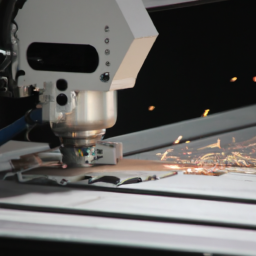

Did you know that the average lifespan of a laser cutter is significantly reduced by common mistakes made during operation? In fact, these mistakes can lead to costly repairs and even the need for a replacement machine sooner than expected.

To help you avoid these pitfalls and maximize the lifespan of your laser cutter, we have compiled a list of 7 common mistakes that you should be aware of. By addressing these issues, you can ensure that your laser cutter remains in optimal condition and continues to deliver precise and efficient cutting for years to come.

From ignoring regular maintenance to using incorrect materials, each mistake has the potential to cause irreversible damage to your machine.

So, if you want to extend the life of your laser cutter and avoid unnecessary expenses, read on to learn how to avoid these common mistakes.

Key Takeaways

- Regular maintenance is crucial for maximizing the lifespan of a laser cutter.

- Understanding material compatibility and properly preparing materials before cutting is important for preventing damage and achieving quality results.

- Rest time and proper ventilation are necessary to prevent overheating and reduce wear and tear on the machine.

- Prioritizing safety and ensuring adequate training and knowledge are essential for safe and efficient operation, preventing costly mistakes and potential damage.

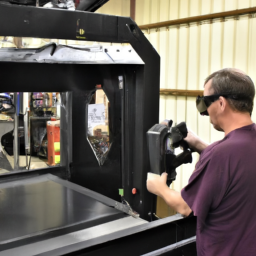

Ignoring Regular Maintenance

Don’t ignore regular maintenance – it’s like neglecting to change the oil in your car, causing your laser cutter to break down sooner than expected.

Just like any other machine, your laser cutter requires a regular maintenance schedule to ensure optimal performance and longevity. By following a maintenance routine, you can prevent major issues from arising and keep your laser cutter running smoothly.

Regular maintenance includes tasks such as cleaning the lenses, checking for loose screws, and lubricating moving parts. These simple tasks may seem insignificant, but they play a crucial role in preventing breakdowns and extending the lifespan of your laser cutter.

Ignoring regular maintenance can lead to costly repairs and downtime.

Now let’s discuss the next section about using incorrect materials.

Using Incorrect Materials

When using a laser cutter, it’s crucial to understand material compatibility. Using incorrect materials can lead to damage to your machine and reduce its lifespan.

Avoid materials with harmful chemicals that can release toxic fumes when cut, and always properly prepare materials for cutting by removing any protective coatings or adhesives.

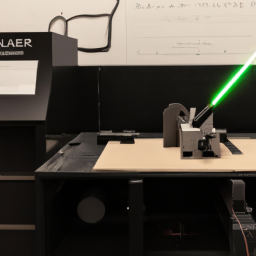

Understanding Material Compatibility

Understanding material compatibility is key to ensuring that your laser cutter doesn’t bite off more than it can chew, like a fish out of water.

Material compatibility challenges can arise when trying to cut or engrave certain materials that are not suitable for laser cutting. Using incorrect materials can lead to a range of problems, from damaging your equipment to producing poor quality results.

To avoid these issues, it’s crucial to optimize laser settings for each specific material. This involves adjusting factors such as power, speed, and focus to achieve the best possible outcome.

By understanding material compatibility and optimizing laser settings, you can maximize the lifespan of your laser cutter and achieve accurate and precise cuts.

Additionally, avoiding materials with harmful chemicals is another important aspect to consider, which will be discussed in the subsequent section.

Avoiding Materials with Harmful Chemicals

To ensure optimal performance and longevity of your laser cutter, it’s important to steer clear of materials that contain harmful chemicals. Chemical safety should be a top priority when selecting materials for laser cutting.

Avoid using materials that contain toxic substances such as lead or mercury, as they can pose serious health risks and damage the internal components of the laser cutter.

Proper ventilation is also crucial to prevent the release of harmful fumes during the cutting process. Make sure your workspace is well-ventilated or consider using an exhaust system to remove any potentially dangerous chemicals from the air.

