Did you know that inadequate ventilation in your laser cutter workspace can pose serious health risks? According to a study conducted by the Occupational Safety and Health Administration (OSHA), exposure to laser cutter fumes and particles can lead to respiratory issues, eye irritation, and even cancer. To ensure the safety of both yourself and your projects, it is crucial to secure proper ventilation.

In this article, we will discuss seven effective ways to achieve this. By assessing your workspace and equipment, installing an exhaust system, using ventilation fans, creating a dedicated ventilation system, implementing air filtration systems, and maintaining and cleaning your ventilation system, you can minimize the risks associated with laser cutter projects.

Let’s dive into the details and learn how to prioritize your health and safety while maximizing the quality of your work.

Key Takeaways

- Assess workspace and equipment for proper ventilation

- Install an exhaust system based on laser cutter size, power, and materials used

- Position the exhaust system near the laser cutter properly

- Use ventilation fans to circulate air and remove fumes from the workspace

Assess Your Workspace and Equipment

Before diving into your laser cutter projects, take a moment to assess your workspace and equipment to ensure proper ventilation is in place.

Assessing ventilation needs is crucial to prevent the buildup of harmful fumes and smoke that can be generated during the laser cutting process.

Evaluate potential hazards by considering the size of your workspace, the type of materials you will be working with, and the ventilation options available to you.

Look for any potential obstructions that may impede airflow, such as furniture or equipment.

Additionally, consider the proximity of your laser cutter to windows or doors that can provide natural ventilation.

By thoroughly assessing your workspace and equipment, you can identify any ventilation deficiencies and take appropriate measures to address them.

This will create a safer environment for your laser cutter projects.

Now, let’s move on to the next section about installing an exhaust system.

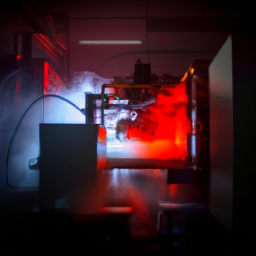

Install an Exhaust System

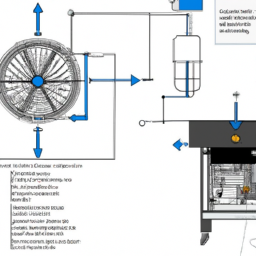

To ensure proper ventilation for your laser cutter projects, it’s crucial to choose the right type of exhaust system. Consider factors such as the size and power of your laser cutter, as well as the materials you’ll be working with.

Additionally, proper positioning and installation of the exhaust system in your workspace is essential. Place the exhaust system near the laser cutter to effectively remove fumes and smoke, and make sure it’s securely connected to the cutter and the outside ventilation system.

Choose the right type of exhaust system for your laser cutter

When selecting the appropriate exhaust system for your laser cutter, ensure you opt for a solution that effectively removes harmful fumes, with up to 95% efficiency, to safeguard both your health and the environment. The exhaust system’s effectiveness is crucial in maintaining a safe working environment, as it directly affects the quality of air in your workspace.

Regular ventilation system maintenance is essential to ensure optimal performance. Choose an exhaust system that is designed specifically for laser cutters, as it’ll have the necessary features to effectively capture and remove fumes generated during the cutting process. Consider factors such as the airflow capacity, filtration efficiency, and noise level when making your decision.

By selecting the right type of exhaust system, you can ensure a clean and healthy workspace.

Now, let’s move on to properly positioning and installing the exhaust system in your workspace.

Properly position and install the exhaust system in your workspace

Position your exhaust system strategically in your workspace to ensure optimal removal of harmful fumes and create a safe and enjoyable environment for laser cutting. When installing ventilation equipment, consider the layout of your workspace and the laser cutter’s proximity to walls or windows.

Ideally, place the exhaust system near the laser cutter to minimize the distance traveled by the fumes. Ensure proper air circulation by positioning the exhaust outlet away from any obstacles or obstructions. This will allow for efficient removal of the fumes and prevent them from lingering in your workspace.

Additionally, make sure the exhaust system is securely installed to prevent any leaks or loose connections. By properly positioning and installing your exhaust system, you can effectively vent the fumes generated during laser cutting. This will set the stage for the subsequent section on the use of ventilation fans.

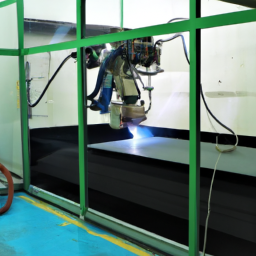

Use Ventilation Fans

Using ventilation fans helps circulate air and remove fumes from your laser cutter projects, ensuring a safe and clean working environment.

Here are some important points to consider regarding ventilation fan maintenance and alternative ventilation methods:

-

Regularly clean and inspect your ventilation fans to ensure they’re functioning properly and free of any debris or obstructions.

