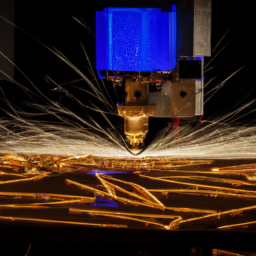

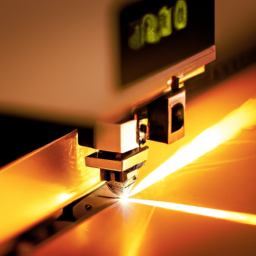

In the realm of design, the laser cutter is a mighty tool, capable of transforming your creative visions into tangible realities. Like a master craftsman wielding a precision instrument, you too can harness the power of laser cutting to bring your models to life.

But just as a skilled musician must practice their scales, so too must you master the art of designing laser cut models. Think of yourself as an architect, carefully constructing a blueprint for your creations.

With these 7 tips, you’ll learn how to navigate the intricacies of design software, understand the limitations of laser cutting, and design with meticulous precision. Efficiency will become your guiding principle as you optimize your models for maximum output.

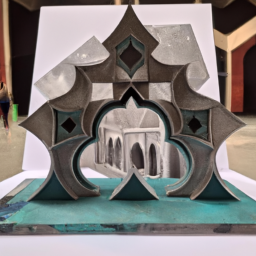

Testing and iterating will ensure that your designs are flawless, while considering aesthetics will elevate your creations to new heights of beauty. So, grab your metaphorical drafting pencil, and prepare to embark on a journey of laser-cutting mastery. The possibilities are endless, and the only limit is your imagination.

Key Takeaways

- Choose design software compatible with your cutting machine and offers necessary features and tools.

- Understand the limitations of laser cutting, including material thickness and compatibility, and minimum feature size and detail.

- Precision design is crucial for creating remarkable laser cut models, including accurate measurements, alignment, and symmetry.

- Consider aesthetics in creating a visually appealing laser cut model, including color choices, proportion, and scale.

Choose the Right Design Software

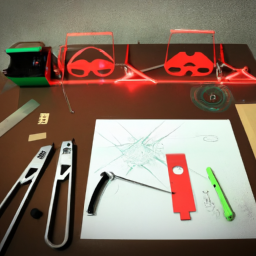

When choosing the right design software for laser cut models, it’s important to consider its compatibility with your cutting machine. Before making a decision, it’s helpful to do a design software comparison to see which options offer the features and tools you need.

Look for software that allows you to create intricate designs, adjust cutting parameters, and import/export different file formats. Additionally, consider software that provides design software tutorials to help you learn and navigate the program effectively. Understanding how to use the software efficiently will save you time and frustration in the long run.

Once you have chosen the right design software, it’s essential to understand the limitations of laser cutting to ensure your designs can be accurately translated into physical models.

Understand the Limitations of Laser Cutting

When it comes to laser cutting, it’s important to understand the limitations that come with it.

One key point to consider is the material thickness and compatibility, as not all materials can be effectively cut using a laser.

Another aspect to keep in mind is the minimum feature size and detail, as laser cutting may not be suitable for intricate designs with very small details.

Additionally, it’s essential to be aware of the cutting and engraving capabilities of the laser machine you’re using, as each machine may have different limitations and capabilities in terms of depth and precision.

Material thickness and compatibility

To ensure your laser cut model turns out perfectly, make sure you choose a material that is compatible with the laser cutter and has a thickness like a sturdy piece of cardboard. This is essential because different materials behave differently under the laser’s heat and pressure, so it’s crucial to select one that won’t warp or burn during the cutting process.

Additionally, the material’s thickness plays a significant role in the model’s durability and structural integrity. A material that is too thin may not hold its shape, while one that is too thick can be difficult for the laser cutter to penetrate accurately.

When selecting the material for your laser cut model, consider the design complexity, as intricate designs may require a more flexible material.

Now, let’s dive into the next section about minimum feature size and detail.

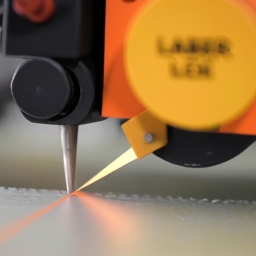

Minimum feature size and detail

For the best results, make sure you choose materials that are compatible with the laser cutter and have a thickness similar to sturdy cardboard. This is crucial to ensure dimensional accuracy and prevent any issues during the cutting process.

