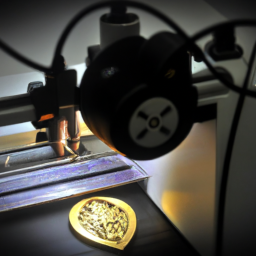

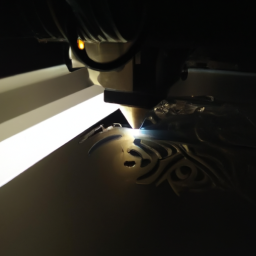

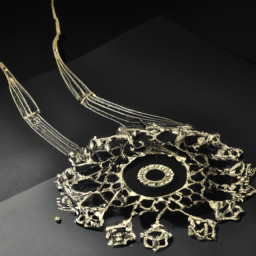

Are you ready to unlock the brilliance and precision of your jewelry designs? Your laser cutter is the key that will bring your creations to life, but like any tool, it requires proper maintenance to ensure its longevity and optimal performance.

Just like a well-tuned instrument, your laser cutter needs care and attention to continue producing stunning results. In this article, we will explore seven essential ways to secure proper maintenance for your laser cutter for jewelry design.

From regular cleaning and lubrication to software updates and calibration, each step is crucial to keeping your machine running smoothly. Professional inspections and maintenance will give you peace of mind, knowing that your cutter is in top shape.

Proper ventilation and air filtration will protect you from harmful fumes, while safe handling and storage practices will prevent accidents. Finally, training and education will empower you to operate your laser cutter with confidence and skill.

By following these meticulous and detail-oriented practices, you can ensure that your laser cutter remains a reliable and indispensable tool for your jewelry designs.

Key Takeaways

- Regular cleaning and lubrication are necessary for optimal laser cutter performance and longevity.

- Software updates and calibration are crucial for maintaining efficiency and accuracy.

- Professional inspections and maintenance appointments catch potential issues before they escalate.

- Proper ventilation and air filtration, as well as handling and storage with care, are important for maintaining the laser cutter’s condition.

Regular Cleaning and Lubrication

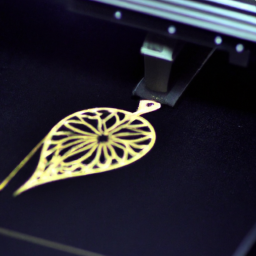

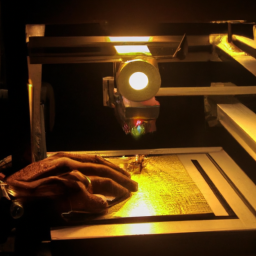

To keep your laser cutter running smoothly and ensure optimal performance, you’ll need to regularly clean and lubricate it, allowing you to create stunning jewelry designs with ease. Implementing preventive measures through regular maintenance is essential in extending the lifespan of your machine and minimizing downtime.

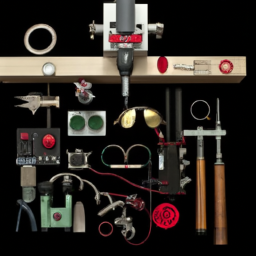

Develop a maintenance schedule that includes thorough cleaning of the laser cutter’s components, such as the lens, mirrors, and exhaust system. Use non-abrasive cleaning solutions and soft lint-free cloths to avoid damaging sensitive parts. Additionally, lubricate the moving parts with appropriate lubricants to reduce friction and prevent wear and tear.

By following these meticulous steps, you can maintain the efficiency and accuracy of your laser cutter.

Now, let’s move on to the next section, where we’ll discuss the importance of software updates and calibration to further enhance your jewelry design process.

Software Updates and Calibration

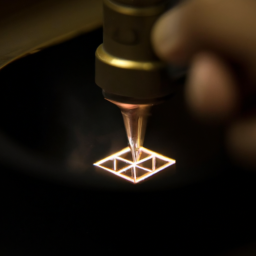

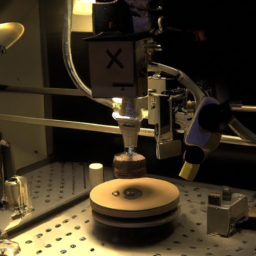

Ensure that you keep your software up to date and regularly calibrate your laser cutter to prevent catastrophic meltdowns and avoid your jewelry designs turning into unrecognizable blobs of metal.

