Are you tired of wasting time and energy on complicated workflows and frustrating integration issues with your laser cutter software? Well, fret no more! In this article, we will reveal seven remarkable ways to simplify your workflow and enhance integration with laser cutter software.

Imagine a world where you can effortlessly optimize your file formats for seamless integration, automate repetitive tasks, and utilize material libraries with ease.

Picture yourself taking advantage of design software integration, collaborating seamlessly with your team members, and implementing efficient workflow management tools.

By following these tried-and-true methods, you can revolutionize your laser cutting experience, saving valuable time and resources.

No more frustration, no more wasted effort – just a streamlined process that allows you to focus on what truly matters: unleashing your creativity and bringing your innovative ideas to life.

Get ready to simplify, optimize, and elevate your laser cutter software workflow like never before!

Key Takeaways

- Optimize file formats for seamless integration, such as using vector file formats like SVG or AI for scalable graphics and accurate cutting paths.

- Utilize material libraries for easy access to pre-set parameters and options, saving time and ensuring correct laser cutter setup for each material.

- Enhance collaboration with team members through design software integration, allowing for easy sharing, iteration, and real-time feedback.

- Streamline tasks and project timelines with workflow management tools, centralizing project progress, assigning responsibilities, and providing deadline reminders for efficient project management.

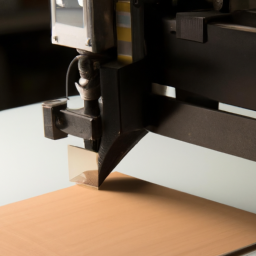

Optimize File Formats for Seamless Integration

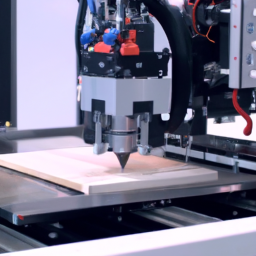

You’ll want to optimize your file formats for seamless integration with laser cutter software. This will save time and eliminate potential compatibility issues. By streamlining your production processes through optimized file formats, you can enhance cutting precision and achieve better results.

One way to do this is by using vector file formats, such as SVG or AI. These formats allow for scalable graphics and accurate cutting paths. They also enable you to easily make adjustments to your designs without compromising quality.

Additionally, it’s important to ensure that your file formats are compatible with the laser cutter software you’re using. Different software may have specific requirements. By optimizing your file formats, you can simplify workflow and achieve efficient integration with laser cutter software.

This will allow you to automate repetitive tasks and further streamline your production processes.

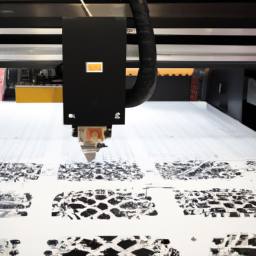

Automate Repetitive Tasks

Save time and effort by automating repetitive tasks in your process, making it more efficient and streamlined.

Streamline production processes and increase efficiency through automation. By automating tasks such as file conversions, resizing, and layout adjustments, you can eliminate the need for manual intervention and reduce the chances of errors.

Laser cutter software often provides scripting capabilities or plugins that allow you to create custom automation workflows. These workflows can automatically perform tasks such as nesting multiple designs on a single sheet, generating cutting paths, and applying specific settings to different materials.

By automating these repetitive tasks, you can free up valuable time and focus on more complex and creative aspects of your work.

Transitioning into the next section, utilizing material libraries can further enhance your workflow and integration with laser cutter software.

Utilize Material Libraries

Get ready to dive into the world of material libraries and unlock a treasure trove of pre-set parameters and options that’ll bring your laser cutting experience to life.

Material selection is a crucial aspect of laser cutting, and with material libraries, you can easily access a wide range of options. These libraries contain detailed information about different materials, such as their thickness, cutting speed, power, and focal length.

By utilizing material libraries, you can save time and ensure that the laser cutter is set up correctly for each material, eliminating the need for manual adjustments. This not only simplifies the workflow but also improves the accuracy and consistency of your laser cutting techniques.

With material libraries, you can streamline the process and focus more on unleashing your creativity.

So, let’s take advantage of design software integration in the next section and explore further possibilities.

Take Advantage of Design Software Integration

Immerse yourself in the seamless fusion of design and laser cutting as your creative ideas seamlessly come to life. By taking advantage of design software integration, you can streamline communication and enhance production efficiency.

