Are you ready to slice through metal like a hot knife through butter? To ensure your laser cutter is operating at peak performance, mastering the art of maintenance is essential. Just like a finely tuned instrument, your laser cutter requires regular care and attention to keep it humming with efficiency.

With these 8 laser cutter maintenance features, you’ll be able to achieve precise and efficient metal cutting every time.

First and foremost, regular cleaning and lubrication are key to keeping your machine running smoothly. By inspecting the lens and mirrors, you can ensure optimal beam quality and avoid any potential issues.

Calibration of laser power and focus will guarantee accurate and consistent cutting results.

Don’t forget to check and replace consumables, such as nozzles and lenses, to maintain top-notch performance. Monitoring and adjusting cutting parameters will fine-tune your machine for maximum efficiency.

And lastly, a proper ventilation and air filtration system will keep your workspace safe and clean.

With these maintenance features in your arsenal, you’ll be able to unleash the full potential of your laser cutter, effortlessly transforming metal into precision masterpieces.

Key Takeaways

- Regular cleaning and lubrication, checking and replacing consumables, inspecting the lens and mirrors, and calibration of laser power and focus are important maintenance procedures for efficient metal cutting.

- Proper ventilation and air filtration systems are crucial for maintaining good air quality control and safety measures in laser cutting operations.

- Monitoring and adjusting cutting parameters, inspecting cut quality, and optimizing cutting speed are essential for achieving efficient and precise metal cutting.

- Ensuring workspace safety and cleanliness, prioritizing operator health and efficiency, and enhancing safety and efficiency in metal cutting operations are important for maintaining a productive and safe working environment.

Regular Cleaning and Lubrication

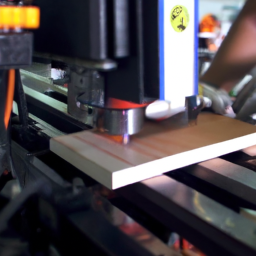

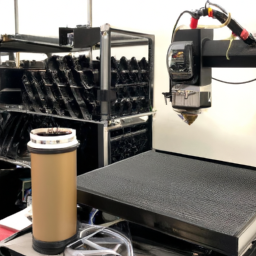

Now it’s time to roll up your sleeves and give your laser cutter some TLC by regularly cleaning and lubricating it. This crucial maintenance task is essential for preventing rust and ensuring the efficient performance of your machine.

Start by cleaning the exterior surfaces using a soft cloth and a mild detergent. Pay close attention to areas prone to dust buildup, such as the ventilation system and the cutting bed.

Next, inspect the moving parts and lubricate them with a high-quality machine oil to reduce friction and enhance their longevity. Regularly check the belts and screws for any signs of wear or loosening, and tighten them if necessary.

By incorporating these cleaning and lubrication practices into your routine, you can troubleshoot common issues and keep your laser cutter in top shape.

Moving on to the next section, let’s discuss the importance of inspecting the lens and mirrors.

Inspection of Lens and Mirrors

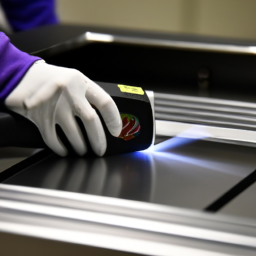

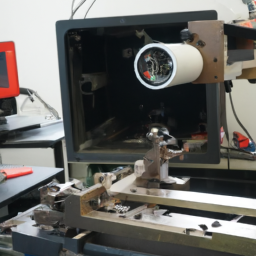

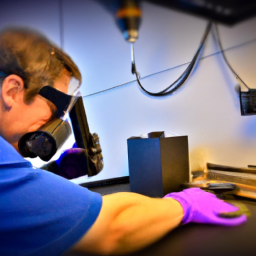

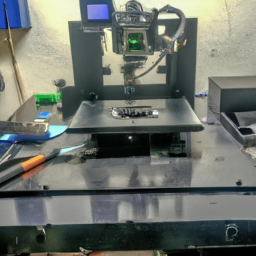

First, take a moment to inspect the lens and mirrors to ensure they’re clean and free from any debris or smudges. Proper cleaning procedures are crucial for maintaining the efficiency of the laser cutter.

