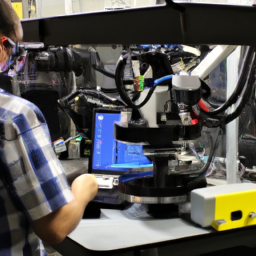

Did you know that laser cutters are used in a wide range of industries, from manufacturing to healthcare? These powerful machines are capable of precision cutting and engraving, making them essential tools in the modern workplace.

However, like any piece of equipment, laser cutters require regular maintenance to ensure optimal performance and longevity. In fact, studies have shown that lack of maintenance can lead to decreased productivity and increased downtime.

To help you keep your laser cutter running smoothly, we have compiled a list of 7 best practices for maintenance in the workplace. From regular cleaning and lubrication to proper ventilation and air filtration, these practices will not only extend the lifespan of your laser cutter but also contribute to a safer working environment.

So, let’s dive in and discover how you can maximize the efficiency and lifespan of your laser cutter through proper maintenance techniques.

Key Takeaways

- Regular cleaning and lubrication are necessary for optimal performance and to prevent downtime.

- Proper ventilation and air filtration are crucial for a safe working environment and to improve air quality.

- Regular inspection and cleaning of the exhaust system are necessary for safety and longevity.

- Training and ongoing education are important for safe operation, maintenance, and to stay updated on safety guidelines and maintenance techniques.

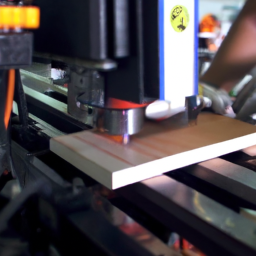

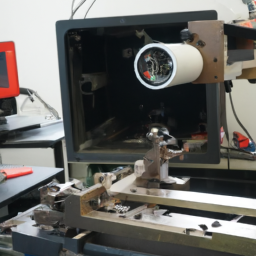

Regular Cleaning and Lubrication

To keep your laser cutter running smoothly, make sure you regularly clean and lubricate it to prevent build-up and ensure optimal performance.

When it comes to cleaning techniques, start by removing any debris or residue from the laser cutter’s surface using a soft cloth or brush. Be careful not to scratch the surface. For more stubborn stains, use a mild detergent or cleaning solution specifically designed for laser cutters. Remember to always follow the manufacturer’s instructions when using any cleaning products.

As for lubrication methods, apply a small amount of lubricant to the moving parts of the laser cutter, such as the rails and bearings, to reduce friction and extend their lifespan. Regular maintenance and lubrication will help your laser cutter operate smoothly and efficiently.

Now, let’s move on to the next topic of proper ventilation and air filtration.

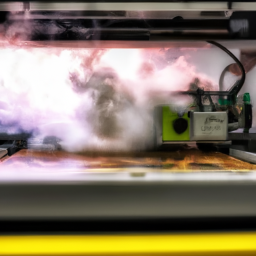

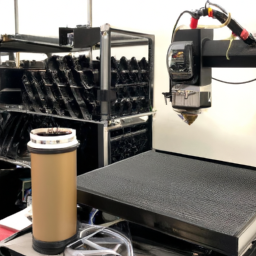

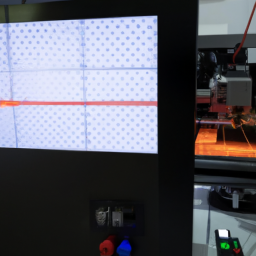

Proper Ventilation and Air Filtration

To ensure adequate airflow in your laser cutter workspace, it’s crucial to use an exhaust system that effectively removes smoke, fumes, and particulates generated during the cutting process.

Installing an air filtration system will further enhance the air quality by removing any remaining contaminants.

By implementing these measures, you can create a safe and healthy working environment for both yourself and your colleagues.

Ensure Adequate Airflow

Maximize the efficiency and longevity of your laser cutter by ensuring that there’s sufficient airflow in your workplace. Proper airflow optimization is crucial for the optimal performance of your laser cutter and the prevention of potential damage. Here are two key factors to consider:

-

Positioning: Place your laser cutter in an area with adequate space around it to allow for proper air circulation. Ensure that there aren’t any obstructions or blockages that could impede airflow.

-

Ventilation: Install an efficient ventilation system that can effectively remove the heat generated by the laser cutter. This’ll help maintain a stable operating temperature and prevent overheating.

