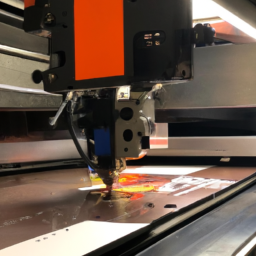

Imagine a laser cutter that operates flawlessly, cutting through materials with precision and efficiency. With the right upgrades, you can transform your laser cutter into a powerhouse of performance. In this article, we will explore seven troubleshooting upgrades that will take your laser cutter to the next level.

First, let’s talk about upgrading your cooling system. By improving the cooling capacity, you can ensure that your laser cutter stays at the optimal temperature, preventing overheating and extending the lifespan of your machine.

Next, enhancing your laser tube is crucial for achieving superior cutting results. By upgrading to a high-quality tube, you can increase the power and stability of your laser cutter, resulting in cleaner cuts and reduced maintenance.

Improving airflow and ventilation is another important upgrade. Proper airflow not only keeps your machine cool but also removes smoke and debris from the cutting area, ensuring a clean and safe working environment.

Calibration and alignment are key to achieving precise cuts. By regularly calibrating and aligning your laser cutter, you can eliminate deviations and ensure consistent and accurate results.

Upgrading your software and control systems is also essential. Newer software versions often come with improved features and enhanced compatibility, allowing you to maximize the capabilities of your laser cutter.

Last but not least, enhancing safety features is crucial for protecting yourself and your machine. By installing safety measures such as emergency stop buttons and interlocks, you can prevent accidents and ensure a secure working environment.

By implementing these seven troubleshooting upgrades, you can unleash the full potential of your laser cutter, achieving improved performance and unlocking a world of possibilities. So, let’s dive in and explore how these upgrades can revolutionize your laser cutting experience.

Key Takeaways

- Upgrading the cooling system prevents overheating and extends the lifespan of the laser cutter.

- Enhancing the laser tube improves cutting results by increasing power and stability.

- Improving airflow and ventilation creates a cleaner working environment by removing smoke and debris.

- Calibration and alignment of the laser cutter ensure precise cuts and accurate positioning.

Upgrade Your Cooling System

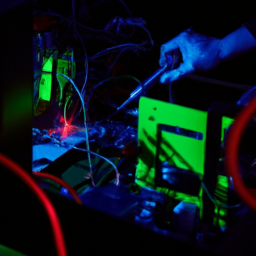

Upgrading your cooling system is essential for maximizing the performance of your laser cutter. To improve efficiency and prevent overheating, it’s crucial to invest in a more advanced cooling setup.

A high-quality water cooling system can effectively remove excess heat generated during laser cutting, ensuring stable and reliable operation. By upgrading to a more efficient cooling system, you can significantly enhance the overall performance of your laser cutter.

It allows for longer cutting sessions without the risk of overheating, resulting in increased productivity. Additionally, a well-designed cooling system can extend the lifespan of your laser tube and other critical components.

With a properly upgraded cooling system in place, you can now move on to enhancing your laser tube for even better performance.

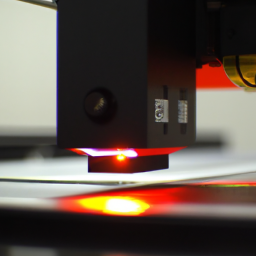

Enhance Your Laser Tube

To get more out of your laser cutter, consider boosting the heart of your machine – your laser tube – with a simple tweak that can make all the difference in your cuts and engraving. Imagine if you could turn a whisper into a roar, unleashing a hidden power that can slice through materials like a hot knife through butter.

Laser tube maintenance is crucial for optimal performance. Regularly cleaning the tube and checking for any signs of damage or wear can extend its lifespan and ensure consistent results. If your laser tube is nearing the end of its life, you may also want to explore tube replacement options. Upgrading to a higher wattage tube or choosing a tube with improved gas composition can greatly enhance the capabilities of your laser cutter.

By enhancing your laser tube, you can take your machine to new heights of precision and power.

Now, let’s explore how to improve airflow and ventilation for even better performance.