By avoiding materials with harmful chemicals and prioritizing proper ventilation, you can ensure the safety of both yourself and your laser cutter.

Now, let’s move on to properly preparing materials for cutting.

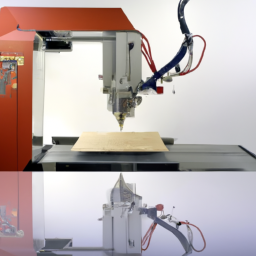

Properly Preparing Materials for Cutting

Ensure that you thoroughly clean and remove any debris or residue from the materials before cutting to ensure optimal results and prevent any potential damage to the machine. Proper material preparation techniques are crucial for maximizing the lifespan of your laser cutter. By removing any dirt, dust, or contaminants, you can prevent them from interfering with the cutting process and causing unnecessary wear and tear on the machine. Additionally, optimizing cutting speed is essential to avoid overworking the machine. Adjusting the speed according to the material being cut can prevent overheating and prolong the life of the laser cutter. Taking the time to properly prepare your materials and optimize cutting speed will not only improve the quality of your cuts but also extend the longevity of your laser cutter.

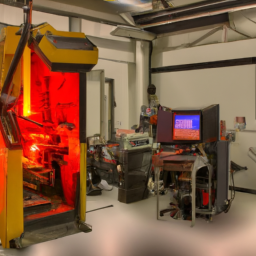

Overworking the Machine

To ensure the longevity of your laser cutter, it’s crucial to understand the machine’s limitations. Pushing the machine beyond its capabilities can lead to unnecessary wear and tear, reducing its lifespan.

Give the machine time to rest between operations to prevent overheating and to allow for proper maintenance. Avoid continuous operation for extended periods, as this can cause excessive strain on the machine’s components, leading to premature failure.

Understanding the Machine’s Limitations

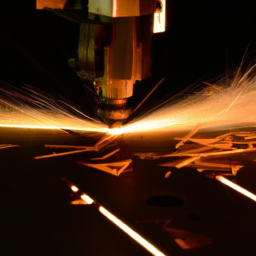

Laser cutters can be powerful tools, but it’s important to understand their limitations in order to maximize their lifespan. By recognizing and respecting the machine’s limitations, you can effectively manage its workload and prevent unnecessary wear and tear.

One of the primary machine limitations to consider is the maximum cutting speed. Pushing the machine beyond this limit can lead to decreased accuracy and premature failure of vital components.

Another important limitation is the maximum material thickness that the laser cutter can handle. Exceeding this limit can cause the laser to struggle, resulting in poor quality cuts and potential damage to the machine.

Understanding these limitations and operating within them will not only maximize efficiency but also prolong the life of your laser cutter. Speaking of efficiency, the next step is to give the machine time to rest and recover, ensuring optimal performance and longevity.

Giving the Machine Time to Rest

Maximizing the machine’s efficiency and prolonging its lifespan can be achieved by giving it adequate time to rest and recover, which is essential for optimal performance and longevity.

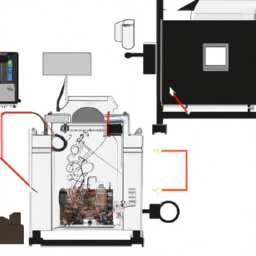

Did you know that allowing the laser cutter to rest for at least 30 minutes after every 2 hours of continuous operation can reduce the risk of overheating and potential damage? Giving the machine proper ventilation and incorporating cooling systems are crucial in facilitating this resting period.

Proper ventilation ensures that hot air is effectively expelled from the machine, preventing the buildup of heat that can lead to malfunctions. Cooling systems, such as air or water cooling, help dissipate heat generated during operation.

By implementing these measures, you can protect your laser cutter from overheating and extend its lifespan. This will be further discussed in the next section, which emphasizes the importance of avoiding continuous operation for extended periods.

Avoiding Continuous Operation for Extended Periods

Taking breaks and allowing your machine to rest is essential for its long-term performance and reliability. To avoid continuous operation for extended periods, make sure you understand the power requirements of your laser cutter. Running the machine for prolonged periods without giving it a break can lead to overheating and premature wear of critical components.

