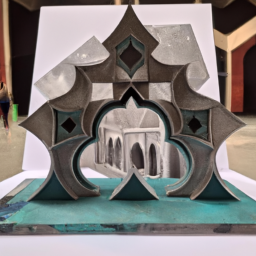

Imagine you’re a skilled craftsman working on a masterpiece. You meticulously carve and shape each piece, pouring your heart and soul into creating a one-of-a-kind model. But what if there was a way to take your craftsmanship to the next level? Enter laser cutters, the ultimate tool for precision and efficiency in model making.

With the right upgrades, your laser cutter can become an unstoppable force in your workshop. From software enhancements to safety features, there are seven key upgrades that can revolutionize your model making process. By investing in these upgrades, you’ll be able to achieve unparalleled precision, versatility, and speed.

Upgrade your laser cutter software to unlock a world of possibilities, add a rotary attachment for 360-degree engraving, and install an air assist system to prevent scorching and improve cutting quality.

Consider upgrading to a high-quality lens for sharper details, invest in a laser cooling system to prolong the lifespan of your machine, and don’t forget to prioritize safety with a comprehensive safety upgrade.

In this article, we’ll explore these seven model making upgrades in detail, providing you with the knowledge and insights to elevate your craftsmanship to new heights. Get ready to unleash the full potential of your laser cutter and create models that will leave a lasting impression.

Key Takeaways

- Upgrading the laser cutter software enhances cutting precision, speed, and efficiency.

- Installing an air assist system improves cutting precision and prevents heat buildup.

- Upgrading to a high-quality lens improves cutting precision, engraving capabilities, and results.

- Investing in a laser cooling system prevents overheating and extends the operating time of the machine.

Upgrade Your Laser Cutter Software

You should consider upgrading your laser cutter software in order to enhance its capabilities and improve the precision of your designs. Upgrading your software can provide you with a range of benefits, including the ability to improve cutting precision, increase speed, and enhance overall efficiency.

With upgraded software, you can achieve more intricate and detailed designs, ensuring that your final products are of the highest quality. The improved precision allows for cleaner cuts and smoother edges, resulting in a professional finish.

Additionally, upgraded software often comes with advanced features that can streamline your workflow and reduce production time. By upgrading your laser cutter software, you can take your design capabilities to the next level.

Now, let’s explore how adding a rotary attachment can further expand your options.

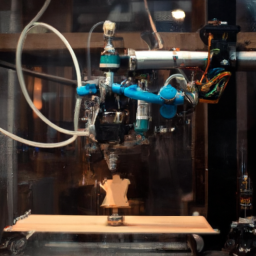

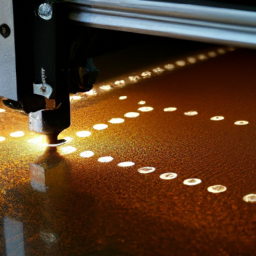

Add a Rotary Attachment

Adding a rotary attachment to your laser machine can significantly enhance its capabilities and allow for intricate designs to be engraved on cylindrical objects, increasing your creative possibilities.

With a rotary attachment, you can improve precision by precisely rotating the object while the laser engraves, ensuring even and accurate results.

This upgrade also enhances versatility as you can now work on a wider range of materials and products, such as glasses, bottles, and even pens.

The rotary attachment allows for precise and consistent engraving, enabling you to achieve intricate and detailed designs on curved surfaces.

By adding this attachment, you can take your laser cutter to the next level and unlock new creative opportunities.

Now, let’s explore the next upgrade to consider: installing an air assist system.

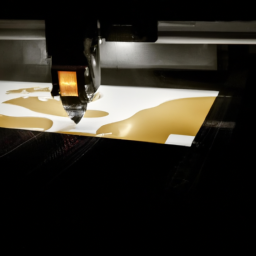

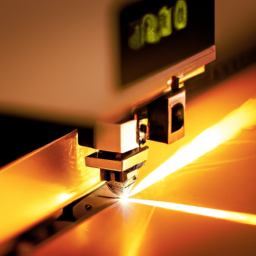

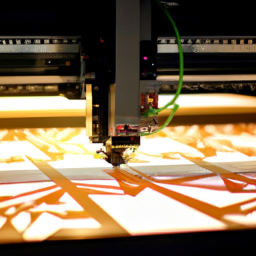

Install an Air Assist System

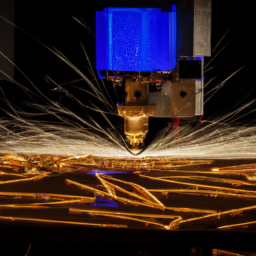

To truly enhance the performance of your laser machine, don’t forget to install an air assist system. This upgrade is essential for increasing efficiency and improving cutting precision.

An air assist system works by blowing a stream of compressed air onto the material being cut, which helps to remove debris and prevent fires. By clearing away smoke, dust, and vaporized material, the air assist system ensures that the laser can maintain a clear and precise path, resulting in cleaner cuts and more accurate designs. It also helps to prevent heat buildup, which can damage the material or cause the laser to lose focus.

