Are you aware of the intricate dance between safety and creativity in the world of laser cutting? As a laser cutter enthusiast, you understand the importance of maintaining a safe and healthy work environment. That’s why it’s crucial to familiarize yourself with the 8 Laser Cutter Ventilation Standards and Regulations that you should follow.

These guidelines, carefully crafted by experts in the field, ensure that your workspace remains free from harmful fumes and particles. By implementing an effective ventilation system, utilizing exhaust fans, and incorporating a filtration system, you can safeguard yourself and those around you from potential health hazards.

Regular maintenance and adherence to local and industry regulations are also essential to guarantee a safe and compliant working environment. So, join us as we explore these standards and regulations, equipping you with the knowledge to create, design, and cut with confidence.

Key Takeaways

- Proper ventilation is essential for safe and efficient laser cutting.

- Select a ventilation system designed for laser cutters with noise-reducing features and powerful fans.

- Regular maintenance and cleaning of the ventilation system are crucial for optimal performance.

- Compliance with local and industry regulations ensures safety, air quality, and employee training.

Understand the Importance of Proper Ventilation for Laser Cutters

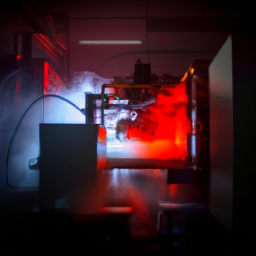

Proper ventilation is crucial for laser cutters as it not only ensures the removal of harmful fumes and particles, but also helps maintain optimal operating conditions and prolongs the lifespan of the machine.

The importance of ventilation in the laser cutting process cannot be overstated. Inadequate ventilation can lead to a range of health risks, including respiratory issues, eye irritation, and even long-term complications.

Laser cutting produces hazardous fumes, such as volatile organic compounds and toxic gases, which must be properly extracted to protect both the operator and the environment.

Additionally, without proper ventilation, the accumulation of debris and particles can negatively impact the performance and accuracy of the laser cutter.

To ensure a safe and efficient working environment, it’s essential to install an effective ventilation system that efficiently removes fumes and maintains a clean workspace.

Install an Effective Ventilation System

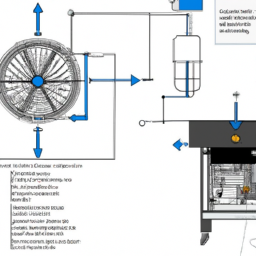

Is it possible to install an efficient ventilation system for a laser cutter without compromising safety? Absolutely! When it comes to laser cutter ventilation, reducing noise levels and ensuring proper airflow are key.

To achieve this, start by selecting a ventilation system that’s specifically designed for laser cutters. These systems are equipped with noise-reducing features and powerful fans to effectively remove fumes and maintain a safe working environment.

Proper installation is crucial to maximize the system’s efficiency. Make sure to position the exhaust vents strategically to minimize noise and ensure that the air is flowing properly. Additionally, consider using flexible ducting to further reduce noise levels.

By installing an effective ventilation system, you can protect yourself from harmful fumes while maintaining a quiet and efficient working space.

Now, let’s move on to the next section about using exhaust fans to remove harmful fumes.

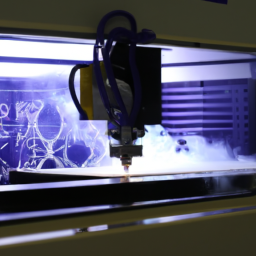

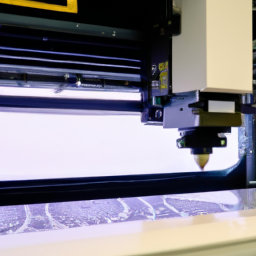

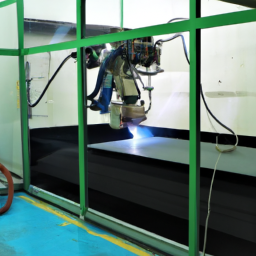

Use Exhaust Fans to Remove Harmful Fumes

To effectively remove harmful fumes, make sure to utilize exhaust fans that are specifically designed for your laser cutting setup. These fans play a crucial role in maintaining exhaust fan safety and ensuring the effectiveness of your ventilation system. By properly removing the fumes generated during laser cutting, you can protect yourself and those around you from potential health risks.

To give you an idea of the importance of exhaust fan safety and ventilation system effectiveness, let’s take a look at the following table:

| Exhaust Fan Safety | Ventilation System Effectiveness |

|---|---|

| Reduces health risks associated with fume inhalation | Ensures proper air circulation |

| Removes toxic gases and particles from the work area | Prevents the buildup of fumes |

| Helps maintain a clean and healthy working environment | Minimizes the risk of fire or explosion |

| Protects the laser cutter from damage caused by excessive heat | Improves overall cutting quality |

| Contributes to compliance with safety regulations | Enhances the lifespan of the laser cutter |

By understanding the importance of exhaust fan safety and ventilation system effectiveness, you can now implement a filtration system to remove particles and further enhance the air quality in your workspace.

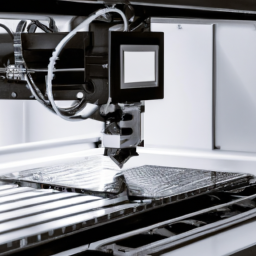

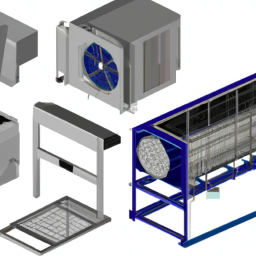

Implement a Filtration System to Remove Particles

Imagine transforming your workspace into a serene oasis by implementing a filtration system that effortlessly removes particles and enhances the air quality.

