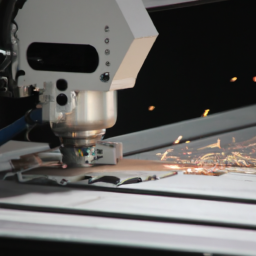

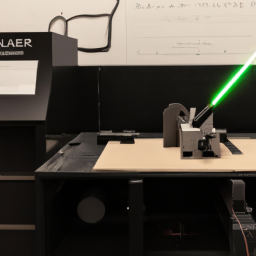

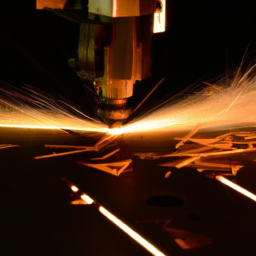

Imagine you have a trusty companion, always ready to help you bring your creative visions to life. This companion is none other than your laser cutter, a powerful tool that allows you to cut and engrave with precision and finesse.

Just like any loyal companion, your laser cutter requires regular care and attention to ensure its longevity and optimal performance. In this article, we will explore eight laser cutter maintenance standards and regulations that will help you extend its lifespan and keep it operating at its best.

From regular cleaning and maintenance to proper ventilation and air filtration, we will delve into the technical aspects of caring for your laser cutter. We will also discuss the importance of regular inspection and calibration, safe operation and training, as well as the significance of software and firmware updates.

Lastly, we will touch upon the necessity of scheduled servicing and professional maintenance to keep your laser cutter in top shape.

So, let’s dive in and discover how to keep your loyal companion shining bright for years to come.

Key Takeaways

- Regular cleaning and maintenance are necessary for longevity and optimal performance.

- Proper ventilation and air filtration are important for a safe and healthy working environment.

- Regular inspection and calibration are essential for maintaining efficiency and accuracy.

- Follow manufacturer’s guidelines for maintenance and calibration.

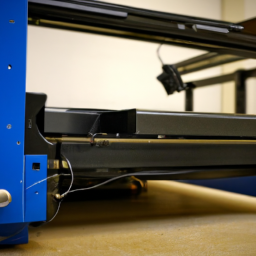

Regular Cleaning and Maintenance

To extend the lifespan of your laser cutter, it’s crucial that you regularly clean and maintain it according to the recommended standards and regulations. The importance of maintenance can’t be overstated, as neglecting this aspect can lead to decreased performance and costly repairs.

When it comes to cleaning, there are some common mistakes that you should avoid. Firstly, never use abrasive materials or harsh chemicals, as they can damage the delicate components of the cutter. Instead, opt for soft, lint-free cloths and mild cleaning solutions.

Secondly, make sure to clean both the exterior and interior of the machine, paying attention to areas that accumulate dust and debris. Regular cleaning not only helps to keep your laser cutter in optimal condition, but it also ensures the safety of both the machine and the operator.

Moving onto the next section about proper ventilation and air filtration, it’s important to create a well-ventilated environment to dissipate fumes and prevent the buildup of potentially harmful particles.

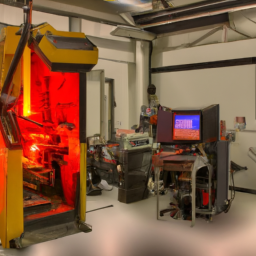

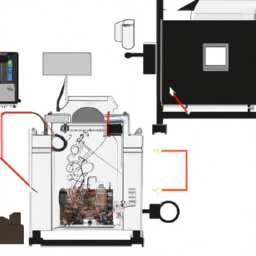

Proper Ventilation and Air Filtration

Ensure you have a highly efficient ventilation and air filtration system in place, or risk turning your workspace into a suffocating cloud of toxic fumes. Proper airflow management is crucial for maintaining a safe and healthy environment when operating a laser cutter.

The laser cutting process releases various harmful substances, such as volatile organic compounds (VOCs) and particulate matter, into the air. Without adequate ventilation and filtration, these pollutants can accumulate and pose serious health risks to you and your colleagues. To prevent this, invest in a ventilation system that can effectively remove the fumes and maintain a steady airflow throughout the workspace. Additionally, install a high-quality air filtration system to further remove any remaining contaminants.

Regularly check and clean the ventilation and filtration components to ensure optimal performance.

Transitioning into the next section, regular inspection and calibration of your laser cutter is essential for maintaining its efficiency and accuracy.

Regular Inspection and Calibration

To ensure optimal performance and extend the lifespan of your laser cutter, it’s crucial to regularly inspect and calibrate various aspects of the machine.

Begin by inspecting the laser alignment and beam quality, ensuring they’re aligned and focused correctly.

Next, calibrate the power settings and focus depth to achieve precise and accurate cuts.

Lastly, check and adjust the mirrors and lenses to maintain the highest level of laser performance.

