In a world where time is of the essence and precision is paramount, laser cutter software has emerged as a game-changer for those seeking to enhance their workflow. With its advanced features and tools, it allows you to unleash your creativity and maximize efficiency in ways that were once unimaginable. Gone are the days of laborious manual tasks and tedious design processes.

Today, laser cutter software offers a plethora of benefits that can revolutionize your work. From design optimization to automation of repetitive tasks, these software features streamline your workflow and save you valuable time. Moreover, with a comprehensive material library and precision tools at your disposal, you can achieve unparalleled accuracy and consistency.

Seamlessly integrating with your existing workflow and providing insightful data analysis and reporting, laser cutter software empowers you to take your projects to new heights. Discover the six ways to boost your productivity and efficiency with laser cutter software features and witness the transformation it brings to your work.

Key Takeaways

- Design optimization features for maximum efficiency

- Automation of repetitive tasks saves time and minimizes errors

- Nesting algorithms minimize waste and maximize productivity

- Real-time collaboration allows multiple team members to work on the same file simultaneously

Design Optimization

To boost your workflow with the laser cutter software’s design optimization features, you’ll need to fine-tune your designs for maximum efficiency.

Design customization plays a crucial role in this process as it allows you to tailor your designs to specific requirements, saving time and material. With the software’s advanced tools, you can easily modify shapes, sizes, and dimensions to achieve the desired outcome.

Additionally, the software provides real-time feedback on the feasibility of your design, enabling you to make necessary adjustments before sending it to the cutter. This level of precision ensures that your workflow efficiency is maximized, reducing the need for rework and minimizing errors.

By optimizing your designs, you pave the way for the subsequent section on automation of repetitive tasks, streamlining your entire laser cutting process.

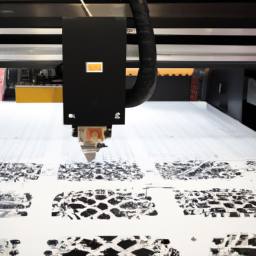

Automation of Repetitive Tasks

Ironically, the laser cutter software can take care of those mind-numbing repetitive tasks for you. By automating these tasks, you can experience a range of benefits and productivity enhancements.

The software allows you to create templates and presets for commonly used designs or settings, eliminating the need to manually input them every time. This automation also minimizes human error and ensures consistent results.

Additionally, the software can automatically generate cutting paths, saving you time and effort. It can optimize the layout of your designs on the material, reducing waste and maximizing the use of your resources.

With automation, you can focus on more important aspects of your workflow, such as design creativity and problem-solving.

Transitioning into the subsequent section about the material library and settings, you can further streamline your workflow by utilizing the software’s extensive library and customizable settings.

Material Library and Settings

Discover how the extensive material library and customizable settings can revolutionize your laser cutting experience.

With laser cutter software, you can access a vast collection of customizable templates for various materials, including wood, acrylic, and metal. These templates provide a starting point for your designs, saving you time and effort.

Additionally, the software’s advanced nesting algorithms optimize material usage, allowing you to maximize productivity and minimize waste. You can adjust settings such as speed, power, and frequency to achieve the desired cutting and engraving results for different materials. This level of customization ensures precision and accuracy in your projects.

Now, let’s explore the next section on precision and accuracy tools for even greater control over your laser cutting process.

Precision and Accuracy Tools

To achieve the highest level of precision and accuracy when using a laser cutter, you can utilize various software features.

Fine-tuning cutting parameters through software allows you to make precise adjustments and achieve optimal results. By adjusting power, speed, and frequency settings, you can ensure that your cuts are clean and accurate.

Additionally, using camera or sensor alignment systems enables you to position your materials with utmost precision, guaranteeing that your cuts are aligned exactly as intended.

Use software features to fine-tune cutting parameters

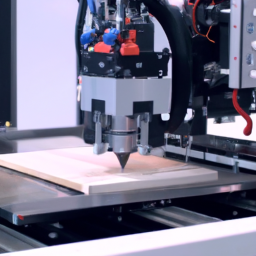

Maximize your laser cutting potential by tweaking the parameters with precision using the powerful software features. Take advantage of the cutting techniques offered by the software to achieve the desired results.

