Are you ready to take your laser cutting operations to the next level? Then you need to ensure that your large-scale laser cutting machine is running at peak performance. To achieve this, you must prioritize essential maintenance features that are crucial for the smooth operation of your equipment. In fact, these maintenance features are so important that they can make or break your laser cutting business.

From regular cleaning and lubrication to inspection and replacement of parts, each maintenance feature plays a vital role in maximizing the efficiency and lifespan of your machine. Calibration and alignment are also crucial to ensure accurate and precise cutting. Additionally, proper maintenance of the cooling system is essential to prevent overheating and ensure consistent performance.

Safety measures should never be overlooked, as they protect your operators and your investment. Lastly, providing training and education for your staff will ensure that they are equipped with the knowledge and skills necessary to maintain and operate your laser cutting machine effectively.

By implementing these eight essential maintenance features, you can confidently take on large-scale laser cutting projects, knowing that your machine is in optimal condition and ready to deliver exceptional results.

Key Takeaways

- Regular cleaning and lubrication are crucial for optimal performance and longevity of large-scale laser cutting machines.

- Regular inspection and replacement of parts are necessary for efficiency and longevity of the machines.

- Calibration and alignment ensure accurate and precise cutting, preventing errors and inaccuracies in the final product.

- Proper maintenance of the cooling system is essential to prevent overheating and ensure efficient operation.

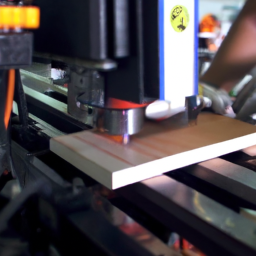

Regular Cleaning and Lubrication

Make sure you keep your laser cutting machine running smoothly by regularly cleaning and lubricating it.

Cleaning techniques are essential to remove any debris or residue that can accumulate on the machine’s components. Use compressed air or a soft brush to gently remove dust and particles from the machine’s surfaces.

Additionally, wipe down the machine with a lint-free cloth and a mild cleaning solution to remove any stubborn stains or dirt.

Lubrication is equally important to ensure smooth and efficient operation of the machine. Follow lubrication best practices by applying a small amount of lubricant to the moving parts, such as the rails and bearings, using a designated lubricant recommended by the manufacturer. This will help reduce friction and prevent premature wear and tear.

By regularly performing these maintenance tasks, you will ensure optimal performance and longevity of your laser cutting machine.

Now, let’s move on to the inspection and replacement of parts to further enhance the machine’s functionality.

Inspection and Replacement of Parts

Regular inspection and replacement of parts is crucial for maintaining the efficiency and longevity of your large-scale laser cutting machine. By conducting regular inspections, you can identify worn-out or damaged parts before they cause any major issues. This allows you to replace them promptly, minimizing downtime and ensuring optimal performance of your laser cutting equipment.

Importance of regular inspection

Surprisingly, neglecting to inspect the laser cutting machine on a consistent basis can lead to catastrophic consequences. Regular inspection benefits are crucial for the smooth operation and longevity of the equipment. Preventive maintenance plays a significant role in identifying potential issues before they escalate into major problems. By conducting routine inspections, you can detect any signs of wear and tear, misalignment, or damage in crucial components such as the laser tube, mirrors, lenses, and nozzle. Ignoring these warning signs may result in decreased cutting quality, increased downtime, and even safety hazards. To emphasize the importance of regular inspection, consider the following table:

| Component | Inspection Frequency | Potential Consequences |

|---|---|---|

| Laser Tube | Monthly | Reduced cutting power |

| Mirrors | Weekly | Misalignment, decreased beam quality |

| Lenses | Monthly | Decreased focus, reduced cutting accuracy |

Identifying worn-out or damaged parts and replacing them promptly is the next crucial step in maintaining a large-scale laser cutting machine.

Identifying worn-out or damaged parts and replacing them

Once worn-out or damaged parts are identified, you should promptly replace them to ensure optimal performance and longevity of the machine. Identifying maintenance needs is crucial for preventing major breakdowns and minimizing downtime.

Regular inspections play a vital role in this process, as they enable you to detect any signs of wear or damage in the laser cutting system. Pay close attention to key components such as the laser tube, lenses, mirrors, and focusing optics. These parts are prone to degradation over time due to the intense heat and high energy involved in the cutting process.