By optimizing airflow and implementing a suitable dust management system, you can minimize the risk of dust accumulation on sensitive components and avoid potential malfunctions. These measures’ll also help improve the overall air quality in your workplace.

In the next section, we’ll explore the importance of using an exhaust system for further protection.

Use Exhaust System

Using an exhaust system is essential for ensuring the safety and longevity of your laser cutter while creating a healthier work environment. Proper exhaust system maintenance is crucial to keep your laser cutter running smoothly.

Regularly inspect the exhaust system for any signs of damage or wear, such as leaks or loose connections. Clean the exhaust system regularly to remove any debris or buildup that may obstruct the airflow. Troubleshooting exhaust issues should be done promptly to prevent any potential hazards. Check for any obstructions in the exhaust ducts and ensure that the exhaust fan is functioning properly.

Regularly replace worn-out filters to maintain the efficiency of the exhaust system. By properly maintaining your exhaust system, you can prevent fumes and particles from circulating in the workplace.

In the next section, we’ll discuss the importance of installing an air filtration system.

Install Air Filtration System

Installing an air filtration system is a crucial step in creating a healthier and safer work environment for your laser cutting operations. This system plays a vital role in improving air quality by removing harmful particles and fumes generated during the cutting process. It ensures that the air in the workplace remains clean, reducing the risk of respiratory issues for employees.

Regular filter replacement is essential to maintain the effectiveness of the air filtration system. Filters should be inspected and changed according to the manufacturer’s guidelines to prevent clogging and maintain optimal performance. By installing an air filtration system and regularly replacing filters, you can significantly enhance the air quality in your workplace and promote the well-being of your employees.

Moving on to calibration and alignment, it is another critical aspect of laser cutter maintenance.

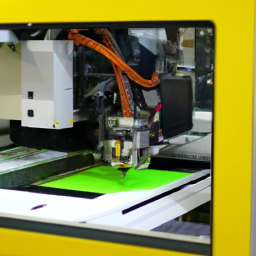

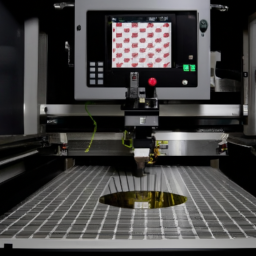

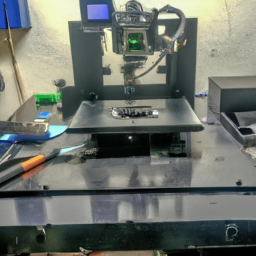

Calibration and Alignment

To ensure optimal performance, it’s essential to regularly calibrate and align the laser cutter in the workplace.

Calibration techniques involve fine-tuning the laser’s power, speed, and focus to achieve accurate cutting, engraving, and etching results. This can be done by adjusting the laser power settings, checking the beam alignment, and verifying the focal length.

Alignment methods ensure that the laser beam is properly aligned with the cutting bed, ensuring precise and consistent cuts. This can be achieved by adjusting the mirrors and lenses in the laser system.

Regular calibration and alignment prevent issues like uneven cuts, misaligned designs, and wasted materials. By maintaining precise calibration and alignment, you not only enhance the quality of your laser cutting projects but also extend the lifespan of the laser cutter.

Moving on to safety measures, it is crucial to prioritize the well-being of everyone in the workplace.

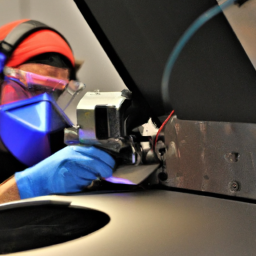

Safety Measures

Safety is paramount when operating a laser cutter, ensuring the well-being of everyone in the workplace. To maintain a safe environment, it’s crucial to have a comprehensive emergency response plan in place.

This plan should include protocols for evacuating the area, contacting emergency services, and providing first aid if necessary. Additionally, all employees should be trained on these procedures to ensure a swift and efficient response in case of an accident.

Furthermore, the use of appropriate personal protective equipment (PPE) is essential. This includes safety glasses, gloves, and fire-resistant clothing to safeguard against potential hazards. Regular inspections of the PPE should be conducted to ensure its effectiveness.

Transitioning into the subsequent section about the regular maintenance schedule, it’s important to note that safety measures should also be incorporated into this routine to prevent accidents and promote a secure working environment.

