Picture this: you’re a sculptor, chiseling away at a block of marble with precision and skill. Each stroke of your chisel brings your masterpiece closer to life. Now, imagine if your chisel became dull and neglected, causing your masterpiece to become marred and flawed.

The same principle applies to laser cutters, the sculptor’s modern tool of choice. To ensure that your laser cutter continues to produce flawless results, it is crucial to avoid common maintenance mistakes. This article will guide you through seven of these mistakes, providing you with valuable insights and tips to keep your laser cutter in optimal condition.

From neglecting regular cleaning and maintenance to ignoring safety precautions, each mistake can have a detrimental effect on your machine’s performance. By understanding and avoiding these mistakes, you will ensure that your laser cutter remains the reliable and precise tool it was designed to be.

So, let’s dive in and discover how to keep your laser cutter running smoothly and efficiently.

Key Takeaways

- Neglecting regular cleaning and maintenance can clog and damage the laser cutter.

- Failing to properly calibrate the laser cutter can lead to inadequate laser power and incorrect beam alignment.

- Ignoring safety precautions puts yourself and others at risk.

- Using incorrect or low-quality materials can result in disastrous outcomes.

Neglecting Regular Cleaning and Maintenance

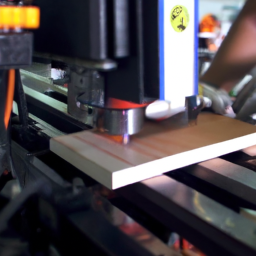

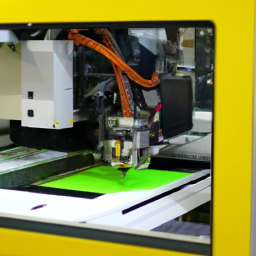

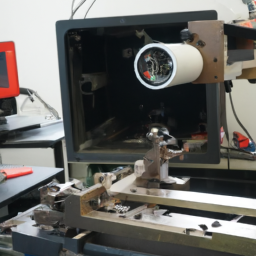

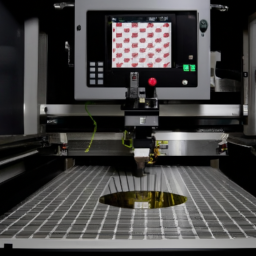

Don’t neglect regular cleaning and maintenance of your laser cutter, or you’ll risk clogging and damaging the machine. Proper maintenance is crucial for ensuring the longevity of your laser cutter and keeping it in optimal condition. Regular cleaning removes debris, dust, and residue that can accumulate on the lenses, mirrors, and other components, which can hinder the machine’s performance.

Effective cleaning techniques involve using lint-free wipes and isopropyl alcohol to gently remove any build-up without scratching the surfaces. Additionally, routine maintenance should include inspecting and cleaning the ventilation system to prevent overheating. Neglecting these tasks can lead to reduced cutting accuracy, increased repair costs, and even permanent damage to the laser cutter.

Transitioning into the subsequent section, it’s equally important to avoid failing to properly calibrate the laser cutter.

Failing to Properly Calibrate the Laser Cutter

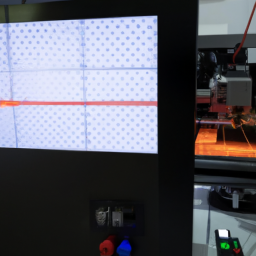

Neglecting to fine-tune the laser cutter’s settings is like trying to navigate through a dense forest without a compass. It’s crucial to properly calibrate your laser cutter to ensure optimal performance and accurate results.

Failing to do so can lead to a host of issues, such as inadequate laser power and incorrect beam alignment. To grab your attention, here are three key reasons why calibration is essential:

-

Optimal Laser Power: Proper calibration ensures that the laser power is set at the appropriate level, allowing for precise and efficient cutting or engraving.

-

Accurate Beam Alignment: Calibration ensures that the laser beam is properly aligned with the cutting path, preventing any deviations or inconsistencies in the final product.