By replacing worn-out or damaged parts, you can maintain the precision and accuracy of the laser cutting system. Additionally, incorporating preventative maintenance measures, such as cleaning and lubricating the machine regularly, will further enhance its performance and extend its lifespan.

Transitioning into the subsequent section about calibration and alignment, it’s essential to ensure that all replaced parts are properly calibrated and aligned for seamless operation.

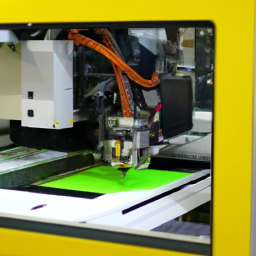

Calibration and Alignment

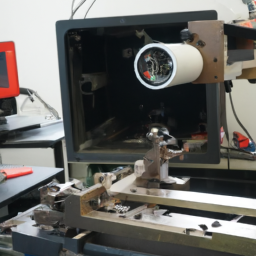

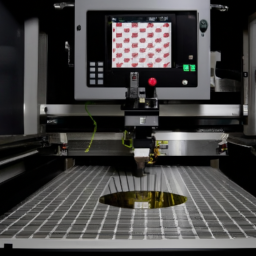

To ensure accurate cutting, it’s crucial that you properly calibrate the laser cutting machine. This involves adjusting the machine’s settings and parameters to ensure the laser beam is aligned correctly.

Aligning the laser beam is of utmost importance as it directly affects the precision of the cuts and prevents any errors or inaccuracies in the final product.

Ensuring the machine is properly calibrated for accurate cutting

Ensuring the machine’s calibration is on point is crucial for achieving laser-cutting precision that cuts through metal like a hot knife through butter. Machine calibration plays a vital role in achieving accurate cutting results.

It involves adjusting and fine-tuning various components within the laser cutting system to ensure optimal performance. Proper calibration ensures that the laser beam is aligned accurately, maintaining consistent cutting dimensions and avoiding any errors.

Calibration involves checking and adjusting parameters such as beam power, focus, beam diameter, and beam quality. Regular calibration is necessary to compensate for any changes due to wear and tear or environmental factors. By ensuring the machine is properly calibrated, you can achieve precise cutting results with minimal errors.

This leads us to the next important step, which is aligning the laser beam for precise cutting.

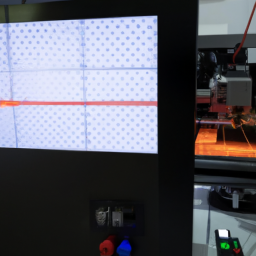

Importance of aligning the laser beam for precise cutting

Aligning the laser beam accurately is crucial for achieving precise cuts, as it ensures the beam follows the desired path and avoids any deviations that could compromise the final result. Laser beam alignment is the process of adjusting the position and direction of the beam to ensure it is perfectly aligned with the cutting path. This involves using specialized tools and techniques to adjust the mirrors and lenses that control the direction and focus of the beam.

Precise cutting requires the laser beam to be aligned to the micron level, as even the slightest misalignment can result in inaccuracies in the cut. Regularly checking and readjusting the laser beam alignment is essential to maintain the high level of precision required for large-scale laser cutting. By ensuring the laser beam is properly aligned, you can minimize material waste and produce high-quality cuts.

Transitioning into the subsequent section about cooling system maintenance, it is equally important to maintain the cooling system to prevent overheating and ensure optimal performance.

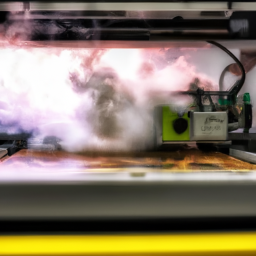

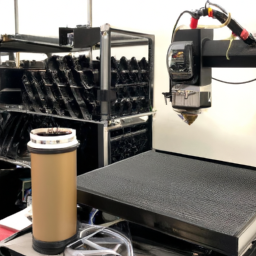

Cooling System Maintenance

Regular maintenance of the cooling system is crucial for optimal performance and longevity of the laser cutting equipment. The cooling system plays a vital role in maintaining the right temperature for the laser, preventing overheating and ensuring efficient operation. Ignoring cooling system maintenance can result in reduced cooling efficiency, higher maintenance costs, and even damage to the laser components. To help you understand the importance of cooling system maintenance, here is a table showcasing the key tasks and their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Check coolant level | Weekly |

| Inspect coolant quality | Monthly |

| Clean coolant filters | Quarterly |

| Flush and replace coolant | Annually |

| Inspect water pump and hoses | Annually |

| Check for leaks | Annually |

By regularly performing these maintenance tasks, you can ensure the cooling system operates at its peak efficiency, reducing the risk of downtime and costly repairs. Moving on to the next section, let’s discuss the essential safety measures to protect both the operators and the laser cutting equipment.

