Are you tired of troubleshooting issues that slow down your metal cutting process?

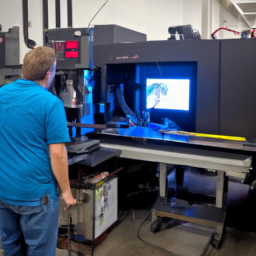

Imagine having access to cutting-edge laser cutter features that not only detect errors in real-time but also provide automatic calibration and alignment.

With an extensive material compatibility and settings database, you can optimize your cutting parameters for maximum efficiency.

But that’s not all – intelligent power control and beam quality monitoring ensure precise and consistent cuts every time.

Say goodbye to overheating and ventilation problems with an integrated cooling and ventilation system that keeps your laser cutter running smoothly.

And the best part? You can now remotely monitor and troubleshoot any issues with the help of advanced support systems.

In this article, we will explore the top eight laser cutter troubleshooting features that will revolutionize your metal cutting process, saving you time, effort, and ensuring efficient results.

Key Takeaways

- Real-time error detection and alerts

- Automatic calibration and alignment techniques

- Extensive material compatibility and settings database

- Remote monitoring and troubleshooting support

Real-Time Error Detection and Alerts

You’ll be amazed at how our laser cutter’s real-time error detection and alerts will save you time and frustration. It ensures precise metal cutting every time. With our advanced technology, the laser cutter constantly monitors the cutting process. It detects any errors or deviations from the desired specifications and provides instant alerts. This allows you to take immediate action and avoid costly mistakes.

Additionally, our laser cutter is equipped with predictive maintenance capabilities. It analyzes the error log to identify potential issues before they even occur. This proactive approach prevents unexpected breakdowns and minimizes downtime.

As we move into the next section about automatic calibration and alignment, you can trust that our laser cutter will continuously deliver exceptional performance and accuracy. It makes your metal cutting tasks effortless.

Automatic Calibration and Alignment

Utilizing its innovative technology, the laser cutter effortlessly fine-tunes its precision, ensuring seamless calibration and alignment for flawless results. Here are four automatic calibration techniques and alignment optimization strategies implemented by the laser cutter:

-

Self-Calibration: The laser cutter automatically checks and adjusts its internal components to maintain optimal performance.

-

Laser Beam Alignment: Through advanced algorithms, the laser cutter continuously monitors and adjusts the beam alignment for accurate cutting.

-

Material-Specific Calibration: The laser cutter detects the type and thickness of the material being cut, automatically adjusting its settings for optimal results.

-

Real-Time Monitoring: The laser cutter constantly analyzes cutting performance, making real-time adjustments to ensure precise alignment and calibration.

By employing these automatic calibration techniques and alignment optimization strategies, the laser cutter guarantees efficient and accurate metal cutting.

Transitioning to the next section, it also incorporates a comprehensive material compatibility and settings database for further customization.

Material Compatibility and Settings Database

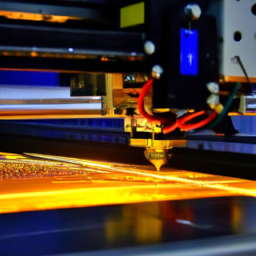

With its extensive database of material compatibility and settings, the laser cutting machine offers a tailored and hassle-free experience for achieving flawless results. The laser cutter maintenance is made easier with this feature as it allows users to quickly and accurately select the appropriate settings for different materials. By optimizing cutting speed, the machine ensures efficient and precise metal cutting, reducing production time and costs.

The material compatibility and settings database also helps users avoid common issues such as material burning or incomplete cuts. Additionally, this feature enables the laser cutter to adapt to various types of metals, including stainless steel, aluminum, and copper.

By seamlessly transitioning into the subsequent section about intelligent power control and beam quality monitoring, the laser cutter ensures continuous operation and high-quality cutting results.

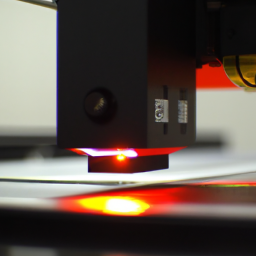

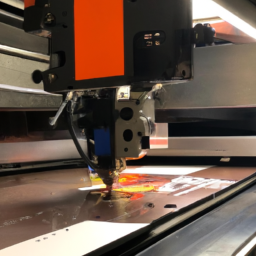

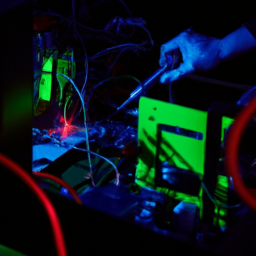

Intelligent Power Control and Beam Quality Monitoring

Keep an eye on the power control and beam quality of your machine to ensure smooth and precise cutting, while maintaining the highest level of performance. Laser cutting precision is crucial for achieving accurate results, and the intelligent power control feature allows you to adjust the power output according to the specific requirements of your metal cutting project. By optimizing the cutting speed, you can achieve faster and more efficient results without compromising on accuracy.

Additionally, the beam quality monitoring system continuously assesses the quality of the laser beam, ensuring consistent and reliable performance. This feature helps to minimize errors and ensures that each cut is executed with the utmost precision.