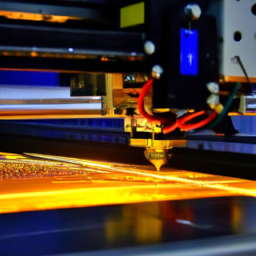

Improve Airflow and Ventilation

Enhance your laser cutting experience by ensuring that the airflow and ventilation in your workspace is optimized, allowing for improved precision and power in your cuts and engravings. To achieve this, it is crucial to improve your filtration system and optimize the exhaust design. By upgrading your filtration system, you can effectively remove harmful particles and gases from the air, creating a healthier work environment. Additionally, optimizing the exhaust design will help to efficiently remove smoke and fumes, preventing them from obstructing the laser beam and affecting the quality of your cuts.

To illustrate the importance of airflow and ventilation, consider the following table:

| Problem | Solution | Benefit |

|---|---|---|

| Poor airflow | Install additional fans or blowers | Enhanced cooling for the laser tube |

| Inadequate exhaust | Upgrade to a larger exhaust fan | Improved removal of smoke and fumes |

| Insufficient filtration | Install a high-quality air filter | Cleaner air for better laser performance |

Ensuring proper airflow and ventilation is a crucial step towards achieving optimal laser cutting results. Next, we will discuss the importance of calibration and alignment in further improving your laser cutter’s performance.

Calibration and Alignment

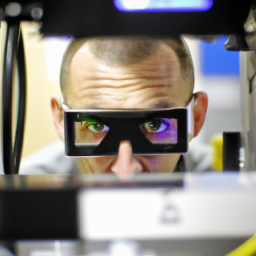

To ensure optimal performance of your laser cutter, it’s important to check and adjust the mirrors regularly. This involves examining the mirrors for any dirt or debris that may affect the laser beam’s accuracy and cleaning them if necessary.

Additionally, aligning the laser head is crucial for precise cutting and engraving. This can be done by adjusting the mirrors and ensuring the laser beam is properly focused.

Lastly, calibrating the X and Y axes is essential for accurate positioning of the laser cutter’s movements. This process involves adjusting the stepper motors to ensure precise movement and alignment.

Check and Adjust Mirrors

Make sure you carefully inspect and adjust the mirrors to improve the performance of your laser cutter. Here’s a step-by-step guide to help you with the cleaning procedure and troubleshooting techniques:

-

Begin by turning off the laser cutter and allowing it to cool down completely.

-

Use a lint-free cloth and isopropyl alcohol to gently clean the mirrors. Avoid using excessive force to prevent any damage.

-

Inspect the mirrors for any signs of dirt, dust, or residue that may affect the laser beam’s quality.

-

Adjust the mirrors by using the adjustment screws or knobs provided. Make small, incremental changes and test the laser cutter after each adjustment to ensure optimal alignment.

Once you’ve checked and adjusted the mirrors, you can proceed to align the laser head for further improvement in performance.

Align the Laser Head

Get ready to align the laser head for a precision upgrade and unleash the true power of your machine! Proper laser head maintenance is crucial for optimal performance and avoiding troubleshooting issues.

Begin by ensuring that the laser head is securely attached to the carriage and that all fasteners are tightened.

Next, carefully inspect the alignment of the laser head with the rest of the system. Use a laser alignment tool or the beam itself to check if the laser head is parallel to the x and y axes. Make any necessary adjustments to ensure proper alignment.

Additionally, check for any debris or obstructions that may hinder the movement of the laser head.

Once the laser head is aligned and free of obstructions, you can move on to calibrating the x and y axes to further enhance the performance of your laser cutter.

Calibrate the X and Y Axes

Enhance your laser cutting precision by fine-tuning the calibration of your X and Y axes. Accurate calibration is crucial for achieving precise and consistent cuts. To calibrate the X and Y axes, adjust the steps per millimeter values in your laser cutter’s settings. This will ensure that the laser head moves the correct distance for each command. Additionally, check and adjust the belt tension to prevent any slack that may cause inaccuracies in movement.

To further optimize your laser cutter’s performance, consider adjusting the laser power and speed settings. Higher laser power can result in deeper cuts, while faster speeds can improve efficiency. However, finding the right balance is key, as excessive power can lead to material burning and excessive speed may cause incomplete cuts. Experiment with different combinations to achieve the desired results.

In the next section, we will explore how upgrading your software and control systems can enhance your laser cutter’s capabilities.