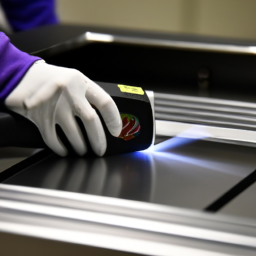

Safety Measures

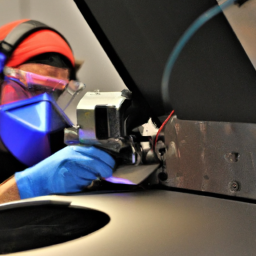

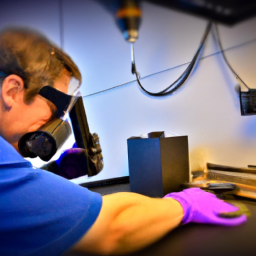

When operating the machine, it’s crucial that you follow all safety protocols. This includes wearing the proper protective gear and ensuring that all safety features, such as emergency stop buttons and interlocks, are regularly inspected and in working condition.

By adhering to these measures, you can minimize the risk of accidents and ensure the safety of yourself and others in the vicinity.

Importance of following safety protocols while operating the machine

For your own safety, it’s crucial to adhere to the necessary protocols while operating the machine at a large-scale laser cutting facility. Safety precautions and risk management should be at the forefront of your mind, as laser cutting machines can pose significant hazards if not operated correctly.

First and foremost, always wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself from potential laser beams and flying debris. Additionally, ensure that you’re familiar with the emergency stop buttons and interlocks, as they’re essential for quickly halting the machine in case of any emergencies. Regular inspection of these safety features is paramount to ensure they’re functioning correctly.

By following these safety protocols diligently, you can mitigate risks and create a safe working environment for yourself and others.

Transitioning into the subsequent section, it’s also important to regularly inspect and maintain other safety features, such as emergency stop buttons and interlocks.

Regular inspection of safety features such as emergency stop buttons and interlocks

Ensuring the proper functioning of safety mechanisms like emergency stop buttons and interlocks is a key aspect of maintaining a secure environment in a laser cutting facility. Regular inspection of these safety features is crucial to identify any potential issues and prevent accidents.

The inspection frequency should be determined based on the manufacturer’s guidelines and the level of usage of the machine. This may involve daily or weekly checks to ensure that emergency stop buttons are easily accessible and functioning correctly, and that interlocks are properly engaged.

It’s also important to have an emergency response plan in place in case of any safety breaches. By regularly inspecting safety features and having an effective emergency response plan, you can create a safe working environment for operators and minimize the risks associated with laser cutting.

Moving on to the next section about ‘training and education’…

Training and Education

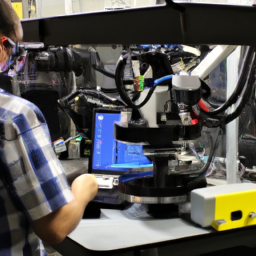

Proper training is crucial for ensuring the safe and efficient operation of large-scale laser cutting machines. It is essential for operators to have a thorough understanding of the machine’s operation, as well as the necessary skills to perform routine maintenance tasks.

Ongoing education is also important to keep operators up to date with the latest advancements in the field and to ensure optimal machine performance. This includes learning new techniques and best practices in laser cutting maintenance.

The significance of proper training for machine operators

Effective training is crucial in order to ensure that machine operators have the necessary skills and knowledge to safely and efficiently operate large-scale laser cutting equipment. Proper training for machine operators is essential for several reasons:

-

Safety: A well-trained operator understands the potential hazards associated with laser cutting and knows how to prevent accidents and injuries.

-

Efficiency: With proper training, operators can maximize the productivity of the equipment, minimizing downtime and optimizing production output.

-

Quality: Skilled operators are able to achieve precise cuts and maintain consistent quality throughout the cutting process.

