Incorporate appropriate filtration systems like HEPA filters for fine particulate matter.

- Regularly inspect and clean the ventilation system to maintain proper airflow.

Understand the Importance of Ventilation in Laser Cutting

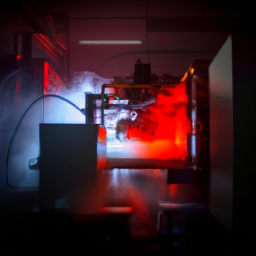

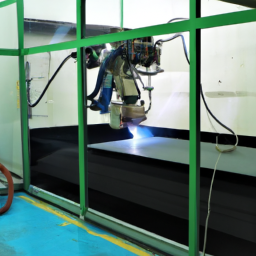

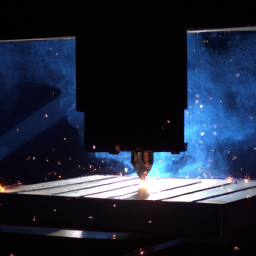

You need to understand the importance of ventilation in laser cutting to ensure your safety and the quality of your cuts. Ventilation plays a crucial role in laser engraving, as it helps to remove the fumes, dust, and harmful particles generated during the cutting process. Without proper ventilation, these byproducts can accumulate in the air, posing health risks to both you and others in the vicinity.

Inadequate ventilation can lead to respiratory problems, eye irritation, and even long-term health complications. It’s essential to have a well-ventilated workspace that allows for the efficient removal of these pollutants. This ensures a clean and safe environment for laser cutting operations.

So, let’s move on to the next section and learn how to choose a well-ventilated workspace.

Choose a Well-Ventilated Workspace

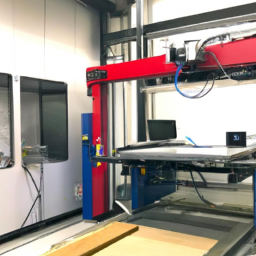

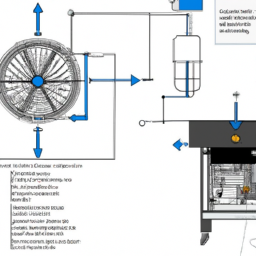

Opt for a workspace with proper ventilation to ensure a healthy environment while using lasers, as studies show that inadequate airflow can lead to a 40% increase in harmful fumes. When it comes to ventilation options, you have two choices: natural ventilation or mechanical ventilation.

Natural ventilation involves the use of windows, doors, or vents to allow fresh air to circulate in the workspace. The advantage of natural ventilation is that it can be cost-effective and energy-efficient. However, it is important to consider the weather conditions and the potential for outside pollutants to enter the workspace.

On the other hand, mechanical ventilation utilizes fans or exhaust systems to remove fumes and bring in fresh air. This option provides more control over the airflow and can effectively remove harmful particles. However, it may require additional expenses for installation and maintenance.

Having proper ventilation in laser cutting offers several benefits, including reducing the risk of respiratory issues, minimizing the accumulation of hazardous gases, and improving overall air quality. To ensure a safe laser cutting environment, opt for a workspace with proper ventilation and consider the pros and cons of natural and mechanical ventilation. Next, we will discuss how to install an effective exhaust system.

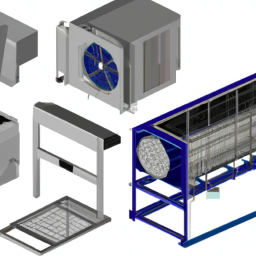

Install an Effective Exhaust System

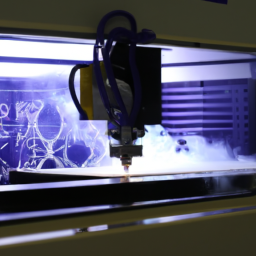

Installing an effective exhaust system ensures proper removal of fumes and improves air quality in the workspace, creating a healthier environment for laser cutting. To achieve this, it’s crucial to consider ventilation system design and maintenance. Here are four key aspects to focus on:

-

Ductwork: Ensure the ducts are properly sized and positioned to efficiently capture and remove the fumes generated during laser cutting.

-

Exhaust Fans: Install high-quality exhaust fans capable of generating sufficient airflow to effectively carry away the fumes. Regularly inspect and maintain these fans to ensure optimal performance.

-

Filtration: Incorporate appropriate filtration systems, such as HEPA filters, to remove fine particulate matter from the air. These filters should be regularly cleaned or replaced to maintain their efficiency.

-

Ventilation System Maintenance: Regularly inspect and clean the entire ventilation system, including ducts, fans, and filters, to prevent clogging and maintain proper airflow.

By following these guidelines for ventilation system design and maintenance, you can ensure a safe and healthy laser cutting workspace.

Transitioning into the next section, it’s also important to use proper air filtration to further enhance the overall ventilation system.

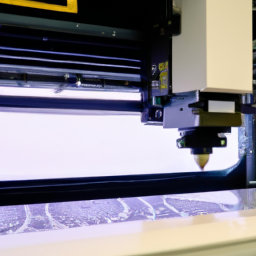

Use Proper Air Filtration

Using proper air filtration is essential for maintaining a clean and healthy workspace during laser cutting. Proper filtration ensures that fine particulate matter, such as smoke, fumes, and dust, is effectively removed from the air. This not only helps to improve air quality but also reduces the risk of respiratory issues and potential health hazards.