Begin by gently removing any loose debris using compressed air or a soft brush. Then, use a lint-free cloth and a mild cleaning solution to wipe the lens and mirrors, being careful not to scratch them. If you encounter stubborn smudges or stains, you can use isopropyl alcohol.

Troubleshooting techniques involve checking for any signs of damage or misalignment in the lens and mirrors. Any distortion or dirt can affect the laser’s focus and accuracy.

By regularly inspecting and cleaning the lens and mirrors, you can ensure optimal performance and prevent potential issues.

Moving onto the next section about calibration of laser power and focus, it’s important to understand the importance of precise settings to achieve desired cutting results.

Calibration of Laser Power and Focus

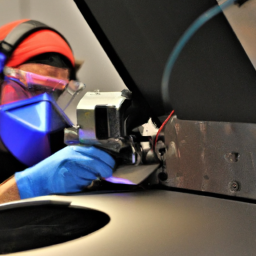

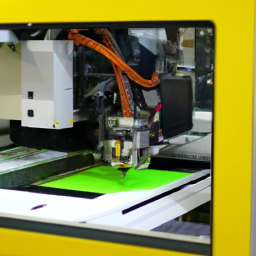

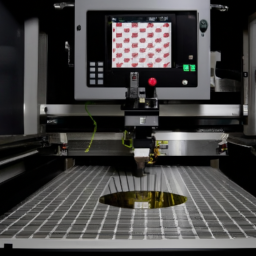

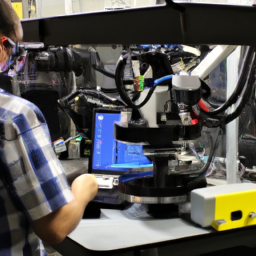

To achieve optimal cutting results, you need to ensure that your laser power and focus are precisely calibrated. Laser cutter safety precautions must be taken when performing these tasks. Follow these steps to properly calibrate your laser power and focus:

-

Start by checking the laser power settings and adjusting them as needed. This will ensure that the laser is providing the right amount of energy for cutting metal.

-

Next, carefully inspect the focal length of the lens and mirrors to ensure they’re clean and in good condition. Any dirt or damage can affect the accuracy of the laser focus.

-

Finally, troubleshoot any laser cutter issues that may arise during the calibration process. This can include checking for loose connections, adjusting the beam alignment, or replacing faulty components.

By following these steps, you can ensure that your laser cutter is properly calibrated for efficient metal cutting. Once you’ve completed these tasks, it’s important to move on to the next section about checking and replacing consumables to maintain the performance of your laser cutter.

Checking and Replacing Consumables

Once you’ve completed the crucial step of calibrating your laser power and focus, it’s time to address the important task of checking and replacing consumables to maintain optimal performance.

Following a regular maintenance schedule is vital to ensure that your laser cutter operates efficiently and reliably. Begin by inspecting the focal lens for any signs of damage or dirt accumulation. Clean it carefully using a lint-free cloth or an appropriate cleaning solution.

Next, examine the nozzle and replace it if worn out or clogged. It’s also essential to check the condition of the assist gas and replace it as needed.

Lastly, troubleshoot any issues that may arise during the process, such as inconsistent beam quality or irregular cutting results. By diligently maintaining and troubleshooting your laser cutter’s consumables, you can achieve consistent and precise metal cutting.

Transitioning into the subsequent section about ‘monitoring and adjusting cutting parameters,’ it is crucial to ensure the continued efficiency of your laser cutter.

Monitoring and Adjusting Cutting Parameters

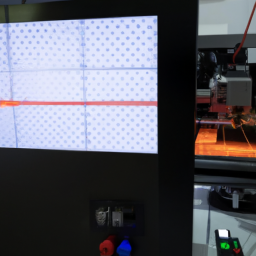

Regularly monitoring and adjusting cutting parameters is like fine-tuning a musical instrument, ensuring that every note is played with precision and accuracy. To achieve optimal results, it is crucial to closely monitor the cut quality throughout the metal cutting process. This involves inspecting the edges of the cut for smoothness, checking for any signs of burning or discoloration, and ensuring that the dimensions of the cut match the required specifications.

Additionally, optimizing cutting speed is essential for efficient metal cutting. By finding the right balance between cutting speed and the power of the laser, you can minimize production time without compromising the quality of the cut. Remember, monitoring and adjusting cutting parameters are key steps in achieving consistent and precise metal cutting results.

