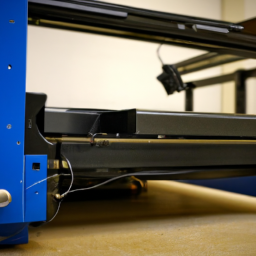

Did you know that the lifespan of your laser cutter can be significantly extended by incorporating a few key features?

In fact, studies have shown that laser cutters with these features can last up to 50% longer than those without. So, if you want to maximize the efficiency and durability of your metal cutting operations, it’s crucial to invest in the right technology.

To help you make informed decisions, we’ve compiled a list of 8 essential features that can revolutionize your metal cutting process. From advanced cooling systems that prevent overheating to automatic focus adjustment for precise cuts every time, these features are designed to enhance productivity and accuracy.

Additionally, high-power laser sources and precision cutting heads ensure faster and cleaner cuts, while intelligent control systems streamline operations and minimize errors.

But it doesn’t stop there. Regular maintenance and inspections are vital to keep your laser cutter in top shape and prevent costly breakdowns. By implementing these features and following a comprehensive maintenance routine, you can prolong the lifespan of your laser cutter and optimize performance.

So, let’s dive into the details and discover how these features can take your metal cutting capabilities to new heights.

Key Takeaways

- Laser cutters with key features last up to 50% longer.

- Advanced cooling systems prevent overheating and extend lifespan.

- Automatic focus adjustment ensures precise and accurate cuts.

- High-power laser sources provide faster cutting speeds and improved precision.

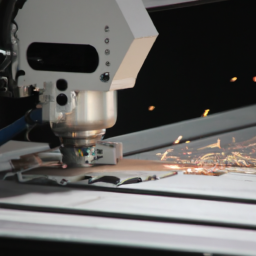

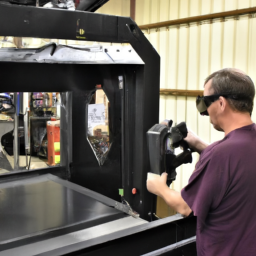

Advanced Cooling Systems

Get ready to take your metal cutting game to the next level with advanced cooling systems that’ll keep your laser cutter running smoothly for longer.

By employing advanced cooling techniques, you can optimize cutting parameters and achieve more efficient metal cutting. These cooling systems are designed to maintain the ideal temperature within the laser cutter, preventing overheating and ensuring consistent performance. With precise temperature control, you can minimize thermal stress on the machine and extend its lifespan.

Advanced cooling systems also help in dissipating heat generated during the cutting process, allowing for faster cutting speeds and improved accuracy. With these cooling systems in place, you can achieve higher productivity and reduce downtime.

As we move on to the next section about automatic focus adjustment, you’ll learn how this feature further enhances the efficiency of your laser cutter.

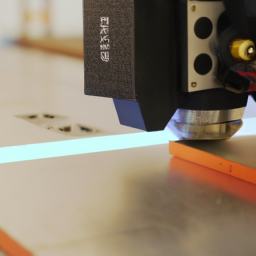

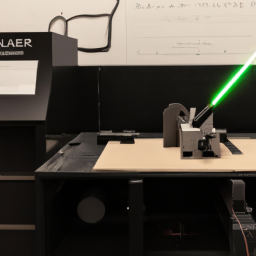

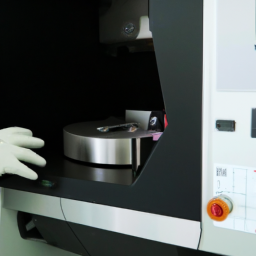

Automatic Focus Adjustment

Improve the precision of your laser cutting with an automatic focus adjustment feature. This feature allows the laser cutter to automatically adjust the focus of the cutting head based on the material being cut. It ensures that the laser beam is always focused at the optimal distance, resulting in precise and accurate cuts.

The automatic focus adjustment feature works by using sensors to measure the distance between the cutting head and the material surface. It then adjusts the position of the cutting head to maintain the correct focus. This eliminates the need for manual adjustments, saving time and reducing the risk of human error.

By utilizing automatic focus adjustment, you can achieve consistent and high-quality cuts across a variety of materials. This feature is particularly useful when working with materials of different thicknesses or when cutting intricate designs.

As we move into the next section about high-power laser sources, it’s important to consider how automatic focus adjustment can further enhance the performance of your laser cutter.

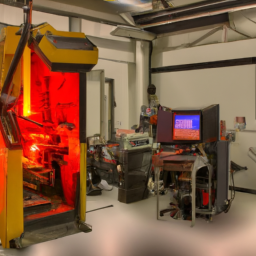

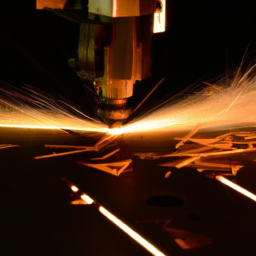

High-Power Laser Source

The high-power laser source plays a crucial role in efficient metal cutting by providing the necessary energy for the process. It allows for faster cutting speeds and improved precision, resulting in increased productivity and reduced production time.