Now, let’s move on to the next section about the integrated cooling and ventilation system, which plays a vital role in maintaining the optimal operating conditions of your laser cutter.

Integrated Cooling and Ventilation System

Ensure optimal operating conditions for your machine by taking advantage of the integrated cooling and ventilation system. This system is designed to enhance energy efficiency optimization and reduce noise levels during the metal cutting process.

Here are three features of the system that contribute to its effectiveness:

-

Efficient Cooling: The integrated cooling system efficiently removes heat generated during the laser cutting process, preventing overheating and maintaining consistent performance.

-

Air Filtration: The ventilation system includes advanced filters that effectively remove dust and fumes, ensuring a clean working environment and protecting both the machine and the operator.

-

Noise Reduction: Noise reduction measures are integrated into the cooling and ventilation system, minimizing the sound produced during operation, creating a quieter and more comfortable working environment.

By utilizing the integrated cooling and ventilation system, you can optimize energy efficiency, reduce noise levels, and ensure a smooth metal cutting process.

Transitioning into the subsequent section, remote monitoring and troubleshooting support further enhances the efficiency of your laser cutter.

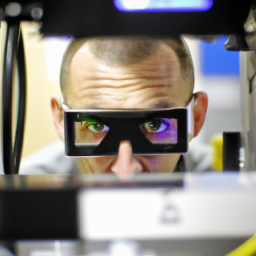

Remote Monitoring and Troubleshooting Support

Take advantage of the remote monitoring and troubleshooting support to effortlessly monitor and resolve any issues that may arise, allowing you to confidently focus on your metalworking projects.

With integrated remote diagnostics, you can remotely access and analyze the performance of your laser cutter, ensuring optimal efficiency. This feature enables you to identify potential problems before they escalate, minimizing downtime and maximizing productivity.

Additionally, the system utilizes predictive maintenance algorithms to forecast maintenance needs based on real-time data, preventing unexpected breakdowns and reducing maintenance costs.

By leveraging remote monitoring and troubleshooting support, you can stay ahead of any potential issues and ensure seamless metal cutting operations. Trust in the reliability and convenience of this feature to keep your laser cutter running smoothly and efficiently.

Frequently Asked Questions

How does real-time error detection and alerts work in a laser cutter?

Real-time error detection in a laser cutter is a crucial feature that ensures smooth and efficient metal cutting. By continuously monitoring the machine’s performance, it can quickly identify any errors or malfunctions in the system.

Once detected, the laser cutter immediately sends alerts to the operator, allowing them to take prompt action. This real-time feedback minimizes downtime and prevents costly mistakes, ensuring optimal productivity and accuracy during the metal cutting process.

Can automatic calibration and alignment be done by the user or does it require a technician?

Automatic calibration and alignment can typically be done by the user without the need for a technician. Laser cutters often come equipped with built-in features that allow users to easily calibrate and align the machine. These features include laser beam alignment guides, automatic bed leveling, and software-based calibration tools. By following the manufacturer’s instructions and utilizing these tools, users can ensure that the laser cutter is properly calibrated and aligned for efficient metal cutting.

Is there a limit to the number of materials stored in the material compatibility and settings database?

The material compatibility database for laser cutters has a limitation on the number of materials it can store. Regular maintenance is crucial for laser cutters to ensure optimal performance and prevent issues. By keeping the machine well-maintained, you can minimize the risks of material incompatibility and maximize the lifespan of the equipment.

It’s recommended to consult the manufacturer’s guidelines and perform routine checks to avoid any potential problems.

How does intelligent power control and beam quality monitoring contribute to efficient metal cutting?

Intelligent power control and beam quality monitoring are crucial for efficient metal cutting. By monitoring and adjusting the power output, the laser cutter ensures optimal cutting conditions, minimizing waste and maximizing productivity.

Beam quality monitoring helps maintain consistent and precise cutting results, reducing errors and rework.

Additionally, remote monitoring and troubleshooting support enable quick identification and resolution of any issues, minimizing downtime and improving overall efficiency.

What kind of support is offered for remote monitoring and troubleshooting of laser cutter issues?

Imagine you’re a laser cutter operator, facing a perplexing issue. Don’t fret! With our remote troubleshooting support, you can resolve problems swiftly and efficiently.

By utilizing remote monitoring capabilities, you gain real-time insights into your laser cutter’s performance, enabling prompt identification of potential issues. This not only saves valuable time but also minimizes costly downtime.

Embrace the benefits of remote monitoring and experience a seamless troubleshooting process, ensuring optimal metal cutting efficiency.

Conclusion

Congratulations! You’ve now learned about the top-notch features that make laser cutters efficient for metal cutting. These machines ensure precise and flawless results with real-time error detection and automatic calibration. The cutting process is enhanced by the material compatibility database and intelligent power control. Optimal performance is guaranteed with the integrated cooling and ventilation system. And let’s not forget the remote monitoring and troubleshooting support, which saves you valuable time and effort. These laser cutters are truly a game-changer, revolutionizing the metal cutting industry like never before!