Moving forward, let’s explore the importance of a proper ventilation and air filtration system.

Proper Ventilation and Air Filtration System

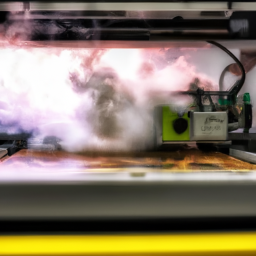

Now that you understand the importance of monitoring and adjusting cutting parameters, let’s move on to another crucial aspect of laser cutter maintenance: proper ventilation and air filtration systems.

When it comes to laser cutting, ensuring good air quality control and implementing appropriate safety measures is paramount. The laser cutting process generates smoke, fumes, and potentially harmful particles, which can pose health risks to operators and compromise the efficiency of the laser cutter.

To address this, a well-designed ventilation system should be in place to remove these byproducts and maintain a safe working environment. Additionally, an effective air filtration system should be installed to capture and filter out any harmful particles before they are released into the atmosphere.

By prioritizing proper ventilation and air quality control, you can enhance both the safety and efficiency of your metal cutting operations.

Frequently Asked Questions

What are the potential safety hazards associated with laser cutting and how can they be mitigated?

To ensure safety in laser cutting operations, it’s crucial to address potential hazards and adopt appropriate precautions.

Some common safety concerns include exposure to laser radiation, electrical hazards, and the release of harmful fumes and gases.

Mitigation techniques involve implementing safety protocols, providing proper training, and using personal protective equipment such as safety glasses and ventilation systems.

Proper safety measures are essential to protect operators from potential injuries and health risks associated with laser cutting.

How often should a laser cutter be serviced by a professional technician?

To ensure optimal performance and minimize downtime, a laser cutter should be serviced by a professional technician at least once every six months. Regular maintenance by a trained expert ensures that the machine remains in peak condition, prolonging its lifespan and preventing costly repairs.

Professional service includes thorough cleaning, calibration, and inspection of components, guaranteeing precise and efficient metal cutting. By adhering to the recommended service frequency, you can enjoy the benefits of increased productivity, reliability, and safety.

Are there any specific training requirements for operating a laser cutter?

To operate a laser cutter, you must meet specific training requirements and adhere to safety precautions. Training ensures that you understand the equipment’s operation, maintenance, and emergency protocols. It covers topics such as laser safety, material handling, and machine setup.

Safety precautions involve wearing appropriate personal protective equipment (PPE), such as safety glasses and gloves, and following standard operating procedures to prevent accidents or injuries. Being trained and cautious is essential for efficient and safe laser cutting operations.

What are the common mistakes to avoid when using a laser cutter for metal cutting?

Common mistakes in laser cutter operation can lead to costly errors. Avoiding these errors requires careful attention and adherence to proper procedures.

One common mistake is neglecting to properly clean the laser lens, resulting in reduced cutting efficiency.

Another mistake is using incorrect power settings, leading to inconsistent or ineffective cuts.

Additionally, failing to properly secure the metal material can cause misalignment and inaccurate cuts.

By avoiding these common mistakes, you can ensure efficient and precise metal cutting with a laser cutter.

How can I maximize the lifespan of my laser cutter and ensure it operates at optimal efficiency?

To maximize the lifespan of your laser cutter and optimize its efficiency, there are several key steps you can take.

Regularly inspect and clean the machine, paying special attention to the optics and mirrors.

Ensure proper ventilation and cooling to prevent overheating.

Calibrate the laser power and focus regularly.

Implement a schedule for replacing consumable parts, such as nozzles and lenses.

Additionally, follow the manufacturer’s guidelines for maintenance and avoid pushing the machine beyond its recommended usage limits.

Conclusion

In conclusion, maintaining a laser cutter is crucial for efficient metal cutting. By regularly cleaning and lubricating the machine, inspecting lens and mirrors, calibrating laser power and focus, checking and replacing consumables, monitoring and adjusting cutting parameters, as well as ensuring proper ventilation and air filtration, you can optimize the performance and longevity of your equipment.

Did you know that according to a recent survey, companies that prioritize laser cutter maintenance experience a 30% increase in productivity and a 20% decrease in downtime? Taking these maintenance measures seriously will not only improve efficiency but also save valuable time and resources.