Looking to optimize the performance and safety of your laser cutter? Look no further. In this article, we will explore seven ventilation upgrades that you should consider implementing for your laser cutter.

These upgrades will not only enhance the efficiency of your machine but also ensure the well-being of those working with it.

Firstly, let’s talk about the installation of an exhaust fan. By doing so, you can effectively remove harmful fumes and particles from the air, guaranteeing a cleaner and healthier working environment. Additionally, implementing a filtration system will further purify the air, eliminating any remaining contaminants.

To enhance the overall airflow, upgrading to a ventilation duct is highly recommended. This will provide a direct pathway for the expelled air, preventing any potential build-up or blockages. Alternatively, you may opt for an external ventilation system, which will allow for the venting of fumes directly outside, reducing their concentration indoors.

Moreover, installing a laser cutter enclosure will provide an extra layer of protection, reducing the risk of exposure to harmful substances. Lastly, don’t forget to equip yourself with the necessary Personal Protective Equipment (PPE) to ensure your safety while operating the laser cutter.

By implementing these seven ventilation upgrades, you can optimize the performance, efficiency, and safety of your laser cutter. So, let’s dive in and explore each upgrade in detail.

Key Takeaways

- Proper ventilation upgrades for laser cutters can optimize performance and ensure safety.

- Upgrading to an exhaust fan, implementing a filtration system, and installing a ventilation duct or external ventilation system are key considerations.

- The installation of a laser cutter enclosure is important for containing fumes and particles and creating a controlled environment.

- Minimizing exposure to fumes and particles can be achieved through efficient fume extraction, the use of HEPA filters, air quality monitoring, and the use of a ventilation hood or enclosure.

Install an Exhaust Fan

You’ll want to install an exhaust fan to efficiently remove smoke and fumes from your laser cutter’s workspace. Proper ventilation is crucial to ensure a safe and clean working environment.

By exploring alternative options, you can find the most suitable exhaust fan for your specific needs. The benefits of proper ventilation are numerous. It helps to eliminate harmful particles and gases, preventing health issues for both you and your laser cutter. Additionally, it reduces the risk of fire hazards by removing combustible materials from the air.

Implementing an exhaust fan will significantly improve air quality and maintain the integrity of your laser cutter. Once you have the ventilation system in place, the next step is to consider implementing a filtration system to further enhance the efficiency of your workspace.

Implement a Filtration System

To effectively tackle the issue at hand, it’s crucial to install a top-notch filtration system for improved air quality during laser cutting operations. A high filtration efficiency is essential to remove harmful particles and gases generated during the cutting process.

Look for a filtration system that can effectively capture both particulate matter and volatile organic compounds (VOCs). Additionally, consider investing in an air quality monitoring system that can continuously monitor and alert you to any potential air quality issues. This will allow you to take immediate action and ensure the safety of your workspace.

Once you’ve implemented a filtration system, the next upgrade to consider is to upgrade to a ventilation duct, which will further enhance the air circulation and extraction capabilities.

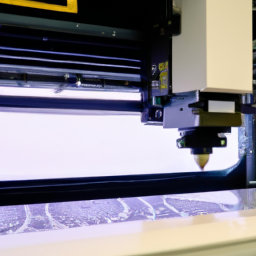

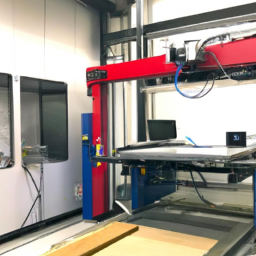

Upgrade to a Ventilation Duct

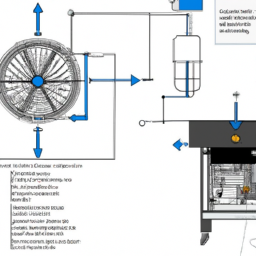

One way to improve the air circulation and extraction capabilities in your workspace is by adding a ventilation duct. A ventilation duct is an essential component of a laser cutter ventilation system, as it helps to remove fumes and particulates generated during the cutting process.

By installing a duct, you can ensure that the air is properly extracted and filtered, reducing the risk of exposure to harmful substances.

