Looking to enhance the performance of your laser cutter? It’s time to upgrade your ventilation system. By implementing these seven laser cutter ventilation upgrades, you can achieve improved efficiency and precision in your cutting processes.

First and foremost, invest in a high-quality ventilation system. This will ensure that harmful fumes and particles are effectively removed from your workspace, promoting a healthier environment for you and your equipment.

Next, upgrade to a variable speed exhaust fan. This will allow you to adjust the airflow according to your specific cutting needs, maximizing efficiency and reducing noise levels.

Consider using an external air compressor for better air quality control. By supplying clean and dry air to your laser cutter, you can prevent potential damage and ensure optimal performance.

Implementing a closed-loop cooling system is another crucial upgrade. This system will efficiently dissipate heat, preventing overheating and extending the lifespan of your laser cutter.

To further enhance air purification, install a carbon filter. This will effectively trap and remove harmful gases, ensuring a safer working environment.

Lastly, optimize airflow with proper ducting. By carefully designing and positioning your ductwork, you can minimize air resistance and maximize the effectiveness of your ventilation system.

Ready to take your laser cutter performance to the next level? Let’s dive into these ventilation upgrades and unleash the full potential of your cutting processes.

Key Takeaways

- Upgrading to a variable speed exhaust fan allows for adjustable airflow and noise reduction.

- Implementing a closed-loop cooling system prevents overheating and extends the laser cutter’s lifespan.

- Installing a carbon filter enhances air purification and creates a safer working environment.

- Proper ducting optimizes airflow, maximizes the effectiveness of the ventilation system, and reduces noise levels in the workspace.

Install a High-Quality Ventilation System

If you’re looking to maximize the performance of your laser cutter, it’s essential to install a high-quality ventilation system. This will ensure proper airflow and prevent any potential hazards. Proper ventilation is crucial for the efficient operation of a laser cutter. It helps to remove smoke, fumes, and particulates generated during the cutting process, which can be harmful to both the machine and the operator.

Regular ventilation system maintenance is necessary to keep it running smoothly. By maintaining the system, you can ensure that it functions optimally, preventing any disruptions in airflow that could affect the performance of the laser cutter.

Benefits of proper ventilation include improved cutting quality, reduced risk of fire, and a healthier work environment. Upgrading to a variable speed exhaust fan will further enhance the performance of your laser cutter by allowing you to adjust the airflow based on your specific needs.

Upgrade to a Variable Speed Exhaust Fan

You may think a fixed-speed exhaust fan is just what you need for your mediocre setup, but trust me, upgrading to a variable speed fan will revolutionize your whole laser cutting experience. By adjusting the fan speed according to your needs, you can improve ventilation efficiency and reduce noise levels significantly.

Here’s why upgrading to a variable speed exhaust fan is a game-changer:

-

Enhanced Control: With a variable speed fan, you can precisely regulate the airflow in your laser cutter, ensuring optimal ventilation for efficient smoke and fume extraction.

-

Noise Reduction: The ability to adjust the fan speed allows you to find the perfect balance between performance and noise levels. You can reduce the noise generated during operation, creating a more comfortable working environment.

Investing in a variable speed exhaust fan will set the stage for the next step: using an external air compressor to further enhance your laser cutter’s performance.

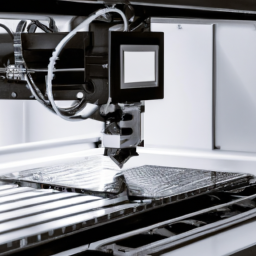

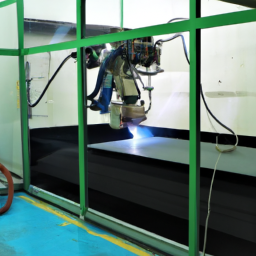

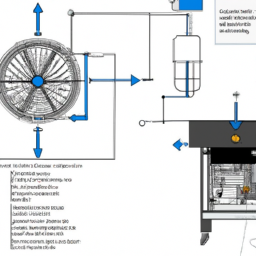

Use an External Air Compressor

When it comes to taking your laser cutting experience to the next level, one essential upgrade to consider is incorporating an external air compressor. By directing a continuous stream of compressed air towards the cutting zone, you can significantly improve efficiency and ensure consistent results.

The compressed air helps to remove debris and smoke from the cutting area, resulting in cleaner cuts and reduced maintenance needs. Additionally, using an external air compressor can also help reduce noise levels, creating a more comfortable working environment.

However, it’s important to choose an air compressor that can provide a sufficient air volume and pressure for your specific laser cutter model. By incorporating this upgrade, you can maximize the performance of your laser cutter and achieve optimal cutting results.

