Imagine the power and precision of a laser cutter, capable of transforming raw materials into intricate designs with ease. It’s a remarkable tool, but its potential for creativity is matched only by its potential for danger. In the blink of an eye, a moment of carelessness can lead to serious injury or even a catastrophic accident.

That’s why it’s crucial to understand the seven common laser cutter safety mistakes and how to avoid them. By wearing the appropriate protective gear, properly ventilating your workspace, and regularly inspecting and testing safety features, you can ensure your well-being while harnessing the laser cutter’s incredible capabilities.

Additionally, by avoiding overloading the machine, cleaning and maintaining it diligently, and following laser cutter safety guidelines, you can safeguard yourself and others from harm.

In this article, we’ll delve into each of these key areas, equipping you with the knowledge and expertise to operate a laser cutter safely and confidently.

Key Takeaways

- Prioritize laser cutter safety guidelines and operator training

- Regularly inspect and maintain the laser cutter and exhaust system

- Use appropriate protective gear and consult manufacturer’s guidelines

- Avoid overloading the machine and ensure proper laser alignment and settings

Understanding Laser Cutter Safety Guidelines

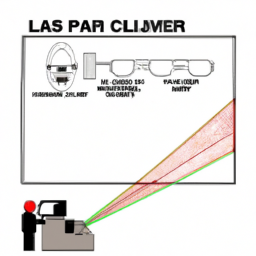

Make sure you’re familiar with the laser cutter safety guidelines to prevent accidents and ensure your own safety. Ensuring operator training is one of the key aspects of laser cutter safety. Before operating a laser cutter, it’s crucial to receive proper training on how to use the machine safely. This training should cover the potential hazards, emergency shutdown procedures, and proper maintenance practices.

Additionally, implementing emergency shutdown procedures is essential in case of any accidents or malfunctions. Operators should be aware of how to quickly and safely shut down the laser cutter in case of an emergency. By following these guidelines, you can significantly reduce the risk of accidents and injuries while using a laser cutter.

Now, let’s move on to the next section about wearing appropriate protective gear.

Wearing Appropriate Protective Gear

Remember, you can’t afford to jeopardize your well-being by neglecting to wear the necessary protective gear when operating a laser cutter. Choosing the right laser cutter is crucial, as different models may require specific gear. It is essential to consult the manufacturer’s guidelines and recommendations to ensure you have the appropriate equipment.

Additionally, undergoing proper training and certification is vital. This will not only familiarize you with the correct use of the laser cutter but also educate you on the necessary protective gear. By receiving training and certification, you’ll gain valuable knowledge about the potential hazards and how to mitigate them effectively. Remember, protecting yourself with the right gear and proper training is the first step towards ensuring a safe work environment.

Moving forward, let’s discuss the importance of properly ventilating the workspace.

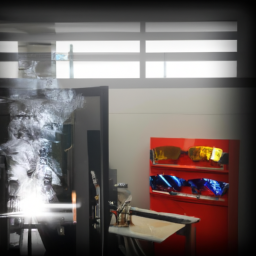

Properly Ventilating the Workspace

To ensure a safe and healthy work environment, it’s crucial to properly ventilate your workspace when operating a laser cutter. Ensuring adequate air circulation is essential to remove any potentially harmful fumes or particulates that may be emitted during the cutting process. Installing a proper exhaust system is an effective way to achieve this. This system should be designed to direct the air outside of the workspace, preventing the accumulation of hazardous substances. It’s important to regularly inspect and maintain the exhaust system to ensure its efficiency and effectiveness. Additionally, consider using a fume extractor to further improve air quality. By taking these precautions, you can minimize the risk of inhaling dangerous substances and create a safer environment for yourself and others. Moving on to the next section about cleaning and maintaining the laser cutter, it’s important to keep the equipment in optimal condition to avoid any potential hazards.

Cleaning and Maintaining the Laser Cutter

Keeping the laser cutter in good condition is essential for preventing potential hazards and ensuring its optimal performance. Regular laser cutter maintenance and cleaning procedures should be followed to keep the machine running smoothly.

Start by checking and cleaning the lens regularly, as any dirt or debris can affect the cutting quality. Use a soft cloth and lens cleaner specifically designed for laser cutters.

Additionally, clean the exhaust system and filter regularly to prevent the buildup of harmful fumes. Inspect the mirrors and clean them if necessary, using a lint-free cloth and isopropyl alcohol.

Lastly, lubricate the moving parts of the laser cutter according to the manufacturer’s guidelines. By following these laser cutter maintenance and cleaning procedures, you can avoid potential issues and ensure safe and efficient operation. Speaking of safe operation, let’s now discuss how to avoid overloading the machine.

