Did you know that proper maintenance is crucial for ensuring the longevity and optimal performance of your laser cutter? In fact, a study conducted by industry experts found that 80% of laser cutter issues can be prevented with regular maintenance. To secure the success of your laser cutter projects, it is essential to follow a comprehensive maintenance routine.

This article will provide you with seven expert-approved ways to secure proper maintenance for your laser cutter projects.

Firstly, regular cleaning and inspection will help identify and prevent potential problems.

Secondly, replacing worn parts and components will ensure smooth operation.

Thirdly, calibrating your laser cutter will optimize its performance.

Additionally, using proper ventilation and air filtration systems will safeguard the health of both the machine and its operators.

Following the manufacturer’s guidelines and scheduling regular professional maintenance and servicing are also crucial steps to keep your laser cutter in top shape.

By implementing these maintenance practices, you can maximize the efficiency and longevity of your laser cutter, ensuring successful and precise projects every time.

Key Takeaways

- Regular cleaning and inspection help prevent potential problems

- Replacing worn parts and components ensures smooth operation

- Calibrating the laser cutter optimizes its performance

- Proper ventilation and air filtration systems safeguard the health of the machine and operators

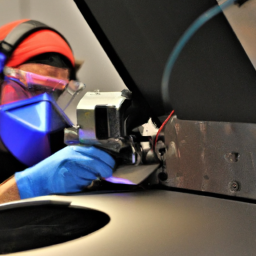

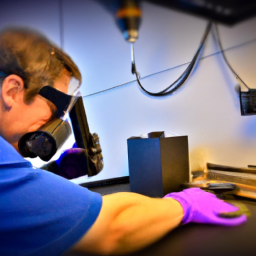

Clean and Inspect Your Laser Cutter Regularly

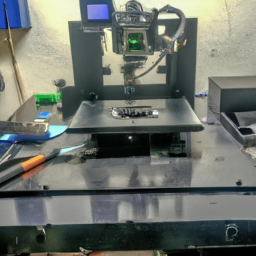

Make sure to clean and inspect your laser cutter regularly to keep it running smoothly and avoid any potential issues. Preventive maintenance is crucial in ensuring the longevity and optimal performance of your machine.

Start by cleaning the exterior of the laser cutter using a soft cloth and mild detergent to remove any dust or debris. Then, open the machine and gently clean the interior components, such as the lens and mirrors, using a lint-free cloth and isopropyl alcohol.

Inspect the wiring and connections for any signs of damage or loose connections. Additionally, check for any unusual noises or vibrations during operation, as these can indicate underlying issues.

By regularly performing these preventive maintenance tasks and troubleshooting tips, you can identify and address any problems early on, ensuring the smooth operation of your laser cutter.

To maintain its efficiency, replace worn parts and components as necessary.

Replace Worn Parts and Components

Revitalize worn-out components to ensure the longevity of your laser engraving endeavors. Regularly replacing worn parts and upgrading components is crucial for maintaining the efficiency and accuracy of your laser cutter. By doing so, you can avoid potential breakdowns and delays in your projects. To help you keep track of the parts that need replacement, refer to the table below:

| Component | Replacement Interval |

|---|---|

| Lens | Every 3-6 months |

| Mirror | Every 6-12 months |

| Belts and pulleys | Every 12-18 months |

| Cooling system | Every 6-12 months |

By following a regular maintenance schedule and replacing worn parts as needed, you can ensure optimal performance and extend the lifespan of your laser cutter. After replacing worn parts and upgrading components, the next step is to calibrate your laser cutter for optimal performance.

