Are you tired of subpar results when laser cutting your models? Looking to take your cutting game to the next level? Look no further!

In this article, we will unveil seven upgrades that will revolutionize your laser cutting experience and deliver unparalleled performance. From optimizing your cutting speed to enhancing your material preparation, these upgrades will ensure precision and efficiency in every cut. Say goodbye to frustrating delays and hello to flawless models.

But that’s not all. We’ll also explore the importance of upgrading your software and improving your cutting techniques. Plus, we’ll share tips on how to maintain and calibrate your equipment for consistent, top-notch results.

Whether you’re a hobbyist or a professional, these upgrades are essential for anyone looking to elevate their laser cutting game. So, buckle up and get ready to transform your cutting process. Your models will thank you!

Key Takeaways

- Upgrading the laser cutting machine with advanced features and improved accuracy can revolutionize the cutting experience and deliver unparalleled performance.

- Finding the right balance between cutting speed and precision is crucial for accurate cuts, and fine-tuning the cutting speed can improve productivity and reduce errors.

- Upgrading the software enhances design capabilities and workflow, while proper cleaning and preparation of material surfaces ensures optimal cutting performance.

- Mastering proper cutting techniques for different shapes, utilizing appropriate cutting tools, and regularly maintaining and calibrating the laser cutting equipment are essential for achieving intricate designs, smooth cuts, and consistent results.

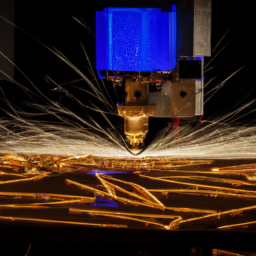

Upgrade Your Laser Cutting Machine

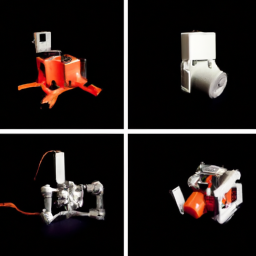

If you want to take your laser cutting to the next level, it’s time to upgrade your machine and unlock a world of precision and efficiency. Laser cutting maintenance and troubleshooting can only get you so far. Investing in a new laser cutting machine can provide a significant boost in performance.

Newer machines offer advanced features such as enhanced cutting speeds, improved accuracy, and better overall reliability. These upgrades can greatly reduce the time spent on maintenance and troubleshooting, allowing you to focus on what matters most – cutting your models with precision and efficiency.

Once you’ve upgraded your machine, you can optimize your cutting speed to further enhance your productivity and achieve even better results.

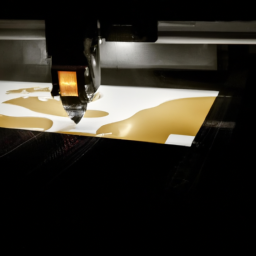

Optimize Your Cutting Speed

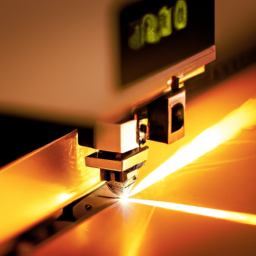

To boost your efficiency, rev up the velocity of your precision slicing like a racecar on the track. Optimizing your cutting speed is crucial for maximizing efficiency and reducing cutting errors in laser cutting.

Increasing the speed at which your laser moves across the material can significantly improve the overall performance of your machine. However, it’s important to find the right balance between speed and precision to ensure accurate cuts. By gradually increasing the cutting speed and monitoring the results, you can find the optimal setting for your specific machine and materials.

Remember to also consider the power of your laser beam, as increasing the speed may require adjusting the power to maintain the desired cutting quality. By fine-tuning your cutting speed, you can achieve faster, more efficient laser cutting. This will result in improved productivity and reduced cutting errors.

Now, let’s dive into the next section about upgrading your software.

Upgrade Your Software

Boost your efficiency and take your precision slicing to the next level by upgrading your software. Upgrading your design software can greatly improve your workflow and make your laser cutting process more efficient. Here are four ways upgrading your software can enhance your laser cutting experience:

-

Advanced Design Tools: Upgrade your software to access a wide range of advanced design tools that can help you create intricate and complex designs with ease.

-

Seamless Integration: Upgrade your software to ensure seamless integration with other design and manufacturing tools, allowing for a smooth workflow from design to production.

-

Enhanced Control: Upgrade your software to gain more control over the laser cutting process, including precise control over speed, power, and cutting parameters.

-

Improved File Compatibility: Upgrade your software to support a wider range of file formats, making it easier to import and export designs from different software platforms.

By upgrading your software, you can improve your design capabilities, streamline your workflow, and ultimately enhance your overall laser cutting experience. Now, let’s explore how you can enhance your material preparation.

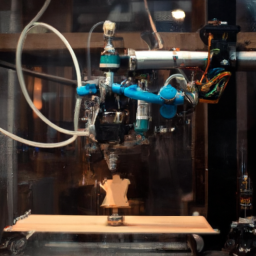

Enhance Your Material Preparation

When enhancing your material preparation for laser cutting, there are three key points to consider.