Another important factor to consider is maintaining proper ventilation. Laser cutters generate a significant amount of heat and toxic fumes during operation, so it’s crucial to have adequate ventilation to prevent overheating and protect your health. Remember to clean or replace the filters regularly to ensure optimal airflow.

Neglecting these precautions can result in a reduced lifespan and increased risk of accidents.

Transitioning into the next section, let’s discuss the importance of not neglecting safety precautions.

Neglecting Safety Precautions

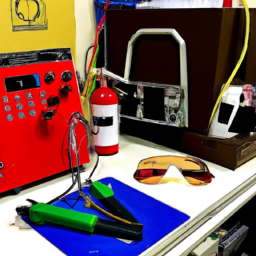

Neglecting safety precautions is like playing with fire in a dry forest – it’s only a matter of time before disaster strikes. When operating a laser cutter, it is essential to prioritize safety to avoid accidents and extend the lifespan of the machine.

Wearing proper safety gear, such as goggles and gloves, is crucial to protect yourself from potential hazards. Additionally, implementing fire prevention measures, such as having a fire extinguisher nearby and keeping flammable materials away from the laser cutter, is vital to minimize the risk of fire outbreaks. Ignoring these safety precautions can lead to irreversible damage to the machine and endanger the operator.

So, it is imperative to take safety seriously and not underestimate its importance. Failing to do so can also result in inadequate training and knowledge, which we will delve into in the next section.

Inadequate Training and Knowledge

Acquiring proper training and knowledge is like equipping yourself with a map in an unfamiliar terrain – it guides you through the intricacies of operating a laser cutter safely and efficiently. The effectiveness of training directly impacts the longevity of your laser cutter.

Without adequate training, operators may not understand the complexities of the machine, leading to costly mistakes and potential damage. It is crucial to ensure that the training program covers all essential aspects, such as laser safety protocols, material handling, and maintenance procedures.

Furthermore, knowledge retention is key to prevent accidents and extend the lifespan of the equipment. Regular refresher courses and ongoing support can help operators stay up-to-date with the latest techniques and best practices. Failing to invest in comprehensive training and knowledge retention can jeopardize both the safety of operators and the lifespan of your laser cutter.

Failing to Monitor and Address Issues

To ensure the longevity of your laser cutter, it’s crucial to regularly check for error messages and address them promptly. By monitoring the machine’s performance and troubleshooting common problems, you can prevent minor issues from escalating into major malfunctions.

However, it’s important to recognize when a problem requires professional expertise and seek help accordingly. Taking these proactive measures will help maintain the efficiency and lifespan of your laser cutter.

Regularly Checking for Error Messages

By staying vigilant and regularly checking for error messages, you’ll ensure your laser cutter’s longevity, avoiding potential pitfalls that could hinder your productivity.

To effectively troubleshoot error messages, follow these guidelines:

- Familiarize yourself with common error codes and their meanings.

- Consult the user manual or manufacturer’s website for specific troubleshooting steps.

- Check for any physical issues, such as loose connections or debris obstructing the laser path.

- Keep a record of error messages and their occurrence to identify patterns or recurring issues.

Regularly monitoring and addressing error messages will help you identify and resolve problems promptly, minimizing downtime and maximizing the lifespan of your laser cutter.

In the next section, we’ll discuss troubleshooting common problems, building upon the knowledge gained from error message interpretation.

Troubleshooting Common Problems

Quickly troubleshoot typical technical issues to optimize performance and prevent production problems with your laser machine.

When troubleshooting power issues, first check the power supply and ensure it’s properly connected. Inspect the power cord for any damage or loose connections. If the power supply and cord are functioning correctly, examine the laser tube and its connections. A faulty or worn-out tube can cause power problems.

Additionally, troubleshooting alignment problems involves checking the mirrors and lens for any misalignment or dirt. Clean the optics carefully using a lint-free cloth and ensure they’re properly aligned. Regularly calibrate the laser beam to maintain accurate cutting and engraving.

