Coincidence or not, it seems like the perfect time to upgrade your laser cutter software. With a plethora of benefits that can significantly enhance your workflow, it’s an opportunity you don’t want to miss.

In this article, we’ll explore the top seven reasons why upgrading your laser cutter software can revolutionize the way you work.

First and foremost, you’ll experience enhanced speed and efficiency. Imagine completing your projects in a fraction of the time it used to take, allowing you to tackle more tasks and increase productivity. Moreover, improved precision and accuracy will ensure that every cut is flawless, saving you time and materials.

But that’s not all – advanced design capabilities are at your fingertips with upgraded software. From intricate patterns to intricate designs, you’ll have the tools to bring your vision to life. And with compatibility with the latest technology, you’ll stay ahead of the curve and seamlessly integrate your laser cutter into your existing setup.

Additionally, a streamlined workflow and time savings await you. With upgraded software, you’ll navigate through your projects effortlessly, reducing downtime and maximizing output. Plus, regular updates and access to new features will keep your laser cutter at the forefront of innovation.

So why wait? Upgrade your laser cutter software today and unlock a world of possibilities for improved workflow.

Key Takeaways

- Upgraded laser cutter software enhances speed and efficiency

- Improved precision and accuracy save time and materials

- Advanced design capabilities bring visions to life

- Streamlined workflow and time savings

Enhanced Speed and Efficiency

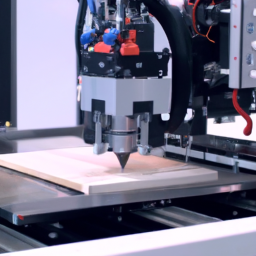

You’ll be amazed at how much faster and more efficient your laser cutter can be when you upgrade your software. With the latest software, you’ll experience increased productivity and an enhanced user experience.

The upgraded software is designed to optimize the laser cutter’s performance, allowing it to complete tasks in a fraction of the time. You’ll notice a significant improvement in speed, allowing you to complete more projects in less time.

The enhanced user experience means that the software is more intuitive and user-friendly, making it easier for you to navigate and control the laser cutter. This streamlined workflow will save you precious time and effort.

Plus, the software upgrade will lead us to the next section, where we’ll explore the improved precision and accuracy of your laser cutter.

Improved Precision and Accuracy

Your projects will be as precise as a surgeon’s scalpel when you enhance the accuracy and precision of your laser cutting process. Upgrading your laser cutter software can greatly improve the reliability and consistency of your cuts, saving you time and money in the long run. Here are four reasons why upgrading your software will lead to improved precision and accuracy:

-

Advanced algorithms: The latest software versions incorporate advanced algorithms that optimize cutting paths, ensuring every detail is executed with utmost precision.

-

Real-time monitoring: Upgraded software provides real-time monitoring of the cutting process, allowing you to make adjustments on the fly and maintain accuracy throughout.

-

Enhanced calibration options: The software offers a range of calibration options, allowing you to fine-tune your machine for maximum accuracy and minimize any errors.

-

Cost-effective solutions: Upgrading your software can provide cost-effective solutions by reducing material waste and eliminating the need for rework.

With improved precision and accuracy, you’ll be able to take advantage of the advanced design capabilities in the subsequent section, creating even more intricate and detailed projects.

Advanced Design Capabilities

Unleash your creativity with the cutting-edge design possibilities of the latest laser cutting software. This advanced software offers a wide range of creative possibilities, allowing you to bring your ideas to life with precision and ease.

With enhanced user experience and intuitive design tools, you can create intricate patterns, shapes, and designs that were previously unimaginable. The software enables you to experiment with different materials, colors, and textures, giving your projects a unique and professional touch.

Whether you’re a professional designer or a hobbyist, the latest laser cutting software will revolutionize your workflow and take your designs to the next level.

So, why wait? Upgrade your software today and experience the seamless integration and compatibility with the latest technology, ensuring that you stay ahead in the fast-paced world of laser cutting.

Compatibility with Latest Technology

With the seamless integration of the latest technology, this cutting-edge laser cutting software ensures unparalleled compatibility for a streamlined and efficient design process. Here are four reasons why upgrading to this software will greatly enhance your workflow:

-

Integration with 3D printing: This software allows you to easily import and work with 3D designs, giving you the ability to create intricate and complex laser-cut objects with precision and accuracy.