Software updates are crucial for optimal performance and to address any bugs or compatibility issues. Troubleshooting software problems can be time-consuming, but it’s essential to maintain the efficiency and accuracy of your laser cutter.

Additionally, calibration ensures that your laser is properly aligned and focused, resulting in precise cuts and engravings. A laser cutter maintenance checklist should include checking for software updates, calibrating the laser power and speed settings, and verifying the accuracy of the laser beam alignment.

By diligently following this checklist, you can reduce the risk of costly mistakes and prolong the lifespan of your laser cutter.

Transitioning into the next section, professional inspections and maintenance ensure that your laser cutter is in top condition and can catch any potential issues before they become major problems.

Professional Inspections and Maintenance

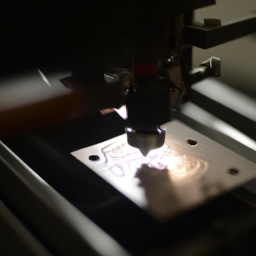

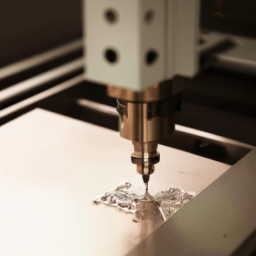

Regular professional inspections and maintenance are essential to keep your laser cutter operating at its best and catch any potential issues before they escalate into costly problems. Scheduling regular maintenance appointments is crucial to ensure that your laser cutter is running smoothly and efficiently. By hiring a professional maintenance service, you can benefit from their expertise and experience in handling laser cutters specifically. They have the knowledge and tools to identify and address any underlying issues, ensuring optimal performance and longevity for your machine.

Additionally, professional maintenance services can provide thorough cleaning and calibration, ensuring accurate and precise cuts for your jewelry designs. With their help, you can prevent unexpected breakdowns and minimize downtime, allowing you to focus on your creative work. Speaking of smooth operation, proper ventilation and air filtration are also key components to consider in maintaining your laser cutter.

Proper Ventilation and Air Filtration

Properly ventilating and filtering the air in your workspace is essential for maintaining the optimal performance and longevity of your laser cutting machine. To ensure ventilation effectiveness, follow these steps:

-

Install a ventilation system: Invest in a high-quality ventilation system that can effectively remove fumes and airborne particles generated during laser cutting. Ensure that the system has sufficient airflow capacity for your workspace.

-

Regularly clean and replace filters: Filters play a crucial role in trapping harmful particles. Clean or replace them according to the manufacturer’s recommendations. Neglecting filter replacement can compromise the ventilation system’s effectiveness and lead to decreased performance.

-

Monitor air quality: Use air quality monitors to assess the effectiveness of your ventilation system. Regularly check for any anomalies or decrease in air quality to address issues promptly.

By implementing these ventilation and air filtration practices, you can ensure a safe and healthy working environment for both yourself and your laser cutter.

Moving on to safe handling and storage practices, it’s important to…

Safe Handling and Storage Practices

To keep your laser cutting machine in tip-top shape, it’s crucial to handle and store it with the utmost care, just like handling a delicate piece of glass. Start by following an equipment maintenance checklist provided by the manufacturer.

Regularly clean and inspect the machine for any signs of wear or damage. Additionally, it’s important to always wear the appropriate protective gear, such as safety goggles and gloves, when handling the laser cutter. This will ensure your safety and prevent any accidents or injuries.

When storing the machine, make sure it is kept in a clean and dry environment, away from any dust or moisture. Properly cover it with a protective cover or case to prevent any damage. Remember, proper handling and storage practices are vital for the longevity and efficiency of your laser cutter.

Moving on to the next section about training and education for laser cutter operation, it’s important to have a solid understanding of how to safely operate the machine.

