Are you ready to unlock the dazzling potential of jewelry design? Picture a symphony of precision, versatility, and efficiency. Imagine a tool that can transform raw materials into exquisite works of art with a single stroke. Welcome to the world of laser cutting.

Like a maestro conducting a masterpiece, laser cutting orchestrates the creation of stunning jewelry designs with unrivaled finesse. With its ability to slice through various materials like a hot knife through butter, laser cutting offers endless possibilities for your creative vision. Say goodbye to tedious manual cutting methods and embrace the future of jewelry design.

From delicate filigree to bold statement pieces, laser cutting delivers unparalleled customization and personalization, ensuring your creations stand out from the rest. Not only does it enhance the quality of your products, but it also streamlines production, saving you time and money.

Join us as we explore the eight reasons why laser cutting is the ultimate tool for jewelry design. Prepare to be amazed.

Key Takeaways

- Laser cutting in jewelry design offers precision up to 0.1mm, enabling intricate and impossible designs.

- Laser cutting allows for versatility by working on metals like gold, silver, and platinum, as well as different gemstones, adding color and texture.

- Laser cutting improves efficiency in production by minimizing errors, saving time with quick cutting of complex designs, and optimizing material usage to minimize waste.

- Laser cutting in jewelry design allows for customization and personalization, with options for precise engraving, etching, and the creation of unique shapes, patterns, and textures.

Precision in Cutting

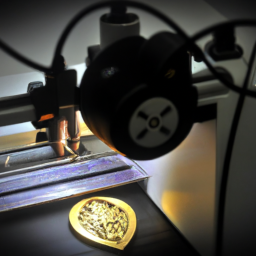

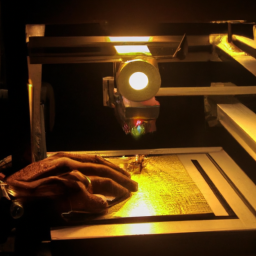

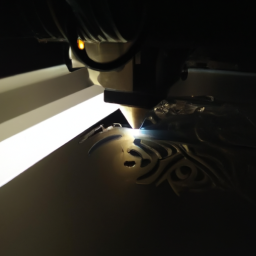

Laser cutting brings a touch of magic to jewelry design with its unparalleled precision. The precision in laser cutting allows for the creation of intricate designs that would be impossible to achieve with traditional methods.

The laser beam is incredibly precise, cutting through materials with an accuracy of up to 0.1mm. This level of precision ensures that even the most delicate and intricate designs are executed flawlessly. Whether it’s a complex filigree pattern or a tiny intricate shape, laser cutting can handle it all with ease.

The ability to create such precise designs opens up a world of possibilities for jewelry designers, allowing them to push the boundaries of their creativity. With precision as its foundation, laser cutting sets the stage for the next section about the versatility in material.

Versatility in Material

When it comes to cutting various metals, laser cutting offers you the versatility you need in jewelry design.

With laser cutting, you can effortlessly create intricate patterns and designs on metals such as gold, silver, and platinum.

Additionally, laser cutting allows you to work with different gemstones, giving you the freedom to incorporate a wide range of colors and textures into your jewelry pieces.

So whether you’re looking to create a delicate gold necklace or a bold statement ring with vibrant gemstones, laser cutting provides the flexibility to bring your vision to life.

Cutting Various Metals

While using laser cutting technology, you can effortlessly create intricate jewelry designs from a variety of metals, eliciting awe and admiration from your audience.

Laser cutting offers precise cutting techniques that allow you to work with different metals such as gold, silver, and platinum, giving you endless possibilities for your jewelry creations.

Whether you want to experiment with bold, statement pieces or delicate, intricate designs, laser cutting can bring your vision to life.

With jewelry trends constantly evolving, laser cutting provides the flexibility to adapt and stay ahead of the curve.

Now that you’ve mastered cutting various metals, let’s delve into the exciting world of working with different gemstones and how laser cutting can enhance their beauty and sparkle.

Working with Different Gemstones

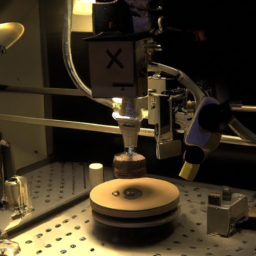

Elevate your craftsmanship by exploring the enchanting world of different gemstones. Each radiant stone becomes a sparkling symbol of elegance and sophistication. Laser cutting is ideal for jewelry design because it allows for precise gemstone selection and setting.

