Are you the captain of your laser cutter ship, navigating through the vast sea of projects with precision and finesse? Just as a skilled sailor must be well-versed in the rules of the sea, you too must familiarize yourself with the standards and regulations that govern laser cutter troubleshooting. Like a compass guiding you through uncharted waters, these guidelines ensure smooth sailing in your laser cutting endeavors.

In this article, we will delve into eight laser cutter troubleshooting standards and regulations that will not only keep you on course but also safeguard your well-being and that of your crew. From conducting regular maintenance checks to staying up to date with industry regulations, we will equip you with the knowledge and technical expertise necessary to tackle common cutting issues, address laser alignment problems, and handle emergencies and malfunctions safely.

So batten down the hatches, secure your safety goggles, and prepare to embark on a journey where precision meets regulation. Let’s dive into the world of laser cutter troubleshooting and ensure your success on the high seas of fabrication.

Key Takeaways

- Regular maintenance checks and equipment calibration are necessary for efficient and high-performance laser cutting.

- Following proper safety protocols and wearing personal protective equipment (PPE) is crucial to prevent accidents.

- Troubleshooting common cutting issues involves addressing power fluctuations and optimizing cutting parameters.

- Staying up to date with industry regulations and standards is important for a safe and compliant working environment.

Conduct Regular Maintenance Checks

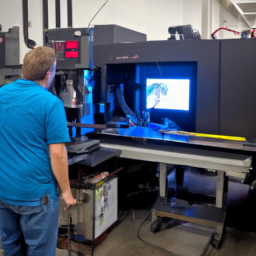

It’s imperative to consistently perform regular maintenance checks on the laser cutter to ensure compliance with standards and regulations. By taking preventive measures and conducting routine inspections, you can identify and address any issues before they become major problems.

Regular maintenance checks involve inspecting and cleaning the machine thoroughly, ensuring that all components are in proper working order. Additionally, equipment calibration is essential to ensure accurate and precise cutting. This involves adjusting the laser power, speed, and focus to achieve optimal results.

Regular maintenance checks and equipment calibration not only help maintain the efficiency and performance of the laser cutter, but also contribute to the safety of the operators and compliance with regulations. Following proper safety protocols is crucial to prevent accidents and ensure a secure working environment, as we’ll discuss in the subsequent section.

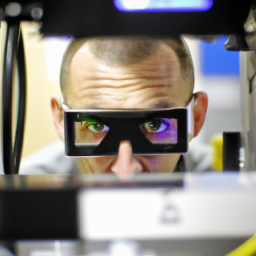

Follow Proper Safety Protocols

Make sure to adhere to the established safety protocols to ensure a smooth and accident-free laser cutting experience. To guarantee your safety and the safety of others, it’s crucial to undergo proper training before operating a laser cutter. Familiarize yourself with the equipment and its potential risks.

Regularly inspect the laser cutter for any signs of damage or malfunctioning parts. This includes checking the alignment of mirrors, ensuring proper ventilation, and inspecting the laser power supply. Additionally, always wear appropriate personal protective equipment (PPE) such as safety goggles and gloves.

Lastly, make sure to keep the work area clean and organized to minimize potential hazards.

By following these safety protocols and conducting equipment inspections, you can prevent accidents and ensure a productive laser cutting process.

Moving on to troubleshooting common cutting issues, it’s important to address any problems that may arise.

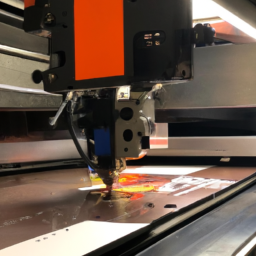

Troubleshoot Common Cutting Issues

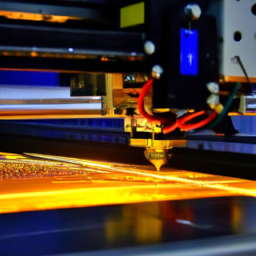

To ensure a successful cutting process, you need to quickly identify and address common issues that may arise, allowing you to achieve precise and flawless results.

One common issue to troubleshoot is power fluctuations. These fluctuations can affect the laser cutter’s performance and result in inconsistent cuts. To tackle this problem, check the power supply and ensure it’s stable and properly grounded.

Additionally, optimize cutting parameters such as speed, power, and focus to ensure the laser is cutting at the appropriate settings for the material being used. Adjusting these parameters can help eliminate issues like incomplete cuts or excessive charring.

By troubleshooting power fluctuations and optimizing cutting parameters, you can minimize the risk of errors and produce high-quality cuts.

Now, let’s move on to addressing laser alignment problems.