To optimize the performance of your ventilation duct, consider the following factors:

-

Ductless ventilation: If your workspace doesn’t have access to an external vent, a ductless ventilation system can be a viable option. It uses a combination of filters to purify the air before recirculating it back into the room.

-

Ventilation requirements: Make sure that the ventilation duct meets the specific requirements of your laser cutter. Factors like airflow rate, duct diameter, and length should be taken into consideration to ensure efficient extraction.

Considering an external ventilation system for your laser cutter can further enhance the air quality in your workspace. By implementing these ventilation upgrades, you can create a safer and healthier environment for both you and your laser cutter.

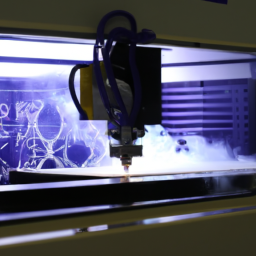

Consider an External Ventilation System

Installing an external ventilation system for your workspace is like a breath of fresh air, ensuring the optimal performance and air quality for your laser cutting projects. By venting the fumes and smoke outside, you can minimize the health risks associated with inhaling these harmful byproducts. Additionally, an external ventilation system helps to maintain a clean and clutter-free work environment, allowing you to focus on your laser cutting tasks without distractions.

Consider the following benefits and tips when installing an external ventilation system:

| Benefits | Installation Tips |

|---|---|

| Removes harmful fumes and smoke | Choose a suitable location for the vent |

| Improves air quality | Ensure proper duct sizing and installation |

| Reduces health risks | Use high-quality ventilation equipment |

| Minimizes workspace odors | Regularly clean and maintain the system |

| Enhances overall safety | Seek professional assistance if needed |

By incorporating an external ventilation system, you are taking an important step towards creating a safe and efficient laser cutting workspace. In the next section, we will discuss the installation of a laser cutter enclosure.

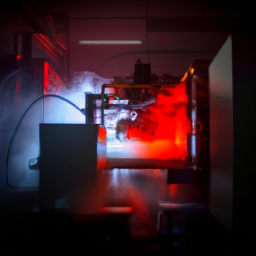

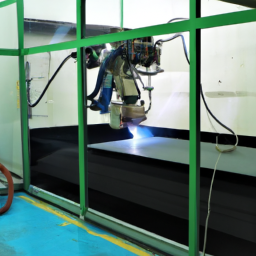

Install a Laser Cutter Enclosure

To effectively contain fumes and particles generated by a laser cutter, it’s crucial to install a laser cutter enclosure. This enclosure creates a controlled environment where the fumes and particles can be captured and filtered. This ensures a cleaner and safer work area. By implementing this solution, you can enhance the overall ventilation system’s efficiency and minimize the risk of exposure to hazardous airborne contaminants.

Contain Fumes and Particles

Minimizing exposure to harmful fumes and particles is crucial for ensuring the safety of both you and your laser cutter. To effectively contain fumes and particles, consider the following ventilation upgrades:

- Install an efficient fume extraction system to remove hazardous airborne contaminants generated during laser cutting.

- Use HEPA filters to capture fine particles and prevent them from being released into the surrounding air.

- Implement air quality monitoring to continuously assess the level of pollutants and ensure compliance with health and safety regulations.

- Utilize a ventilation hood or enclosure specifically designed for laser cutters to further contain fumes and particles.

By implementing these upgrades, you can create a controlled environment that prioritizes safety and reduces the risk of harmful exposure.

This will be further discussed in the subsequent section about creating a controlled environment.

Create a Controlled Environment

To further enhance the ventilation upgrades for your laser cutter, it’s essential to create a controlled environment. By doing so, you can improve air quality and prevent overheating, ensuring optimal performance and safety.

Controlling the environment involves carefully regulating temperature, humidity, and airflow to maintain a stable and suitable condition for the laser cutter to operate. This can be achieved by installing an HVAC system specifically designed for the laser cutter’s needs. Additionally, incorporating exhaust fans or ductwork can facilitate proper air circulation. It’s also important to implement temperature and humidity sensors for real-time monitoring.

A controlled environment not only minimizes the risk of overheating but also helps maintain the integrity of the laser cutter and extends its lifespan. Moving forward, it’s crucial to explore the use of personal protective equipment (PPE) to further enhance safety during laser cutting operations.