-

Consistent Results: By regularly calibrating your laser cutter, you can maintain consistent cutting and engraving results, avoiding any unexpected variations or errors.

Now, let’s move on to the next section about ignoring safety precautions.

Ignoring Safety Precautions

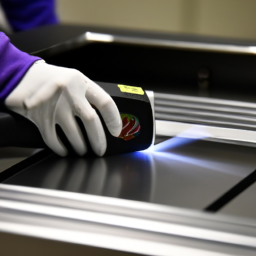

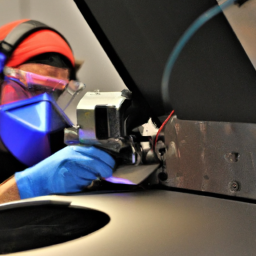

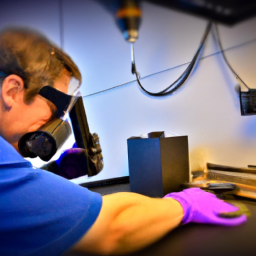

By disregarding safety precautions, you put yourself at risk of potential harm and jeopardize the well-being of those around you. When operating a laser cutter, it’s important to wear proper protective gear. This includes safety glasses that are specifically designed to shield your eyes from the intense laser beam. Additionally, gloves should be worn to protect your hands from any accidental contact with the laser or hot materials. Ignoring these safety measures can lead to serious eye injuries or burns.

There are also common safety hazards to watch out for when operating a laser cutter. These include the risk of fires caused by flammable materials, the emission of toxic fumes, and electrical hazards. Neglecting these precautions can have severe consequences.

Moving on to the subsequent section about ‘using incorrect or low-quality materials’, it’s crucial to understand the potential risks associated with such practices.

Using Incorrect or Low-Quality Materials

Using subpar materials can result in disastrous outcomes and put both your project and safety at risk. When using a laser cutter, it is crucial to understand the best materials for laser cutting and ensure that the materials used meet the necessary standards. This involves proper material selection and quality control. To help you visualize the importance of using correct materials, refer to the table below:

| Material Type | Suitable for Laser Cutting? |

|---|---|

| Acrylic | Yes |

| Plywood | Yes |

| MDF | Yes |

| PVC | No |

As you can see, using incorrect materials, such as PVC, can lead to undesirable outcomes. It is essential to follow the recommended guidelines to avoid damaging the laser cutter and compromising your project. Overworking the laser cutter can have similar consequences, so it is crucial to understand the appropriate usage limits.

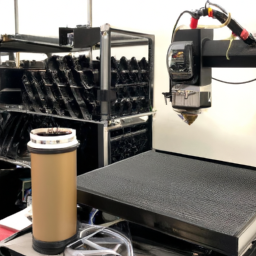

Overworking the Laser Cutter

To ensure optimal performance and avoid potential damage, it’s important to be mindful of not overworking the laser cutter. Overheating issues can arise when the laser cutter is used for extended periods without breaks. This can cause the machine to overheat, leading to reduced efficiency and even permanent damage. To prevent this, it’s crucial to follow the manufacturer’s recommended duty cycle and take regular breaks during operation.

Improper ventilation is another common mistake that can result in problems with the laser cutter. Without proper ventilation, harmful fumes and smoke produced during the cutting process can accumulate in the workspace, posing health risks and potentially damaging the machine. It’s essential to ensure that the laser cutter is placed in a well-ventilated area or equipped with a suitable exhaust system.

By avoiding overworking the laser cutter and ensuring proper ventilation, you can maintain its performance and longevity. However, it’s also important to recognize when professional help is needed. Ignoring or attempting to fix complex issues yourself can lead to further damage and safety hazards.