First, make sure you use high-quality materials to achieve optimal results.

Second, properly clean and prepare the surface of the material to prevent any debris or impurities from affecting the laser cutting process.

Lastly, consider using protective coatings or adhesives to further enhance the durability and quality of the final product.

Use High-Quality Materials

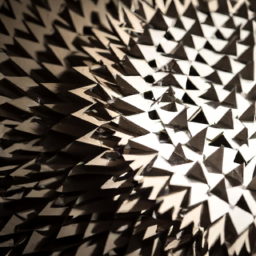

Using top-notch materials in your laser cutting process is like fueling your creativity with rocket-grade propellant. When it comes to laser cutting, it’s essential to source your materials from high-quality suppliers. High-quality materials ensure that your laser cuts are precise and clean, resulting in a superior final product.

Additionally, using high-quality materials guarantees better material compatibility with your laser cutting machine, reducing the risk of damage or subpar results. Properly clean and prepare the material surface to remove any dust, debris, or contaminants that could affect the quality of your laser cuts.

By using high-quality materials and taking the time to prepare them properly, you’re setting yourself up for success in achieving improved performance when laser cutting models.

Properly Clean and Prepare the Material Surface

By ensuring that you properly clean and prepare the surface of your materials, you can unleash the full potential of your creativity and achieve flawless results with your laser cuts.

Surface cleaning is essential to remove any dust, dirt, or debris that could interfere with the cutting process. Before cutting, use a lint-free cloth or compressed air to remove any loose particles from the material.

Additionally, material prepping involves removing any protective films or coatings that may be present. This step ensures that the laser can effectively penetrate the material and achieve clean, precise cuts.

Proper surface cleaning and material prepping are crucial for optimal laser cutting performance.

Now, consider using protective coatings or adhesives to further improve the quality and durability of your laser-cut models.

Consider Using Protective Coatings or Adhesives

To enhance the longevity and resilience of your laser-cut creations, it’s worth considering the application of protective coatings or adhesives.

Protective coatings offer a range of benefits, such as preventing corrosion, reducing friction, and enhancing the overall appearance of the finished product. These coatings create a barrier between the material and external factors, ensuring that your models remain in pristine condition for longer periods.

When applying a protective coating, it’s important to follow proper techniques. This includes cleaning the surface thoroughly, using a suitable primer, and applying the coating evenly.

Additionally, adhesives can be used to strengthen joints and improve the overall structural integrity of your designs. Choosing the right adhesive and applying it correctly is crucial to ensure a strong bond.

By considering these protective measures, you can improve the performance and durability of your laser-cut models.

Now, let’s delve into techniques to improve your cutting precision and efficiency.

Improve Your Cutting Techniques

To improve your cutting techniques, you need to master the art of focusing the laser. This involves adjusting the beam to achieve the optimal intensity for cutting your materials.

Additionally, it’s important to use proper cutting techniques for different shapes. By understanding the best approach for each shape, you can ensure clean and precise cuts.

Finally, don’t be afraid to experiment with different cutting angles. This can help you achieve unique and intricate designs, while also maximizing the efficiency of the laser cutting process.

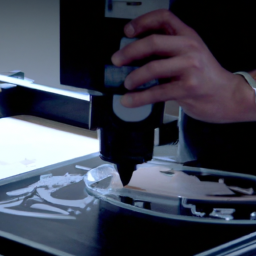

Master the Art of Focusing the Laser

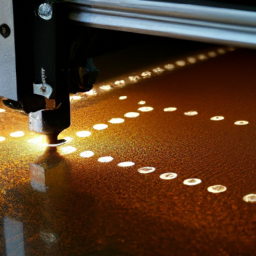

Achieve laser-cutting mastery by honing your ability to focus the laser beam and unlock improved performance for your models.

To improve laser focus, start by adjusting the height of the laser head to ensure the optimal focal point. This will enhance the precision of your laser cutting, resulting in cleaner and more accurate cuts.

Additionally, consider using a laser focus tool to measure and fine-tune the focus point. By doing so, you can ensure consistent results across different materials and thicknesses. Keep in mind that the focus point may vary depending on the material being cut, so take the time to test and adjust accordingly.

With a well-focused laser beam, you’ll be ready to move on to the next step and use proper cutting techniques for different shapes.

Use Proper Cutting Techniques for Different Shapes

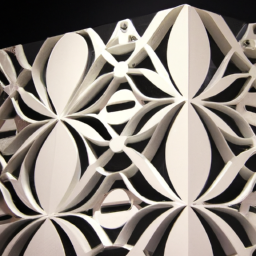

Mastering proper cutting techniques for different shapes will allow you to effortlessly create intricate designs and smoothly cut through various materials with your laser.

When working with different shapes, it’s essential to utilize the appropriate cutting tools and precision cutting techniques. For straight lines and simple shapes, a continuous cutting technique works best, ensuring clean and precise cuts. However, when dealing with complex shapes or curves, you may need to employ the stop and start method to maintain accuracy.