With software compatibility, you can easily import your designs and fine-tune the cutting parameters to ensure accuracy and efficiency. Adjust power, speed, and frequency settings to optimize your cuts for different materials and thicknesses. The software allows you to experiment with various combinations, helping you find the perfect balance for each project.

By fine-tuning these parameters, you can achieve cleaner cuts, reduce material waste, and increase productivity. With the ability to customize and refine your settings, you can unlock the full potential of your laser cutter.

Transitioning into the next section, you can also adjust power, speed, and frequency settings for optimal results.

Adjust power, speed, and frequency settings for optimal results

Fine-tuning the power, speed, and frequency settings of your laser cutter will unlock the full potential of your projects, allowing you to achieve optimal results and leave a lasting impression. Adjusting the power level determines the intensity of the laser beam, influencing the depth and quality of the cuts. By optimizing the power, you can ensure clean and precise cuts without excessive burning or charring.

Similarly, adjusting the speed of the laser cutter affects the rate at which it moves, directly impacting the overall efficiency and accuracy of the process. Finding the right balance between speed and power is crucial to achieve the desired outcome.

Additionally, adjusting the frequency settings can help optimize efficiency by controlling the number of laser pulses per second. By fine-tuning these parameters and adjusting focus, you can ensure superior cutting performance.

Transitioning to the next section, you can further enhance precision by utilizing camera or sensor alignment systems for precise positioning.

Utilize camera or sensor alignment systems for precise positioning

To achieve optimal results when using a laser cutter, it’s crucial to fine-tune the power, speed, and frequency settings. However, there’s another feature that can take your precision to the next level: camera or sensor alignment systems.

By utilizing these tools, you can ensure precise positioning of your materials, allowing for accurate cuts and engravings. The camera calibration feature provides real-time feedback, allowing you to make adjustments on the spot and eliminate any potential errors.

With this technology, you can easily align your designs with the exact placement on your materials, saving you time and reducing waste.

By incorporating camera or sensor alignment systems into your laser cutter workflow, you can enhance your efficiency and precision. This seamless integration will streamline your processes and help you achieve flawless results with every project.

Workflow Integration

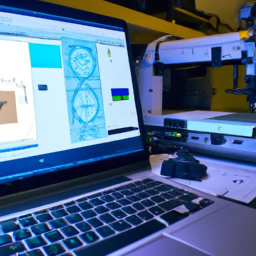

To optimize your workflow, integrate your laser cutter software with your design or CAD software. This will allow for seamless transfer of files and streamline the process from design to cutting.

Import and export files in various formats to ensure compatibility and ease of use. You can also collaborate with your team members by sharing and accessing files remotely, enabling efficient communication and teamwork.

Integrate laser cutter software with design or CAD software

Maximize your productivity by seamlessly connecting your laser cutter software with your favorite design or CAD software. This allows you to effortlessly transform your creative ideas into stunning laser-cut masterpieces. With seamless compatibility between the laser cutter software and design or CAD software, you can easily import your designs and make precise adjustments before sending them to the laser cutter.

This integration enhances productivity by eliminating the need for manual file conversions or recreating designs in different software programs. Whether you prefer working in Adobe Illustrator, AutoCAD, or other popular design software, the laser cutter software can seamlessly import your files in various formats, such as SVG, DXF, or AI.

Furthermore, you can export your finished designs back to your design or CAD software for further modifications or future projects. This streamlined process ensures a seamless workflow from design to the final product.

Import and export files in various formats for seamless workflow

Now that you’ve successfully integrated your laser cutter software with design or CAD software, it’s time to explore the next crucial aspect of boosting your workflow: file compatibility and conversion.

Laser cutter software should allow you to import and export files in various formats, ensuring seamless integration with your existing design files. This feature is essential for maintaining the integrity of your designs and avoiding time-consuming rework.

Whether you’re working with vector files, raster images, or even 3D models, the ability to import and export in a wide range of formats will save you valuable time and effort.

Additionally, file conversion capabilities enable you to convert files from one format to another, opening up possibilities for collaboration and ensuring compatibility with different software tools.

With these file compatibility and conversion features, you can now seamlessly transition into the subsequent section about collaborating with team members by sharing and accessing files remotely.

Collaborate with team members by sharing and accessing files remotely

Enhance your team’s efficiency by easily sharing and accessing files remotely. With laser cutter software features, remote collaboration becomes seamless, allowing team members to work together effortlessly.