With laser technology, you can easily cut and shape gemstones to fit perfectly into your design, enhancing its overall beauty. Whether you’re working with delicate diamonds or vibrant colored stones, laser cutting ensures that each gemstone is flawlessly incorporated into your jewelry piece.

The laser’s accuracy and precision enable you to create intricate designs and patterns that highlight the unique characteristics of each gemstone. By utilizing laser cutting, you can achieve a level of craftsmanship that is unparalleled in traditional jewelry making techniques.

As we delve into the next section about efficiency in production, you’ll discover how laser cutting revolutionizes the jewelry industry.

Efficiency in Production

Moreover, laser cutting allows for increased productivity and streamlined production processes in jewelry design. With the use of laser cutting technology, jewelry designers can significantly reduce production time and increase productivity. Here are four reasons why laser cutting is ideal for efficient jewelry production:

-

Precision: Laser cutting offers precise and accurate cuts, ensuring consistent results and minimizing errors in jewelry making.

-

Speed: Laser cutting machines can quickly cut complex designs and intricate patterns, saving time compared to traditional methods.

-

Material Optimization: Laser cutting allows for efficient material usage, minimizing waste and maximizing the use of expensive gemstones and metals.

-

Repetition: Laser cutting machines can easily replicate designs, making it ideal for mass production and meeting high demand.

With these advantages, laser cutting revolutionizes the jewelry industry, providing faster production times and increased productivity.

As we transition to the next section on customization and personalization, laser cutting enables designers to create unique and bespoke pieces for their customers.

Customization and Personalization

When it comes to customization and personalization in jewelry design, laser cutting offers endless possibilities. With laser cutting, you have the freedom to create unique designs that truly stand out.

Additionally, laser cutting allows for precise engraving and etching options, allowing you to add intricate details and personal touches to your jewelry pieces. Whether it’s a special message, a meaningful symbol, or a delicate pattern, laser cutting can bring your vision to life with stunning precision and craftsmanship.

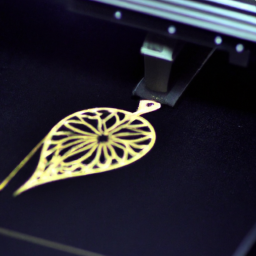

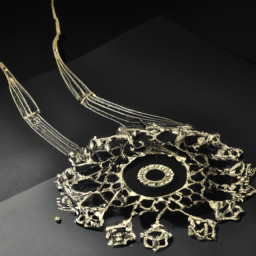

Creating Unique Designs

Imagine the endless possibilities of crafting one-of-a-kind jewelry designs with laser cutting. Laser cutting allows you to create unique designs that are not easily achievable with traditional jewelry making techniques. With laser cutting, you can experiment with intricate patterns, shapes, and textures, bringing your design inspirations to life. The precision and accuracy of laser cutting ensure that every detail of your design is captured, resulting in stunning and flawless pieces.

To give you an idea of the creative potential of laser cutting in jewelry design, here is a table showcasing different design elements that can be achieved:

| Design Element | Description | Example |

|---|---|---|

| Intricate Patterns | Laser cutting can create intricate and delicate patterns that are difficult to achieve by hand. | A necklace with a lace-like pattern that adds a touch of elegance to any outfit. |

| Unique Shapes | Laser cutting allows for the creation of unique and unconventional shapes, giving your jewelry a distinct look. | A pair of earrings in the shape of a feather, adding a whimsical touch to your style. |

| Textured Surfaces | Laser cutting can add textures to your jewelry, making it more visually interesting and tactile. | A bracelet with a laser-cut texture resembling tree bark, adding a natural and rustic charm to your accessories. |

By utilizing laser cutting, you can not only create these unique designs but also explore the various engraving and etching options available, adding even more personalization to your jewelry pieces.

Engraving and Etching Options

Incorporating engraving and etching techniques into your designs adds an extra layer of personalization and intricacy to your jewelry pieces. Laser cutting technology provides a precise and efficient way to achieve these techniques, offering endless possibilities for creating unique and eye-catching designs.

Engraving techniques involve using laser beams to cut shallow grooves into the surface of the jewelry, creating intricate patterns, names, or messages. On the other hand, etching processes utilize the laser to remove a thin layer of material, resulting in a textured or frosted appearance.

Whether you want to add delicate engravings or intricate etchings to your jewelry, laser cutting provides the precision and flexibility needed to bring your designs to life. Moreover, the cost-effectiveness of laser cutting makes it an ideal choice for jewelry designers looking to enhance their creations without breaking the bank.