Use Personal Protective Equipment (PPE)

Ensure you’re suited up with the necessary PPE to safeguard yourself while operating the laser cutter, as it’s like stepping into a lion’s den without any armor. Utilizing Personal Protective Equipment (PPE) has numerous advantages, including minimizing the risk of injuries and protecting against hazardous materials.

Here are three key items of PPE you should prioritize:

-

Safety Glasses: These protect your eyes from potential laser radiation, stray particles, and debris. It’s crucial to choose glasses that comply with the appropriate safety standards.

-

Respirator: Laser cutting releases harmful fumes and gases, which can be detrimental to your respiratory system. Wearing a respirator with filters designed for particulate matter and volatile organic compounds is essential.

-

Gloves: Protect your hands from cuts, burns, and chemical exposure by wearing appropriate gloves. Opt for gloves made from materials that provide thermal insulation and chemical resistance.

Remember, training on the proper usage of PPE is vital to understanding its significance and maximizing its effectiveness in ensuring your safety.

Frequently Asked Questions

What are some common health risks associated with laser cutting that proper ventilation can help mitigate?

Proper ventilation is crucial for mitigating health risks associated with laser cutting. Without it, operators are exposed to hazardous fumes and particles that can have detrimental effects on their health.

Ventilation benefits include removing harmful gases, such as volatile organic compounds (VOCs) and toxic fumes, from the cutting area. This ensures a safer working environment by reducing the risk of respiratory issues, eye irritation, and potential long-term health complications.

Implementing effective ventilation upgrades is essential for safeguarding the well-being of laser cutter operators.

Are there any specific regulations or guidelines that need to be followed when installing an exhaust fan or ventilation system for a laser cutter?

When it comes to installing an exhaust fan or ventilation system for your laser cutter, it’s essential to adhere to ventilation regulations and guidelines. These rules act as guiding lights, steering you towards a safe and compliant path.

Similar to how a lighthouse illuminates treacherous waters, these regulations safeguard against potential hazards. Ventilation regulations ensure proper airflow and the removal of harmful fumes, while ventilation guidelines provide specific instructions for installation and maintenance.

By following these guidelines, you can ensure a well-ventilated workspace and reduce health risks.

Can a filtration system effectively remove all harmful particulates and gases generated during laser cutting?

A filtration system can effectively remove a significant portion of harmful particulates and gases generated during laser cutting, thereby mitigating health risks. It employs advanced technology to capture and filter out these hazardous substances, ensuring cleaner air quality in the workspace.

However, it’s important to note that while filtration systems can greatly reduce the presence of harmful particles, they may not eliminate them entirely. Therefore, it’s crucial to complement the filtration system with other ventilation upgrades to achieve optimum safety and compliance.

Is it necessary to upgrade to a ventilation duct if an exhaust fan is already installed?

Upgrading to a ventilation duct may be necessary to enhance ventilation effectiveness, even if an exhaust fan is already installed. While an exhaust fan helps remove harmful particulates and gases, it may not provide sufficient airflow to adequately circulate and expel them.

A ventilation duct, on the other hand, can ensure an efficient removal of contaminants. By upgrading, you can optimize the ventilation system’s performance and minimize potential health risks associated with laser cutting processes.

How much does it typically cost to install a laser cutter enclosure, and what are the benefits of having one?

Installing a laser cutter enclosure typically costs between $500 to $2000, depending on the size and materials used. The benefits of having one are numerous. It provides a controlled environment, reducing the risk of dust and debris interfering with the laser’s performance.

It also improves safety by containing any fumes and smoke produced during cutting. Proper ventilation is crucial for maintaining air quality and preventing potential health hazards.

Remember, a well-enclosed laser cutter is an investment in both efficiency and safety.

Conclusion

In conclusion, by implementing these ventilation upgrades for your laser cutter, you can ensure a safer and more efficient working environment.

Installing an exhaust fan and filtration system will effectively remove harmful fumes and particles from the air, while upgrading to a ventilation duct and external system will enhance air circulation.

Additionally, installing a laser cutter enclosure and using personal protective equipment will provide an added layer of safety.

These upgrades are like a breath of fresh air, clearing away any potential hazards and allowing your laser cutter to perform at its best.