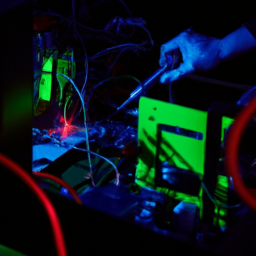

Address Laser Alignment Problems

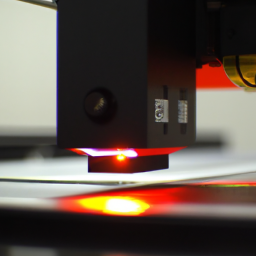

Ensuring precise alignment of your laser beam is essential for achieving accurate and professional cutting results. Laser calibration plays a crucial role in maintaining alignment and should be regularly performed to ensure optimal performance. One common issue that can arise is beam divergence, where the laser beam spreads out as it travels, resulting in a larger cutting area than intended. To address this problem, you can adjust the focus of the laser beam to minimize divergence. Additionally, checking and adjusting the mirrors and lenses in the optical path can help maintain proper alignment. Remember to follow the manufacturer’s guidelines and safety regulations when performing any adjustments or maintenance tasks. By addressing laser alignment problems promptly, you can ensure consistent and precise cutting results. In case of emergencies or malfunctions, it is important to handle them safely to prevent any accidents or further damage to the laser cutter.

| Issue | Possible Cause | Solution |

|---|---|---|

| Beam Divergence | Improper focus adjustment | Adjust the focus of the laser beam to minimize divergence |

| Beam Divergence | Misaligned mirrors or lenses | Check and adjust the mirrors and lenses in the optical path |

| Beam Divergence | Dirty or damaged optics | Clean or replace the optics as necessary |

To handle emergencies and malfunctions safely, follow the appropriate protocols and guidelines provided by the manufacturer.

Handle Emergencies and Malfunctions Safely

In case of emergencies or malfunctions, it’s crucial to handle them safely and follow the appropriate protocols and guidelines provided by the manufacturer to ensure the well-being of both the operator and the equipment.

To effectively respond to emergencies, you should have a clear understanding of the emergency response procedures. This includes knowing how to shut down the equipment quickly and safely. Ensure that all operators are trained in these procedures and have access to emergency contact information.

Additionally, it’s important to regularly inspect and maintain the laser cutter to minimize the risk of malfunctions. This involves conducting routine checks, such as inspecting the power supply and cooling system, and promptly addressing any issues that arise.

By prioritizing safety and being prepared for emergencies, you can minimize downtime and ensure the longevity of your equipment. Moving forward, it’s crucial to stay up to date with industry regulations and standards to maintain a safe working environment.

Stay Up to Date with Industry Regulations and Standards

Keep yourself informed and up to date with the latest industry regulations and standards to ensure a safe and compliant working environment. Staying up to date with industry compliance is crucial for laser cutter operators.

Regulatory updates are constantly being made to enhance safety measures and address emerging risks. By staying informed, you can ensure that your laser cutter is operating within the legal parameters and meeting all necessary safety standards. Regularly check for updates from regulatory bodies and industry associations to stay ahead of any changes.

It’s also important to attend seminars, workshops, and training sessions to stay informed about the latest guidelines and best practices. Remember, maintaining compliance not only protects your own safety but also helps to safeguard the well-being of others who work with or around laser cutters.

Frequently Asked Questions

What are the consequences of not following proper safety protocols while using a laser cutter?

Not following proper safety protocols while using a laser cutter can have severe consequences. Ignoring safety measures puts you at risk of serious injuries, such as burns, eye damage, and even fire hazards.

Without proper training, you may not be aware of the potential dangers or how to handle emergencies. Safety protocols are crucial to protect yourself and others in the workspace.

It’s essential to prioritize safety and undergo thorough training to ensure a secure laser cutting environment.

How often should regular maintenance checks be conducted on a laser cutter?

Regular maintenance checks should be conducted on a laser cutter at least once every three months to ensure optimal performance and prevent potential issues. These checks involve inspecting the machine for any signs of wear or damage, cleaning the optics and ventilation system, and verifying the alignment of mirrors and lenses. It’s crucial to follow the recommended laser cutter maintenance frequency to prolong the lifespan of the equipment and maintain a safe working environment.

What are some common cutting issues that can arise with a laser cutter?

When troubleshooting a laser cutter, you may encounter common cutting issues that require your attention. These can include problems like uneven cuts, charring or burning of materials, or incomplete cuts.

To address these issues, you can try troubleshooting techniques such as adjusting the laser power, checking the focus, or cleaning the lens. By identifying and resolving these common errors, you can ensure optimal performance and accuracy from your laser cutter.

How can laser alignment problems affect the quality of the cuts?

To achieve flawless laser cuts, laser alignment is crucial. Imagine trying to hit a bullseye with a crooked arrow – the precision would be off. Similarly, laser alignment problems can greatly affect the quality of the cuts.

When the laser beam is not properly aligned, it may deviate from the intended path, resulting in inaccurate cuts and compromised cutting precision.

Ensuring meticulous laser alignment is essential for achieving the desired level of accuracy and precision in laser cutting operations.

Are there any upcoming changes or updates to industry regulations and standards for laser cutters?

Industry updates and future regulations for laser cutters are constantly being developed to ensure safety and efficiency. These updates aim to address emerging technologies, improve user experience, and enhance overall performance.

It is crucial to stay informed about these changes to comply with the latest standards and regulations. By keeping up with industry updates, you can ensure that your laser cutter operates within the prescribed guidelines, reducing risks and maximizing productivity.

Conclusion

In conclusion, following the 8 laser cutter troubleshooting standards and regulations is crucial for maintaining the safety and efficiency of your laser cutting machine. By conducting regular maintenance checks and adhering to proper safety protocols, you can ensure the smooth operation of your equipment.

Troubleshooting common cutting issues, addressing laser alignment problems, and handling emergencies and malfunctions safely are essential for minimizing downtime and maximizing productivity.

Staying up to date with industry regulations and standards is like a compass guiding you through the complex world of laser cutting, helping you navigate with precision and accuracy.