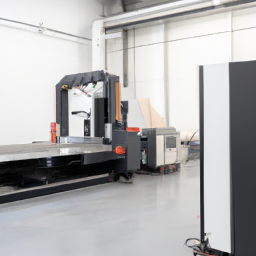

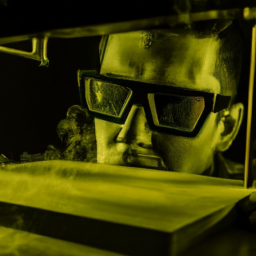

Are you tired of your laser cutter acting up and ruining your home decor designs? Well, fear not! In this article, we will provide you with seven foolproof ways to ensure proper maintenance for your laser cutter.

Whether you’re a seasoned pro or just starting out in the world of home decor design, these tips will help keep your laser cutter in tip-top shape.

First and foremost, it’s essential to clean and inspect your laser cutter regularly. Dust and debris can build up over time and affect its performance. Additionally, lubricating the moving parts will ensure smooth operation and prevent any unnecessary wear and tear.

To guarantee accurate cutting, make sure to calibrate and align your laser cutter correctly. Any misalignment can result in uneven and imprecise cuts. Don’t forget to replace worn or damaged parts promptly to avoid any further complications.

Furthermore, following the manufacturer’s guidelines for safe operation is crucial. This includes wearing protective gear and understanding the machine’s limitations.

Lastly, don’t underestimate the importance of scheduling regular professional maintenance and servicing. By entrusting your laser cutter to the experts, you can rest assured that it will receive the care it deserves.

So, buckle up and get ready to become a laser cutter maintenance pro. Your home decor designs will thank you!

Key Takeaways

- Regular cleaning and inspection are essential for proper maintenance of a laser cutter.

- Lubricating moving parts and replacing worn or damaged components is crucial for efficient operation.

- Following manufacturer’s guidelines and scheduling regular professional maintenance ensures optimal performance and longevity.

- Installing proper ventilation, wearing safety gear, and using quality replacement parts are important for safe and reliable operation.

Clean and Inspect Your Laser Cutter Regularly

Regularly clean and inspect your laser cutter to ensure optimal performance and longevity. Implement preventive measures and troubleshooting techniques to identify and address potential issues before they become major problems.

Begin by cleaning the exterior of your laser cutter using a soft cloth and non-abrasive cleaner. Pay special attention to the ventilation system, removing any dust or debris that may have accumulated.

Next, inspect the interior components, such as the lens, mirrors, and belts, for any signs of wear or damage. Clean these parts carefully using lint-free wipes and isopropyl alcohol.

Additionally, regularly check the alignment of the laser beam and adjust if necessary. By performing these routine cleaning and inspection tasks, you can ensure the proper functioning of your laser cutter.

Moving forward, let’s discuss how to lubricate the moving parts to ensure smooth operation.

Lubricate Moving Parts to Ensure Smooth Operation

To ensure smooth operation, it’s important to regularly lubricate the moving parts of your laser cutter for optimal performance. Preventive maintenance is essential to keep your machine running efficiently and extend its lifespan. Here are three reasons why lubrication is important:

-

Reduces friction: Lubricating the moving parts reduces friction, preventing wear and tear. This helps to maintain the precision and accuracy of your laser cutter, ensuring that it operates smoothly.

-

Increases efficiency: Proper lubrication helps the machine to run more efficiently, reducing the strain on its components. This can result in faster cutting speeds and improved productivity.

-

Prevents damage: Lack of lubrication can lead to parts seizing or breaking. Regularly applying lubricant to the moving parts prevents this, protecting your investment and avoiding costly repairs.

By keeping your laser cutter properly lubricated, you can ensure its smooth operation and prevent potential issues.

Next, we will discuss how to calibrate and align your laser cutter for accurate cutting.

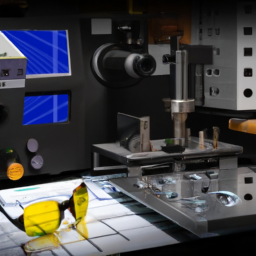

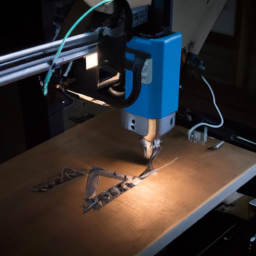

Calibrate and Align Your Laser Cutter for Accurate Cutting

Make sure you calibrate and align your laser cutter properly for accurate cutting to achieve precise and high-quality results.

As part of your laser cutter maintenance checklist, this step is crucial to ensure the optimal performance of your machine. Start by checking the alignment of the laser beam with the cutting bed and make any necessary adjustments. Use a calibration tool to ensure that the laser is focused correctly and that the beam is properly aligned with the cutting path.

Troubleshooting laser cutter calibration issues may involve adjusting the mirrors, checking the lens for dirt or damage, and calibrating the power settings. By taking the time to calibrate and align your laser cutter, you can avoid cutting errors and achieve the best possible cutting results.

Once you’ve completed this step, you can move on to the next section about replacing worn or damaged parts as needed.

