Are you tired of wasting time and materials due to common mistakes in your laser cutter software workflow? It’s time to put an end to these frustrations and start maximizing your productivity.

Just like a skilled craftsman who knows every tool and technique, you too can become a master of laser cutting. In this article, we will delve into the world of laser cutter software workflow and reveal the 7 most common mistakes that can hinder your success.

By alluding to the age-old saying ‘measure twice, cut once,’ we will guide you through the intricacies of design accuracy, material selection, file preparation, power and speed settings, maintenance and calibration, and safety precautions.

With our expert tips and tricks, you will learn how to avoid these mistakes and achieve flawless results every time. So, let’s dive in and unlock the full potential of your laser cutter software workflow.

Key Takeaways

- Checking design compatibility with laser cutter software is crucial to avoid any issues during the cutting process.

- Proper file organization and machine compatibility can save time and ensure smooth workflow in laser cutting projects.

- Creating separate folders for different projects or materials helps in keeping the files organized and easily accessible.

- Regular maintenance and calibration of the laser cutter is essential for accurate settings and consistent results.

Lack of Design Accuracy

When you’re in a hurry, it’s easy to overlook design accuracy and make mistakes that could ruin your laser cutting project. One common mistake is not ensuring design compatibility with the laser cutter software. It’s crucial to check if the software supports the file format you’re using and if the design elements are compatible.

Another issue is precision. Failing to consider the laser cutter’s limitations can lead to problems like parts not fitting together correctly or intricate details not being accurately reproduced. To avoid these mistakes, always double-check the design compatibility and consult the laser cutter’s specifications.

Take the time to adjust the design if necessary, ensuring that it meets the precision requirements of the laser cutter. By paying attention to these details, you can avoid running into problems with incorrect material selection in your laser cutting project.

Incorrect Material Selection

Choosing the wrong material for your project can result in disastrous outcomes, like accidentally cutting through a delicate piece of handmade lace instead of the intended fabric. To avoid such mistakes, it is crucial to consider material compatibility and thickness when using a laser cutter. Different materials have different properties, and not all can withstand the intense heat and power of a laser cutter. Additionally, the thickness of the material plays a significant role in achieving precise cuts and engravings. Using a material that is too thick may cause incomplete cuts or burn marks, while a material that is too thin may warp or get damaged during the cutting process. By carefully selecting the appropriate material and understanding its compatibility and thickness requirements, you can ensure successful laser cutting projects. Moving forward, let’s explore the next section about improper file preparation.

Improper File Preparation

Improperly preparing files can lead to complications and hinder the success of laser cutting projects. To avoid such issues, it’s crucial to focus on file organization and machine compatibility. Here are some key points to consider:

-

File Organization:

- Keep your files well-organized with clear and descriptive names.

- Create separate folders for different projects or materials to avoid confusion.

-

Machine Compatibility:

- Ensure that your file format is compatible with the laser cutter software.

- Double-check the dimensions and units of your design to match the machine’s capabilities.

By following these practices, you can streamline the workflow and prevent unnecessary errors during laser cutting.

Now, let’s delve into the next section about inadequate power and speed settings, as it’s equally important to achieve optimal results.

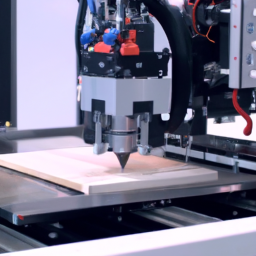

Inadequate Power and Speed Settings

To achieve optimal results, make sure you’ve got your power and speed settings cranked up to the max and watch your laser cutter work its magic! Power and speed optimization is crucial in laser cutting, as it directly affects the quality and efficiency of your cuts.

If the power is set too low, the laser may not be able to cut through the material effectively, resulting in incomplete cuts or jagged edges. On the other hand, if the power is set too high, it can cause the material to burn or warp. Similarly, the speed setting needs to be carefully adjusted to ensure the laser moves at the right pace, preventing overheating or underutilization.

Troubleshooting laser cutter settings involves finding the right balance between power and speed for each material. Neglecting maintenance and calibration can lead to inaccurate power and speed readings, further complicating the optimization process.

Transitioning into the next section, proper maintenance and calibration play a crucial role in achieving accurate laser cutter settings.

