Are you tired of your laser cutter giving you subpar performance and constantly breaking down? Well, you’re in luck! In this article, we will explore seven upgrades that will not only improve the performance of your laser cutter, but also extend its lifespan.

It’s ironic, isn’t it? The very machine that’s supposed to make your life easier ends up causing you more headaches. But fear not, with these upgrades, you’ll be able to cut through materials with precision and efficiency like never before.

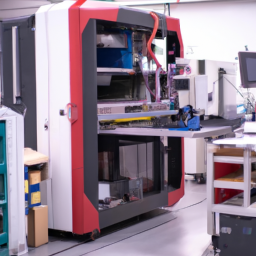

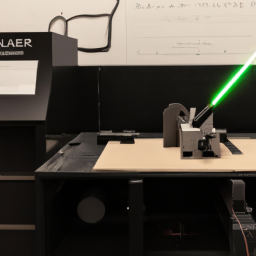

First on the list is upgrading the ventilation system. A well-functioning ventilation system is crucial for maintaining a clean and safe working environment.

Next, installing a water chiller will help regulate the temperature of your laser cutter, preventing overheating and ensuring optimal performance.

Enhancing the laser power will allow you to tackle thicker and tougher materials with ease.

But that’s not all, we’ll also discuss how to improve the cutting bed, upgrade the laser tube, and optimize the software settings. These upgrades will enhance the overall functionality of your laser cutter, prolonging its lifespan and saving you from costly repairs.

So, if you’re ready to take your laser cutting game to the next level, let’s dive into these seven upgrades and transform your laser cutter into a powerhouse of precision and longevity.

Key Takeaways

- Upgrading the laser tube and lens can enhance the laser power and improve the accuracy of cuts.

- Ventilation system upgrades are essential for maintaining a clean and safe working environment, reducing fumes, and preventing the build-up of harmful substances.

- Installing a water chiller helps regulate temperature, prevent overheating, and extend the lifespan of the laser tube by dissipating the heat generated during the cutting process.

- Cutting bed improvements, such as increasing versatility and improving adhesion, contribute to overall efficiency, reduce the risk of damage, and enable the cutting of larger materials.

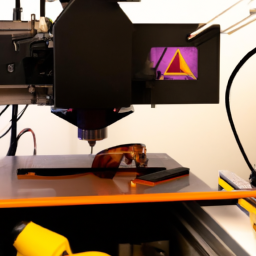

Upgrade the Ventilation System

Looking to give your laser cutter a boost? Let’s talk about upgrading the ventilation system to keep it running smoothly for even longer!

One of the key ways to improve the performance of your laser cutter is by enhancing the air circulation and reducing the fumes generated during the cutting process. By upgrading the ventilation system, you can ensure that the air around the machine is constantly refreshed, preventing any build-up of harmful fumes. This not only creates a safer working environment but also helps to maintain the longevity of your laser cutter.

Once you’ve upgraded the ventilation system, the next step is to install a water chiller, which will further enhance the overall performance and extend the lifespan of your laser cutter.

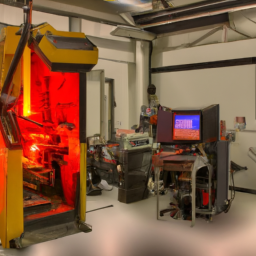

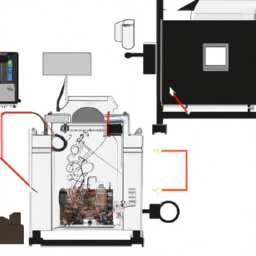

Install a Water Chiller

To get the most out of your machine, you’ll want to consider installing a water chiller. A water chiller is an essential upgrade that can greatly improve cooling efficiency and prevent overheating in your laser cutter. It works by circulating chilled water through the laser tube, effectively dissipating the heat generated during the cutting process. This not only helps to maintain optimal operating temperatures but also extends the lifespan of the laser tube.

To help you understand the benefits of installing a water chiller, here is a comparison table:

| Without Water Chiller | With Water Chiller |

|---|---|

| Higher risk of overheating | Improved cooling efficiency |

| Limited usage time before cooldown | Prolonged usage without overheating |

| Increased risk of damage to components | Enhanced lifespan of laser tube |

By installing a water chiller, you can ensure that your laser cutter performs at its best and avoids any issues related to overheating. This will set the stage for the subsequent section on how to enhance the laser power.