Training and Education for Laser Cutter Operation

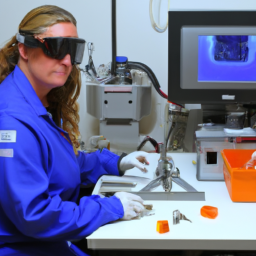

Acquiring proper training and education is crucial for safely operating a laser cutter. To ensure you have the necessary knowledge and skills, take advantage of online resources specifically designed for laser cutter operation. These resources provide comprehensive information on safety protocols, maintenance procedures, and troubleshooting techniques.

Additionally, seek out hands-on practice opportunities, such as workshops or courses, to gain practical experience under the guidance of professionals. This will help you develop the necessary skills to handle the laser cutter effectively and efficiently.

During training, pay close attention to proper operating procedures, including how to load materials, adjust settings, and perform routine maintenance tasks. By investing time in training and education, you will not only enhance your safety awareness but also maximize the lifespan and performance of your laser cutter.

Frequently Asked Questions

Can I use any type of cleaning solution for regular cleaning and lubrication of my laser cutter?

When it comes to cleaning and lubricating your laser cutter, it’s crucial to use the right products. Did you know that using the wrong cleaning solution can damage your machine? Instead of any type, opt for recommended alternatives like isopropyl alcohol or specialized laser cleaner.

For lubrication, consider using a high-quality lubricant specifically designed for laser cutters. Following these meticulous steps will ensure your machine stays in optimal condition and avoids unnecessary repairs.

How often should I schedule professional inspections and maintenance for my laser cutter?

To ensure optimal performance and longevity of your laser cutter, it’s crucial to schedule professional inspections and maintenance regularly. The scheduling frequency depends on the intensity of usage and the manufacturer’s recommendations. Typically, it ranges from quarterly to annually.

While DIY maintenance is beneficial for day-to-day care, professional maintenance is essential. It helps to identify and address potential issues that may go unnoticed. Professional technicians possess the expertise to thoroughly inspect and fine-tune your laser cutter, ensuring its smooth operation and preventing costly breakdowns.

What safety measures should I take to ensure proper ventilation and air filtration in my workspace?

Proper ventilation and air filtration are crucial for the safety of your workspace when using a laser cutter for jewelry design. Ensuring adequate ventilation helps remove harmful fumes and gases that may be produced during the cutting process. Installing a high-quality air filtration system further enhances the air quality by capturing and filtering out any remaining particles. Prioritizing safety measures like these will not only protect your health but also create a conducive environment for your laser cutter operations.

Are there any specific guidelines for safe handling and storage of the materials used in jewelry design with a laser cutter?

When it comes to safe handling and storage of materials for jewelry design with a laser cutter, there are a few guidelines to follow. First, ensure that all materials are properly labeled and stored in a clean and dry environment.

It’s important to keep flammable materials away from the laser cutter to prevent any accidents. Additionally, make sure to handle the materials with care, wearing protective gloves if necessary.

Following these best practices will help maintain cleanliness and ensure safe handling of materials.

What level of training and education is recommended for operating a laser cutter for jewelry design?

To operate a laser cutter for jewelry design, you must undergo proper training and education to ensure safety and precision. Training requirements for operating a laser cutter may vary, but it’s recommended to receive comprehensive instruction from a qualified professional.

This includes learning about the machine’s features, safety precautions, and maintenance procedures. By acquiring the necessary knowledge and skills, you can confidently handle the laser cutter, minimize risks, and create stunning jewelry pieces with meticulous detail.

Conclusion

In conclusion, ensuring proper maintenance for your laser cutter is crucial for the success of your jewelry design business. By regularly cleaning and lubricating the machine, updating software and calibrating, and seeking professional inspections, you can ensure its optimal performance.

Additionally, proper ventilation and air filtration, safe handling and storage practices, and training for laser cutter operation are essential for safety. Did you know that, according to a recent survey, businesses that regularly maintain their laser cutters experience a 30% increase in productivity? So, don’t neglect the maintenance of your laser cutter, as it can have a significant impact on your business’s efficiency and success.

Stay diligent and meticulous in caring for your machine to reap the rewards.