To further enhance your laser cutter’s performance, the next step is to implement a closed-loop cooling system.

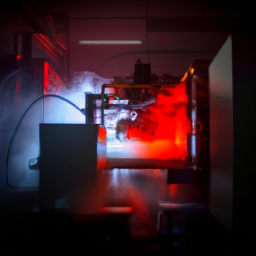

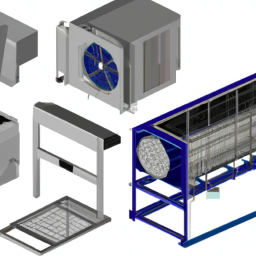

Implement a Closed-Loop Cooling System

To maintain consistent temperature control for your laser tube, it’s crucial to implement a closed-loop cooling system. This system continuously monitors and adjusts the temperature, ensuring optimal performance and preventing overheating.

By keeping the temperature within the recommended range, you can significantly extend the lifespan of your laser cutter. This minimizes the risk of costly repairs or replacements.

Maintain consistent temperature control for the laser tube

Ensuring a laser tube’s temperature remains constant is crucial for achieving maximum cutting power and preventing any potential damage. Laser tube maintenance plays a vital role in optimizing temperature control.

Regularly checking and cleaning the cooling system components, such as the water pump, filter, and radiator, is essential to ensure efficient heat dissipation. Additionally, monitoring the water temperature and flow rate is imperative to maintain a stable operating temperature for the laser tube.

Installing a temperature sensor and controller can help automate this process, ensuring precise temperature control throughout the cutting process. By implementing these measures, you can extend the lifespan of your laser cutter and minimize the risk of overheating or fluctuating temperatures.

This will lead to improved performance and consistent, high-quality cuts.

Extend the lifespan of your laser cutter

By implementing these maintenance measures, you can significantly increase the lifespan of your laser cutting machine and optimize its overall functionality. Regularly cleaning and lubricating the moving parts of the machine is essential to ensure smooth operation and prevent unnecessary wear and tear.

Additionally, it’s important to regularly check and replace any worn-out components, such as belts or mirrors, to maintain efficient performance. Properly aligning the laser beam and ensuring consistent temperature control for the laser tube are also crucial for extending the lifespan of your machine.

By following these maintenance steps, you can increase efficiency, reduce maintenance, and prolong the life of your laser cutter.

To further enhance performance, the next section will discuss the installation of a carbon filter to improve ventilation.

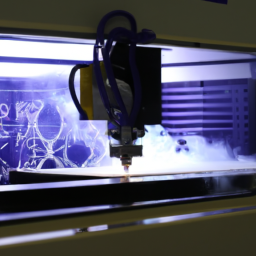

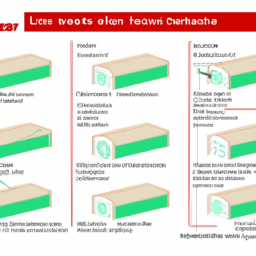

Install a Carbon Filter

When considering the installation of a carbon filter in your closed-loop cooling system, you can effectively remove odors and harmful gases from the air. This will result in a safer and more pleasant workspace environment. By incorporating this filtration method, you can enhance the overall air quality, reducing potential health risks and improving the efficiency and performance of your laser cutter. Upgrade your ventilation system today and experience the benefits of cleaner and healthier air in your workspace.

Remove odors and harmful gases from the air

To truly clear the air of unwanted odors and harmful gases, the laser cutter ventilation system becomes a breath of fresh air, whisking away any unpleasantness. By installing a carbon filter in the ventilation system, you can effectively remove harmful particles and improve indoor air quality. Here are four reasons why this upgrade is essential:

- Activated carbon filters are designed to adsorb and trap odors and harmful gases.

- The filter media has a large surface area, allowing for maximum filtration capacity.

- Carbon filters are highly effective in removing volatile organic compounds (VOCs) and other air pollutants.

- Regularly replacing the carbon filter ensures optimal performance and maintains a clean working environment.

By removing odors and harmful gases from the air, the carbon filter upgrade enhances the overall air quality in your workspace, promoting a healthier and more comfortable environment for everyone.

Enhance the overall air quality in your workspace

Installing a carbon filter in your workspace’s ventilation system is essential for creating a healthier and more comfortable environment. It enhances the overall air quality by improving air circulation and reducing airborne particles. A carbon filter effectively filters out harmful pollutants, such as odors, gases, and volatile organic compounds (VOCs), ensuring that you and your colleagues breathe in cleaner air.

