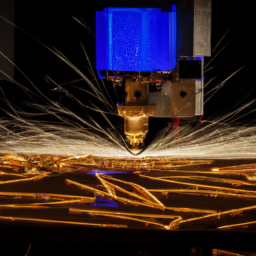

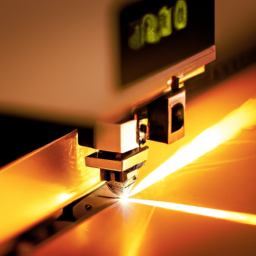

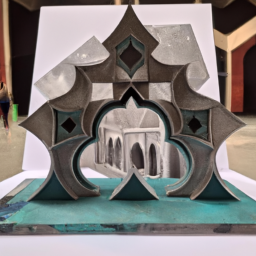

Imagine you are a sculptor, carefully chiseling away at a block of marble to reveal a masterpiece hidden within. Now, replace the chisel with a laser, and the marble with a sheet of material. As a laser cutter, you have the power to shape and create intricate models with precision.

However, with great power comes great responsibility, and in this case, the responsibility lies in controlling the dust that is generated during the cutting process.

Dust may seem insignificant, but it can cause serious health hazards and damage to your equipment. That’s why it is crucial to invest in effective dust control solutions.

In this article, we will explore six products that will help you maintain a clean and safe environment when laser cutting models.

From air filtration systems to vacuum devices, dust masks to dust shields, cleaning tools to maintenance schedules, we will provide you with a comprehensive guide to keeping dust at bay.

So, let’s dive in and discover the tools that will ensure your laser cutting experience is not only precise and efficient but also dust-free.

Key Takeaways

- Investing in dust control solutions is important for safety when laser cutting models.

- Air filtration systems and dust extraction systems are effective in removing airborne particles and ensuring a clean working environment.

- Using vacuum devices and portable dust collectors helps to collect and remove dust and debris from the cutting area.

- Regular maintenance and cleaning, including the use of brushes, swabs, and lint-free cloths, are essential for maintaining the efficiency and longevity of the laser cutter.

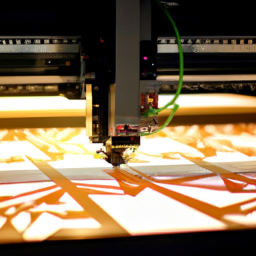

Air Filtration Systems

You’ll want to invest in an air filtration system to ensure that the dust particles from laser cutting models are effectively removed from the air, keeping your workspace clean and safe. Air purifiers and dust extraction systems are key components of an effective dust control strategy in laser cutting.

These systems work by capturing and filtering the airborne particles, preventing them from settling on surfaces and minimizing the risk of inhalation. Air purifiers use high-efficiency filters to trap even the smallest particles, while dust extraction systems use powerful suction to draw in and collect the dust.

By incorporating these technologies into your workspace, you can significantly reduce the amount of dust generated during laser cutting.

Now, let’s move on to the next section about vacuum devices.

Vacuum Devices

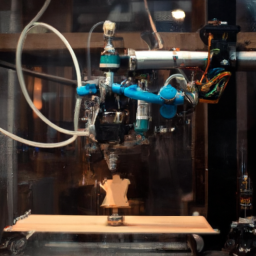

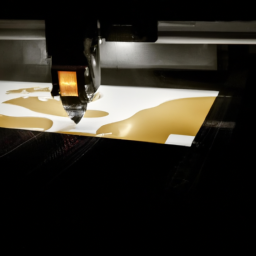

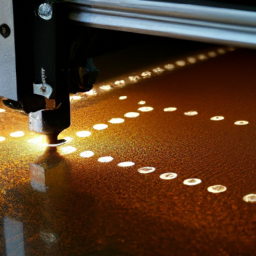

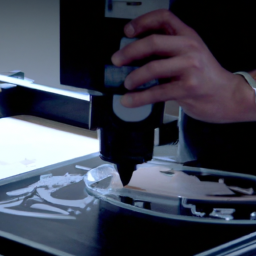

For better results, grab a vacuum device to keep those pesky particles at bay while laser cutting your masterpieces. Vacuum attachments are essential tools that can be easily attached to your laser cutting machine to effectively collect dust and debris as you work.