Upgrade Software and Control Systems

By optimizing the software and control systems, the laser cutter can effortlessly glide through materials, producing precise and flawless designs. To achieve this, consider the following upgrades:

-

Software Optimization: Update the laser cutter software to the latest version, ensuring compatibility with new operating systems and improving overall performance.

-

Control System Compatibility: Upgrade the control system to a more advanced model that offers enhanced functionality and compatibility with various file formats.

-

Streamlined User Interface: Opt for a user-friendly interface that simplifies the laser cutting process, allowing for easier navigation and control.

-

Real-time Monitoring: Install software that provides real-time monitoring of the laser cutter’s performance, allowing for immediate adjustments and preventing potential issues.

-

Automation Features: Explore options for automating certain tasks, such as material alignment and focusing, to increase efficiency and reduce human error.

By implementing these upgrades, you can enhance the laser cutter’s performance and ensure smoother operation.

In the next section, we will discuss how to enhance safety features to further optimize the laser cutting process.

Enhance Safety Features

To optimize the laser cutting process, you can take advantage of advanced safety features that ensure your experience is both secure and efficient. One crucial upgrade is implementing an emergency shutdown system. This feature allows you to halt the laser cutter immediately in case of any unforeseen dangers or emergencies. By pressing a simple button or switch, you can instantly stop the machine, preventing any potential harm or damage.

Another essential safety enhancement is the interlock system. This system ensures that the laser cutter cannot operate if certain conditions are not met. For example, the interlock system may require the machine’s enclosure to be fully closed before it can be activated.

By incorporating these safety features, you can protect yourself, your equipment, and those around you, creating a safer and more reliable laser cutting environment.

Frequently Asked Questions

How much does it cost to upgrade the cooling system of a laser cutter?

Upgrading the cooling system of a laser cutter can vary in cost depending on the specific model and requirements. However, the benefits of such an upgrade are numerous. A more efficient cooling system ensures better heat dissipation, which in turn improves the overall performance and longevity of the laser cutter. It prevents overheating, reduces downtime for maintenance, and allows for higher cutting speeds and precision.

Investing in laser cutter maintenance, like upgrading the cooling system, is essential for optimal performance.

Can I upgrade the laser tube myself or do I need professional help?

Upgrading the laser tube yourself may seem tempting, but it’s highly recommended to seek professional help. The process involves delicate adjustments that require precise technical knowledge. A professional can ensure that the upgrade is done correctly and safely, minimizing the risk of damaging your laser cutter.

Additionally, when upgrading laser cutter power or optics, it’s crucial to have the expertise to choose the right components and make necessary adjustments for optimal performance.

Are there any specific safety regulations or certifications I need to consider when enhancing safety features?

When enhancing safety features on your laser cutter, it’s important to consider safety regulations and certification requirements. These regulations are in place to ensure the safe operation of the equipment and protect users from potential hazards.

Before making any upgrades, familiarize yourself with the specific safety regulations and certification considerations for laser cutters. This will help you ensure that your modifications meet the necessary standards and maintain a safe working environment.

What are some common signs that indicate the need for calibration and alignment of a laser cutter?

To ensure optimal performance of your laser cutter, it’s crucial to look out for certain signs that indicate the need for calibration and alignment. Signs such as inconsistent cutting depth, irregular shapes, or burnt edges could indicate calibration issues.

Proper alignment is equally important as it ensures accurate positioning of the laser beam, resulting in precise cuts. Regularly checking and adjusting the calibration and alignment of your laser cutter will help maintain its efficiency and improve overall performance.

Is it possible to upgrade the software and control systems of an older laser cutter model?

Yes, it’s possible to upgrade the software and control systems of an older laser cutter model. Upgrading the software allows for improved functionality and compatibility with newer operating systems.

Upgrading the control systems can enhance the precision and speed of the laser cutter, resulting in more efficient and accurate cuts. These upgrades can be done by replacing outdated components, installing new firmware, and updating the software interface.

Conclusion

To conclude, by implementing these laser cutter troubleshooting upgrades, you can significantly improve the performance of your machine.

Upgrading your cooling system, enhancing the laser tube, and improving airflow and ventilation will all contribute to more efficient and precise cutting.

Additionally, calibration and alignment, along with upgrading software and control systems, will ensure optimal functionality.

Lastly, enhancing safety features will provide a secure working environment. So don’t hesitate to invest in these upgrades and witness the transformation in your laser cutter’s performance.