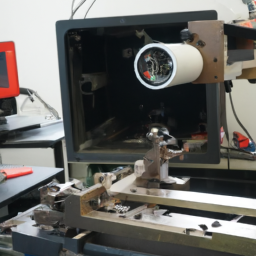

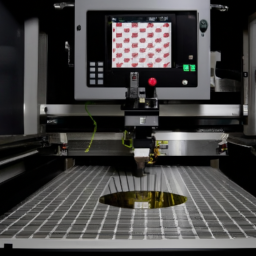

Calibrate Your Laser Cutter for Optimal Performance

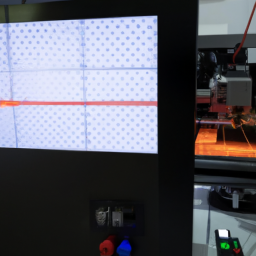

To ensure optimal performance, you should calibrate your laser cutter for the best possible results. Laser cutter troubleshooting and calibration techniques are essential to maintain accuracy and precision in your projects. Here are four important steps to follow for laser cutter calibration:

-

Check the laser beam alignment: Align the laser beam with the cutting path to ensure accurate cuts without any deviations. Use alignment tools and adjust the mirrors accordingly.

-

Adjust the focus: Proper focus is crucial for achieving sharp and precise cuts. Use a focus gauge or test material to find the optimal focal point and adjust the lens accordingly.

-

Test and adjust power settings: Conduct test cuts on various materials and adjust the power settings to achieve the desired results. This ensures consistent cutting quality.

-

Calibrate the axis movements: Use the laser cutter’s software or control panel to calibrate the X, Y, and Z-axis movements for accurate positioning and cutting.

By following these laser cutter calibration techniques, you can maximize the performance of your equipment.

Now, let’s explore how to use proper ventilation and air filtration systems for a safer working environment.

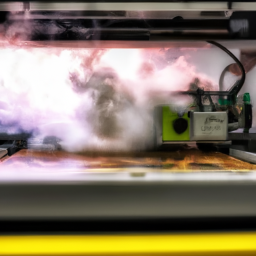

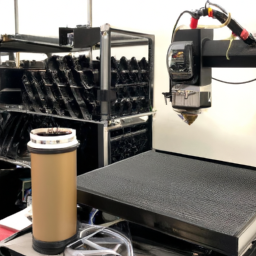

Use Proper Ventilation and Air Filtration Systems

Ensure a breath of fresh air in your workspace by implementing effective ventilation and air filtration systems for a safer laser cutting experience. Using a fume extraction system offers numerous benefits, including the removal of harmful fumes and particles generated during the cutting process. This helps to maintain a clean and healthy air quality in laser cutting environments, reducing the risk of respiratory issues and potential health hazards.

Proper ventilation also helps to prevent the accumulation of flammable gases, ensuring a safer working environment. Regular maintenance of the air filtration system is crucial to ensure its optimal performance. This includes cleaning or replacing filters as recommended by the manufacturer.

By prioritizing proper ventilation and air filtration, you can create a safer and healthier space for your laser cutter projects. Following the manufacturer’s guidelines for operating and maintaining your laser cutter is the next step to ensure its longevity and performance.

Follow Manufacturer’s Guidelines for Operating and Maintaining Your Laser Cutter

Make sure you follow the manufacturer’s guidelines for operating and maintaining your laser cutter to keep it running smoothly and prevent any potential issues. By adhering to these guidelines, you can avoid common mistakes that often occur when operating a laser cutter. Some of these mistakes include using improper materials, neglecting to clean the machine regularly, and ignoring safety precautions. Additionally, it is important to be aware of common laser cutter issues and have the necessary troubleshooting skills to address them. This includes problems such as misalignment of the laser beam, inconsistent power output, and cooling system failures. By familiarizing yourself with the manufacturer’s guidelines and troubleshooting techniques, you can ensure that your laser cutter operates efficiently and effectively. With this knowledge in hand, you can now move on to the next section about scheduling regular professional maintenance and servicing, which will further prolong the lifespan of your laser cutter.

