Did you know that the global market for metal jewelry is projected to reach $480 billion by 2025? With such a vast and lucrative industry, it’s crucial for jewelry manufacturers to employ efficient laser cutting techniques to stay ahead of the competition.

In this article, we will explore eight essential features that can enhance the efficiency of laser cutting for metal jewelry production.

First and foremost, adjustable power settings allow you to precisely control the intensity of the laser beam, ensuring optimal cutting results for different types of metals.

Additionally, automatic material recognition saves you time and effort by automatically detecting the type of metal being cut, eliminating the need for manual adjustments.

High precision cutting is another crucial feature, offering intricate and flawless cuts, even on the most delicate jewelry pieces.

Multiple cutting modes further enhance efficiency by enabling the simultaneous cutting of multiple jewelry pieces, maximizing productivity.

Efficient workflow integration is vital for streamlining the production process, allowing seamless integration with other machinery.

Lastly, advanced software capabilities provide a user-friendly interface and comprehensive control over the laser cutting process.

By incorporating these eight features into your laser cutting setup, you can achieve greater efficiency, precision, and productivity in the production of metal jewelry.

Key Takeaways

- Adjustable power settings and automatic material recognition are essential features for precise control and time-saving in laser cutting of metal jewelry.

- Efficient workflow integration and advanced software capabilities are crucial for seamless integration with other machinery and comprehensive control over the cutting process.

- Real-time analysis and automatic adjustments in power, speed, and focus optimize cutting conditions for each type of metal, resulting in improved efficiency and productivity.

- Integration with jewelry design software, automatic nesting, and real-time monitoring contribute to maximizing material utilization, reducing costs, and enhancing the overall quality of the final jewelry pieces.

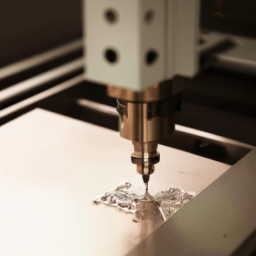

Adjustable Power Settings

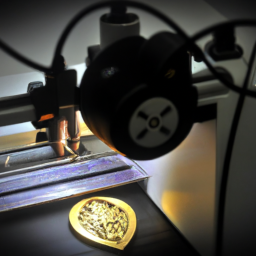

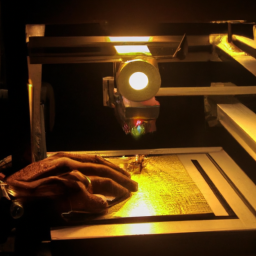

You’ll love how easily you can customize the power settings to achieve precise and efficient laser cuts on your metal jewelry. With adjustable power control, you have full control over the intensity of the laser beam, allowing you to optimize the cutting process for different types of metals.

Whether you’re working with delicate gold or sturdy stainless steel, the ability to fine-tune the power ensures clean and accurate cuts every time.

In addition to power control, laser beam focus is another crucial feature for efficient metal jewelry cutting. By adjusting the focal length, you can concentrate the laser beam to a specific point, resulting in sharper and more precise cuts. This feature is especially beneficial when working with intricate designs or small details.

Transitioning into the next section about automatic material recognition, you’ll appreciate how seamlessly the laser cutter can identify the type of metal you’re working with. This allows for automatic adjustments in power and speed, ensuring optimal cutting conditions without the need for manual intervention.

Automatic Material Recognition

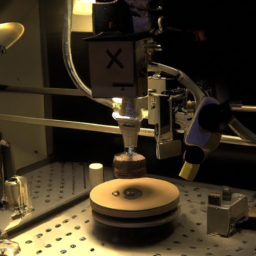

When using this technology, it’s fascinating how the machine can automatically recognize the type of material being worked on, enabling precise and accurate cuts every time.

Through real-time analysis, the laser cutting machine is able to identify the specific properties of the metal jewelry being processed.

This automatic material recognition feature is crucial for ensuring that the laser parameters are optimized for each specific material, resulting in efficient and effective cutting.

By analyzing factors such as reflectivity, thickness, and composition, the machine can adjust the power, speed, and focus of the laser beam to achieve the best cutting results.

This not only saves time and effort but also minimizes material waste.

With automatic material recognition, the laser cutting machine guarantees high precision cutting for intricate metal jewelry designs.

Consequently, this feature enhances the overall efficiency of the laser cutting process.