Cost-Effectiveness

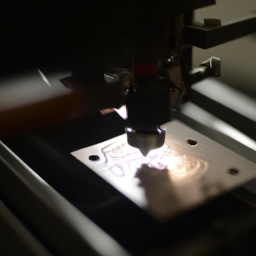

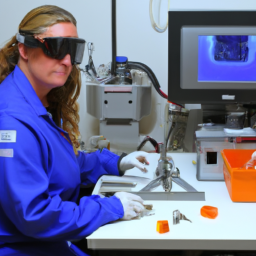

When it comes to cost-effectiveness, laser cutting offers significant advantages. Firstly, it reduces labor costs as it requires minimal human intervention. With the use of advanced technology, the laser can precisely cut intricate designs, eliminating the need for manual labor.

Secondly, laser cutting minimizes material wastage by efficiently utilizing the raw materials. The laser beam is highly focused, resulting in precise cuts and minimizing the amount of material that goes to waste.

Overall, laser cutting proves to be a cost-effective option for jewelry designers, allowing them to allocate their resources efficiently and produce high-quality pieces.

Reduced Labor Costs

Little did jewelry designers know that with laser cutting, they could finally save money on labor costs. Laser cutting technology has revolutionized the jewelry design industry by reducing the time and effort required for intricate designs. Here are three reasons why laser cutting is a game-changer for reducing labor costs in jewelry design:

-

Increased Precision: Laser cutting allows for precise cuts and intricate detailing, eliminating the need for manual labor-intensive tasks like filing and polishing.

-

Streamlined Production: Laser cutting machines can quickly and accurately cut multiple pieces simultaneously, significantly improving efficiency and reducing the number of hours spent on production.

-

Minimized Errors: With laser cutting, the risk of human error is greatly reduced. The machines follow programmed designs precisely, ensuring consistent and accurate results every time.

By utilizing laser cutting technology, jewelry designers can now save time and money on labor costs while maintaining the highest level of precision and quality. This efficiency also extends to minimizing material wastage, which will be explored in the next section.

Less Material Wastage

By utilizing laser cutting technology, you can significantly reduce material wastage in jewelry production. Laser cutting allows for precise and accurate cuts, minimizing the amount of material that goes to waste. Traditional jewelry production methods often result in a significant amount of material being discarded due to human error or the limitations of tools. However, with laser cutting, you can maximize the use of your materials, ultimately saving on costs and promoting environmental sustainability.

To illustrate the impact of laser cutting on material wastage, consider the following table:

| Traditional Jewelry Production | Laser Cutting |

|---|---|

| High material wastage | Minimal wastage |

| Increased production costs | Cost savings |

| Environmental impact | Environmental sustainability |

| Inefficient use of resources | Efficient resource utilization |

By reducing material wastage through laser cutting, you not only save on costs but also contribute to a more sustainable and environmentally friendly jewelry production process. This improved efficiency sets the stage for the subsequent section on improved product quality.

Improved Product Quality

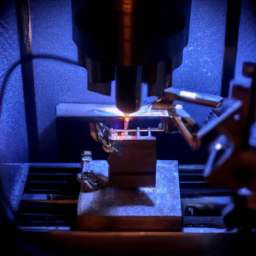

When it comes to improved product quality in jewelry design, laser cutting offers a higher level of detail that is unparalleled. The precision and accuracy of laser cutting technology allows for intricate designs and delicate patterns to be achieved with ease.

Additionally, laser cutting ensures consistency in design elements, eliminating any variations or imperfections that can occur with manual cutting methods. With laser cutting, you can be confident that your jewelry pieces will have a flawless finish and a stunning level of detail that will captivate anyone who sees them.

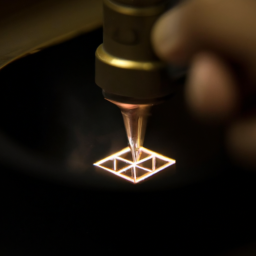

Higher Level of Detail

With laser cutting, you can achieve a much higher level of detail in your jewelry designs. The precision of laser cutting allows for intricate and precise designs that would be difficult to achieve with traditional methods. Here are three ways laser cutting enhances the level of detail in jewelry design:

-

Fine Lines: Laser cutting can create incredibly thin lines, allowing for delicate and intricate patterns in your jewelry.

-

Intricate Shapes: Laser cutting can cut through metal with extreme precision, making it possible to create complex shapes and designs that would be challenging to achieve by hand.

-

Intricate Engravings: Laser cutting can also be used to engrave intricate patterns and designs onto jewelry, adding an extra level of detail and personalization.

By utilizing laser cutting technology, jewelry designers can achieve a higher level of precision and create intricate designs that were once only possible through painstaking manual labor. This level of detail contributes to the overall consistency in design elements.