These attachments are designed to capture particles directly at the source, ensuring a clean and safe working environment. Additionally, portable dust collectors are another option to consider. These devices are specifically designed to provide powerful suction and filtration, effectively removing dust particles from the air.

With their compact size and mobility, portable dust collectors can be easily moved around your workspace to target specific areas where dust is generated. By using vacuum devices and portable dust collectors, you can significantly reduce airborne particles and maintain a clean workspace for optimal laser cutting results.

Now, let’s discuss the importance of dust masks in ensuring your safety during the process.

Dust Masks

Imagine the relief you’ll feel when you slip on a dust mask and take a deep breath, knowing that your lungs are protected from harmful particles during the laser cutting process. Dust masks are an essential tool for effective dust control, but it’s important to choose the right one for the job.

Here are some key factors to consider when selecting a dust mask:

- Particle filtration: Look for masks that have a high filtration efficiency, capable of trapping even the smallest particles.

- Fit and seal: A proper fit is crucial to ensure that no particles can bypass the mask. Look for masks with adjustable straps and a nose clip for a secure seal.

- Comfort: Opt for masks that are lightweight, breathable, and comfortable to wear for extended periods.

- Certification: Choose masks that meet the appropriate safety standards for respiratory protection.

Now that you understand the importance of dust mask effectiveness and choosing the right one, let’s delve into the next section about ‘dust shields’.

Dust Shields

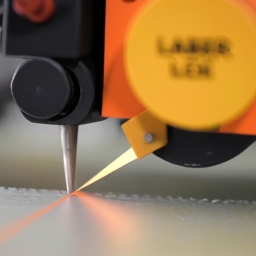

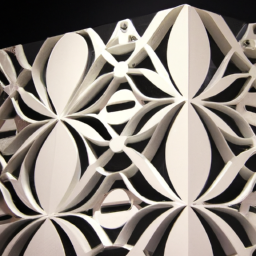

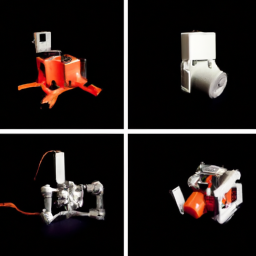

To effectively control dust when laser cutting models, it’s essential to cover the laser cutter with a dust shield. This not only helps contain the dust within the cutting area but also prevents it from settling on the machine itself.

By implementing this simple yet crucial step, you can maintain a clean and efficient laser cutting environment. This ensures optimal performance and longevity of the equipment.

Cover the Laser Cutter to Contain Dust

One way to make laser cutting more enjoyable is by covering the laser cutter to keep the dust contained. Dust shields are one of the containment measures used to prevent the dispersion of dust particles into the surrounding environment. These shields are typically made from transparent materials, such as acrylic or polycarbonate, that allow the operator to observe the cutting process while also providing a barrier against dust.

Additionally, some dust shields are equipped with built-in dust extraction systems, which effectively capture and remove the dust generated during laser cutting. By utilizing a dust shield with a dust extraction system, you can ensure that the dust is efficiently collected and prevented from settling on the machine. This helps maintain the cleanliness of the laser cutter and prolong its lifespan.

Transitioning into the subsequent section, it’s important to take additional steps to prevent dust from settling on the machine.