By installing an air assist system, you can significantly improve the overall performance and longevity of your laser machine.

Now, let’s move on to the next section about upgrading to a high-quality lens.

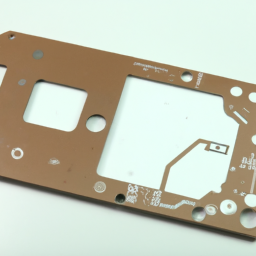

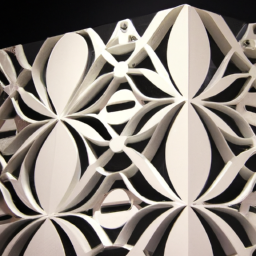

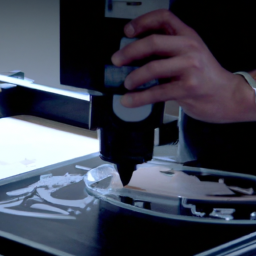

Upgrade to a High-Quality Lens

Upgrading to a high-quality lens can significantly improve the precision and clarity of your laser machine, with studies showing that it can increase cutting accuracy by up to 30%. By replacing your standard lens with a high-quality one, you can enhance engraving capabilities and achieve finer details in your designs. The table below highlights the key benefits of upgrading to a high-quality lens:

| Benefits of Upgrading to a High-Quality Lens |

|---|

| Improved cutting precision |

| Enhanced engraving capabilities |

| Clearer and crisper results |

| Reduced maintenance and downtime |

Investing in a high-quality lens not only improves the performance of your laser cutter but also saves you time and money in the long run. By achieving better cutting precision and enhancing engraving capabilities, you can take your laser cutting projects to the next level. To further optimize your laser cutter, consider the next step: investing in a laser cooling system.

Invest in a Laser Cooling System

To prevent overheating and ensure consistent performance, it’s crucial to invest in a laser cooling system for your laser cutter. This system will effectively dissipate heat generated during the cutting process, allowing your machine to operate at optimal temperatures.

Additionally, the cooling system will extend the operating time of your laser cutter. It will be able to handle longer cutting sessions without overheating. By reducing the risk of overheating, you can also minimize maintenance and downtime. Excessive heat can cause damage to the machine and lead to costly repairs.

Prevent Overheating and Ensure Consistent Performance

One way to keep your laser cutter running smoothly is by making sure it doesn’t overheat, which can be achieved through various upgrades. Overheating can cause damage to the machine and reduce its efficiency, so it’s important to take measures to prevent it. One upgrade to consider is installing a laser cooling system, which helps regulate the temperature and prevent overheating. Additionally, you can improve the efficiency of your laser cutter by upgrading the ventilation system to ensure proper airflow and prevent heat buildup. Another upgrade to consider is installing a temperature monitoring system that alerts you if the temperature exceeds safe limits. By implementing these upgrades, you can prevent overheating, ensure consistent performance, and extend the operating time of your laser cutter.

Extend the Operating Time of Your Laser Cutter

To prevent overheating and ensure consistent performance of your laser cutter, there are several upgrades you can consider. But now, let’s focus on how you can extend the operating time of your laser cutter to improve its efficiency and productivity.

One way to achieve this is by installing a cooling system that effectively dissipates heat generated during operation. This will prevent the laser cutter from overheating and allow it to run for longer periods without any issues.

Additionally, optimizing the laser cutter’s power settings and using high-quality optics can also contribute to increased productivity. By implementing these upgrades, you can maximize the operating time of your laser cutter and achieve higher output levels.

Now, let’s explore another essential aspect of upgrading your laser cutter: reducing maintenance and downtime.

Reduce Maintenance and Downtime

By minimizing the need for frequent repairs and interruptions, you can keep your laser cutting machine operating smoothly and efficiently. To reduce laser downtime and improve maintenance efficiency, there are several key steps you can take.

First, establish a regular maintenance schedule and adhere to it strictly. This includes cleaning the machine regularly and checking for any signs of wear or damage.

Additionally, invest in high-quality replacement parts and components to minimize the risk of breakdowns. Implementing preventive measures such as installing filters to remove debris and dust can also help extend the lifespan of your machine.

By taking these measures, you can significantly reduce the amount of time your laser cutter is out of commission for repairs or maintenance. Consider a safety upgrade to further enhance the performance and reliability of your machine.

Consider a Safety Upgrade

When considering a safety upgrade for your laser cutter, there are three key points to keep in mind.

First, it’s essential to install a fume extraction system to remove potentially harmful fumes and particles from the air.

Second, implementing safety measures to protect against accidents, such as emergency stop buttons and safety interlocks, is crucial to ensure the well-being of operators.

Finally, it’s important to comply with safety regulations and standards to maintain a safe working environment and avoid any legal or regulatory issues.

Install a Fume Extraction System

Consider installing a fume extraction system for your laser cutter to protect your health and reduce the risk of respiratory problems. Studies show that long-term exposure to laser cutter fumes can increase the chances of developing lung cancer by up to 43%.