Consistency in Design Elements

To achieve a consistent and cohesive look in your jewelry creations, it’s important to pay attention to every element of the design. Laser cutting provides a precise and efficient way to ensure consistency in design elements, saving you time and effort. With laser cutting, you can easily replicate intricate patterns, shapes, and textures, resulting in a harmonious collection of jewelry pieces. The use of computerized design software allows you to create and modify designs with ease, ensuring that each piece adheres to your desired aesthetic. Additionally, laser cutting allows for the creation of intricate designs that would be difficult to achieve by hand. By utilizing this time-saving technique, you can streamline your production process and focus on other aspects of your jewelry business.

| Design Element | Laser Cutting Benefits | Handmade Limitations |

|---|---|---|

| Intricate Patterns | Precise replication | Time-consuming |

| Shapes and Textures | Efficient production | Inconsistency |

| Computerized Design | Easy modification | Limited complexity |

| Aesthetic Adherence | Consistent results | Human error |

| Streamlined Process | Time-saving technique | Slower production |

Frequently Asked Questions

How does laser cutting technology ensure precision in jewelry design?

Laser cutting technology ensures precision in jewelry design by offering numerous benefits. With laser cutting precision, intricate and delicate designs can be achieved with utmost accuracy. The laser beam allows for precise cuts and intricate etchings, resulting in clean edges and precise details.

This technology also allows for customization and the ability to work with a wide range of materials, giving jewelry designers endless creative possibilities. The precision offered by laser cutting technology elevates the quality and craftsmanship of jewelry design to new heights.

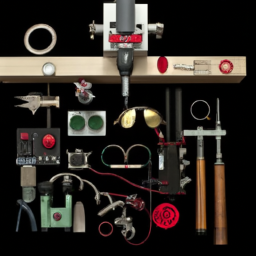

What types of materials can be used with laser cutting in jewelry design?

Laser cutting applications in jewelry design are vast and varied, allowing for the use of numerous materials. Laser cutting techniques enable the precision cutting of materials like gold, silver, acrylic, wood, and even leather. This versatility opens up a world of possibilities for designers, as they can experiment with different textures, colors, and finishes.

Laser cutting technology ensures that each material is handled with care, resulting in intricately crafted jewelry pieces that are both visually stunning and durable.

How does laser cutting improve the efficiency of jewelry production?

Laser cutting significantly improves the efficiency of jewelry production by revolutionizing traditional manufacturing processes. With laser cutting, intricate designs can be accurately and precisely cut in a fraction of the time compared to manual methods.

This technology allows for increased production rates, reducing the overall manufacturing time. Moreover, laser cutting eliminates the need for extensive manual labor, resulting in cost savings and increased productivity. Its advantages in jewelry production make it an indispensable tool for designers and manufacturers alike.

Can laser cutting be used to create custom and personalized jewelry designs?

Yes, laser cutting can be used to create custom and personalized jewelry designs. Laser cutting is perfect for producing intricate designs in jewelry making. The advantages of using laser cutting in jewelry design are numerous.

It allows for precise and detailed cuts, ensuring accuracy and consistency in the final piece. Laser cutting also offers versatility in materials, allowing jewelers to work with a wide range of metals and other materials. With laser cutting, the possibilities for custom and personalized jewelry designs are endless.

Is laser cutting a cost-effective option for jewelry designers?

Laser cutting is indeed a cost-effective option for jewelry designers when compared to traditional manufacturing techniques. By utilizing laser technology, designers can significantly reduce production costs. Laser cutting allows for precise and intricate designs without the need for expensive molds or tools. Additionally, the speed and efficiency of laser cutting enable designers to create custom and personalized jewelry at a faster rate, resulting in increased productivity and potential cost savings.

Embracing laser cutting is a smart choice for jewelry designers looking to optimize their budget and create unique pieces with ease.

Conclusion

Congratulations! You’ve now discovered the dazzling world of laser cutting for jewelry design. With its precise cuts that are as sharp as a diamond’s edge, laser cutting guarantees perfection in every piece.

Its versatility allows you to experiment with a wide range of materials, unleashing your creativity like a painter’s brush on a canvas.

Say goodbye to tedious production processes as laser cutting ensures efficiency, saving you valuable time and energy.

And let’s not forget the ability to personalize and customize your designs, making each piece a true masterpiece.

Not only is laser cutting cost-effective, but it also enhances the quality of your products, ensuring flawless craftsmanship.

So, embrace the brilliance of laser cutting and let your jewelry designs shine like stars in the night sky.