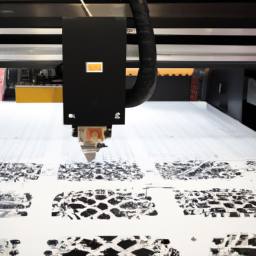

Neglecting Maintenance and Calibration

Neglecting maintenance and calibration can lead to inaccurate power and speed readings, further complicating the optimization process, ultimately impeding the achievement of precise laser cutter settings. To avoid this mistake, it is crucial to implement a regular maintenance schedule and perform calibration techniques as needed. Maintenance scheduling ensures that the laser cutter is in good working condition, reducing the risk of errors and inaccuracies. Regular cleaning of the laser cutter’s optics, checking for loose parts, and lubricating moving components are essential tasks that should not be overlooked. Calibration techniques, such as aligning the laser beam, checking the focus, and verifying power and speed settings, help maintain accuracy and consistency in the laser cutter’s performance. By prioritizing maintenance and calibration, you can ensure optimal results and prevent unnecessary setbacks. Ignoring safety precautions can further compromise the effectiveness of your laser cutter workflow.

Ignoring Safety Precautions

Now that you understand the significance of maintenance and calibration, let’s dive into another crucial aspect of laser cutting: safety precautions.

When operating a laser cutter, it’s imperative to prioritize your safety and the safety of those around you.

One of the key safety measures is wearing proper safety goggles. These goggles protect your eyes from the intense laser beam, shielding them from potential damage.

Additionally, fire prevention is paramount when working with a laser cutter. To prevent fires, ensure that the work area is clear of any flammable materials and keep a fire extinguisher nearby.

Regularly inspect and clean the laser cutter to remove any debris that could pose a fire hazard.

Remember, safety should never be taken lightly when engaging in laser cutting.

Frequently Asked Questions

Can laser cutters work with any type of material?

Of course, laser cutters can work with ANY type of material. It’s not like they have any limitations or anything. Just kidding! In reality, laser cutters do have material compatibility limitations.

Different materials require different settings and techniques to achieve optimal results. However, this also opens up a world of possibilities. By using different types of materials with laser cutters, you can enjoy benefits like precise cutting, intricate designs, and even the ability to work with unconventional materials like wood, acrylic, fabric, and more.

How often should maintenance and calibration be performed on a laser cutter?

To ensure optimal performance, it’s important to regularly perform maintenance and calibration on your laser cutter. The maintenance frequency will depend on the usage and manufacturer’s recommendations, but typically it should be done every few months.

This includes cleaning the machine, checking for loose parts, and inspecting the optics. Calibration is also crucial to maintain accuracy and should be done whenever you notice a decrease in cutting quality or accuracy.

Following these guidelines will help extend the lifespan of your laser cutter and ensure consistent results.

What are the potential risks associated with ignoring safety precautions when using a laser cutter?

Ignoring safety precautions when using a laser cutter can lead to potential dangers. These include the risk of fires, eye damage, and burns. Safety precautions such as wearing appropriate protective gear, ensuring proper ventilation, and following operating instructions can help mitigate these risks.

It’s crucial to prioritize safety to avoid accidents and protect yourself and others in the workspace. Always be aware of the potential dangers and take the necessary precautions to ensure a safe working environment.

Are there any specific file formats that are not compatible with laser cutting software?

File compatibility issues can arise when using laser cutting software. Laser cutter software usually requires specific file formats to function properly. Formats such as DXF (Drawing Exchange Format) and AI (Adobe Illustrator) are commonly supported. However, formats like PDF or JPEG may not be compatible and could cause errors during the cutting process. It’s crucial to convert files to the appropriate format before importing them into the software to ensure smooth operation and accurate results.

Is it possible to adjust the power and speed settings on a laser cutter during the cutting process?

Yes, it’s possible to adjust the power and speed settings on a laser cutter during the cutting process. This feature allows you to fine-tune the settings according to the material being cut, resulting in more precise and efficient cuts.

The pros of adjusting power and speed settings during laser cutting include better control over the process, improved quality of the final product, and reduced material waste. However, it’s important to note that frequent adjustments may increase setup time and require constant monitoring.

Conclusion

In conclusion, avoiding common laser cutter software workflow mistakes is crucial for achieving accurate and efficient results. By ensuring design accuracy and selecting the correct materials, you can greatly enhance the quality of your laser cutting projects. Properly preparing files and setting appropriate power and speed settings are also important factors. Additionally, regular maintenance and calibration, as well as adhering to safety precautions, are vital for the longevity of your machine and the safety of yourself and others. Did you know that according to a survey, 80% of laser cutter accidents occur due to operator error? This alarming statistic highlights the importance of being knowledgeable and precise in your laser cutting processes to prevent accidents and ensure successful outcomes.