Additionally, consider adjusting the laser power and speed based on the material’s thickness and density for optimal results. By employing these different cutting techniques, you can achieve flawless cuts and enhance the overall performance of your laser cutter.

Transitioning into the subsequent section, it’s also crucial to experiment with different cutting angles to further refine your cutting skills.

Experiment with Different Cutting Angles

By exploring various cutting angles, you can unlock a world of creativity and precision, allowing your laser cutter to dance across the material with grace and finesse. Different cutting techniques can be employed to achieve optimal cutting parameters for different shapes.

When cutting intricate designs or sharp corners, using a smaller cutting angle can help to maintain the integrity of the material and prevent burning or charring. On the other hand, larger cutting angles are more suitable for cutting thicker materials or creating beveled edges.

Experimenting with different cutting angles will enable you to find the perfect balance between speed and quality. As you move forward to the next section about maintaining and calibrating your equipment, remember that the right cutting angle is just one piece of the puzzle in achieving superior laser cutting performance.

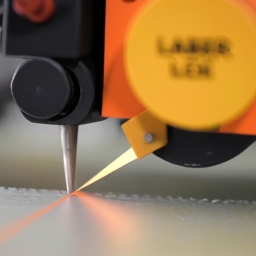

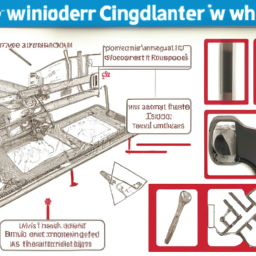

Maintain and Calibrate Your Equipment

Make sure you regularly maintain and calibrate your laser cutting equipment to ensure optimal performance and precise cuts.

Equipment maintenance is crucial in keeping your laser cutter running smoothly and efficiently. Regularly clean the machine to remove any debris or residue that may affect its performance. Check and replace any worn-out parts, such as the lens or mirrors, as they can greatly impact the quality of the cuts.

Calibration techniques are also essential to ensure accurate and consistent results. Use a calibration tool to align the laser beam and adjust the focal length for different materials. Regularly test and adjust the power and speed settings to optimize cutting performance.

By properly maintaining and calibrating your equipment, you can achieve improved precision and efficiency in your laser cutting projects.

Frequently Asked Questions

How can I reduce the amount of smoke and odor produced during laser cutting?

To reduce smoke and odor during laser cutting, proper ventilation is crucial. For example, a manufacturing company implemented a ventilation system that effectively extracted fumes and minimized the release of harmful odors. This reduced the health risks for workers and created a cleaner work environment.

Additionally, ensuring the laser cutting machine is regularly maintained and cleaned can help minimize smoke and odor production. Implementing these measures will improve air quality and overall cutting efficiency.

What are some common mistakes to avoid when laser cutting models?

To ensure successful laser cutting, there are several common mistakes to avoid. First, make sure your design files are properly prepared and scaled. Check for any overlapping or intersecting lines that could cause cutting errors.

Additionally, ensure that the material is securely held in place to avoid movement during cutting. Proper maintenance of the laser machine, such as regular cleaning and calibration, is also crucial.

Following these tips will help you achieve precise and efficient laser cutting results.

Are there any specific safety precautions to take while operating a laser cutting machine?

To ensure safe operation of a laser cutting machine, there are several important safety precautions to follow.

Firstly, always wear appropriate protective gear, such as safety glasses and gloves.

Secondly, ensure proper ventilation in the cutting area to minimize exposure to potentially harmful fumes and particles.

Additionally, be cautious of the laser beam and avoid direct contact with it.

Lastly, regularly inspect and maintain the machine to prevent any potential hazards.

Can laser cutting machines cut through all types of materials?

Laser cutting machines are incredibly powerful and versatile tools that can cut through a wide range of materials with ease. However, they do have some limitations.

While they can effortlessly slice through materials like acrylic, wood, and metal, they may struggle with highly reflective surfaces or materials that are too thick.

Despite these limitations, the advantages of laser cutting are numerous. It offers precision, speed, and the ability to create intricate designs with minimal waste.

How often should I clean and maintain my laser cutting equipment to ensure optimal performance?

To ensure optimal performance of your laser cutting equipment, it’s crucial to clean and maintain it regularly. The cleaning frequency depends on the usage and materials being cut, but a general guideline is to clean it after every 8 hours of operation.

A maintenance checklist should include inspecting and cleaning the lens, mirrors, and exhaust system, as well as checking for any loose or damaged parts. Following this checklist will help maintain the efficiency and longevity of your equipment.

Conclusion

In conclusion, by implementing these 7 upgrades, you can significantly enhance the performance of your laser cutting machine.

Optimizing cutting speed, upgrading software, and improving material preparation will ensure precise and efficient results.

Additionally, honing cutting techniques and regularly maintaining and calibrating your equipment will guarantee optimal performance.

With these enhancements, your laser cutting process will be streamlined, yielding flawless models with utmost precision.

Embrace these upgrades and witness a visual symphony of accuracy and efficiency in your laser cutting endeavors.