Additionally, the high-power laser source offers advantages for cutting different types of metals, such as stainless steel, aluminum, and titanium, by delivering sufficient power to overcome their specific properties and achieve optimal cutting results.

The role of high-power laser source in efficient metal cutting

Imagine your laser cutter as a powerful conductor, with the high-power laser source acting as its symphony conductor, directing the precision and intensity needed for efficient metal cutting. The role of a high-power laser source in metal cutting is crucial, as it determines the quality and speed of the process.

Here are three key benefits of using a high-power laser source for efficient metal cutting:

-

Enhanced Cutting Speed: The high-power laser source generates a beam with intense energy, allowing for faster cutting speeds and increased productivity.

-

Improved Precision: With its high power output, the laser source can create precise cuts with minimal heat affected zones, resulting in cleaner edges and reduced material distortion.

-

Versatile Cutting Capability: High-power laser sources can effortlessly cut through a wide range of metals, including stainless steel, aluminum, and titanium, making them suitable for various applications.

By utilizing a high-power laser source, you can unlock the advantages of efficient metal cutting across different types of metals.

Advantages of using high-power laser source for different types of metals

Unlock the full potential of your metalworking projects by harnessing the advantages of a high-power laser source for cutting different types of metals. The benefits of using a high-power laser source for various metal cutting applications are numerous.

Firstly, the high-power laser provides a significantly faster cutting speed compared to lower power lasers, allowing for increased productivity.

Secondly, the high-power laser can cut through thicker and harder metals with ease, expanding the range of materials that can be processed.

Additionally, the high-power laser source offers improved precision, resulting in cleaner cuts and reduced material waste.

Moreover, the high-power laser source produces less heat-affected zones, minimizing distortion and ensuring the quality of the final product.

By utilizing a high-power laser source, you can optimize your metal cutting process for maximum efficiency and quality.

Transitioning into the subsequent section about "precision cutting heads," you can further enhance the performance of your laser cutter.

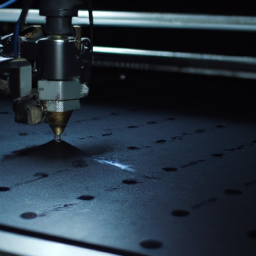

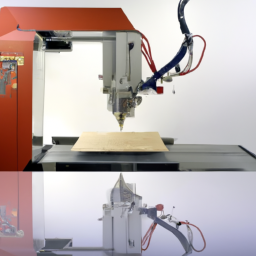

Precision Cutting Heads

Enhance the lifespan of your laser cutter with precision cutting heads that slice through metal like a hot knife through butter. These cutting heads are equipped with advanced laser cutting techniques and precision cutting technology, allowing for precise and efficient metal cutting.

Here are four key features of precision cutting heads that can extend the lifespan of your laser cutter:

-

High-speed cutting capabilities: Precision cutting heads can achieve faster cutting speeds, reducing production time and increasing productivity.

-

Enhanced cutting accuracy: These cutting heads offer improved precision, ensuring clean and accurate cuts, even on complex metal shapes.

-

Adjustable focus position: Precision cutting heads allow for easy adjustment of the focus position, optimizing cutting performance for different types and thicknesses of metal.

-

Automatic height control: With intelligent automatic height control systems, precision cutting heads ensure consistent cutting quality by maintaining the correct cutting distance throughout the process.

By incorporating precision cutting heads into your laser cutter, you can optimize metal cutting efficiency and quality. Transitioning into the subsequent section about intelligent control systems, these features work seamlessly with intelligent control systems to further enhance the performance of your laser cutter.

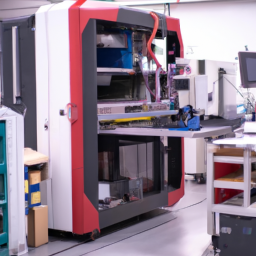

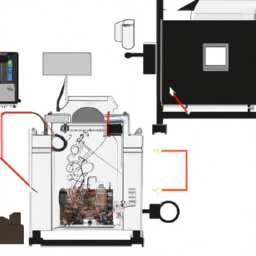

Intelligent Control Systems

Boost the capabilities of your laser cutter with intelligent control systems that optimize performance and ensure precise and efficient operations. Integrated software plays a crucial role in these control systems, allowing you to program and monitor your laser cutter with ease. This software enables seamless communication between the different components of the laser cutter, ensuring smooth operation and preventing any potential issues.

Real-time monitoring is another essential feature offered by intelligent control systems. It allows you to closely track the performance of your laser cutter, providing valuable insights into its operation and identifying any potential errors or inefficiencies. By utilizing this technology, you can make necessary adjustments on the fly, maximizing the productivity and lifespan of your laser cutter.

As we transition into the subsequent section about maintenance and regular inspections, it’s crucial to understand how intelligent control systems can help you identify and address potential issues before they become major problems.