One effective way to achieve this is by implementing HEPA filters in your laser cutter ventilation system. HEPA (High-Efficiency Particulate Air) filters are designed to capture even the tiniest particles, ensuring that the air you breathe is clean and safe. These filters are highly efficient and can effectively trap particles as small as 0.3 microns in size.

By regularly monitoring the air quality and replacing the filters when necessary, you can maintain a healthy and pollutant-free environment.

With an efficient filtration system in place, you can now move on to the next important step of regularly maintaining and cleaning the ventilation system to ensure its optimal performance.

Regularly Maintain and Clean the Ventilation System

Regularly maintaining and cleaning your filtration system will ensure that it operates at its best, keeping the air in your workspace clean and refreshing. Proper ventilation system maintenance is crucial for optimal performance and longevity.

Start by inspecting and cleaning the filters regularly, as they tend to accumulate dust and debris over time. Replace them as necessary to maintain proper airflow and filtration efficiency. Additionally, check the fan and motor for any signs of wear or damage and clean them if needed. It’s important to follow the manufacturer’s instructions for cleaning procedures to avoid damaging the system.

By regularly maintaining and cleaning your ventilation system, you can ensure that it remains effective in removing harmful particles from the air.

Moving forward, let’s discuss the importance of following local and industry regulations for laser cutter ventilation.

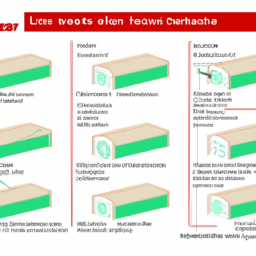

Follow Local and Industry Regulations for Laser Cutter Ventilation

Make sure you’re aware of and comply with the local and industry rules for keeping the air in your workspace clean and refreshing when using a laser cutter. Compliance with environmental regulations is essential to ensure the safety of both the operators and the environment. These regulations may vary depending on your location, so it’s crucial to familiarize yourself with the specific requirements in your area. Implementing safety measures for laser cutter ventilation is vital to minimize the risk of exposure to harmful fumes and ensure proper air circulation. This can include installing a proper exhaust system, using filters to capture particulate matter, and regularly monitoring air quality. By following these regulations and taking necessary safety precautions, you can create a healthier and safer working environment for yourself and those around you.

| Local Regulations | Industry Regulations |

|---|---|

| Set limits on air pollutant emissions | Specify ventilation requirements |

| Mandate regular inspection and maintenance | Establish guidelines for air quality testing |

| Require proper disposal of hazardous materials | Provide recommendations for filtration systems |

| Enforce penalties for non-compliance | Promote employee training on ventilation safety |

| Promote education and awareness | Encourage best practices for air circulation |

Frequently Asked Questions

What are the potential health risks associated with improper ventilation in laser cutter operations?

Improper ventilation in laser cutter operations can pose potential health risks that mustn’t be overlooked. Without proper ventilation, harmful fumes and particulates released during the cutting process can accumulate in the workspace. This can lead to respiratory issues, eye irritation, and even long-term health complications. It’s crucial to prioritize adequate ventilation systems to ensure a safe working environment and protect both the operators and those nearby from the dangers associated with inadequate air quality.

Are there any specific ventilation requirements for different types of materials being used with laser cutters?

To ensure the safety of your laser cutter operations, it’s crucial to adhere to specific material requirements and prioritize proper ventilation. Different materials have varying properties that can generate hazardous fumes or particles when cut with a laser. By implementing appropriate ventilation systems, you can effectively remove these potentially harmful substances from the air, protecting both yourself and those around you.

Following these specific material requirements and maintaining proper ventilation is essential for a safe and healthy working environment.

How often should the ventilation system be inspected and tested for optimal performance?

Like a well-oiled machine, your ventilation system requires regular maintenance to ensure optimal performance. Testing and inspecting the system should be done at least once a year, but it’s best to schedule these checks every six months.

This meticulous approach ensures that any issues are identified and resolved promptly, preventing potential hazards and ensuring the smooth operation of your laser cutter. Adhering to this ventilation system maintenance routine guarantees a safe and efficient working environment.

Are there any alternative methods or technologies available for laser cutter ventilation?

There are indeed alternative methods and advanced technologies available for laser cutter ventilation. One option is the use of fume extraction systems, which are designed to remove hazardous fumes and particles from the air. These systems utilize advanced filters and fans to effectively capture and remove the pollutants generated during laser cutting.

Another alternative is the installation of local exhaust ventilation, which involves the use of hoods and ductwork to directly capture and remove fumes at the source. These alternative methods and technologies can greatly enhance the ventilation efficiency and ensure a safe working environment.

What are the consequences of not following the local and industry regulations for laser cutter ventilation?

Not following the local and industry regulations for laser cutter ventilation can have serious consequences and health risks. By neglecting these regulations, you’re putting yourself and others at risk of inhaling harmful fumes and particles emitted during the laser cutting process. These fumes can contain toxic substances and carcinogens that can lead to respiratory issues, eye irritation, and even long-term health problems.

Additionally, not following ventilation standards may result in poor air quality and increased fire hazards in the workspace.

Conclusion

In conclusion, it’s crucial for you to prioritize proper ventilation when using laser cutters. By installing an effective ventilation system and using exhaust fans, you can effectively remove harmful fumes and ensure a safe working environment.

Implementing a filtration system will further remove particles, enhancing the quality of air. Regular maintenance and cleaning of the ventilation system are essential to ensure its efficiency.

Lastly, always follow local and industry regulations to ensure compliance and safety. Imagine ventilation as the oxygen mask in an airplane, providing a steady flow of clean air to keep you safe and protected from harmful substances.