Do you know that feeling when you’re driving down the road, and suddenly your car starts making weird noises? It’s like a sinking feeling in your stomach, right?

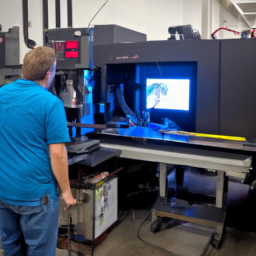

Well, imagine that feeling multiplied by ten when you’re working with a laser cutter and something goes wrong. It’s not just a noise, it’s a potential disaster waiting to happen. That’s why it’s crucial to avoid these seven troubleshooting mistakes with laser cutters.

By properly maintaining and cleaning your machine, following safety precautions, aligning materials correctly, calibrating power levels, addressing cooling system issues, and keeping up with software updates and calibration, you can ensure smooth and efficient operation.

Don’t let a lack of knowledge or attention to detail turn your laser cutter into a ticking time bomb. Stay informed, stay safe, and keep your laser cutter running like a well-oiled machine.

Key Takeaways

- Proper maintenance and cleaning are crucial for optimal laser cutter performance

- Adequate ventilation control is necessary to prevent overheating and decreased performance

- Regular cleaning of lens and mirrors is essential for maintaining optimal laser power

- Correct focus adjustment and material alignment are important for precise cuts and reduced waste.

Lack of Proper Maintenance and Cleaning

Don’t make the rookie mistake of neglecting regular maintenance and cleaning for your laser cutter – it’s like inviting trouble and smudges to crash your perfectly precise party.

Improper ventilation is a common consequence of neglecting maintenance. Without proper airflow, the laser cutter can become overheated, leading to decreased performance and potential damage.

Additionally, failing to clean the lens and mirrors regularly can result in reduced laser power and distorted cuts.

Another crucial aspect of maintenance is ensuring the correct focus adjustment. If the focus is off, it can lead to uneven cuts and wasted materials.

Neglecting these maintenance tasks can result in costly repairs and downtime.

Speaking of downtime, ignoring safety precautions can further exacerbate the issues caused by lack of maintenance and cleaning, so let’s dive into that next.

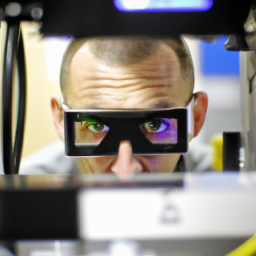

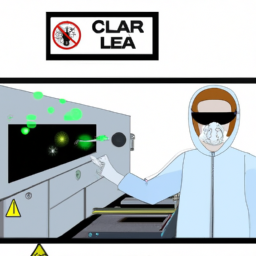

Ignoring Safety Precautions

Ensure you prioritize safety by following all necessary precautions when operating this powerful machine. Improper ventilation control is a critical safety concern when using laser cutters. The process of cutting and engraving materials releases fumes and dust that can be hazardous to your health. Make sure the ventilation system is properly installed and functional to remove these harmful substances from the working area.

Additionally, inadequate training and supervision can lead to accidents and injuries. Ensure that all operators receive thorough training on the correct use of the laser cutter and are closely supervised, especially during initial operation. Neglecting safety precautions can have severe consequences.

Moving forward, let’s discuss the next section on the importance of correct material alignment.

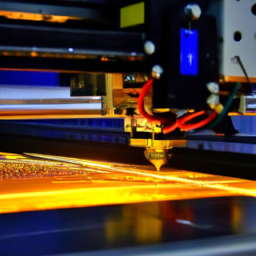

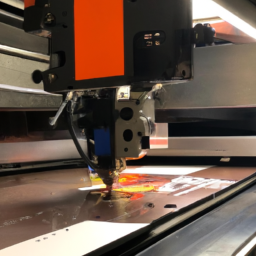

Incorrect Material Alignment

To achieve precise cuts and engravings, it’s crucial that you align the materials correctly. Material compatibility is key to ensuring successful laser cutting. Using materials that are not suitable for laser cutting can result in damage to the machine or produce undesirable results.

Make sure you understand the specific requirements of each material you plan to use. Additionally, improper ventilation is another factor to consider. Some materials, such as PVC or acrylic, release toxic fumes when cut with a laser. Without adequate ventilation, these fumes can be harmful to your health and may damage the laser cutter.

Pay attention to the ventilation system and ensure that it is properly functioning before operating the machine.

Now, let’s move on to the next section about inadequate power calibration.

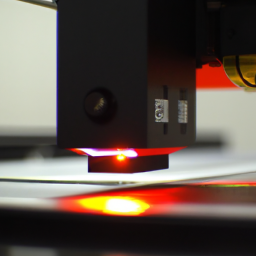

Inadequate Power Calibration

Insufficient power calibration can lead to imprecise cuts and engravings, compromising the quality of your laser cutting projects. Power fluctuations can occur if the laser cutter isn’t properly calibrated, resulting in inconsistent cutting depths and uneven engraving depths.