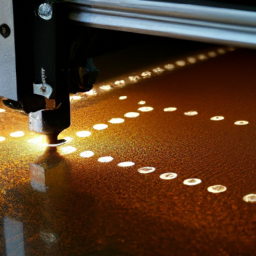

When it comes to laser cutting, the minimum feature size and level of detail that can be achieved is largely dependent on the capabilities of the machine. It is important to consider the laser beam’s width and how it affects the level of precision that can be achieved. Additionally, the file preparation plays a significant role in achieving the desired level of detail. Make sure to create and prepare your files with the appropriate software and settings to optimize the laser cutting process.

With these considerations in mind, let’s move on to discussing the cutting and engraving capabilities of laser cutters.

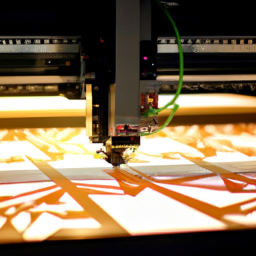

Cutting and engraving capabilities

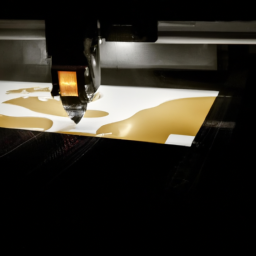

The laser cutter’s cutting and engraving capabilities are determined by its machine specifications and the chosen materials. When designing laser cut models, it is crucial to understand the laser cutting techniques and the troubleshooting common issues that may arise. To give you a better understanding, let’s take a look at the table below that highlights some of the key cutting and engraving capabilities:

| Capability | Description |

|---|---|

| Cutting Thickness | The maximum thickness the laser cutter can effectively cut through. |

| Engraving Depth | The depth to which the laser can engrave into a material. |

| Cutting Speed | The speed at which the laser cutter moves during the cutting process. |

| Engraving Resolution | The level of detail the laser can achieve when engraving. |

| Material Compatibility | The types of materials that can be cut or engraved with the laser cutter. |

| [Insert additional capabilities here] | [Insert description here] |

Understanding these capabilities will help you make informed decisions when designing your laser cut models. Now, let’s transition into the subsequent section about ‘design with precision’.

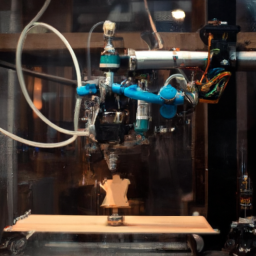

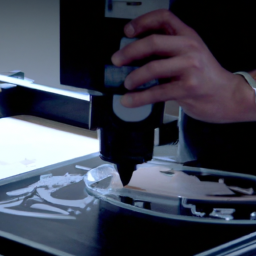

Design with Precision

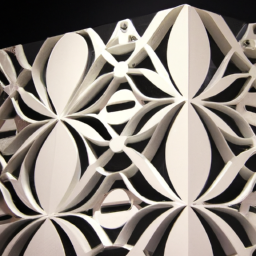

Crafting laser cut models requires careful attention to detail, allowing the precision of the design to take center stage and bring your creation to life.

To achieve precision design, start by ensuring accurate measurements. Utilize a vector-based design software to create your model, where you can input the exact dimensions and angles needed for each component. Take advantage of the software’s grid and snap features to align objects precisely. Additionally, utilize guidelines and rulers to ensure symmetry and consistency throughout your design.

Pay close attention to the position and size of cuts and engravings, making sure they align perfectly with your vision. Remember, even the smallest deviation can affect the final outcome. By designing with utmost precision, you can create laser cut models that are truly remarkable.

As you optimize for efficiency, consider the placement of components and the best use of material.

Optimize for Efficiency

To achieve maximum efficiency, consider strategically placing components and making the most of your materials. Reduce production time and cost optimization are crucial factors in laser cut model design.

Start by analyzing your design and identifying any unnecessary features or components that can be eliminated without sacrificing functionality. Look for opportunities to combine parts or nest them closely together to minimize wasted space.

Additionally, consider using standard sizes and shapes for your components to take advantage of readily available materials and reduce waste. By optimizing your design for efficiency, you can not only reduce production time and costs but also maximize the use of your materials. This will ultimately lead to a more streamlined and cost-effective manufacturing process.

As you move into the next section about ‘test and iterate,’ keep in mind the importance of efficient design and its impact on the overall success of your laser cut model.