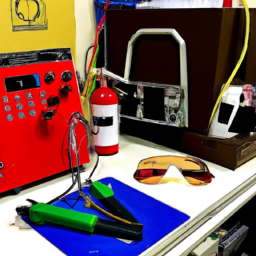

Maintenance and Regular Inspections

Regular maintenance and inspections are crucial for ensuring the efficient performance and longevity of your laser cutter. By conducting regular checks, you can identify any potential issues early on and take necessary corrective actions to prevent costly breakdowns.

To prolong the lifespan of your laser cutter, it’s important to follow the manufacturer’s guidelines for cleaning, lubrication, and calibration. Additionally, it’s essential to keep a record of maintenance activities for future reference.

Importance of regular maintenance and inspections for laser cutters

Maintaining and inspecting your laser cutter is absolutely crucial to ensure its longevity and prevent any potential breakdowns or malfunctions. Regular maintenance plays a vital role in keeping your machine in optimal condition.

By conducting routine inspections, you can identify any issues early on and address them promptly, preventing them from escalating into major problems. These inspections allow you to check for worn-out parts, loose connections, or any signs of damage.

By keeping your laser cutter well-maintained, you can extend its lifespan and maximize its performance. Regular maintenance also ensures that your machine operates at its peak efficiency, resulting in higher productivity and accuracy. Additionally, frequent inspections provide an opportunity to clean and lubricate the necessary components, reducing friction and minimizing wear and tear.

By prioritizing regular maintenance and inspections, you can proactively address any potential issues and keep your laser cutter operating at its best, ultimately prolonging its lifespan.

Transition: Now that you understand the importance of regular maintenance and inspections, let’s delve into some tips for maintaining and prolonging the lifespan of your laser cutter.

Tips for maintaining and prolonging the lifespan of your laser cutter

Now that you understand the importance of regular maintenance and inspections for your laser cutter, let’s dive into some tips for maintaining and prolonging its lifespan. By implementing proper maintenance techniques, you can ensure optimal performance and extend the longevity of your machine.

Regularly cleaning the lens, mirrors, and other components is crucial to prevent debris buildup and maintain the accuracy of the laser beam. Additionally, lubricating moving parts and checking for loose screws or belts can prevent unnecessary wear and tear.

Troubleshooting common issues such as misalignment or power fluctuations promptly can prevent further damage and costly repairs. By following these maintenance tips and promptly addressing any issues that arise, you can maximize the lifespan of your laser cutter and ensure its efficient metal cutting capabilities.

Frequently Asked Questions

How often should maintenance and regular inspections be performed on a laser cutter?

To ensure optimal performance and prolong the lifespan of your laser cutter, it’s essential to adhere to a regular maintenance and inspection schedule. The maintenance frequency and regular inspections should be conducted at regular intervals to identify and address any potential issues before they escalate.

These inspections will help in detecting wear and tear, ensuring proper alignment, cleaning the optics, and verifying the functionality of various components. By following a consistent maintenance routine, you can maximize the efficiency and longevity of your laser cutter.

Are there any additional benefits of using an advanced cooling system for metal cutting?

An advanced cooling system can significantly improve the efficiency of your metal cutting process. In fact, studies have shown that using an advanced cooling system can increase cutting speeds by up to 20%. This means you can complete your cutting tasks faster, saving valuable time and increasing productivity.

Additionally, the advanced cooling system helps to prevent overheating, which can extend the lifespan of your laser cutter and reduce the need for frequent repairs.

Can the automatic focus adjustment feature be used for different types of materials?

Yes, the automatic focus adjustment feature can be used for different types of materials. It ensures optimal material cutting settings by adjusting the focus point according to the material’s thickness and density. This feature allows for precise and efficient cutting, minimizing the risk of damage to the material and extending the lifespan of your laser cutter. By automatically adapting to different materials, it saves time and effort in manual adjustments, making it a valuable tool for various cutting applications.

Does a high-power laser source affect the overall lifespan of a laser cutter?

A high-power laser source can significantly impact the overall lifespan of a laser cutter. The increased power leads to higher cutting speeds and improved efficiency. However, it also places greater stress on the machine, resulting in increased wear and tear.

To counteract this, it’s crucial to ensure that the laser cutter is designed to handle the demands of a high-power laser. Regular maintenance and proper cooling mechanisms should be in place to prolong its longevity.

Are precision cutting heads compatible with all laser cutter models?

Precision cutting heads are like the perfect dance partners for laser cutter models. They effortlessly glide across the metal surface, leaving behind precise and clean cuts. These cutting heads are designed to work seamlessly with various laser cutter models, ensuring compatibility and optimal performance.

So, whether you have a small desktop laser cutter or a large industrial one, you can trust that precision cutting heads will enhance your cutting experience and deliver exceptional results.

Conclusion

In conclusion, to ensure an extended lifespan for your laser cutter and achieve efficient metal cutting, implementing these 8 features is paramount. The advanced cooling systems, coupled with automatic focus adjustment, will optimize performance. A high-power laser source and precision cutting heads guarantee precise and powerful cuts. Intelligent control systems enable seamless operation.

Lastly, regular maintenance and inspections ensure the longevity of your machine. Incorporating these features will enhance productivity, precision, and proficiency, propelling your metal cutting endeavors to new heights.