-

Consider installing multiple ventilation fans strategically placed around your workspace to optimize air circulation and fume extraction.

-

Utilize adjustable speed settings on your ventilation fans to customize the airflow according to the specific needs of your laser cutter projects.

-

Explore alternative ventilation methods, such as using an air purifier or opening windows and doors to create cross ventilation.

By incorporating these ventilation fan maintenance practices and exploring alternative ventilation methods, you can effectively ensure proper airflow and fume extraction for your laser cutter projects.

Now, let’s move on to the next section where we’ll discuss how to create a dedicated ventilation system.

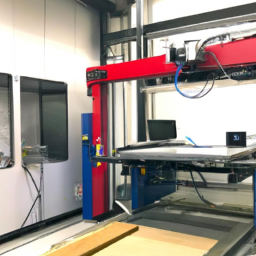

Create a Dedicated Ventilation System

To ensure proper ventilation for your laser cutter projects, it’s crucial to design a dedicated ventilation system. By doing so, you can effectively manage fumes and particles that are emitted during the cutting process.

Use ductwork and vents to direct these harmful substances away from your workspace, minimizing the risk of inhaling them and maintaining a clean and safe environment.

Design a dedicated ventilation system for your laser cutter

Creating a dedicated ventilation system for your laser cutter is like designing a secret escape route for the smoke and fumes, ensuring your projects are both safe and clean.

When designing this system, there are several design considerations and ventilation requirements to keep in mind. Determine the size of the ventilation system based on the laser cutter’s power and the amount of fumes generated. Select an appropriate exhaust fan that can handle the air volume and pressure necessary to effectively remove the fumes. Install a high-quality filter to capture any particles and prevent them from being released back into the environment.

By carefully considering these design aspects, you can create a ventilation system that effectively removes smoke and fumes from your workspace, ensuring a safe and clean environment for your laser cutter projects.

In the next section, we will explore how to use ductwork and vents to direct fumes and particles away from your workspace.

Use ductwork and vents to direct fumes and particles away from your workspace

Ductwork and vents efficiently direct fumes and particles away from your workspace, significantly reducing the risk of respiratory issues and improving air quality. Imagine being able to breathe in clean, fresh air as you work on your laser cutting projects. Ductwork installation is a crucial step in creating an effective ventilation system for your laser cutter. It involves strategically placing ducts and vents throughout your workspace to ensure proper airflow and efficient removal of fumes and particles. By using ductwork, you can control the direction of the airflow, ensuring that all harmful substances are directed away from your working area. This prevents them from circulating in the air and posing a health risk. To further enhance the ventilation effectiveness, consider incorporating a combination of different types of vents, such as intake and exhaust vents, to create a balanced airflow. Implementing air filtration systems can further improve the air quality in your workspace.

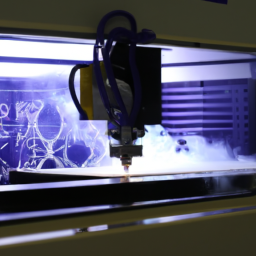

Implement Air Filtration Systems

To ensure the safety of your laser cutter projects, it’s crucial to install air filtration systems that effectively remove harmful particles from the air. By implementing these filtration systems, you can minimize the risk of inhaling hazardous fumes and protect yourself from potential health hazards.

It’s important to carefully choose the appropriate type of filtration system that suits your specific laser cutter projects to ensure optimal air quality and ventilation.

Install air filtration systems to remove harmful particles from the air

Install an air filtration system in your laser cutter workshop to ensure that the noxious fumes are banished from your creative haven, like a fearless knight vanquishing the toxic dragons of airborne particles. By implementing air purification measures, you prioritize not only the quality of your work but also your respiratory health.

Here are some key considerations when choosing the appropriate type of filtration system:

-

HEPA Filters: These high-efficiency particulate air filters effectively capture tiny particles, including harmful gases and volatile organic compounds (VOCs).

-

Activated Carbon Filters: These filters excel at adsorbing chemicals and odors, ensuring a cleaner and fresher working environment.

-

Pre-Filters: These filters trap larger particles, extending the lifespan of the primary filters and reducing maintenance frequency.

By installing an air filtration system that combines HEPA, activated carbon, and pre-filters, you can breathe easy knowing that harmful particles are being effectively removed from the air.

This sets the stage for the subsequent section on choosing the appropriate type of filtration system for your laser cutter projects.

