Are you ready to cut through the complexities of laser cutting software? Just like a laser beam slicing through metal, mastering the art of seamless workflow and integration with laser cutter software requires precision, finesse, and a strategic approach.

In this article, we will unveil seven strategies that will revolutionize your laser cutting game.

First and foremost, familiarize yourself with the software interface. It’s like getting acquainted with a new tool in your workshop—knowing its ins and outs will save you time and frustration.

Next, organize and prepare your design files, ensuring they are in the right format and ready to be transformed into beautiful creations.

Don’t forget to leverage the software’s features and tools to enhance your designs and make them truly stand out.

To achieve optimal results, testing and adjusting settings is crucial. Think of it as fine-tuning your instrument to produce the perfect melody.

Additionally, streamline your workflow with automation and batch processing, allowing you to tackle multiple projects with ease.

Lastly, stay updated with software updates and enhancements. Think of them as upgrades to your laser cutting arsenal, providing new capabilities and improved performance.

With these seven strategies at your disposal, you’ll be well on your way to a seamless and integrated laser cutting experience.

Key Takeaways

- Familiarize yourself with the laser cutting software interface and its tools and features.

- Customize software settings according to specific requirements for efficient operation.

- Regularly update the software to ensure compatibility with the laser cutter and access new features.

- Streamline workflow with automation and batch processing to optimize material usage and save time.

Familiarize Yourself with the Software Interface

Get ready to dive into the software interface, where you’ll familiarize yourself with all the tools and features needed for a seamless workflow with the laser cutter. Understanding the interface functionalities is crucial to efficiently operate the laser cutter software.

Take the time to explore the different menus, buttons, and icons, and learn their purpose and functions. Familiarize yourself with the layout and navigation of the software, so you can easily access the tools you need.

Additionally, make sure to customize the software settings according to your specific requirements. Adjusting parameters like cutting speed and power will enable you to achieve optimal results for your laser cutting projects.

With a solid understanding of the software interface and customized settings, you’ll be ready to organize and prepare your design files for laser cutting.

Organize and Prepare Your Design Files

Make sure you’re ready for a smooth ride by organizing and prepping your design files like a well-packed suitcase before a trip, ensuring everything is easily accessible and ready to go.

Effective design file management and file organization are crucial for a seamless workflow and integration with laser cutter software.

Start by creating a clear folder structure that categorizes your design files based on their purpose or project. Use descriptive file names that accurately reflect the contents of each file. Additionally, consider creating subfolders within each main category to further organize your files.

Remember to keep all relevant files, such as images or vector files, in the same folder as your design file for easy access.

By organizing and preparing your design files in this manner, you’ll save time and avoid unnecessary confusion.

Now, let’s explore how you can take advantage of software features and tools to enhance your laser cutting experience.

Take Advantage of Software Features and Tools

To make the most of your design software, take advantage of its built-in design templates and libraries. These resources provide a starting point for your designs and can save you time and effort.

Additionally, explore advanced features like nesting and material optimization, which can help you maximize your material usage and minimize waste.

By utilizing these tools, you can streamline your workflow and create more efficient designs.

Use the built-in design templates and libraries

Utilize the laser cutter software’s pre-designed templates and libraries to effortlessly enhance your workflow and seamlessly integrate your designs.

The software comes equipped with a wide range of built-in design resources, including templates for various shapes and objects. These templates can serve as a starting point for your projects, saving you time and effort in creating designs from scratch.

Furthermore, the software offers customization options, allowing you to modify and personalize the templates to suit your specific needs. With just a few clicks, you can adjust dimensions, add text, or incorporate additional elements to make the design your own.

By leveraging these built-in resources and customization options, you can easily create stunning designs with minimal effort.

As you explore the software further, you can also delve into advanced features like nesting and material optimization, which we will discuss in the next section.

Explore advanced features like nesting and material optimization

Discover the hidden gems of the laser cutter software by diving into its advanced features, like nesting and material optimization, to unlock a world of efficiency and creativity. These advanced techniques are essential for maximizing efficiency in laser cutting projects and implementing precise cuts with minimal material waste. Nesting, for instance, allows you to arrange multiple designs on a single sheet of material, minimizing scrap and maximizing production. Material optimization algorithms analyze the design and suggest the most efficient cutting path, reducing processing time and material usage. By exploring these advanced features, you can streamline your workflow, save time, and achieve superior results. In the next section, we will delve into the importance of test and adjust settings for optimal results.

Test and Adjust Settings for Optimal Results

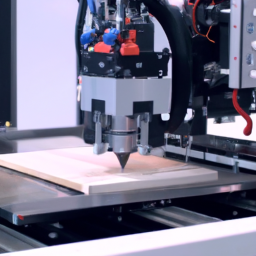

To achieve optimal results with your laser cutter, it’s crucial to conduct test cuts to determine the best settings for different materials. By fine-tuning parameters such as speed, power, and frequency, you can ensure precise cuts and avoid potential damage to your materials. Take advantage of software features and tools to seamlessly integrate with your laser cutter software, allowing for a seamless workflow and efficient production process.

Conduct test cuts to determine the best settings for different materials

Once you’ve got your materials selected, it’s time to roll up your sleeves and start experimenting with test cuts to find the perfect settings for each different material. Trial and error is the name of the game here, as different materials have different properties that affect how they respond to laser cutting. To ensure optimal results, it’s important to determine the compatibility of your chosen material with the laser cutter software. Here are some key tips to help you in this process:

- Start with a small test cut to gauge the initial settings.

- Gradually increase the power and speed to find the optimal combination.

- Pay attention to the quality of the cut edges and any signs of burning or discoloration.