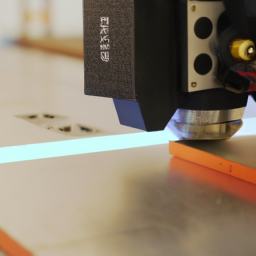

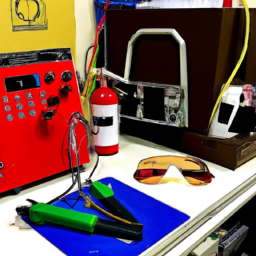

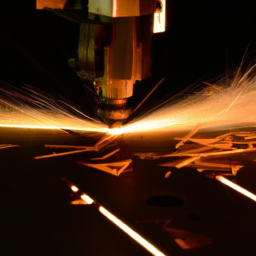

Enhance the Laser Power

Boosting the laser’s power will unleash its full potential, leaving you in awe of the incredible cutting precision and speed. By increasing the laser power, you can significantly enhance the efficiency and precision of your laser cutter. Higher power means faster cutting speeds and the ability to cut through thicker materials with ease.

With increased power, you can achieve cleaner, smoother cuts, reducing the need for additional finishing work. Additionally, increased laser power allows for more intricate and detailed designs, ensuring that every cut is precise and accurate.

To enhance the laser power, consider upgrading to a higher wattage laser tube or installing a more powerful laser module. By doing so, you can unlock a new level of performance for your laser cutter. This increased power will set the foundation for the subsequent section on how to improve the cutting bed.

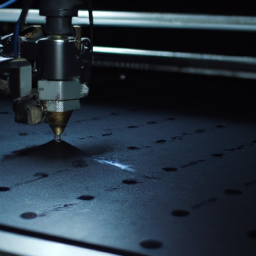

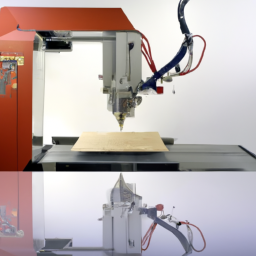

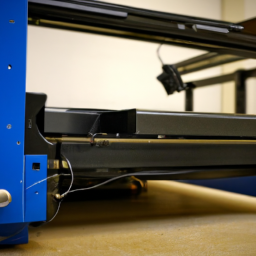

Improve the Cutting Bed

Enhancing the cutting bed allows for greater versatility in materials and sizes that can be accommodated, resulting in a more efficient and diverse range of cutting capabilities for the laser cutter.

Design improvements to the cutting bed can include adjustable height settings, allowing for precise positioning of materials and reducing the risk of damage. Additionally, a larger cutting bed size enables the laser cutter to handle larger sheets of material, increasing productivity and reducing the need for multiple cuts.

Material compatibility is also crucial, as different materials require different cutting bed surfaces to achieve optimal results. Upgrading the cutting bed to include specialized surfaces for various materials, such as honeycomb or slat beds, ensures better adhesion and reduces the chance of material warping.

By improving the cutting bed, you can enhance the overall performance and efficiency of your laser cutter.

This leads us to the subsequent section on upgrading the laser tube.

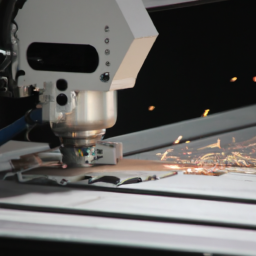

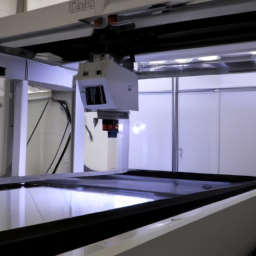

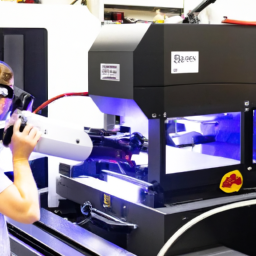

Upgrade the Laser Tube

By replacing the laser tube with a more powerful and efficient one, you’ll be able to unleash the laser cutter’s full potential and achieve precise and mesmerizing cuts.

Upgrading the laser tube is a crucial step in improving the performance and extending the lifespan of your laser cutter. A more advanced laser tube will provide a higher power output and increased stability, allowing for faster cutting speeds and improved overall efficiency.