Prevent Dust from Settling on the Machine

Keep your laser cutter clean and dust-free by taking proactive measures to prevent dust from settling on the machine. Preventing dust accumulation not only helps maintain the efficiency of the machine but also reduces machine downtime. To achieve this, consider using the following methods:

| Method | Description |

|---|---|

| Air purifiers | Install air purifiers in the vicinity of your laser cutter to filter out airborne particles, preventing them from settling on the machine. This helps maintain a cleaner working environment and reduces the risk of dust interfering with the laser cutting process. |

| Vacuum systems | Implement vacuum systems specifically designed for laser cutters. These systems capture and remove dust produced during the cutting process, preventing it from accumulating on the machine and other surfaces in the workspace. |

| Regular cleaning | Establish a regular cleaning routine to remove any dust or debris that may have settled on the machine. Use lint-free cloths or compressed air to gently wipe or blow away the dust. Avoid abrasive materials that could damage the machine’s delicate components. |

By implementing these preventive measures, you can significantly reduce the amount of dust that settles on your laser cutter, ensuring its optimal performance and longevity. In the next section, we will discuss the necessary cleaning tools to maintain your machine effectively.

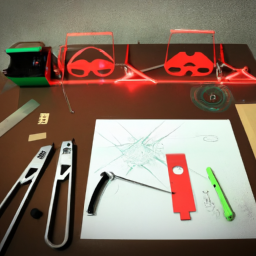

Cleaning Tools

To maintain the efficiency of your laser cutter and prevent dust build-up, it’s essential to use brushes and swabs specifically designed for cleaning.

These tools effectively remove dust and debris from the machine’s surfaces and components, ensuring optimal performance.

Regular cleaning with brushes and swabs not only keeps your laser cutter in top condition but also extends its lifespan, minimizing the need for costly repairs or replacements.

Use Brushes and Swabs to Clean Dust Build-Up

Using brushes and swabs to clean dust build-up feels like gently sweeping away a shimmering curtain of tiny particles, revealing the pristine surface beneath.

Brush and swab techniques are essential for effectively removing dust from your laser cutter. When it comes to cleaning, these tools offer precision and control, allowing you to target specific areas and remove even the smallest particles.

Whether you’re using a soft-bristle brush or a specialized swab, these tools ensure thorough cleaning without causing any damage to the delicate components of your laser cutter.

While there are alternative cleaning methods available, brushes and swabs remain the most efficient and reliable options. By incorporating these techniques into your regular maintenance routine, you can maintain the efficiency of your laser cutter and ensure optimal performance for years to come.

Maintain the Efficiency of Your Laser Cutter

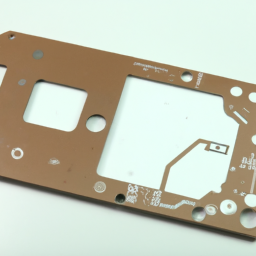

Maintaining the efficiency of your laser cutter is crucial for ensuring its long-lasting performance and avoiding any potential issues down the line. To improve laser cutting precision and reduce material waste, there are several key steps you can take.

First, regularly check and calibrate the laser beam alignment to ensure accurate cutting. Additionally, keep the lens clean and free from debris to optimize focus and minimize distortion. Properly maintaining and replacing consumable parts, such as nozzles and filters, is also essential for consistent cutting performance.

Finally, regularly inspect and clean the exhaust system to prevent dust buildup, which can affect both the machine’s efficiency and the quality of cuts. By following these guidelines, you can ensure optimal performance and extend the lifespan of your laser cutter.

Transitioning into the subsequent section on maintenance and cleaning schedule, it’s important to establish a regular routine for these tasks.

Maintenance and Cleaning Schedule

To ensure the optimal functioning and longevity of your laser cutter, it’s crucial to establish a regular cleaning routine.

By regularly cleaning and maintaining your machine, you can minimize the accumulation of dust and debris. This can lead to poor cutting quality and potential damage to the components.

This proactive approach will not only extend the lifespan of your laser cutter but also result in consistent and precise cutting results.

Establish a Regular Cleaning Routine

Make sure to regularly clean your workspace to keep it free from dust when laser cutting models. Dust accumulation can hinder the performance of your laser cutter and affect the quality of your cuts. Establishing a cleaning routine is crucial for maintaining optimal efficiency. Here’s a step-by-step guide to help you establish a regular cleaning routine:

-

Start by wiping down the laser cutter’s exterior with a lint-free cloth.

-

Use compressed air to blow away any loose dust and debris from the machine’s interior.