Regular Maintenance Schedule

Make sure you regularly check and clean the laser cutter to keep it in optimal condition and prevent any potential issues. Follow these safety protocols and equipment inspection procedures to ensure a safe and efficient workplace:

-

Check the laser cutter’s ventilation system regularly to ensure proper airflow and prevent the buildup of harmful fumes.

-

Inspect the laser tube and replace it if necessary to maintain consistent cutting power.

-

Clean the lens regularly to remove dust and debris that can affect the beam quality.

-

Check the alignment of the laser beam to ensure accurate cutting and engraving.

By following this regular maintenance schedule, you can minimize downtime, extend the lifespan of the laser cutter, and ensure the safety of your employees.

Moving forward into the section on ‘training and education,’ it’s important to understand the proper procedures for using the laser cutter to prevent accidents and maximize productivity.

Training and Education

Now that you understand the importance of a regular maintenance schedule for your laser cutter, let’s discuss the significance of training and education in ensuring workplace safety and equipment maintenance.

Proper training is crucial to prevent accidents and injuries when operating a laser cutter. It is essential that all employees who operate or work near the laser cutter are trained on its safe operation, including how to properly handle materials, use the appropriate safety gear, and follow established procedures.

Additionally, ongoing education is necessary to stay updated on new safety guidelines and maintenance techniques. Regular training sessions should be conducted to refresh employees’ knowledge and address any concerns or questions.

By investing in training and education, you can create a safer work environment and prolong the lifespan of your laser cutter.

Frequently Asked Questions

Can I use any type of lubricant for the laser cutter, or is there a specific one that should be used?

When it comes to lubricating your laser cutter, it’s crucial to use the recommended lubricants. Alternative lubricants may seem tempting, but they can pose potential risks to the machine’s performance and longevity.

The recommended lubricants are specifically designed to withstand the high temperatures and pressures involved in laser cutting operations. They ensure optimal functionality and minimize wear and tear.

As part of your maintenance routine, make sure to follow the manufacturer’s guidelines and use the appropriate lubricants to keep your laser cutter in top condition.

How often should the air filters in the ventilation system be replaced?

To ensure optimal performance and safety of your laser cutter, it’s crucial to regularly replace the air filters in the ventilation system. The frequency of air filter replacement depends on various factors such as the air quality in your workplace and the usage of the laser cutter.

As a general guideline, it’s recommended to replace the air filters every 3 to 6 months.

Additionally, when it comes to lubricating your laser cutter, it’s important to use only the recommended lubricants to prevent any damage or malfunctions.

Is it necessary to recalibrate the laser cutter after a power outage or electrical surge?

After a power outage or electrical surge, recalibrating the laser cutter is as essential as applying the proper lubricant. Just like a dancer who finds their rhythm, recalibration ensures the laser cutter performs with precision and accuracy.

It aligns the mirrors, adjusts the focus, and ensures optimal beam quality. Neglecting recalibration can lead to subpar results and potential damage to the machine. Don’t underestimate the importance of this step in maintaining your laser cutter’s performance.

What safety precautions should be taken when working with the laser cutter?

When working with a laser cutter, it’s crucial to follow laser cutter safety precautions to ensure a safe working environment. Always wear appropriate personal protective equipment, including safety glasses and gloves. Make sure the laser cutter is properly lubricated to prevent friction and maintain optimal performance.

Regularly inspect the machine for any loose or damaged parts and report them immediately. Additionally, always follow the manufacturer’s guidelines and operating procedures to minimize the risk of accidents or injuries.

Are there any specific training or certification requirements for operating a laser cutter in the workplace?

To operate a laser cutter in the workplace, there are specific training and certification requirements that must be met. These requirements ensure that operators are knowledgeable about the machine’s operation, safety protocols, and potential hazards.

Certification programs typically cover topics such as laser safety, machine operation, maintenance, and emergency procedures. By completing the necessary training and obtaining certification, operators demonstrate their competence in safely operating a laser cutter, minimizing the risk of accidents and injuries.

Conclusion

In conclusion, maintaining a laser cutter in the workplace is crucial for its efficiency and longevity. Just as a well-oiled machine operates smoothly, regular cleaning and lubrication ensure optimal performance.

Proper ventilation and air filtration act as the lungs of the cutter, safeguarding the entire workspace. Calibration and alignment guarantee precision, like a compass guiding a ship. Implementing safety measures protects not only the equipment but also the operators.

By following a regular maintenance schedule and providing training, you ensure that the laser cutter remains a powerful tool in your arsenal.