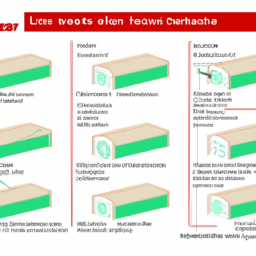

Choose the appropriate type of filtration system for your laser cutter projects

When it comes to ensuring the air in your laser cutter workshop is clean and safe for your creative endeavors, choosing the right filtration system is essential. Ensuring proper air circulation is crucial in maintaining a healthy working environment. There are different types of filtration systems available, each with its own advantages and disadvantages. To help you make an informed decision, consider the following table:

| Filter Type | Description |

|---|---|

| HEPA Filters | Highly efficient at capturing small particles, such as dust and pollen, providing excellent air quality. |

| Activated Carbon Filters | Effective at removing odors and gases, making them suitable for filtering out fumes produced by laser cutting. |

| Electrostatic Precipitators | Use an electric charge to trap particles, providing efficient filtration, but may produce ozone as a byproduct. |

| UVGI Filters | Utilize ultraviolet light to kill bacteria and viruses, ensuring a germ-free environment. |

| Hybrid Filters | Combine different filtration technologies to achieve comprehensive air purification. |

Now that you have chosen the appropriate filtration system, it is essential to maintain and clean your ventilation system regularly. This will ensure optimal performance and longevity.

Maintain and Clean Your Ventilation System

Regularly cleaning and maintaining your ventilation system ensures a safe and efficient laser cutting experience. It allows you to focus on unleashing your creativity without worrying about harmful fumes or inadequate air circulation. To keep your ventilation system in optimal condition, it’s important to follow proper cleaning techniques.

Start by turning off the system and disconnecting any power source. Remove any filters and clean them using a mild detergent or warm soapy water. Rinse thoroughly and allow them to dry completely before reinstalling. Use a soft brush or cloth to remove any dust or debris from the fan blades and ductwork.

Additionally, create a maintenance schedule to ensure regular cleaning and inspection of the system. This will help identify any potential issues and allow for timely repairs or replacements, keeping your laser cutter projects safe and well-ventilated.

Frequently Asked Questions

How often should I clean and maintain my ventilation system?

You must clean and maintain your ventilation system frequently to ensure its optimal performance. Neglecting this crucial task can lead to disastrous consequences!

To troubleshoot ventilation system issues, start by inspecting the air filters for any blockages or debris buildup. Regularly clean or replace them to maintain proper airflow.

Additionally, clean the exhaust fan blades and check for any signs of wear and tear. Following these best practices will ensure a well-functioning ventilation system for your laser cutter projects.

Are there any safety precautions I should take when installing an exhaust system for my laser cutter?

When installing an exhaust system for your laser cutter, it’s crucial to take safety precautions to ensure a secure and efficient setup.

Firstly, make sure to wear appropriate protective gear, such as gloves and goggles, when handling any components.

Secondly, follow the manufacturer’s instructions carefully and accurately to avoid any potential hazards.

Additionally, ensure proper ventilation and clearance around the exhaust system to prevent overheating and potential fire risks.

Lastly, regularly inspect and maintain the system to ensure optimal functionality and safety.

Can I use any type of ventilation fan for my laser cutter projects, or are there specific requirements?

To ensure the safety and effectiveness of your laser cutter projects, it’s crucial to use a ventilation fan that meets specific requirements. The ventilation fan should have a high enough CFM (cubic feet per minute) rating to effectively remove smoke, fumes, and particulate matter generated during cutting. It should also be equipped with a filter to remove harmful substances.

Proper ventilation is of utmost importance as it prevents the accumulation of hazardous materials and maintains a healthy working environment.

What are the benefits of creating a dedicated ventilation system for my laser cutter?

Creating a dedicated ventilation system for your laser cutter offers numerous benefits. Proper ventilation ensures the removal of harmful fumes and particles generated during laser cutting, safeguarding your health and maintaining a clean working environment.

Adequate airflow is crucial in laser cutting as it helps dissipate heat, prevents material ignition, and enhances the quality of the cut. By investing in a dedicated ventilation system, you prioritize safety, improve cutting efficiency, and prolong the lifespan of your laser cutter.

How do air filtration systems help in maintaining a safe and clean workspace for laser cutter projects?

Using an external air filtration system for laser cutting is like having a superhero protecting your workspace from harmful fumes and particles. These systems offer numerous benefits, such as removing hazardous substances, reducing odor, and preventing health issues.

When comparing different types of air filtration systems, consider factors like filtration efficiency, airflow capacity, and maintenance requirements. HEPA filters are highly effective in capturing tiny particles, while activated carbon filters can eliminate odors. A combination of both ensures a safe and clean environment for your laser cutter projects.

Conclusion

So there you have it, seven ways to ensure proper ventilation for your laser cutter projects.

By assessing your workspace and equipment, installing an exhaust system, using ventilation fans, creating a dedicated ventilation system, implementing air filtration systems, and maintaining and cleaning your ventilation system, you can ensure a safe and efficient working environment.

While some may argue that implementing these measures can be time-consuming and costly, the peace of mind and long-term benefits they provide far outweigh any initial inconvenience.

By prioritizing proper ventilation, you can protect not only your health but also the quality of your laser cutter projects.