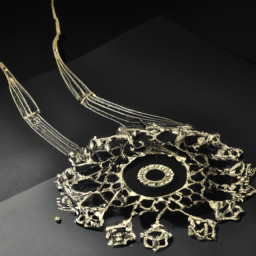

High Precision Cutting

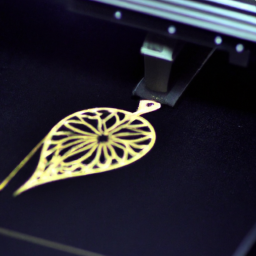

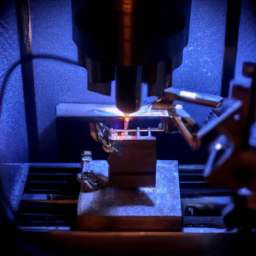

Utilizing advanced technology, the machine’s unparalleled precision ensures flawlessly intricate cuts, leaving you in awe of the exquisite craftsmanship. Laser cutting techniques play a crucial role in achieving high precision cuts for metal jewelry.

By focusing a concentrated beam of light onto the metal surface, the laser vaporizes or melts the material, resulting in precise and clean cuts. The laser’s ability to cut through various metal thicknesses makes it an ideal tool for creating intricate designs with fine details. However, laser cutting does have its limitations. The process can generate heat, which may cause material distortion or discoloration. Additionally, the laser beam’s width can affect the precision of the cut.

To overcome these challenges, manufacturers continuously refine laser cutting techniques to improve accuracy and minimize any negative effects.

Transitioning into the subsequent section about ‘multiple cutting modes,’ let’s explore how these modes further enhance the laser cutting process.

Multiple Cutting Modes

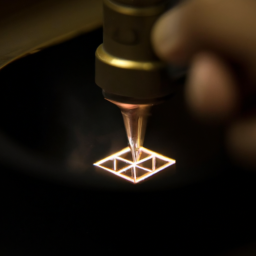

By employing different cutting modes, the machine unveils its artistic prowess, seamlessly transforming sheets of metal into intricate masterpieces. Laser beam control plays a crucial role in achieving high precision and accuracy during the cutting process.

The machine’s advanced technology allows for precise manipulation of the laser beam, ensuring clean and smooth cuts without any deformities or irregularities. Additionally, cutting speed optimization is another key feature of the multiple cutting modes. The machine intelligently adjusts the cutting speed based on the thickness and type of metal, maximizing efficiency while maintaining the desired quality of the final product.

This dynamic control over the laser beam and cutting speed enables the machine to adapt to a wide range of metal jewelry designs and intricacies.

As we move forward to discuss efficient workflow integration, it’s important to understand how these cutting modes facilitate seamless production processes.

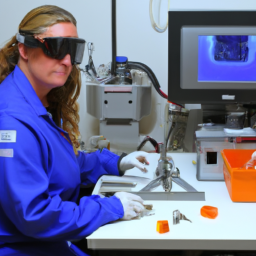

Efficient Workflow Integration

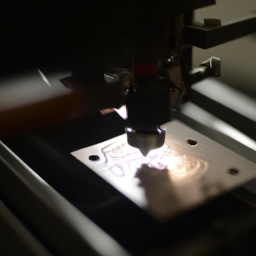

To seamlessly incorporate this technology into your production process, you need to integrate the machine’s capabilities with your workflow. Streamlined production processes are essential for efficient laser cutting of metal jewelry.

By seamlessly integrating the laser cutting machine with your existing jewelry design software, you can achieve a more efficient and streamlined workflow. This integration allows you to easily transfer design files to the laser cutting machine, eliminating the need for manual file conversion or rework. Additionally, the machine’s capabilities can be synchronized with your design software, enabling real-time adjustments and ensuring accurate cutting results.

With this seamless integration, you can optimize your production process, reduce errors, and increase productivity.

Transitioning into the subsequent section about ‘advanced software capabilities’, you can further enhance your workflow and achieve even more precise laser cutting results.