By diligently performing these inspections and calibrations, you’ll maximize the efficiency and longevity of your laser cutter.

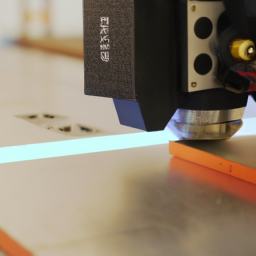

Inspect laser alignment and beam quality

Check if the laser alignment and beam quality are up to par, so you can maximize the lifespan of your laser cutter. Proper beam alignment is crucial for the efficient operation of your laser cutter. Misaligned beams can lead to decreased cutting accuracy and reduced overall performance.

Regularly inspect the alignment of the laser beam to ensure it’s correctly focused on the desired cutting area. Additionally, assess the beam stability to avoid fluctuations that can negatively impact the quality of your cuts. Keep an eye out for any signs of beam misalignment, such as uneven cutting or inconsistent engraving depth.

If any issues are detected, consult the laser cutter manual or contact a professional technician for assistance. Properly maintaining the alignment and beam quality will lay the foundation for the subsequent section on calibrating power settings and focus depth.

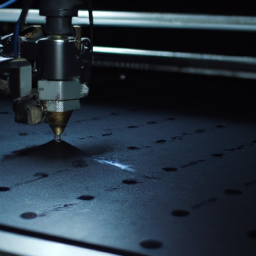

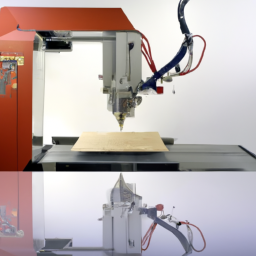

Calibrate power settings and focus depth

Make sure you fine-tune the power settings and focus depth to achieve precise and sharp cuts, allowing your laser cutter to unleash its full potential.

Optimizing the power settings is crucial for maintaining consistent laser beam quality and extending the lifespan of your machine. By calibrating the power settings, you can ensure that the laser delivers the right amount of energy to the material, preventing overexposure or underexposure.

Additionally, adjusting the focus depth is essential for achieving the desired cutting depth and minimizing the risk of damaging the material or the machine. To optimize power settings and focus depth, refer to the manufacturer’s guidelines and perform regular tests to verify the accuracy of the settings.

Once you have calibrated the power and focus, it’s time to move on to the next step: checking and adjusting mirrors and lenses.

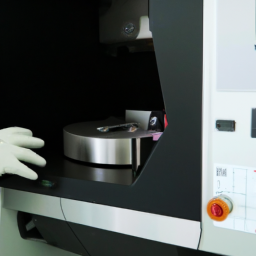

Check and adjust mirrors and lenses

To ensure optimal performance and extend the lifespan of your laser cutter, it’s crucial to regularly check and adjust the mirrors and lenses. Proper mirror alignment is essential for maintaining accurate beam positioning, while lens replacement is necessary when signs of wear or damage appear.

Start by examining the mirrors for any misalignment or dirt buildup, making necessary adjustments or cleaning as needed. Next, inspect the lenses for any scratches, cracks, or debris that might affect beam quality. Replace any damaged lenses promptly to avoid compromising cutting or engraving precision.

By regularly checking and adjusting the mirrors as well as replacing worn-out lenses, you can ensure consistent and high-quality laser cutting results.

Now, let’s move on to the next section about safe operation and training, where you’ll learn about the best practices for operating your laser cutter.

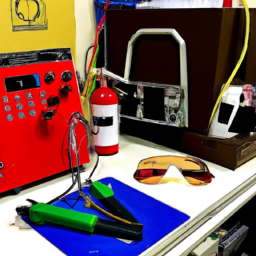

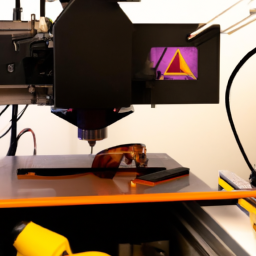

Safe Operation and Training

When using a laser cutter, it’s crucial to ensure you receive proper training to operate it safely and extend its lifespan. Workplace safety is of utmost importance when dealing with such powerful machinery. Laser cutter certification programs provide comprehensive training on safe operation, maintenance, and emergency procedures.

These programs cover topics like hazard identification, personal protective equipment, and proper ventilation requirements. By following these guidelines, you can minimize the risk of accidents and ensure the longevity of your laser cutter.

Additionally, regular software and firmware updates are essential to keep your machine running smoothly and efficiently. These updates often include performance enhancements, bug fixes, and new features that can optimize your workflow. By staying up to date with the latest software and firmware updates, you can ensure your laser cutter operates at its best without any interruptions.

Regular Software and Firmware Updates

By staying on top of the latest software and firmware updates, you’ll ensure your laser cutting machine is constantly evolving and performing at mind-blowing levels of efficiency. Laser cutter troubleshooting becomes much easier when you have the most up-to-date software and firmware. These updates often include bug fixes, performance improvements, and new features that can enhance your laser cutting experience.