To effectively remove harmful fumes from your workspace, invest in a reliable fume filtration system. This will ensure that the air is properly filtered before being released back into the environment. Additionally, consider implementing ventilation systems to maintain proper airflow and prevent the accumulation of fumes. This can be achieved through the installation of exhaust fans or duct systems that efficiently remove fumes from the laser cutting area.

By taking these precautions, you can create a safer working environment and minimize the potential health risks associated with laser cutter fumes.

Transitioning into the subsequent section, it’s also crucial to implement safety measures to protect against accidents.

Implement Safety Measures to Protect Against Accidents

To ensure a safe working environment, it’s essential to prioritize the implementation of accident prevention measures. One crucial step is to implement training programs that educate all users on the proper operation and maintenance of the laser cutter. This includes understanding the potential hazards, safety protocols, and emergency procedures.

Additionally, it’s important to use proper ventilation to minimize the risk of harmful fumes and particulates. This can be achieved by installing an efficient ventilation system or ensuring that the laser cutter is used in a well-ventilated area.

By implementing these safety measures, you can significantly reduce the risk of accidents and protect both users and the surrounding environment.

Moving forward, it’s also crucial to comply with safety regulations and standards to maintain a safe working environment.

Comply with Safety Regulations and Standards

Ensure that you follow the rules of the safety dance and march in line with regulations and standards to maintain a secure working environment.

When it comes to operating a laser cutter, it’s crucial to comply with safety regulations and implement safety measures to protect yourself and others. Start by familiarizing yourself with the specific safety regulations and standards that apply to laser cutter operation in your region. This may include guidelines on ventilation, fire prevention, and personal protective equipment.

Adhere to these regulations by conducting regular inspections and maintenance on your laser cutter, ensuring it’s in proper working condition. Implement safety measures such as installing emergency stop buttons, interlocks, and warning signs. Additionally, provide proper training and education to all operators to ensure they understand and follow safety protocols.

By complying with safety regulations and implementing necessary measures, you can create a safe and secure working environment for yourself and others.

Frequently Asked Questions

How much does it cost to upgrade the laser cutter software?

Upgrading the software for your laser cutter can vary in cost depending on the specific software you choose. The cost of maintenance for the software upgrade should be factored in, as it ensures your laser cutter continues to function optimally.

When considering an upgrade, it’s crucial to prioritize software compatibility with your laser cutter model. This will ensure smooth operation and prevent any potential compatibility issues that may arise.

Can a rotary attachment be added to any laser cutter model?

Rotary attachment compatibility is dependent on the specific laser cutter model. Not all laser cutter models are compatible with a rotary attachment due to limitations in their design and functionality. It’s essential to check the specifications and documentation of your laser cutter to determine if it supports a rotary attachment. If your laser cutter model doesn’t have the necessary features or capabilities, it may not be possible to add a rotary attachment to it.

What are the benefits of installing an air assist system?

Installing an air assist system for your laser cutter brings a multitude of benefits. It’s a game-changer!

Picture this: flawless cuts, impeccable engraving, and faster production speeds. The installation process is straightforward, requiring minimal effort. Once installed, the system delivers a continuous stream of air to blow away debris, resulting in cleaner cuts and reduced material damage.

Additionally, it helps prevent flare-ups and fires, ensuring a safer working environment. Experience the remarkable advantages of an air assist system today!

What factors should be considered when upgrading to a high-quality lens?

When upgrading to a high-quality lens for your laser cutter, there are several factors to consider.

Firstly, the focal length plays a crucial role in determining the laser’s focus and precision. Opt for a lens with a shorter focal length for fine details and a longer focal length for larger projects.

Secondly, choose a lens material that is resistant to heat and has low absorption properties, such as fused silica or zinc selenide. These materials ensure optimal performance and longevity of your laser cutter.

Are laser cooling systems compatible with all laser cutter models?

Laser cooling systems may not be compatible with all laser cutter models. When considering laser cutter maintenance, it’s important to choose the right laser cutter for your needs. Some laser cutter models may already have built-in cooling systems, while others may require additional modifications.

It’s crucial to research and consult with experts to ensure compatibility and optimal performance. Proper maintenance and choosing the right equipment are essential for a smooth laser cutting experience.

Conclusion

In conclusion, by implementing these model making upgrades to your laser cutter, you can significantly enhance its functionality and efficiency.

Upgrading your laser cutter software will enable you to unlock advanced features and improve your workflow.

Adding a rotary attachment will allow you to create detailed and intricate designs on cylindrical objects.

Installing an air assist system will ensure cleaner and more precise cuts.

Upgrading to a high-quality lens will result in sharper and more accurate engraving.

Investing in a laser cooling system will prevent overheating and extend the lifespan of your machine.

Lastly, considering a safety upgrade will provide peace of mind and protect both you and your equipment.

With these enhancements, your laser cutter will be transformed into a powerhouse of precision and productivity.