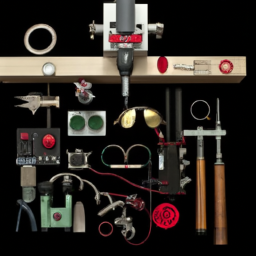

Advanced Software Capabilities

Now that we have discussed the importance of efficient workflow integration in laser cutting of metal jewelry, let’s delve into the current subtopic of advanced software capabilities. One of the key factors in achieving efficiency in laser cutting is software customization. Advanced software systems allow for precise control over the laser cutting process, enabling jewelers to optimize their designs and minimize material wastage. These software solutions offer a wide range of features, including CAD/CAM integration, automatic nesting, and real-time monitoring. They also incorporate laser technology advancements, such as improved beam quality and higher power densities, to enable faster and more precise cutting. With the ability to customize software settings and leverage the latest laser technology, jewelers can significantly enhance their productivity and achieve superior results in metal jewelry laser cutting.

| Feature | Description | Benefits | ||||

|---|---|---|---|---|---|---|

| CAD/CAM integration | Seamlessly transfer designs from CAD software to the laser cutting machine | Streamlined workflow, reduced manual errors | ||||

| Automatic nesting | Optimize the arrangement of jewelry pieces on the material sheet for maximum material utilization | Minimize material wastage, reduce costs | ||||

| Real-time monitoring | Monitor the cutting process in real-time, including power, speed, and accuracy | Immediate feedback, effective troubleshooting | ||||

| Improved beam quality | Higher beam quality for cleaner and more precise cuts | Enhanced aesthetics, reduced post-processing | ||||

| Higher power densities | Increased laser power for faster cutting speeds | Improved productivity, shorter production times | Improved cutting precision and accuracy | resulting in higher quality and more intricate designs | Enhanced product quality and customer satisfaction |

Frequently Asked Questions

What type of metals can be cut using laser cutting technology?

Laser cutting technology is a powerful tool, capable of transforming metals into exquisite jewelry with precision and finesse. However, not all metals can be tamed by this remarkable technique.

While laser cutting offers numerous advantages over traditional methods, such as increased accuracy and intricate designs, it does have limitations. Certain metals like titanium and tungsten, known for their high melting points and hardness, pose challenges for laser cutting.

Can laser cutting be used to create intricate designs and patterns on metal jewelry?

Yes, laser cutting can be used to create intricate designs and patterns on metal jewelry. The pros of laser cutting for metal jewelry include precise and detailed cuts, the ability to cut complex shapes, and minimal material wastage.

However, there are also some cons to consider such as the high cost of laser cutting machines and the limitations on the thickness of metal that can be cut. To achieve precision in laser cut metal jewelry, it’s important to use high-quality laser cutting machines, optimize the cutting parameters, and ensure proper maintenance and calibration of the equipment.

What safety precautions should be taken when using laser cutting machines for metal jewelry?

Proper safety precautions are crucial when using laser cutting machines for metal jewelry. Did you know that 70% of laser-related accidents occur due to lack of ventilation and inadequate eye protection?

To ensure your safety, it’s important to have proper ventilation in your workspace to remove harmful fumes. Additionally, always wear protective eyewear to shield your eyes from potential laser beam reflections.

Avoid common mistakes like neglecting ventilation or not wearing eye protection to prevent accidents and ensure a safe working environment.

How long does it typically take to cut a piece of metal jewelry using laser cutting technology?

Factors affecting the cutting time in laser cutting of metal jewelry include the thickness and type of metal, complexity of the design, laser power, and cutting speed.

Laser cutting is generally faster than traditional methods for metal jewelry, as it offers high precision and efficiency. However, the cutting time can vary depending on the aforementioned factors.

Laser cutting technology allows for quick and precise cutting of metal jewelry, resulting in high-quality finished pieces.

Can laser cutting be used for both small-scale and large-scale production of metal jewelry?

Laser cutting is a game-changer for metal jewelry production, whether you’re a small-scale artisan or a large-scale manufacturer. Its advantages over traditional methods are plentiful.

With laser cutting, you can achieve intricate and precise designs, saving time and ensuring consistent quality. It’s also cost-effective, as it eliminates the need for expensive molds and tooling.

By harnessing the power of lasers, you can revolutionize your metal jewelry production and meet the demands of the market efficiently.

Conclusion

In conclusion, investing in laser cutting equipment with these eight features will significantly enhance the efficiency of metal jewelry production.

With adjustable power settings, you’ll have full control over the cutting process, ensuring accurate and consistent results.

The automatic material recognition feature eliminates the need for manual adjustments, saving valuable time.

High precision cutting guarantees intricate designs with minimal errors.

Multiple cutting modes allow for versatility and customization.

Efficient workflow integration streamlines the entire production process.

Lastly, advanced software capabilities enable precise control and optimization.

By implementing these features, you’ll be cutting through metal jewelry like a hot knife through butter, achieving exceptional results and maximizing productivity.