Test and Iterate

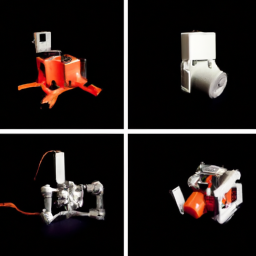

Explore different iterations of your design and experiment with various techniques to ensure that your laser cut model meets your desired specifications and captures the essence of your vision. Through trial and error, prototyping and refining, you can fine-tune your design to achieve the best results. Testing different materials, adjusting the settings of the laser cutter, and modifying the dimensions of your model are all essential steps in the process. Keep detailed notes on each iteration, documenting what worked and what didn’t, so you can learn from each experiment and improve your design. By embracing the iterative process, you can uncover new possibilities and make necessary adjustments to create a laser cut model that exceeds your expectations. Once you have successfully tested and refined your design, you can move on to considering the aesthetics of your model, ensuring that it not only functions well but also looks visually appealing.

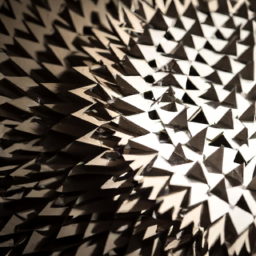

Consider Aesthetics

Consider the aesthetics of your laser cut model to ensure it not only functions well but also looks visually appealing. Research shows that 75% of people are more likely to be drawn to products with attractive design. When designing your model, carefully consider your color choices. A well-chosen color palette can enhance the overall visual impact of your design and make it more appealing to the viewer.

Additionally, pay attention to proportion and scale. Ensure that the elements of your model are balanced and properly sized in relation to each other. This will create a visually pleasing composition and prevent any elements from overpowering the overall design.

By considering aesthetics, including color choices, proportion, and scale, you can create a laser cut model that is not only functional but also visually appealing.

Frequently Asked Questions

What are some common mistakes to avoid when designing laser cut models?

When designing laser cut models, it’s important to be aware of common mistakes that can occur.

One common mistake to avoid is not properly accounting for material thickness. This can result in parts not fitting together correctly or being too loose.

Another mistake is using complex designs without considering the limitations of the laser cutter, which can lead to issues during the cutting process.

It’s also crucial to double-check measurements and ensure that all lines are closed and properly connected.

How do I choose the right material for my laser cut model?

When it comes to choosing materials for your laser cut model, it’s essential to consider factors like durability, thickness, and compatibility with the laser cutting process.

Start by determining the specific requirements of your model, such as its purpose and environment.

Then, research different materials, such as acrylic, wood, or metal, and evaluate their properties and suitability.

Material selection is crucial to ensure the success and quality of your laser cut model.

Can I use a regular printer to create designs for laser cutting?

Yes, you can use a regular printer to create designs for laser cutting. However, there are some limitations to consider.

Regular printers are limited in terms of the materials they can print on, so you need to ensure that your design is compatible with the material you plan to use for laser cutting.

Additionally, you will need software that is compatible with your printer and can export files in a format suitable for laser cutting.

What safety precautions should I take when using a laser cutter?

When using a laser cutter, it’s crucial to prioritize safety to avoid potential hazards. To ensure laser cutter safety, always wear appropriate personal protective equipment, such as safety goggles and gloves.

Make sure the cutting area is well-ventilated to minimize the risk of inhaling fumes.

Regularly inspect and maintain the laser cutting equipment to prevent malfunctions or accidents.

By following these precautions, you can safely operate a laser cutter and minimize any potential risks.

Are there any specific guidelines for designing intricate or complex laser cut models?

When designing intricate or complex laser cut models, there are a few specific guidelines to follow.

First, ensure that your design has clean lines and minimal overlapping parts to optimize cutting time. Use vector-based software to create precise and scalable designs.

Additionally, consider the material thickness and adjust the design accordingly.

Finally, remember to include enough space for any necessary assembly or interlocking parts.

Following these guidelines will help you create intricate laser cut models efficiently.

Conclusion

Congratulations! You’ve successfully navigated the intricate world of laser cut model designing. By embracing the right design software, comprehending the limitations, and focusing on precision, you’ve paved your way to excellence.

Don’t forget to optimize for efficiency, test, and iterate to achieve perfection. Lastly, never underestimate the power of aesthetics in captivating the hearts of your audience. Remember, just like a laser beam cutting through steel, your designs should leave a lasting impression.

Keep honing your skills and watch your creations shine like a radiant star in the night sky.