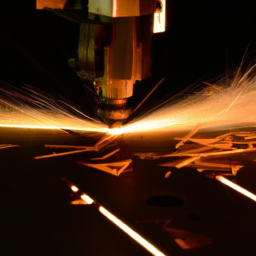

Did you know that the average lifespan of a laser cutter is around 10 years? That’s right, these powerful machines can last for a decade or more with proper care and maintenance. If you want to maximize the lifespan of your laser cutter and ensure that it continues to perform at its best, there are several key steps you can take.

In this article, we will discuss 7 ways to improve the lifespan of your laser cutter. From regular cleaning and maintenance to using high-quality materials and following proper operating procedures, these tips will help you keep your laser cutter in top condition for years to come.

By investing the time and effort into maintaining your laser cutter, you can ensure that it remains a valuable tool in your workshop for many years to come.

Key Takeaways

- Regular cleaning and maintenance

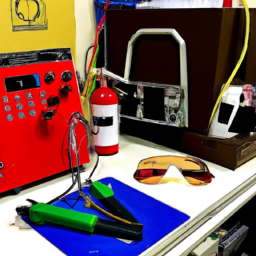

- Proper ventilation and safety precautions

- Use high-quality materials and consumables

- Inspect and replace parts as needed

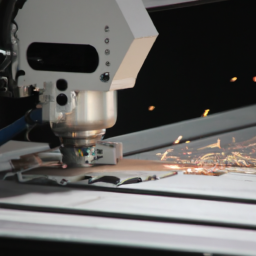

Clean and Maintain Your Laser Cutter Regularly

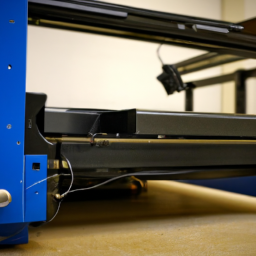

Regularly cleaning and maintaining your laser cutter is essential for maximizing its lifespan, ensuring optimal performance, and avoiding costly repairs down the line.

Proper ventilation is crucial during operation to remove the fumes and smoke generated by the laser cutting process. Make sure the exhaust system is clean and free from any obstructions.

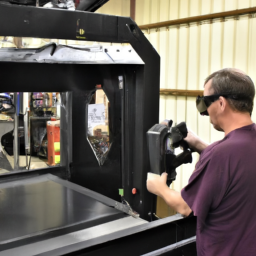

Additionally, follow safety precautions such as wearing protective goggles and gloves to prevent any accidents or injuries.

Regularly inspect the laser cutter for any signs of wear or damage and address them promptly.

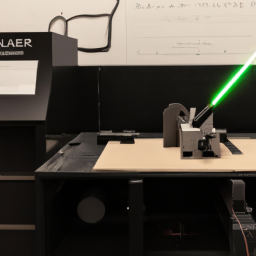

Clean the lens and mirrors regularly using the appropriate cleaning solutions and techniques.

Finally, use high-quality materials and consumables to minimize the wear and tear on your laser cutter.

By following these maintenance practices, you can extend the lifespan of your laser cutter and ensure its optimal performance for years to come.

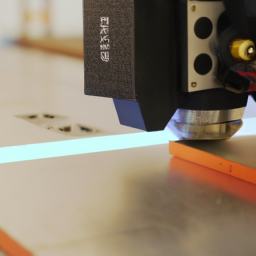

Use High-Quality Materials and Consumables

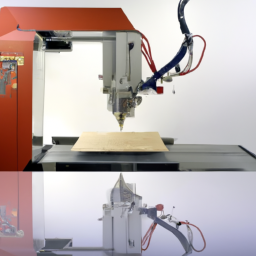

Invest in top-notch materials and consumables to ensure your laser cutter thrives and delivers exceptional results. Using high-quality materials will not only improve the lifespan of your laser cutter, but it’ll also optimize its calibration.

Optimal calibration is crucial for achieving precise and accurate cuts. Additionally, high-quality consumables, such as lenses and mirrors, will help maintain efficient power usage. These consumables are designed to withstand the intense heat and energy generated by the laser cutter, ensuring they last longer and perform at their best.

By using top-notch materials and consumables, you can maximize the lifespan of your laser cutter and minimize the need for costly repairs or replacements. To further enhance the longevity of your machine, it’s important to follow proper operating procedures to ensure its optimal performance.

Follow Proper Operating Procedures

By adhering to proper operating procedures, you can ensure optimal performance and longevity of your laser cutting machine. Proper ventilation is essential to maintain the efficiency of your machine and prevent overheating. Ensure that your workspace has adequate ventilation to remove smoke, fumes, and dust generated during the cutting process. Additionally, regular training and education for machine operators is crucial. This will help them understand the correct settings, maintenance procedures, and safety protocols to follow. By providing the necessary training, you can minimize operator errors and reduce the risk of damage to the machine. Remember, a well-trained operator is the key to maximizing the lifespan of your laser cutter. In the next section, we will discuss how to monitor and control the temperature and humidity to further enhance the performance of your machine.

Monitor and Control the Temperature and Humidity

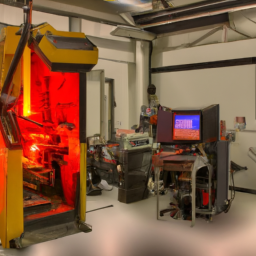

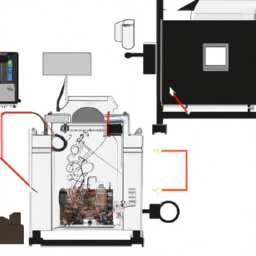

Maintaining optimal temperature and humidity levels is like creating the perfect environment for your laser cutting machine to thrive and perform at its best. Laser cutters are sensitive to changes in temperature and humidity, which can affect the accuracy and quality of the cuts.