Here are two ways you can boost your workflow through remote file sharing:

-

Real-time collaboration: Laser cutter software enables multiple team members to work on the same file simultaneously. This feature facilitates instant communication and feedback, streamlining the design process.

-

Cloud storage integration: By integrating with cloud storage platforms like Google Drive or Dropbox, laser cutter software ensures that files are accessible from anywhere, at any time. This allows team members to retrieve and modify files remotely, eliminating the need for physical file transfers or USB drives.

Transitioning into the next topic of data analysis and reporting, laser cutter software also offers powerful tools for analyzing and reporting on your workflow data.

Data Analysis and Reporting

Improve your workflow by utilizing data analysis and reporting features available in laser cutter software. These features allow you to analyze and interpret data to make informed decisions and optimize your laser cutting process.

With data visualization tools, you can easily understand and interpret complex data sets by representing them visually through charts, graphs, and diagrams. This helps you identify patterns, trends, and outliers that may affect the quality and efficiency of your laser cutting projects.

Additionally, predictive analytics enables you to forecast future outcomes based on historical data, allowing you to anticipate potential issues and take proactive measures to prevent them.

By harnessing the power of data analysis and reporting, you can optimize your laser cutter workflow and achieve greater precision and productivity.

Frequently Asked Questions

Can laser cutter software help me optimize my designs for better efficiency and reduced material waste?

Yes, laser cutter software can significantly enhance your designs by reducing production time and optimizing material usage.

With advanced features like nesting, you can efficiently arrange multiple parts on a single sheet, minimizing waste and maximizing material utilization.

Additionally, the software enables you to precisely adjust cutting parameters, ensuring efficient and accurate cuts.

By harnessing these capabilities, you can streamline your workflow, achieve better efficiency, and minimize material waste, ultimately boosting your overall productivity.

Is it possible to automate repetitive tasks such as file preparation and cutting parameters setup with laser cutter software?

Yes, laser cutter software allows for automating laser cutting processes, enhancing productivity. By utilizing the software’s features, you can automate repetitive tasks like file preparation and cutting parameters setup.

This streamlines the workflow and saves valuable time. The software’s ability to automate these processes ensures consistency and accuracy, reducing the chances of errors.

With laser cutter software, you can optimize your workflow, increase efficiency, and achieve better results in a shorter span of time.

Does laser cutter software provide a material library and settings database to easily select and apply the appropriate settings for different materials?

Yes, laser cutter software often includes a material library and settings database to simplify the process of selecting and applying appropriate settings for different materials. This feature enhances your workflow by providing a user-friendly interface that allows you to easily navigate through the available materials and their corresponding settings.

With this functionality, you can ensure material compatibility and optimize your laser cutting process with precise and technical control over the cutting parameters.

Are there precision and accuracy tools within laser cutter software to ensure precise cuts and engraving?

Looking to ensure precise cuts and engraving with laser cutter software? Does it offer precision measurement and laser alignment tools?

Absolutely! Laser cutter software provides a range of features to guarantee accuracy in your projects. With precision measurement tools, you can precisely set the dimensions of your cuts and engravings.

Additionally, laser alignment tools allow you to align the laser beam exactly where you want it, ensuring precise and accurate results every time.

Can laser cutter software integrate with other software or tools in my workflow, such as design software or CNC machines, for seamless integration and increased productivity?

Yes, laser cutter software can integrate with other software or tools in your workflow, such as design software or CNC machines, to ensure seamless integration and improved productivity.

Laser cutter software compatibility allows you to easily import designs from popular design software programs and directly control your laser cutter machine. This streamlines the workflow by eliminating the need for manual file conversions and allows for precise control over the cutting and engraving process, ultimately improving workflow efficiency.

Conclusion

As you conclude your laser cutter software journey, imagine a symphony of precision and efficiency.

With design optimization, automation of repetitive tasks, material library and settings, precision and accuracy tools, workflow integration, and data analysis and reporting, you have unlocked the secrets to a seamless workflow.

Like a conductor guiding each note, these features work in harmony to elevate your productivity.

Your projects will dance with finesse, as every cut and engraving is executed flawlessly.

Embrace the power of laser cutter software and witness your creative symphony unfold before your eyes.