This can be problematic when working with delicate or intricate designs, as the lack of precision can ruin the final product. Additionally, improper focus can contribute to inadequate power calibration. If the laser beam isn’t focused correctly, it can result in uneven cutting and engraving, leaving some areas underpowered and others overpowered.

To avoid these issues, it’s crucial to regularly calibrate the power settings and ensure that the laser beam is properly focused. Ignoring these steps and overlooking cooling system issues can further impact the performance of your laser cutter.

Overlooking Cooling System Issues

Don’t overlook the importance of properly maintaining your laser cutter’s cooling system. Neglecting this crucial aspect can lead to serious issues that can affect the performance and lifespan of your machine. Here are some key points to keep in mind:

-

Coolant Leaks: Regularly check for any signs of coolant leaks, such as puddles or stains around the cooling system. Leaks can cause overheating and damage to the laser cutter components.

-

Temperature Regulation: Ensure that the cooling system is effectively regulating the temperature of the laser cutter. Proper temperature control is essential for optimal performance and preventing overheating.

-

Regular Maintenance: Schedule regular maintenance checks to clean and inspect the cooling system. This will help identify any potential issues before they become major problems.

-

Correct Coolant Type: Use the recommended coolant specified by the manufacturer. Using the wrong coolant can lead to inefficiencies and potential damage to the cooling system.

-

Filter Cleaning: Clean or replace the filters regularly to prevent clogging and ensure proper airflow.

By paying attention to these cooling system maintenance practices, you can avoid costly repairs and downtime.

Now, let’s discuss the next crucial aspect of laser cutter maintenance: neglecting regular software updates and calibration.

Neglecting Regular Software Updates and Calibration

Now that you understand the importance of addressing cooling system issues, let’s move on to another critical aspect of laser cutter troubleshooting. Neglecting regular software updates and calibration can lead to a host of problems that can drastically affect the performance and accuracy of your laser cutter.

Regular maintenance is key to ensuring that your laser cutter stays in optimal condition. This includes keeping up with software updates, which not only improve functionality but also enhance software compatibility. Additionally, regular calibration is essential to maintain precise cutting and engraving results.

Failing to keep up with these updates and calibration can result in a range of issues, such as inaccurate cuts, misaligned engravings, and even potential safety hazards. So, make it a priority to stay on top of regular software updates and calibration to maximize the efficiency and longevity of your laser cutter.

Frequently Asked Questions

Can I use any type of cleaning solution to clean my laser cutter, or are there specific products I should use?

You might think that any cleaning solution would do the trick, but when it comes to your laser cutter, you need to be extra careful. Using just any product could lead to disastrous results.

To keep your laser cutter in top shape, it’s best to stick to recommended cleaning products specifically designed for laser cutters. These products are formulated to effectively remove debris and maintain the integrity of your machine, ensuring optimal performance and longevity.

What are some common safety precautions that should be followed when operating a laser cutter?

When operating a laser cutter, it’s crucial to follow certain safety precautions to ensure your well-being and prevent accidents.

Firstly, ensure proper laser cutter ventilation by setting up an exhaust system to remove fumes and smoke.

Additionally, wear appropriate protective gear such as safety glasses and gloves.

Regular laser cutter maintenance is also important, including cleaning the machine regularly and using specific cleaning solutions designed for laser cutters.

These precautions will help to create a safe and efficient working environment.

How can I ensure proper material alignment in my laser cutter?

To ensure proper material alignment in your laser cutter, there are several techniques you can employ. One interesting statistic is that 80% of laser cutter issues are related to improper material alignment.

To avoid common issues, start by using a material alignment tool, such as a jig or pins, to precisely position your material. Additionally, always double-check that your laser beam is aligned with the material before starting the cutting process to prevent any misalignments.

What are the consequences of inadequate power calibration in a laser cutter?

Inadequate power calibration in a laser cutter can have serious consequences. Without proper calibration, the laser may not have enough power to cut through the material or may have too much power, causing excessive burning or melting.

This can result in inaccurate cuts, damaged materials, and wasted time and resources. It’s crucial to ensure the power calibration is accurately set to achieve precise and efficient cutting results.

How often should I update the software and calibrate my laser cutter?

To maintain optimal performance, it’s recommended to update your laser cutter’s software regularly. This ensures that you have the latest features, bug fixes, and improvements. The frequency of software updates depends on the manufacturer’s recommendations, but a general rule of thumb is to check for updates every few months.

Laser cutter calibration, on the other hand, should be done more frequently, preferably every few weeks or whenever you notice a decline in cutting quality. Regular calibration ensures precise and accurate results.

Conclusion

In conclusion, it’s crucial to steer clear of these troubleshooting mistakes when operating laser cutters. By ensuring regular maintenance and cleaning and following safety precautions, you can maximize the efficiency and longevity of your machine.

Another important aspect is aligning materials correctly and calibrating power appropriately. Addressing cooling system issues is also essential for smooth operations.

Additionally, don’t overlook the importance of regular software updates and calibration. By staying diligent and proactive, you can avoid unnecessary setbacks.

Remember, a well-maintained laser cutter is a reliable tool that can bring precision and finesse to your projects.