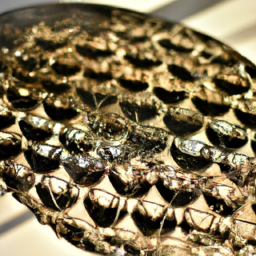

Replace Worn or Damaged Parts as Needed

Replacing worn or damaged parts as needed is crucial for ensuring the optimal performance and longevity of your laser cutter. Troubleshooting common issues with laser cutters is an important part of regular maintenance. By identifying and replacing worn or damaged parts, you can prevent further damage and keep your laser cutter operating smoothly.

Some common issues include misaligned mirrors, worn-out belts, or damaged lenses. Regularly inspecting these components and replacing them as necessary will help maximize the lifespan of your laser cutter. Additionally, following the manufacturer’s guidelines for safe operation is essential for preventing damage to your laser cutter and ensuring your own safety. By adhering to these guidelines, you can maintain the efficiency and effectiveness of your laser cutter for years to come.

Follow Manufacturer’s Guidelines for Safe Operation

Follow the manufacturer’s guidelines for safe operation to ensure a smooth and worry-free experience with your laser cutter. Proper ventilation is crucial when using a laser cutter, as it produces fumes and smoke that can be harmful if inhaled.

Make sure your workspace is well-ventilated and consider installing an exhaust system to remove these pollutants. Additionally, always wear appropriate safety gear such as goggles and gloves to protect yourself from potential hazards. Familiarize yourself with the specific safety precautions outlined by the manufacturer, including any specific materials or settings to avoid.

By following these guidelines, you can minimize the risk of accidents or damage to your laser cutter. With proper ventilation and adherence to safety precautions, you can now transition into the subsequent section about scheduling regular professional maintenance and servicing.

Schedule Regular Professional Maintenance and Servicing

Regularly scheduling professional maintenance and servicing is essential for ensuring the longevity and optimal performance of your laser cutter.

While it may be tempting to take a DIY approach to maintenance, there are several benefits to leaving it to the professionals. They have the expertise and experience to identify and address any issues that may arise, ensuring that your laser cutter operates at its best.

Additionally, using quality replacement parts is crucial for maintaining the efficiency and reliability of your machine. These parts are specifically designed to meet the manufacturer’s specifications and provide a seamless fit, minimizing the risk of damage or malfunction.

By investing in regular professional maintenance and using quality replacement parts, you can extend the lifespan of your laser cutter and avoid costly repairs down the line.

Frequently Asked Questions

How often should I clean and inspect my laser cutter?

Regular maintenance is the key to unlocking optimal performance from your laser cutter. Just like a well-oiled machine, your cutter needs attention to keep it running smoothly. Cleaning and inspecting it should be done on a regular basis to ensure its longevity.

Signs that indicate the need for maintenance include decreased cutting quality, unusual noises, and excessive smoke or debris. By staying vigilant and proactive, you’ll ensure your laser cutter stays in top shape for all your home decor design needs.

What type of lubricant should I use on the moving parts of my laser cutter?

To ensure optimal performance and longevity of your laser cutter, it’s crucial to select the right lubricant for its moving parts. Look for a high-quality lubricant specifically designed for precision machinery, such as a synthetic grease or oil.

The lubrication frequency will depend on the manufacturer’s recommendations, but a general rule of thumb is to lubricate the moving parts every 50-100 hours of operation. Regular lubrication not only reduces friction and wear but also helps maintain the cutter’s accuracy and efficiency.

How do I calibrate and align my laser cutter for accurate cutting?

To calibrate and align your laser cutter for accurate cutting, follow these laser cutter maintenance tips.

First, ensure that the laser beam is properly aligned with the cutting path. Use the laser alignment tool provided with your machine to adjust the laser head accordingly.

Next, check the focus lens and clean it regularly to maintain optimal cutting performance.

If you encounter any issues, refer to the troubleshooting guide in your laser cutter’s manual for further assistance.

Where can I purchase replacement parts for my laser cutter?

Looking for reliable laser cutter replacement parts suppliers? You’re in luck!

There are numerous online stores that specialize in providing high-quality replacement parts for your laser cutter. From lenses and mirrors to motors and belts, you can find everything you need to keep your machine running smoothly.

Take the time to research different suppliers and read reviews to ensure you’re getting the best quality parts for your specific model. Don’t let a broken part slow down your creative process!

Are there any specific safety guidelines I should follow when operating my laser cutter?

When operating your laser cutter, it’s crucial to follow laser cutter safety precautions to ensure your well-being and the longevity of your machine. Always wear appropriate protective gear, such as safety glasses and gloves.

Additionally, proper ventilation is of utmost importance to prevent the buildup of hazardous fumes. Make sure your workspace is well-ventilated or consider installing an exhaust system.

These safety measures will help keep you safe and maintain the functionality of your laser cutter.

Conclusion

In conclusion, maintaining your laser cutter is crucial for ensuring its optimal performance and longevity. By regularly cleaning and inspecting your machine, lubricating moving parts, and calibrating it for accuracy, you can enjoy smooth and precise cutting for your home decor designs.

It’s also important to replace any worn or damaged parts and follow the manufacturer’s guidelines for safe operation. Lastly, don’t forget to schedule regular professional maintenance and servicing to keep your laser cutter in top shape.

Remember, taking care of your equipment will result in exceptional results and a longer lifespan. So, why wait? Start implementing these maintenance tips today and see the difference it makes in your laser cutting projects.