By regularly checking for updates and installing them promptly, you can prevent potential issues and keep your machine running smoothly. Laser cutter troubleshooting guide is often included with these updates, providing you with step-by-step instructions on how to resolve common problems. This proactive approach to software and firmware updates will not only extend the lifespan of your laser cutter but also improve its overall performance.

Speaking of maintenance, let’s now discuss the importance of scheduled servicing and professional maintenance to keep your machine in optimal condition.

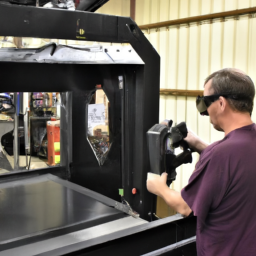

Scheduled Servicing and Professional Maintenance

Don’t forget to schedule regular servicing and professional maintenance to ensure your machine stays in optimal condition. This is crucial for extending the lifespan of your laser cutter and maintaining its efficiency.

Here are some important safety precautions and equipment troubleshooting tips to consider during scheduled servicing and professional maintenance:

-

Inspect and clean the machine thoroughly: Regularly check for dust, debris, and residue buildup that can affect the performance of your laser cutter. Clean the lenses, mirrors, and other components using appropriate cleaning solutions.

-

Check for loose connections: Ensure that all cables, wires, and connections are secure and in good condition. Loose connections can lead to faulty operation and potential safety hazards.

-

Verify alignment and calibration: Regularly verify and adjust the alignment and calibration of your laser cutter to ensure accurate cutting and engraving.

-

Lubricate moving parts: Keep the moving parts of your laser cutter well lubricated to minimize friction and prevent wear and tear.

By following these maintenance standards and regulations, you can prolong the lifespan of your laser cutter and ensure its safe and efficient operation.

Frequently Asked Questions

Can I use any type of cleaning solution or do I need to use a specific one for laser cutter maintenance?

To ensure the longevity of your laser cutter, it’s crucial to use the right cleaning solution for maintenance. Using any type of cleaning solution may not provide the desired results and could potentially damage the machine. It’s recommended to use a specific cleaning solution that’s suitable for laser cutters.

Additionally, taking preventive measures such as regular cleaning and maintenance will further extend the lifespan of your laser cutter.

How often should I replace the air filters in my laser cutter’s ventilation system?

To properly maintain your laser cutter’s ventilation system, it’s important to regularly replace the air filters. It is recommended to replace them every 2 to 3 months, depending on usage.

When cleaning the laser cutter’s lens, use a lint-free cloth and isopropyl alcohol. Gently wipe the lens in a circular motion, being careful not to scratch it.

If you encounter ventilation system issues, troubleshoot by checking for obstructions, ensuring proper airflow, and inspecting the exhaust fan for any damage.

Are there any specific safety precautions I should take while operating a laser cutter?

When operating a laser cutter, it’s crucial to prioritize safety precautions. Think of it as embarking on a perilous journey where preparation is key.

Laser cutter operator training is essential to navigate this intricate machinery. Remember to equip yourself with the knowledge of proper ventilation, as it plays a vital role in keeping the workspace safe.

Adequate airflow is crucial to maintain a healthy environment and prevent the accumulation of harmful fumes.

How frequently should I update the software and firmware of my laser cutter?

To ensure optimal performance and safety, it’s crucial to regularly update the software and firmware of your laser cutter. The frequency of software updates depends on the manufacturer’s recommendations and the availability of new features or bug fixes.

Firmware updates are equally important as they address hardware compatibility and enhance machine functionality. By staying up-to-date with the latest software and firmware versions, you can maximize the efficiency and longevity of your laser cutter.

How often should I schedule professional maintenance for my laser cutter?

To keep your laser cutter humming like a well-oiled machine, regular professional maintenance is key. Just as a skilled surgeon performs delicate procedures, trained technicians will fine-tune your equipment’s intricate components.

They’ll inspect, clean, and calibrate everything from the optics to the power supply, ensuring optimal performance. This diligent attention to detail will prevent costly breakdowns, extend your cutter’s lifespan, and keep your projects cutting-edge.

Don’t underestimate the importance of professional maintenance in maintaining your laser cutter’s efficiency.

Conclusion

In conclusion, adhering to the laser cutter maintenance standards and regulations mentioned above is crucial for prolonging its lifespan and ensuring its optimal performance.

Remember, just like any other piece of machinery, regular cleaning, proper ventilation, inspection, and calibration are essential. Additionally, staying updated with the latest software and firmware, along with scheduled servicing and professional maintenance, will help avoid potential issues.

By following these guidelines, you can keep your laser cutter in top shape, allowing it to continue producing precise and detailed results.