Are you looking for laser cutter software that can streamline your workflow and enhance your productivity? With so many options available, it can be overwhelming to choose the right one for your needs. But fear not, as we have compiled a list of 7 key features to look for in laser cutter software that will help you make an informed decision.

First and foremost, a user-friendly interface is essential to ensure a smooth and intuitive experience.

Additionally, compatibility with different file formats is crucial, allowing you to work with a variety of designs seamlessly.

Advanced design tools and editing capabilities will enable you to unleash your creativity and achieve intricate designs with ease.

Moreover, the software should be compatible with your specific laser cutter machine and materials, ensuring optimal results.

Efficient workflow management features are also vital for organizing and optimizing your laser cutting projects.

Lastly, technical support and regular updates are essential for a seamless experience and to address any issues that may arise.

By considering these 7 key features, you can find laser cutter software that will streamline your workflow and take your laser cutting projects to new heights.

Key Takeaways

- User-friendly interface

- Compatibility with different file formats

- Advanced design tools and editing capabilities

- Compatibility with specific laser cutter machine and materials

User-friendly Interface

Get ready to experience a hassle-free and intuitive laser cutter software interface that’ll make your workflow a breeze!

When it comes to choosing the right software for your laser cutter, ease of use and an intuitive design are key features to look for. You want a user-friendly interface that allows you to navigate through the software effortlessly and quickly. Whether you’re a beginner or an experienced user, a well-designed interface will save you time and frustration.

Look for software that provides clear and organized menus, customizable settings, and easy-to-use tools.

Now, let’s move on to the next section about compatibility with different file formats, which is another crucial aspect to consider when choosing laser cutter software.

Compatibility with Different File Formats

Compatible with a variety of file formats, the software effortlessly imports and translates different design files to ensure a seamless and efficient workflow. Its file conversion capabilities allow you to work with a wide range of file types, including vector files (such as SVG and DXF) and raster images (such as JPG and PNG).

This compatibility ensures that you can easily import designs from various sources without the need for time-consuming manual conversions. Additionally, the software integrates with popular design software, enabling you to directly import files from programs like Adobe Illustrator or CorelDRAW. This integration further streamlines your workflow by eliminating the need to export and import files between different software tools.

With these features, transitioning into the subsequent section about advanced design tools and editing capabilities becomes a natural progression.

Advanced Design Tools and Editing Capabilities

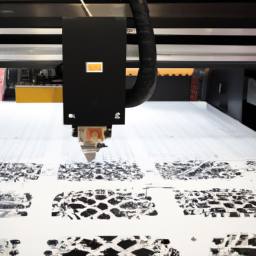

The software’s design tools and editing capabilities are so powerful, it’s like having a team of expert graphic designers at your fingertips. With advanced design tools, you can easily create intricate and complex designs that are perfect for precision cutting. Whether you need to create detailed patterns, intricate engravings, or precise cuts, the software has the tools to bring your ideas to life.

One important feature to look for is the ability to manipulate vector graphics. This allows you to easily resize, rotate, and manipulate shapes with precision. Additionally, the software should offer a variety of editing tools, such as layers, gradients, and effects, to enhance your designs and add depth.

To further streamline your workflow, look for software that offers shortcuts and keyboard commands for quick and easy editing. This will save you time and allow you to make adjustments on the fly.

In the next section about material and machine compatibility, you’ll learn about the importance of ensuring your software can seamlessly integrate with your laser cutter.

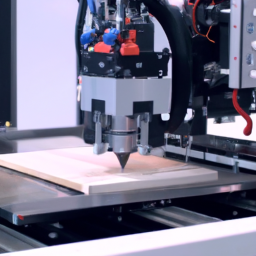

Material and Machine Compatibility

Imagine effortlessly bringing your designs to life by seamlessly integrating your materials and machine with the software. Material compatibility is a crucial factor to consider when choosing laser cutter software. The software should have a wide range of pre-loaded material settings, allowing you to easily select the appropriate settings for your specific material. Additionally, it should provide the option to customize and save new material settings for future use.

Machine compatibility is equally important. The software should support various laser cutter models and have the ability to communicate effectively with your specific machine. This ensures that the software can accurately control the laser power, speed, and other parameters to achieve optimal results.

With the right material and machine compatibility, you can maximize the efficiency and precision of your laser cutting projects. Transitioning into the next section, let’s explore the efficient workflow management features that can further streamline your laser cutting process.