- Keep a record of the settings and material properties for future reference.

- Repeat the test cuts with different materials to create a comprehensive database.

By conducting these test cuts, you’ll be able to fine-tune parameters like speed, power, and frequency for precise cuts. This will ensure that you achieve the best results when working with various materials.

Fine-tune parameters like speed, power, and frequency for precise cuts

Refine your laser cutting technique by adjusting parameters such as speed, power, and frequency. This will allow you to achieve precise and flawless cuts on a variety of materials. Parameter optimization is crucial to maximize cutting efficiency and ensure the best results.

Start by experimenting with different values for each parameter and observe the effects on the material. Increase the speed to reduce cutting time, but be careful not to compromise accuracy. Adjust the power to control the depth of the cut, ensuring it isn’t too shallow or too deep. Lastly, fine-tune the frequency to optimize the laser’s interaction with the material.

By carefully adjusting these parameters, you can achieve exceptional cutting quality.

Transitioning to the next topic, streamline your workflow with automation and batch processing to increase productivity and efficiency.

Streamline Workflow with Automation and Batch Processing

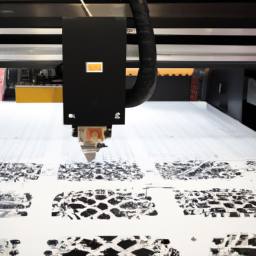

Speed up your workflow and simplify the process by automating tasks and processing multiple files at once with batch processing. This automation benefits users by reducing manual effort and increasing efficiency. With batch processing, you can send a group of files to the laser cutter software, saving time and effort instead of processing each file individually.

Here are three ways batch processing can improve your workflow:

-

Automatically adjust settings: Customize cutting parameters for each file and let the software apply them automatically during batch processing.

-

Optimize material usage: With batch processing, you can nest multiple designs on a single sheet, maximizing material efficiency and reducing waste.

-

Monitor progress: Get real-time updates on the status of batch processing, allowing you to track the progress and address any issues promptly.

By streamlining your workflow with automation and batch processing, you can save time and effort, allowing you to focus on other tasks. Stay updated with software updates and enhancements to further enhance your laser cutter experience.

Stay Updated with Software Updates and Enhancements

Stay in the loop and keep your laser cutting experience fresh by staying updated with the latest software updates and exciting enhancements. Software updates not only provide new features and improvements but also ensure software compatibility with your laser cutter. By regularly updating your software, you can avoid compatibility issues and ensure a seamless workflow. Additionally, staying updated allows you to take advantage of the latest troubleshooting techniques and bug fixes, enhancing the overall performance of your laser cutter. To help you understand the importance of staying updated, refer to the table below, which highlights the benefits of software updates and enhancements:

| Benefits of Software Updates and Enhancements |

|---|

| Improved software compatibility |

| Enhanced troubleshooting techniques |

| Bug fixes and performance improvements |

| Access to new features and functionalities |

By keeping your software up to date, you can optimize your laser cutting process and achieve the best results. Stay informed and make the most of your laser cutter by staying updated with software updates and enhancements.

Frequently Asked Questions

Can laser cutter software be used with any type of laser cutter machine?

Absolutely! Laser cutter software can be used with any type of laser cutter machine. This means you can use the software with different models and brands without any issues. The advantages of using laser cutter software are immense. It allows you to easily create and edit designs, optimize cutting paths for precision, and control the laser cutter settings with precision. This seamless integration ensures a smooth and efficient workflow for all your laser cutting needs.

Is it necessary to have prior experience with graphic design software to use laser cutter software?

To use laser cutter software efficiently, it isn’t necessary to have prior experience with graphic design software. However, some necessary skills include a basic understanding of computer operations and familiarity with the laser cutter machine.

The learning curve for laser cutter software may vary depending on your existing knowledge, but most software provides user-friendly interfaces and tutorials to facilitate the process. With practice and patience, you can quickly master the software and achieve seamless workflow and integration.

Can laser cutter software work with both vector and raster image files?

Yes, laser cutter software can work with both vector and raster image files, allowing for versatile design options. You have the flexibility to use vector files, which are made up of mathematical equations and can be easily scaled without losing quality.

Additionally, you can work with raster image files, which are composed of pixels and are ideal for detailed designs. This compatibility ensures that you can create intricate and precise designs using the laser cutter software.

Are there any limitations to the file size or resolution that laser cutter software can handle?

Laser cutter software does have limitations when it comes to file size and resolution. The software may struggle to handle large file sizes, causing processing delays or even crashing. Similarly, if the resolution of an image is too high, the software may struggle to render it accurately.

To ensure a smooth workflow and integration, it’s important to be mindful of these limitations and adjust file sizes and resolutions accordingly.

Can laser cutter software be used with materials other than wood and metal?

Laser cutter software can indeed be used with materials other than wood and metal. It offers a wide range of options for cutting and engraving materials such as acrylic, leather, fabric, paper, and even glass.

The versatility of laser cutter software makes it applicable in various industries. For example, it can be used in the automotive industry for cutting leather upholstery, in the fashion industry for intricate fabric designs, and in the signage industry for precise engraving on acrylic and glass.

Conclusion

In conclusion, by implementing these strategies, you can ensure a seamless workflow and integration with laser cutter software.

Familiarize yourself with the software interface to navigate it effortlessly.

Organize and prepare your design files for efficient processing.

Take advantage of the software’s features and tools to enhance your designs.

Test and adjust settings to achieve optimal results.

Streamline your workflow with automation and batch processing.

Lastly, stay updated with software updates and enhancements to stay ahead of the curve.

With these tips, you’ll be able to cut through any obstacles like a hot knife through butter.