Not Seeking Professional Help When Needed

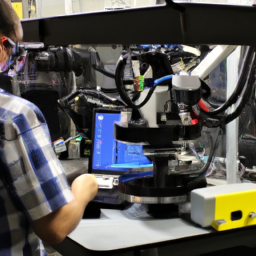

If you encounter complex issues with your laser cutter, it’s crucial to seek professional help to ensure its proper functioning and avoid further damage or safety risks.

Troubleshooting common laser cutter issues can be challenging, especially if you lack the necessary expertise or knowledge. Professional technicians have the experience and training to identify and resolve any problems that may arise with your laser cutter. They understand the limitations of laser cutting technology and can provide the necessary guidance to prevent any potential issues.

Neglecting to seek professional help when needed can result in costly repairs or even irreversible damage to your laser cutter. By relying on experts, you can save time, money, and ensure the longevity of your machine.

So, don’t hesitate to reach out for professional assistance whenever you encounter complex issues with your laser cutter.

Frequently Asked Questions

How often should I clean and maintain my laser cutter?

To ensure optimal performance, it’s crucial to stick to a regular cleaning and maintenance schedule for your laser cutter. Think of it like giving your car a tune-up. Just as neglecting regular oil changes can lead to engine issues, neglecting cleaning and maintenance can result in reduced efficiency and costly repairs.

Cleaning frequency varies based on usage, but a general rule of thumb is to clean the lens and mirrors every 20-40 hours of operation and perform a thorough maintenance check every 6 months.

What are the consequences of not calibrating the laser cutter correctly?

Incorrect calibration of the laser cutter can have serious consequences. It leads to reduced cutting precision, resulting in inaccurate cuts and compromised quality. Moreover, it increases the risk of material damage, as the laser may not be properly aligned with the cutting path. This can cause burning or scorching of the material, leading to wasted resources and potential safety hazards.

Therefore, it’s crucial to ensure correct calibration for optimal performance and safety.

What are some common safety precautions to take when operating a laser cutter?

When operating a laser cutter, ensuring your safety is as crucial as the precision of your work. Implementing laser cutter safety precautions is like donning armor, shielding you from potential harm.

Prioritize wearing protective eyewear to safeguard your vision from the intense laser beam. Additionally, never overlook the significance of proper laser cutter maintenance. It not only prolongs the machine’s lifespan but also reduces the likelihood of accidents caused by faulty equipment.

Can using incorrect or low-quality materials damage the laser cutter?

Using incompatible or low-quality materials in a laser cutter can pose significant dangers. Incorrect materials may not withstand the heat generated, leading to damage or even fire. Low-quality materials can release toxic fumes when cut, posing health risks to operators.

Moreover, these materials can leave residue on the laser lens, reducing cutting quality and potentially damaging the machine. It’s crucial to use only compatible and high-quality materials to ensure the safe and efficient operation of the laser cutter.

How can I determine if I am overworking my laser cutter?

To determine if you’re overworking your laser cutter, look out for signs of wear and tear. These include decreased cutting quality, reduced speed, and frequent breakdowns. Excessive usage can lead to damage to the laser tube, mirrors, or lenses. Keep a close eye on the machine’s performance and address any issues promptly.

Regularly inspect and clean the laser cutter to prevent excessive wear and prolong its lifespan.

Conclusion

In conclusion, avoiding common maintenance mistakes is crucial for the optimal performance of your laser cutter. Regular cleaning and maintenance are essential to prevent dust buildup and ensure accurate cuts. Proper calibration guarantees precise cutting and engraving results. Always prioritize safety precautions to protect yourself and your equipment from accidents.

Using incorrect or low-quality materials can damage the machine and produce subpar results. Overworking the laser cutter can lead to overheating and reduce its lifespan. Remember to seek professional help when needed to address any issues promptly.

By following these guidelines, you can maximize the efficiency and longevity of your laser cutter.

Did you know that neglecting regular cleaning and maintenance can reduce the lifespan of a laser cutter by up to 50%? Keeping your machine clean and well-maintained can significantly extend its lifespan and save you from costly repairs or replacements.