When selecting an air filtration system, it’s important to choose one that’s specifically designed for laser cutting applications. These systems typically consist of high-efficiency particulate air (HEPA) filters, activated carbon filters, and sometimes electrostatic filters. HEPA filters are especially effective at capturing small particles, while activated carbon filters help to remove odors and chemicals.

Regularly maintaining and cleaning your ventilation system is crucial for optimal performance. This includes replacing filters as recommended by the manufacturer and cleaning any accumulated debris or dust. By following these steps, you can ensure that your ventilation system continues to provide clean and safe air, promoting a productive and healthy laser cutting environment.

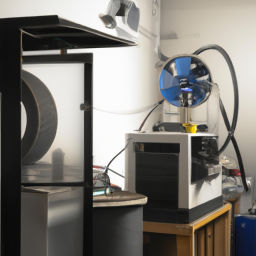

Regularly Clean and Maintain Your Ventilation System

Make sure to regularly clean and maintain your ventilation system to ensure a clean and healthy workspace for laser cutting. Proper ventilation maintenance is crucial for maintaining the efficiency and effectiveness of your system.

Over time, dust, debris, and other particles can accumulate in the filters and ductwork, reducing airflow and compromising the air quality in the workspace. To prevent this, schedule regular cleanings of the filters, ensuring they’re free from any obstructions.

Additionally, inspect the ductwork for any signs of damage or leaks, as these can also affect the functionality of the system.

Maintaining a clean and well-functioning ventilation system will not only improve the air quality but also prolong the life of your laser cutting equipment.

Transitioning into the next section, it’s equally important to educate yourself and others on safe ventilation practices.

Educate Yourself and Others on Safe Ventilation Practices

Ensure that you and your colleagues are well-informed about proper ventilation practices, as studies have shown that workplaces with adequate ventilation can reduce the risk of respiratory illnesses by up to 50%. As laser cutting operators, it is crucial to promote proper ventilation practices in the laser cutting industry and raise awareness about the health risks of inadequate ventilation in laser cutting processes. To help you understand the importance of safe ventilation, here is a table highlighting the key benefits of proper ventilation:

| Benefits of Proper Ventilation |

|---|

| 1. Reduces the concentration of harmful fumes and gases in the air |

| 2. Minimizes the risk of eye and skin irritation |

| 3. Prevents the accumulation of combustible dust |

| 4. Maintains a comfortable working environment |

| 5. Enhances overall health and well-being of operators |

By educating yourself and others on safe ventilation practices, you can ensure a safer and healthier workplace for everyone involved in laser cutting operations. Remember, knowledge is power, and it is essential to prioritize the well-being of yourself and your colleagues.

Frequently Asked Questions

What type of ventilation system is best for laser cutting?

The best type of ventilation system for laser cutting is an exhaust ventilation system. This system effectively removes the fumes and particulates generated during the laser cutting process. Proper ventilation is crucial to maintain a safe working environment and prevent the accumulation of hazardous substances.

Exhaust ventilation systems use a combination of fans, ductwork, and filters to extract and filter the contaminated air. By efficiently removing the pollutants, these systems help protect the health and safety of operators and ensure compliance with regulatory standards.

How often should the exhaust system be cleaned?

The exhaust system of your laser cutting machine needs regular maintenance to ensure its optimal performance. Cleaning the exhaust system at least once every three months is recommended to prevent clogs and maintain proper airflow.

Neglecting regular cleaning can lead to reduced ventilation efficiency and potential health hazards caused by airborne contaminants. Regular inspection and cleaning of the exhaust system are essential for a safe and efficient laser cutting environment.

Are there any specific safety regulations or guidelines for laser cutting ventilation?

To ensure safety during laser cutting, it’s crucial to adhere to specific regulations and guidelines for ventilation. These requirements aim to protect operators from harmful fumes and maintain optimal air quality. The importance of following these best practices can’t be overstated, as inadequate ventilation can lead to health risks and compromised cutting quality.

Necessary precautions include implementing a properly designed exhaust system, using high-quality filters, regularly monitoring air quality, and conducting routine maintenance and cleaning to prevent buildup and ensure efficient operation.

Can laser cutting without proper ventilation cause health hazards?

Laser cutting without proper ventilation can indeed pose significant health hazards. The process releases various airborne contaminants, such as fumes and particulate matter, which can be harmful if inhaled or exposed to the skin. These risks include respiratory irritation, eye irritation, and potential long-term health effects. Adequate ventilation is crucial to remove these hazardous substances from the cutting area and maintain a safe working environment. Therefore, ensuring proper ventilation is of utmost importance in laser cutting operations to mitigate these risks.

What are the consequences of inadequate ventilation in laser cutting?

Inadequate ventilation in laser cutting can result in severe consequences and pose significant health hazards. Without proper ventilation, harmful fumes and particles generated during the cutting process can accumulate in the air, leading to respiratory issues, eye irritation, and skin problems. Prolonged exposure to these pollutants may even cause long-term health conditions, including respiratory diseases and cancer.

Adequate ventilation is crucial to ensure a safe working environment and protect the well-being of individuals involved in laser cutting operations.

Conclusion

In conclusion, ventilation is a crucial aspect of laser cutting safety. By following these six must-know tips, you can ensure a well-ventilated workspace that protects you from harmful fumes and particles.

Remember to choose a workspace with good airflow, install an efficient exhaust system, use proper air filtration, and clean and maintain your ventilation system regularly.

Educate yourself and others on safe ventilation practices to create a safe and enjoyable laser cutting experience, like a breath of fresh air in your creative journey.