To stay ahead in the industry, ongoing education on new techniques and best practices in laser cutting maintenance is necessary. This ensures that operators are equipped with the latest knowledge and skills to address any challenges that arise and optimize the performance of the equipment.

Ongoing education on new techniques and best practices in laser cutting maintenance

Stay ahead in the industry by continuously educating yourself on new techniques and best practices in maintaining laser cutting equipment, as studies show that operators who stay up-to-date with the latest knowledge have a 20% higher machine uptime rate. Keeping up with new laser cutting technologies is crucial to ensure efficient and effective maintenance. By staying informed about advancements in the field, you can identify opportunities to improve your maintenance processes and maximize machine performance. Additionally, troubleshooting common maintenance issues is essential for minimizing downtime and maximizing productivity. A proactive approach to identifying and resolving issues can save valuable time and resources. To help you stay on top of your game, here is a table showcasing some new laser cutting technologies and common maintenance issues to be aware of:

| New Laser Cutting Technologies | Troubleshooting Common Maintenance Issues |

|---|---|

| Fiber Laser Systems | Lens contamination |

| CO2 Laser Systems | Gas leaks |

| High-Speed Cutting | Nozzle wear |

By continuously seeking knowledge and staying updated on new techniques, you can ensure that you are equipped with the skills and expertise needed to maintain large-scale laser cutting equipment effectively.

Frequently Asked Questions

How often should the laser cutting machine be cleaned and lubricated?

Regular cleaning and lubrication of your laser cutting machine is crucial for its optimal performance. Keeping your machine clean and well-lubricated ensures smooth operation and reduces friction and wear on moving parts. It also prevents dust and debris build-up, which is important for maintaining the long-term performance and efficiency of your machine. This maintenance routine is essential for ensuring accurate cuts, extending the lifespan of your machine, and minimizing the risk of breakdowns or costly repairs.

What are some common signs that indicate the need for inspection and replacement of parts?

Common signs for inspection and replacement of parts in large-scale laser cutting machines are crucial indicators to ensure optimal performance. Regular maintenance is essential for identifying these signs. These signs include decreased cutting accuracy, unusual noise or vibrations, inconsistent power output, excessive heat generation, and reduced cutting speed. Ignoring these signs can lead to costly downtime and compromised quality. Therefore, it’s important to conduct routine inspections and promptly replace worn-out or damaged parts to maintain the efficiency and longevity of the machine.

How frequently should calibration and alignment be performed on a large-scale laser cutting machine?

To ensure optimal performance, you should regularly calibrate and align your large-scale laser cutting machine. The calibration frequency depends on the machine’s usage and manufacturer recommendations. Typically, calibration should be performed at least once a month or after a significant change in operating conditions.

Alignment frequency may vary but is usually recommended every three to six months. Regular calibration and alignment will help maintain accuracy, prevent errors, and extend the lifespan of your machine.

What are some essential maintenance steps for the cooling system of a laser cutting machine?

To keep your laser cutting machine running smoothly, the cooling system requires diligent maintenance. Start by treating it like the lifeblood of the machine, ensuring its flow remains unobstructed.

Regularly inspect and clean the cooling system, checking for any leaks or blockages. Troubleshoot common cooling system issues, such as inadequate coolant levels or malfunctioning pumps.

By meticulously tending to the cooling system, you can prevent overheating and maintain optimal performance.

What safety measures should be taken during the maintenance of a large-scale laser cutting machine?

When performing maintenance on a large-scale laser cutting machine, it’s crucial to follow laser cutting machine safety guidelines and adhere to maintenance best practices.

Start by ensuring that the machine is properly powered down and disconnected from any power sources. Use appropriate personal protective equipment such as safety glasses and gloves.

Inspect all components for damage or wear, and clean the machine thoroughly. Regularly check and replace filters, and keep all safety interlocks and guards in place.

Conclusion

In conclusion, maintaining a large-scale laser cutting machine is crucial for its optimal performance. By regularly cleaning and lubricating the machine, inspecting and replacing worn-out parts, and ensuring proper calibration and alignment, you can ensure precise and efficient cutting.

Additionally, maintaining the cooling system and implementing safety measures are essential for the longevity and safety of the equipment. Remember, proper training and education play a vital role in maximizing the machine’s capabilities.

So, why settle for subpar results when meticulous maintenance can elevate your laser cutting experience to new heights?