Design software that integrates with laser cutter software allows for a smooth and efficient workflow, eliminating the need for manual file transfers or conversions. With this integration, you can easily import your designs directly into the laser cutter software, ensuring accuracy and saving time. You can also make adjustments and modifications to your designs within the design software, eliminating the need to switch between multiple programs.

This seamless integration not only simplifies your workflow but also improves collaboration with team members, making it easier to share and iterate on designs. Transitioning into the subsequent section, collaborating with team members becomes even more efficient when using integrated design software.

Collaborate with Team Members

Working together with your teammates becomes a breeze when you can effortlessly share and iterate on designs using integrated design software. By using design software that allows for collaboration, you can improve communication and streamline project updates. With just a few clicks, you can share your designs with team members and receive real-time feedback. This eliminates the need for lengthy email chains or in-person meetings, saving you time and ensuring everyone is on the same page. Additionally, integrated design software allows for easy version control, so you can track changes and revert back to previous versions if needed. By collaborating with your team members using integrated design software, you can ensure a smooth workflow and efficient project completion. Transitioning into the next section about implementing workflow management tools, you can take your collaboration to the next level.

Implement Workflow Management Tools

By seamlessly incorporating workflow management tools into your design process, you can effortlessly streamline tasks. This includes organizing project timelines and assigning responsibilities, allowing for a well-orchestrated and synchronized collaboration among team members. These tools can greatly improve production efficiency by providing a centralized platform where everyone can access and track project progress in real-time.

With features like task assignment and deadline reminders, you can easily streamline project management and ensure that tasks are completed on time. Additionally, workflow management tools enable team members to communicate and collaborate effectively, reducing the need for lengthy email chains or in-person meetings.

By simplifying the workflow and integration with laser cutter software, these tools eliminate unnecessary steps and delays, allowing for a more efficient and productive design process.

Frequently Asked Questions

How can I ensure that the file formats I use are optimized for seamless integration with laser cutter software?

To ensure seamless integration with laser cutter software, optimize your file formats. Start by using compatible file formats such as DXF or SVG. These formats are widely supported by laser cutter software.

Additionally, simplify your design by converting complex shapes into vector paths. This reduces processing time and minimizes errors during the cutting process.

Lastly, double-check that your file is properly scaled and oriented to avoid any issues when importing it into the laser cutter software.

Is there a way to automate repetitive tasks in laser cutter software to save time and improve efficiency?

To automate repetitive tasks in laser cutter software and improve productivity, there are several options available. You can utilize macros or scripting features within the software to create automated sequences of commands.

Additionally, some laser cutter software allows for integration with third-party automation tools, enabling you to streamline your workflow further.

By automating these tasks, you can save time and increase efficiency, allowing you to focus on more important aspects of your work.

Are there any material libraries available in laser cutter software that can help me choose the right materials for my projects?

Material compatibility is crucial when working with a laser cutter, but fear not! Laser cutter software often provides material libraries to simplify your life. These libraries let you choose from a wide range of materials, ensuring that you select the right one for your project.

Additionally, advanced settings in the software allow you to fine-tune the laser cutter’s performance for optimal results. So, don’t waste time guessing, let the software guide you to material success!

Can I integrate design software with laser cutter software to streamline the design process?

To streamline your design process, you can integrate design software with laser cutter software. This integration offers several benefits, such as increased efficiency and productivity. By connecting the two software programs, you can easily transfer your design files to the laser cutter, eliminating the need for manual file conversions.

This saves time and reduces the chances of errors. Additionally, it allows for real-time adjustments and optimizations, ensuring a smooth workflow from design to production.

How can I effectively collaborate with team members on laser cutting projects using the software?

To effectively collaborate with team members on laser cutting projects, utilize collaborative tools and project management features within the software. These tools act as a virtual workshop, where you can seamlessly share ideas, assign tasks, and track progress.

By leveraging this technology, you’ll be able to streamline communication, ensure everyone’s on the same page, and create a harmonious workflow. It’s like having an orchestra conductor guiding each team member towards a symphonic masterpiece.

Conclusion

In conclusion, by implementing these 7 strategies, you can unlock the true potential of laser cutter software and simplify your workflow.

Just like a well-oiled machine, you can optimize file formats, automate tasks, utilize material libraries, integrate with design software, collaborate with team members, and implement workflow management tools.

These steps will streamline your processes, saving you time and effort.

So, embark on this journey and watch as your workflow soars to new heights, like a majestic eagle spreading its wings and soaring through the sky.