Additionally, upgrading the laser lens can further enhance the laser beam quality, resulting in cleaner and more accurate cuts.

By optimizing the software settings, you can harness the full capabilities of the upgraded laser tube and laser lens combination, maximizing the performance and longevity of your laser cutter. This will ensure that your laser cutter continues to deliver exceptional results for years to come.

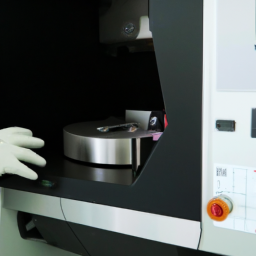

Optimize the Software Settings

Now that you’ve upgraded the laser tube, it’s time to optimize the software settings to further enhance performance and extend the lifespan of your laser cutter. By customizing presets and adjusting the speed, you can achieve more precise and efficient cuts.

Start by exploring the software’s settings and options to find the customization options available. Experiment with different power levels and speed settings to find the optimal combination for your specific materials and projects. Fine-tuning these settings will allow you to achieve cleaner cuts and prevent unnecessary wear and tear on the machine.

Additionally, consider adjusting the speed to accommodate different materials and thicknesses, ensuring that each cut is executed with precision. By taking the time to optimize the software settings, you can maximize the capabilities of your laser cutter and prolong its lifespan.

Frequently Asked Questions

How often should the ventilation system be cleaned or maintained?

Regular maintenance of your laser cutter ventilation system is crucial to ensure optimal performance and extend its lifespan. Proper cleaning and maintenance prevent common issues such as clogged filters and reduced airflow, which can lead to overheating and damage to the machine.

To maintain the ventilation system, clean or replace filters every 3-6 months. Inspect and clean the exhaust fan, and check for any signs of wear or damage. Following these troubleshooting tips will help keep your laser cutter running smoothly and efficiently.

Can I install a water chiller on any model of laser cutter?

Yes, you can install a water chiller on most models of laser cutters. Water chiller compatibility varies depending on the specific model, so it’s important to consult the manufacturer’s guidelines. Installing a water chiller offers several benefits. It helps maintain a consistent temperature, preventing overheating and ensuring optimal laser performance. Additionally, a water chiller extends the lifespan of your laser cutter by reducing wear and tear on the components, resulting in improved overall performance and longevity.

What safety precautions should be taken when enhancing the laser power?

When it comes to enhancing the laser power of your cutter, safety should be your top priority. You don’t want to end up accidentally turning your workshop into a real-life action movie.

So, before you go all Tony Stark on your machine, make sure you have proper laser power safety precautions in place. And don’t forget about your ventilation system maintenance frequency. Because let’s face it, nobody wants to breathe in toxic fumes while they’re trying to be a laser-cutting superhero.

Stay safe and stay awesome, my friend.

Are there any recommended materials for improving the cutting bed?

To improve the cutting bed of your laser cutter, there are several recommended materials you can use. One option is to upgrade to a honeycomb cutting bed, which provides better support and reduces the risk of material warping.

Another option is a metal slat cutting bed, which is ideal for cutting materials such as metal or acrylic.

Additionally, you can consider using a ceramic cutting bed, which offers excellent heat resistance and durability.

These alternative methods for extending your laser cutter’s lifespan will enhance its performance and ensure precise cutting.

Can the laser tube be upgraded on older models of laser cutters?

Looking to enhance your laser cutter’s performance and extend its lifespan? Upgrading your laser tube is the way to go. By enhancing laser power through a tube upgrade, you can push the boundaries of what your cutter can do.

This technical modification allows for more precise, detailed cuts and increased efficiency. Don’t settle for the limitations of older models – take your laser cutting capabilities to the next level with a laser tube upgrade.

Conclusion

In conclusion, by implementing these seven upgrades to your laser cutter, you can significantly improve its performance and extend its lifespan.

Upgrading the ventilation system will ensure proper air circulation and prevent overheating.

Installing a water chiller will maintain optimal temperature levels, resulting in more consistent and efficient cutting.

Enhancing the laser power will enable faster and more precise cutting capabilities.

Improving the cutting bed will provide better support and stability for materials.

Upgrading the laser tube will enhance the overall power and quality of the laser beam.

Lastly, optimizing the software settings will allow for more accurate and customizable cutting parameters.

By coincidentally employing these upgrades, you will undoubtedly take your laser cutting experience to new heights.