By promptly addressing power and alignment issues, you can extend the lifespan of your laser cutter and avoid costly downtime. Transitioning to seeking professional help when needed ensures that complex issues can be resolved effectively.

Seeking Professional Help When Needed

When you encounter complex issues with your laser machine, it’s essential to reach out to a professional for help. This ensures a swift and efficient resolution to keep your production running smoothly. Seeking professional help is crucial for maintaining the longevity of your laser cutter. Here are some reasons why it’s important:

-

Regular calibration: Professionals have the expertise to calibrate your laser machine accurately. Regular calibration ensures optimal performance and prevents premature wear and tear.

-

Identifying signs of machine wear and tear: Professionals can identify early signs of machine wear and tear that may not be obvious to an untrained eye. Addressing these issues promptly can prevent further damage and extend the lifespan of your laser cutter.

-

Technical expertise: Professionals have a deep understanding of laser cutting technology and can provide valuable insights and solutions to complex problems.

-

Efficient repairs: Professionals have access to specialized tools and resources, enabling them to perform repairs quickly and efficiently, minimizing downtime and maximizing productivity.

By seeking professional help when needed, you can avoid common mistakes and ensure the long-lasting performance of your laser cutter.

Frequently Asked Questions

Can I use any type of material in my laser cutter?

When it comes to using your laser cutter, it’s important to be mindful of the materials you choose. Not all materials are compatible with laser cutters, so it’s crucial to consider the type of material you plan to use.

Different materials have different properties, and some may not react well to the intense heat of the laser. To ensure the longevity of your laser cutter, always check the compatibility of the material before using it.

How often should I schedule maintenance for my laser cutter?

To ensure the optimal performance and longevity of your laser cutter, it’s recommended to schedule regular maintenance. Adhering to safety guidelines and implementing a maintenance checklist is crucial. Regular inspections, cleaning, and lubrication should be conducted to prevent issues and extend the lifespan of your machine. By following a consistent maintenance schedule, you can minimize the risk of breakdowns and costly repairs, ensuring smooth and efficient operation of your laser cutter.

Are there any specific safety precautions I should take while operating my laser cutter?

When operating your laser cutter, it’s crucial to adhere to specific safety precautions to ensure optimal performance and longevity.

Firstly, ensure proper ventilation in your workspace to minimize the risk of harmful fumes and smoke.

Additionally, always wear appropriate safety gear, such as protective eyewear and gloves, to protect yourself from potential hazards.

Lastly, regularly inspect and maintain your laser cutter to identify any potential issues and address them promptly.

What are the consequences of overworking my laser cutter?

Overworking your laser cutter can cause potential damage and a decrease in cutting quality. Continuous operation without proper breaks and maintenance can lead to excessive wear and tear on critical components such as the laser tube and mirrors. This can result in reduced cutting accuracy and power output.

Additionally, the excessive heat generated during prolonged use can cause damage to the machine’s internal parts, further compromising its lifespan. It’s crucial to follow recommended usage guidelines and give your laser cutter adequate rest to ensure optimal performance and longevity.

How can I improve my knowledge and skills in laser cutting?

Improve your knowledge and skills in laser cutting by diving into laser cutting techniques and laser cutter troubleshooting.

Like a skilled conductor leading an orchestra, mastering laser cutting techniques will allow you to orchestrate intricate designs with precision and finesse.

Explore resources such as online tutorials, workshops, and forums to expand your understanding.

Troubleshooting common issues will sharpen your problem-solving skills, ensuring optimal performance and longevity for your laser cutter.

Conclusion

In conclusion, taking proper care of your laser cutter is essential for its long-lasting performance. Regular maintenance, using appropriate materials, and avoiding overworking the machine are key factors in ensuring its lifespan.

Neglecting safety precautions and inadequately training yourself on its operation can lead to detrimental consequences. Remember, just like a well-oiled machine, your laser cutter requires attention and monitoring to address any potential issues.

By being diligent and proactive, you can keep your laser cutter running smoothly and seamlessly, like a precision instrument finely tuned to perfection.