Avoiding Overloading the Machine

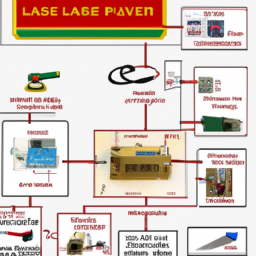

Don’t let the machine become overwhelmed with excessive workloads, as it can lead to potential dangers and hinder its performance. To avoid overloading the laser cutter, it’s crucial to ensure proper laser alignment and follow the recommended power and speed settings for different materials.

Overloading the machine can cause it to overheat, leading to the risk of fires. Regularly inspecting and cleaning the laser cutter’s ventilation system is essential to prevent the buildup of debris and dust that can also contribute to fire hazards.

Additionally, be mindful of the machine’s duty cycle and avoid running it for extended periods without breaks. By following these precautions, you can maintain the laser cutter’s efficiency and prevent potential safety issues.

Now, let’s move on to regularly inspecting and testing safety features.

Regularly Inspecting and Testing Safety Features

Make sure you regularly inspect and test the safety features of your laser cutter to ensure that they’re functioning properly and can effectively protect you from potential hazards. It’s essential to prioritize safety training and familiarize yourself with the emergency shut off button.

Imagine you’re using the laser cutter and suddenly notice that the emergency stop button isn’t working when you need it the most – this highlights the importance of regularly checking and testing the safety features to avoid any unfortunate accidents. By conducting routine inspections, you can identify any malfunctions or issues with the safety features and address them promptly.

Additionally, make sure the emergency shut off button is easily accessible and within reach in case of an emergency. Remember, taking the time to inspect and test the safety features is a crucial step in maintaining a safe working environment with your laser cutter.

Frequently Asked Questions

What are the potential health risks associated with using a laser cutter?

When using a laser cutter, it’s important to be aware of the potential health risks. Exposure to laser radiation can cause eye damage, so always wear protective goggles.

Inhaling fumes from certain materials can lead to respiratory issues, so proper ventilation is crucial.

Long-term effects may include skin burns and increased risk of cancer. To minimize these risks, always wear appropriate protective gear, such as gloves and a lab coat, and ensure that the workspace is well-ventilated.

Are there any safety precautions specifically for working with certain materials, such as acrylic or wood?

When working with materials like acrylic or wood on a laser cutter, it’s crucial to take specific safety precautions.

For acrylic, ensure proper ventilation to avoid inhaling toxic fumes. Use a lower power setting to prevent melting or charring.

When working with wood, be cautious of flammability and always have a fire extinguisher nearby. Additionally, wear appropriate personal protective equipment like safety glasses and gloves to avoid injuries.

Following these safety tips will help you stay safe while laser cutting different materials.

How should I dispose of waste materials generated from laser cutting?

To properly dispose of waste materials generated from laser cutting, there are several disposal methods and recycling options available. One option is to separate the waste by material type and recycle them accordingly. For example, acrylic waste can be recycled by melting it down and creating new acrylic products. Wood waste can be recycled into wood chips or used for biomass energy production.

It’s important to research local recycling facilities or consult with waste management professionals to ensure proper disposal and recycling of laser cutting waste.

Can I use a laser cutter in a residential setting, or is it only suitable for commercial use?

Yes, you can use a laser cutter in a residential setting, but there are important factors to consider. Residential laser cutter use requires proper ventilation to ensure the safety of both the operator and the environment. Ventilation requirements for laser cutters in residential settings vary depending on the specific machine and materials being used. It’s crucial to consult the manufacturer’s guidelines and local regulations to ensure adequate ventilation is in place to prevent the buildup of harmful fumes and protect your health.

Are there any specific training or certification requirements for operating a laser cutter safely?

To operate a laser cutter safely, you must undergo specific training and meet certification requirements. These measures ensure you have the necessary knowledge and skills to handle the equipment properly.

Training programs cover topics such as laser safety protocols, machine operation, and maintenance procedures. Certification verifies that you have successfully completed the training and are qualified to operate a laser cutter.

Following these requirements is crucial for preventing accidents and maintaining a safe working environment.

Conclusion

In conclusion, laser cutter safety is of utmost importance to avoid accidents and ensure a smooth workflow. By understanding the guidelines, wearing the right protective gear, and properly ventilating the workspace, you can greatly reduce the risk of injury.

Regular cleaning and maintenance, along with avoiding overloading the machine, will help prolong its lifespan and prevent malfunctions.

Lastly, regularly inspecting and testing the safety features will give you peace of mind. Remember, "an ounce of prevention is worth a pound of cure," so prioritize safety to avoid any unnecessary mishaps.

Stay informed, take precautions, and work with confidence.