This filtration system traps microscopic particles, preventing them from recirculating in the workspace and causing potential health issues. Moreover, the carbon filter eliminates unpleasant smells, creating a more pleasant working environment. With improved air quality, you can experience increased productivity and reduced health risks associated with poor air circulation.

To optimize airflow with proper ducting, you can further enhance the performance of your laser cutter ventilation system.

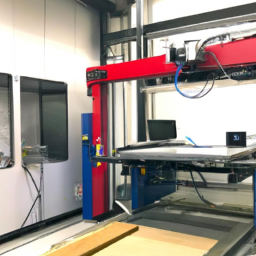

Optimize Airflow with Proper Ducting

Maximize the efficiency of your laser cutter by ensuring that proper ducting is used to optimize airflow. Proper ducting is crucial for improving ventilation efficiency and reducing noise levels in your workspace. By implementing a well-designed ducting system, you can effectively control the direction and flow of air. This ensures that the laser cutter is receiving a sufficient amount of fresh air to maintain optimal performance.

This allows for better cooling of the machine and prevents the build-up of harmful fumes and dust particles. Additionally, proper ducting helps to minimize noise levels by directing the exhaust air away from the operator and reducing the vibration caused by the airflow.

By optimizing airflow through proper ducting, you can enhance the overall performance and longevity of your laser cutter while creating a safer and more comfortable working environment.

Frequently Asked Questions

How much does it cost to install a high-quality ventilation system for a laser cutter?

The cost of installing a high-quality ventilation system for a laser cutter can vary significantly depending on whether you choose to do it yourself or hire a professional. On average, professional installation can range from $500 to $2,000, whereas a DIY approach may only cost around $200 to $500.

This cost comparison highlights the potential savings of opting for a DIY installation, but it’s crucial to consider your technical skills and the complexity of the system before making a decision.

Can I upgrade to a variable speed exhaust fan on my existing laser cutter?

Yes, you can upgrade to a variable speed exhaust fan on your existing laser cutter. This upgrade offers several benefits.

With a variable speed fan, you can adjust the airflow according to your specific needs, improving the overall performance of the laser cutter. The ability to control the fan speed allows for better ventilation, reducing the risk of overheating and ensuring a more efficient cutting process.

Upgrading the ventilation system with a variable speed fan is a technical and precise solution to enhance your laser cutter’s performance.

What are the benefits of using an external air compressor with a laser cutter?

Using an external air compressor with a laser cutter offers several benefits. Firstly, it greatly improves air quality by providing a consistent and clean source of compressed air. This eliminates the risk of contaminants entering the laser cutter and affecting the quality of the cuts.

Additionally, an external air compressor allows for faster cutting speeds as it provides a higher volume of air, ensuring efficient cooling and removal of debris during the cutting process.

How does a closed-loop cooling system benefit the performance of a laser cutter?

A closed-loop cooling system significantly enhances the performance of a laser cutter. By continuously circulating coolant within the system, it maintains a stable and optimal temperature, preventing overheating and ensuring consistent and accurate cutting results.

This cooling method effectively dissipates the heat generated during the laser cutting process, minimizing the risk of damage to the machine and increasing its overall efficiency.

The closed-loop cooling system benefits laser cutter performance by improving precision, reducing downtime, and extending the lifespan of the equipment.

Is it necessary to install a carbon filter in addition to a ventilation system for a laser cutter?

To achieve optimal performance, it’s highly recommended to install a carbon filter in addition to a ventilation system for a laser cutter.

The advantages of using a carbon filter in laser cutter ventilation systems are manifold. It effectively removes harmful fumes and particulates, ensuring a safe working environment. Additionally, it helps to minimize the buildup of contaminants in the ventilation system, reducing the risk of clogging and enhancing overall system efficiency.

Regular maintenance is crucial to ensure the continued effectiveness of the carbon filter and the ventilation system as a whole.

Conclusion

In conclusion, by implementing these 7 laser cutter ventilation upgrades, you can significantly enhance the performance of your machine.

Installing a high-quality ventilation system, upgrading to a variable speed exhaust fan, and using an external air compressor will ensure optimal airflow and eliminate any harmful fumes.

Implementing a closed-loop cooling system will prevent overheating and improve efficiency.

Installing a carbon filter will further purify the air, reducing health risks.

Lastly, optimizing airflow with proper ducting will maximize the effectiveness of the ventilation system.

Coincidentally, these upgrades not only enhance performance but also prioritize safety and well-being.

So, don’t hesitate to make these improvements and take your laser cutting experience to the next level!