-

Remote control capabilities: With this software, you can remotely control your laser cutter, saving you time and effort. You can monitor and adjust settings, start and stop jobs, and even troubleshoot any issues from the convenience of your computer or mobile device.

-

Improved file compatibility: This software supports a wide range of file formats, ensuring that you can seamlessly import and work with designs from various sources without any compatibility issues.

-

Enhanced efficiency: By upgrading to this software, you can experience a streamlined workflow and significant time savings. The advanced features and compatibility with the latest technology enable you to work more efficiently and effectively, ultimately increasing your productivity.

With these benefits in mind, upgrading your laser cutter software will undoubtedly lead to a more streamlined workflow and time savings.

Streamlined Workflow and Time Savings

By seamlessly integrating the latest technology, this cutting-edge laser cutting software allows for a smooth and efficient design process, saving you valuable time and effort. With increased productivity as its primary goal, the software provides a range of cost-effective solutions that streamline your workflow.

By automating repetitive tasks and offering intuitive design tools, you can complete projects faster and with greater accuracy. The software also offers advanced nesting capabilities, optimizing material usage and minimizing waste. Additionally, it allows for real-time monitoring and control of the laser cutter, ensuring optimal performance throughout the entire cutting process.

With these time-saving features, you can increase your output while reducing production costs.

As you move forward, it’s important to consider the benefits of access to new features and updates, which will be discussed in the next section.

Access to New Features and Updates

Take advantage of the latest features and updates available with this advanced laser cutting software. This allows you to stay ahead of the curve and continuously enhance your design capabilities. Upgrading your laser cutter software gives you access to new features that can significantly increase productivity.

These updates are designed to streamline your workflow, making it faster and more efficient. With improved user experience, you can navigate the software with ease, saving you time and frustration. The new features also provide better control over your laser cutter, allowing you to achieve more precise cuts and intricate designs.

By upgrading your software, you can unlock a whole new level of possibilities and take your laser cutting projects to the next level.

Frequently Asked Questions

Can I still use my old laser cutter if I upgrade the software?

Yes, you can still use your old laser cutter if you upgrade the software. Compatibility concerns between the old hardware and new software are unlikely to be an issue. Upgrading the software will bring numerous benefits, such as improved functionality, increased efficiency, and enhanced user experience.

It’s like giving your old laser cutter a new lease on life, unlocking its full potential and making your workflow smoother and more productive.

What are the system requirements for the latest laser cutter software?

To ensure compatibility with the latest laser cutter software, it’s important to consider the system requirements. Before installing the software, check if your computer meets the necessary specifications, such as processor speed and RAM.

Installation time will vary depending on your system’s performance. Additionally, make sure your laser cutter can handle file transfers from the upgraded software.

Finally, be aware that upgrading the software may have warranty implications, so it’s important to review the terms and conditions.

How long does it usually take to install and set up the upgraded software?

Installing and setting up upgraded laser cutter software is a breeze! It’s like watching paint dry or waiting for a sloth to finish a marathon.

In terms of installation time, you’ll be pleasantly surprised. It usually takes less time than it takes to brew a cup of coffee.

As for the learning curve, fear not! It’s as simple as riding a tricycle. You’ll be up and running in no time, maximizing your workflow and leaving your competitors in the dust.

Can I transfer my existing design files to the new software?

Yes, you can transfer your existing design files to the new software. However, it’s important to check for compatibility issues before doing so. Make sure that the new software supports the file formats you’re using. If there are any compatibility issues, you may need to convert your design files to a compatible format.

It’s recommended to backup your existing design files before transferring them to ensure that you don’t lose any important data during the process.

Will upgrading the software void my laser cutter’s warranty?

Upgrading your laser cutter software won’t void your warranty. The new software is designed to enhance your workflow by providing improved features and compatibility with your old cutter. It’s important to note that the upgrade process should be done following the manufacturer’s instructions to ensure a seamless transition.

By upgrading, you can enjoy the benefits of the new software without worrying about the impact on your warranty.

Conclusion

In conclusion, upgrading your laser cutter software can greatly enhance your workflow and productivity.

With improved speed and efficiency, you can complete projects faster and more efficiently. The advanced design capabilities and compatibility with the latest technology allow for greater precision and accuracy in your cuts.

Additionally, the streamlined workflow and time savings can lead to increased productivity and profitability. And here’s an interesting statistic: studies have shown that upgrading laser cutter software can result in a 25% increase in overall productivity.

So why wait? Upgrade your software today and experience the benefits firsthand.