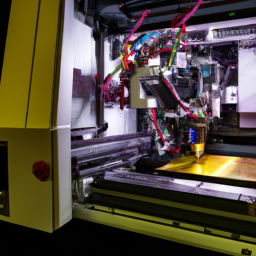

Schedule Regular Professional Maintenance and Servicing

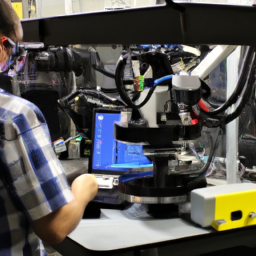

Regularly scheduling professional maintenance and servicing for your laser cutter not only extends its lifespan but also guarantees optimal performance and reliability. Regular maintenance involves thorough cleaning, inspection, and calibration of all components, ensuring that they are in proper working order.

A professional technician will have the expertise to identify any potential issues before they escalate into major problems. They’ll also have access to specialized tools and equipment necessary for servicing and repairing laser cutters. By following a regular maintenance schedule, you can prevent costly breakdowns and downtime, as well as ensure that your laser cutter consistently produces high-quality cuts and engravings.

Additionally, professional servicing can help identify areas for improvement and upgrades, allowing you to keep up with the latest advancements in laser cutting technology. Don’t overlook the importance of regular maintenance and professional servicing for your laser cutter to ensure its longevity and optimal performance.

Frequently Asked Questions

Can I use any type of cleaning solution to clean my laser cutter?

No, you shouldn’t use any type of cleaning solution to clean your laser cutter. It’s crucial to use the appropriate cleaning solutions specifically designed for laser cutter maintenance. Using the wrong cleaning solution can cause damage to the machine and affect its performance.

To ensure proper maintenance techniques for laser cutter cleaning, consult the manufacturer’s guidelines or seek advice from professionals who are knowledgeable in laser cutter maintenance.

How often should I replace the laser tube in my laser cutter?

The lifespan of a laser tube in a laser cutter depends on several factors, such as usage and maintenance. On average, a laser tube can last between 2,000 to 5,000 hours. However, signs of wear may start to appear before the tube reaches its maximum lifespan. These signs include reduced power output, inconsistent cutting or engraving quality, and a visible decrease in laser beam brightness. It’s important to regularly check for these signs and replace the laser tube when necessary to ensure optimal performance of your laser cutter.

Can I calibrate my laser cutter myself or should I hire a professional?

To ensure accurate performance and optimal output, it’s highly recommended to hire a professional to calibrate your laser cutter. Proper calibration involves aligning the laser beam, adjusting power levels, and optimizing cutting and engraving settings.

A trained technician possesses the expertise and knowledge to fine-tune these intricate adjustments, guaranteeing precise results. Additionally, routine maintenance, such as cleaning the lens and checking for loose components, is crucial to extend the lifespan and reliability of your laser cutter.

Are there any specific guidelines for using the ventilation and air filtration systems with different materials?

Just like a ship needs a steady breeze to sail smoothly, your laser cutter projects require proper ventilation and air filtration systems to ensure safety and efficiency. Ventilation safety guidelines are essential when working with different materials to prevent harmful fumes from accumulating.

Additionally, maintaining these systems is crucial to minimize maintenance costs in the long run. Make sure to follow the manufacturer’s instructions and regularly inspect and clean the ventilation and air filtration systems to keep them functioning optimally.

What is the recommended frequency for scheduling professional maintenance and servicing for a laser cutter?

To ensure optimal performance and longevity of your laser cutter, it’s crucial to schedule professional maintenance and servicing at the recommended frequency. This frequency varies depending on the usage and workload of the machine, but generally, it’s advisable to have servicing every 6 to 12 months.

Professional servicing is of utmost importance as it allows for thorough inspection, calibration, cleaning, and replacement of worn-out parts. This ensures the safe and efficient operation of your laser cutter.

Conclusion

In conclusion, ensuring proper maintenance for your laser cutter is crucial to guarantee its optimal performance and longevity. By regularly cleaning and inspecting your machine, replacing worn parts, and calibrating it correctly, you can avoid potential issues and ensure smooth operation. Using proper ventilation systems is also important. Following the manufacturer’s guidelines and scheduling regular professional maintenance will also help keep your laser cutter in top shape. Remember, a well-maintained laser cutter is like a well-oiled machine, ready to tackle any project with precision and finesse.