Efficient Workflow Management Features

Get ready to effortlessly manage your laser cutting process with these efficient features that will keep you organized and in control. Laser cutter software with automated job queue and project organization capabilities can greatly enhance your workflow efficiency. With an automated job queue, you can easily schedule and prioritize your laser cutting projects, ensuring that tasks are completed in a timely and organized manner. Additionally, the software’s project organization features allow you to categorize and store your designs, making it easy to locate and retrieve files whenever needed. To emphasize the importance of these features, consider the following table:

| Feature | Description | Benefits |

|---|---|---|

| Automated Job Queue | Automatically schedules and prioritizes laser cutting projects | Ensures efficient use of machine time |

| Project Organization | Categorizes and stores designs for easy access | Saves time searching for files |

By incorporating laser cutter software with these efficient workflow management features, you can streamline your laser cutting process and maximize productivity. And when it comes to technical support and updates, you can rest assured that you’ll have the necessary assistance to keep your software running smoothly.

Technical Support and Updates

For a more refined experience, you’ll appreciate the availability of technical support and regular updates to ensure the smooth operation of your laser cutting software. Having access to troubleshooting tips can be invaluable when encountering any issues or difficulties. Whether it’s a problem with file compatibility, machine calibration, or software settings, having a reliable source of guidance can save you time and frustration.

Additionally, remote assistance is another essential feature to look for in laser cutter software. This allows experts to remotely access your system and provide real-time assistance, reducing downtime and increasing productivity.

Regular software updates are also crucial to keep up with the latest advancements and improvements. They not only address any bugs or vulnerabilities but also introduce new features and enhancements to optimize your workflow.

Frequently Asked Questions

What are the system requirements for the laser cutter software?

To ensure smooth operation of the laser cutter software, it’s crucial to meet the system requirements. The software should be compatible with various operating systems such as Windows, Mac, and Linux. Make sure to check the minimum hardware specifications, including processor, memory, and storage capacity, as specified by the software manufacturer. Meeting these requirements will ensure optimal performance and avoid any compatibility issues with your laser cutter.

Can the software be used with both Windows and Mac operating systems?

Yes, the laser cutter software is designed to be cross-platform compatible, meaning it can be used with both Windows and Mac operating systems. This ensures that regardless of the operating system you’re using, you’ll be able to seamlessly integrate the software into your workflow.

The software is specifically designed to be compatible with both operating systems, providing flexibility and convenience for users.

Does the software support importing files from popular design software like Adobe Illustrator or CorelDRAW?

Yes, the laser cutter software supports importing files from popular design software like Adobe Illustrator or CorelDRAW. It’s compatible with both Windows and Mac operating systems, ensuring that you can use it regardless of your preferred platform. The software is designed to work seamlessly with these design programs, allowing you to easily transfer your designs and artwork to the laser cutter for precise and efficient cutting. It supports various file formats, ensuring compatibility and flexibility in your workflow.

Is there a limit to the size or complexity of designs that can be processed by the software?

There is a limit to the size and complexity of designs that can be processed by laser cutter software. The software may have restrictions on file size, depending on the specific program.

Additionally, the complexity of the design can impact processing time and performance. It’s important to consider the compatibility of the software with different laser cutter models to ensure seamless integration and optimal results.

Can the software be integrated with other manufacturing software or hardware for a seamless production process?

Yes, laser cutter software can be integrated with other manufacturing software or hardware for a seamless production process. This software integration allows for improved production efficiency by enabling data transfer and communication between different systems.

By connecting the laser cutter software with other manufacturing tools, you can automate tasks, streamline workflows, and optimize the overall production process. This integration eliminates the need for manual data entry and reduces the chances of errors, resulting in a more efficient and streamlined production process.

Conclusion

In conclusion, when selecting laser cutter software, it’s crucial to consider various key features to ensure a streamlined workflow. By opting for a user-friendly interface and compatibility with different file formats, you can enhance your productivity and efficiency. Additionally, advanced design tools can further improve your workflow. Ensuring material and machine compatibility, as well as efficient workflow management features, will optimize your laser cutting process. Lastly, prioritizing technical support and regular updates will guarantee a smooth operation and keep your software up to date.

Investigate the truth of these theories to unlock the full potential of your laser cutter software.