To ensure the longevity of your machine, it’s crucial to invest in a monitoring system that constantly tracks and controls the environmental conditions. This system will provide real-time data on temperature and humidity levels, allowing you to make adjustments as necessary.

By keeping the temperature within the recommended range and controlling the humidity to prevent moisture buildup, you can prevent unnecessary wear and tear on your laser cutter. This careful attention to environmental conditions will extend the lifespan of your machine and optimize its performance.

Moving forward, regularly inspecting and replacing parts as needed will further contribute to the longevity of your laser cutter.

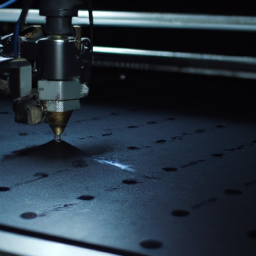

Regularly Inspect and Replace Parts as Needed

To ensure optimal performance, it’s essential to regularly inspect and replace parts as needed.

Inspecting parts is crucial to identify any signs of wear and tear, such as frayed cables, damaged lenses, or worn-out belts. By regularly inspecting these components, you can detect issues early on and prevent further damage to the machine.

When it comes to replacing parts, always use high-quality replacements that are compatible with your specific laser cutter model. This will ensure proper functionality and longevity of the machine. Additionally, refer to the manufacturer’s guidelines for recommended replacement intervals for different parts.

By staying proactive with inspections and timely replacements, you can extend the lifespan of your laser cutter and avoid costly breakdowns.

Transitioning into the subsequent section, investing in professional servicing and repairs can further optimize the performance of your machine.

Invest in Professional Servicing and Repairs

Make sure you get professional servicing and repairs to optimize your machine’s performance and keep it running smoothly. Investing in professional servicing and repairs is crucial to extending the lifespan of your laser cutter. Here are the key reasons why you should prioritize preventive maintenance and hire trained technicians:

-

Preventive maintenance is essential in identifying potential issues before they become major problems, saving you from costly repairs and downtime.

-

Trained technicians have the expertise and knowledge to accurately diagnose and troubleshoot any issues your laser cutter may encounter.

-

Hiring professionals ensures that your machine is serviced with the correct tools and techniques, minimizing the risk of further damage.

-

Professionals can provide you with valuable tips and recommendations for proper maintenance, helping you operate your laser cutter more efficiently.

By investing in professional servicing and repairs, you can significantly prolong the lifespan of your laser cutter while maximizing its performance and minimizing unexpected breakdowns.

Frequently Asked Questions

How often should I clean and maintain my laser cutter?

To keep your laser cutter humming smoothly, it’s crucial to give it some TLC on the regular. Cleaning frequency and maintenance schedule are key.

Make sure to dust off debris and grime from the machine’s nooks and crannies at least once a week. Additionally, perform a thorough deep clean monthly to prevent any buildup.

Stick to a strict maintenance schedule, ensuring all components are properly lubricated and calibrated. Your laser cutter will thank you with extended longevity and top-notch performance.

What are some signs that indicate I am not using high-quality materials and consumables?

Signs of material quality can be identified through various indicators. Look for irregularities in the cutting process, such as inconsistent depths or burnt edges. Poor-quality materials may also cause excessive wear and tear on the laser cutter, resulting in frequent breakdowns.

It’s crucial to prioritize proper maintenance to ensure optimal performance and longevity. Regularly cleaning the cutter, checking for loose or damaged parts, and replacing worn consumables will help maintain the machine’s lifespan.

Are there any safety precautions I should take when operating a laser cutter?

To ensure safe operation of your laser cutter, it’s crucial to follow laser cutter safety precautions. Prioritize wearing appropriate protective gear, such as safety glasses and gloves, to shield yourself from potential harm.

Regular maintenance is equally important as it enhances the longevity of your laser cutter. Keep the machine clean, inspect and replace worn parts, and properly align the laser beam.

By prioritizing safety and maintenance, you can optimize the performance and extend the lifespan of your laser cutter.

How can I effectively monitor and control the temperature and humidity in my laser cutter’s environment?

To effectively monitor and control the temperature and humidity in your laser cutter’s environment, you should invest in a reliable temperature and humidity monitoring system. Regularly check and maintain the temperature and humidity levels within the recommended range to ensure optimal performance and longevity of your laser cutter.

Additionally, it’s essential to clean and maintain your laser cutter at the recommended frequency to prevent dust and debris buildup, which can negatively impact its lifespan.

How do I know when it’s time to replace specific parts of my laser cutter?

Knowing when to replace specific parts of your laser cutter is crucial for maintaining its performance and efficiency. Regular laser cutter maintenance is key to preventing common laser cutter issues.

Keep an eye out for signs of wear and tear, such as decreased cutting quality, unusual noises, or error messages. Consult your laser cutter’s manual for recommended replacement intervals for components like the laser tube, lenses, and mirrors.

Timely part replacements will ensure your laser cutter stays in optimal condition.

Conclusion

In conclusion, by implementing these seven steps, you can significantly improve the lifespan of your laser cutter.

Regularly cleaning and maintaining your equipment, using high-quality materials, and following proper operating procedures will ensure optimal performance.

Monitoring temperature and humidity levels, as well as inspecting and replacing parts as needed, are crucial for longevity.

Additionally, investing in professional servicing and repairs will keep your laser cutter running smoothly.

So, why settle for a shorter lifespan when you can extend it with these simple measures?