-

Clean the laser lens using a specialized lens cleaning solution and a microfiber cloth.

-

Vacuum the surrounding area to remove any dust particles that may have settled.

By following this cleaning routine, you can ensure that your workspace remains dust-free, allowing your laser cutter to perform at its best. This will help extend the lifespan of your laser cutter and maintain the quality of your cuts.

Extend the Lifespan of Your Laser Cutter

By taking proper care of your laser cutter, you can significantly prolong its lifespan and ensure consistent and high-quality performance.

To extend the lifespan of your laser cutter and improve its performance, there are a few key steps you should follow. Firstly, regularly clean the machine’s lenses and mirrors using a lint-free cloth and a specialized lens cleaner. This will prevent dust and debris from accumulating and affecting the laser’s accuracy.

Secondly, ensure that the machine’s ventilation system is properly maintained and free from dust buildup. This will help to prevent overheating and maintain optimal operating conditions.

Lastly, regularly inspect and replace worn-out parts, such as belts and filters, to ensure smooth operation and prevent any potential damage.

By following these maintenance practices, you can significantly extend the lifespan of your laser cutter and enjoy consistent, high-quality performance for years to come.

Frequently Asked Questions

How often should the filters in an air filtration system be replaced?

To properly maintain an air filtration system, it’s important to regularly replace the filters. This is crucial for effective dust control, especially when laser cutting models. Filters should be replaced according to the manufacturer’s recommendations, which can vary depending on usage and the type of filters being used. Regular filter replacement ensures that the system continues to function optimally, removing harmful particles and maintaining clean air quality in the working environment.

Can a vacuum device effectively remove dust particles from tight corners and crevices?

Yes, a vacuum device can effectively remove dust particles from tight corners and crevices. Dust control techniques for woodworking projects often require reaching those hard-to-reach areas, and a vacuum device is ideal for this task.

Proper ventilation is crucial in laser cutting environments, as it helps eliminate harmful fumes and keeps the workspace clean. Incorporating a vacuum device into your dust control strategy ensures thorough cleaning and promotes a safe and efficient working environment.

Are dust masks suitable for people with respiratory conditions?

Dust masks may not be suitable for individuals with respiratory conditions. However, there are alternative dust control measures that can be used. These measures include using a respirator with a higher level of filtration, such as an N95 mask, or using a powered air-purifying respirator (PAPR).

These options provide better protection against dust particles and can be more effective for individuals with respiratory conditions. It’s important to consult with a healthcare professional to determine the best dust control option for your specific condition.

Do dust shields require any special installation or setup?

To install and set up a dust shield, you’ll need a few key steps.

Firstly, ensure you have the necessary tools and materials, including the dust shield itself and any mounting brackets or hardware.

Next, identify the ideal location for the shield, considering the direction of the laser cutting process and the area requiring protection.

Once positioned, securely attach the shield using the provided brackets or other suitable methods.

Finally, verify that the shield is properly aligned and adjusted for optimal dust containment during laser cutting.

What type of cleaning tools are recommended for removing dust from laser cutting machines?

To ensure optimal performance of your laser cutting machine, it’s important to clean and maintain it properly. Using the right cleaning tools is crucial when removing dust. One interesting statistic to note is that 80% of machine failures are caused by improper cleaning techniques. To avoid these issues, it’s recommended to use soft brushes, compressed air, and lint-free cloths for cleaning.

Regular maintenance tips include checking filters, cleaning lenses, and keeping the machine free from debris.

Conclusion

In conclusion, ensuring effective dust control when laser cutting models is crucial for maintaining a clean and healthy working environment. By implementing the use of air filtration systems, vacuum devices, and dust masks, you can greatly reduce the risk of dust-related health issues and equipment damage. Additionally, using dust shields and cleaning tools, as well as following a regular maintenance and cleaning schedule, will help keep your workspace dust-free. So, don’t let the dust settle and compromise your productivity. Stay ahead of the game and keep your workspace dust-free with these cutting-edge solutions.