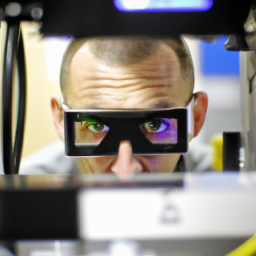

Is your laser cutter giving you sleepless nights? Are you tired of dealing with costly repairs and frustrating downtime? Look no further, because troubleshooting is here to save the day! In fact, troubleshooting is like a superhero for your laser cutter, swooping in to identify and resolve technical issues with lightning speed.

This essential practice not only prevents costly repairs and downtime, but also optimizes cutting performance, ensures safety and compliance, and extends the lifespan of your beloved machine. With troubleshooting, you can improve efficiency and productivity, making your laser cutter the ultimate productivity powerhouse.

So, buckle up and get ready to embark on a journey of technical expertise, as we explore the 8 reasons why troubleshooting is absolutely essential for your laser cutter. Get ready to conquer those technical challenges and unleash the full potential of your laser cutter!

Key Takeaways

- Troubleshooting prevents costly repairs and downtime.

- Regular troubleshooting keeps laser cutter running smoothly and efficiently.

- Troubleshooting optimizes cutting performance by ensuring peak efficiency.

- Following safety guidelines and regulations reduces maintenance costs and meets industry standards.

Identify and Resolve Technical Issues

Now, let’s dive into how to identify and fix any technical issues that may arise with your laser cutter. Troubleshooting techniques are essential for maintaining the optimal performance of your machine. By diligently troubleshooting, you can quickly identify and resolve any technical problems, ensuring minimal downtime and maximum productivity.

One of the key benefits of troubleshooting is that it allows you to pinpoint the root cause of the issue. This enables you to take precise corrective actions, whether it’s adjusting settings, replacing faulty components, or updating software. Additionally, troubleshooting helps you prevent costly repairs and downtime by addressing issues before they escalate into major problems.

By regularly troubleshooting your laser cutter, you can keep it running smoothly and efficiently, minimizing the risk of unexpected breakdowns. Transitioning into the subsequent section, these techniques will also help you prevent costly repairs and downtime.

Prevent Costly Repairs and Downtime

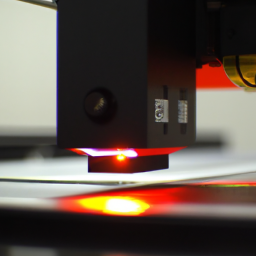

Avoiding timely maintenance can lead to expensive repairs and unnecessary downtime, leaving you frustrated and unable to meet your project deadlines. By regularly troubleshooting your laser cutter, you can reduce maintenance costs and increase machine uptime.

Identifying and resolving technical issues before they escalate can save you from costly repairs that could have been prevented. By conducting routine checks on the machine’s components, such as the laser tube, mirrors, and lenses, you can identify any potential problems early on and address them promptly. This proactive approach not only prevents major breakdowns but also minimizes the duration of downtime, allowing you to resume your cutting operations quickly.

Moreover, troubleshooting helps optimize cutting performance by ensuring the machine is operating at its peak efficiency.

Transitioning into the next section, let’s explore how you can optimize cutting performance and achieve superior results.

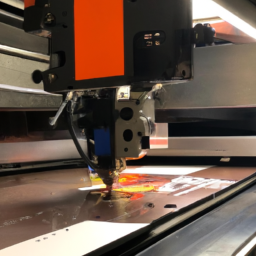

Optimize Cutting Performance

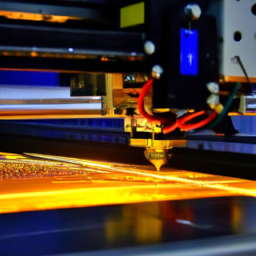

To get the most out of your machine and enjoy superior cutting results, it’s important to optimize its performance. By optimizing the performance of your laser cutter, you can improve cutting precision and enhance material compatibility.

Here are five key ways to achieve this:

-

Calibrate the laser power and speed settings to match the specific material you’re cutting.

-

Ensure proper alignment of the laser beam to maximize cutting accuracy.

-

Regularly clean and maintain the laser optics to prevent any debris or dust from affecting the cutting quality.

-

Use high-quality cutting lenses and nozzles to optimize the focus and beam quality.

-

Stay updated with the latest software updates and firmware upgrades to take advantage of any performance enhancements.

By implementing these optimization techniques, you can ensure that your laser cutter operates at its full potential, providing precise cuts and compatibility with various materials. This will help you achieve optimal results and avoid any safety or compliance issues in the subsequent section about ensuring safety and compliance.

Ensure Safety and Compliance

Make sure you prioritize safety and compliance when operating your laser cutter. Ensuring the safety of yourself and others is crucial, as laser cutters can pose potential hazards.

To reduce maintenance costs and meet industry standards, it is important to follow safety guidelines and comply with regulations. Regularly inspect the machine for any signs of wear or damage, and promptly address any issues. Implement safety measures such as installing interlocks and protective barriers to prevent accidents.

Additionally, make sure to use the appropriate personal protective equipment, such as safety glasses and gloves.

By prioritizing safety and compliance, you can not only protect yourself and others but also extend the lifespan of your laser cutter.

Extend the Lifespan of Your Laser Cutter

By properly maintaining and caring for your laser cutter, you can ensure it remains in optimal condition and continues to serve you efficiently. Here are four ways to extend the lifespan of your laser cutter and improve maintenance, minimizing downtime:

-

Regularly clean and inspect the machine: Dust and debris can accumulate on the lens and mirrors, affecting the laser beam’s quality. By cleaning and inspecting these components regularly, you can prevent issues and ensure accurate cutting.

-

Lubricate moving parts: Friction can cause wear and tear on the moving parts of your laser cutter. Applying lubrication to these parts can reduce friction and prolong their lifespan.

-

Replace worn parts promptly: Over time, certain components of your laser cutter may wear out or become damaged. It’s crucial to identify and replace these parts promptly to prevent further damage and maintain optimal performance.

-

Follow recommended maintenance schedules: Laser cutters come with recommended maintenance schedules outlined by the manufacturer. Adhering to these schedules ensures that your machine receives the necessary maintenance and inspections to keep it running smoothly.

By incorporating these practices, you can improve efficiency and productivity in your laser cutting operations.

Improve Efficiency and Productivity

Boosting efficiency and productivity in your laser cutting operations can be achieved by implementing strategies that streamline your workflow and optimize resource utilization. By troubleshooting your laser cutter regularly, you can identify and address any issues that may be hindering its performance. This not only helps increase output but also ensures that your operations run smoothly without any unexpected downtime. Here are some ways troubleshooting can improve efficiency and productivity:

| Strategy | Benefits |

|---|---|

| Regular maintenance | Prevents breakdowns and reduces the risk of unexpected downtime |

| Upgrading software and firmware | Enhances performance and adds new features |

| Optimizing cutting parameters | Reduces material waste and improves cutting speed |

By implementing these strategies and regularly troubleshooting your laser cutter, you can streamline operations, increase output, and achieve higher levels of efficiency and productivity.

Frequently Asked Questions

What are some common technical issues that can arise with laser cutters?

Some common technical issues that can arise with laser cutters include software malfunctions, such as system crashes or compatibility problems. Troubleshooting techniques for laser cutter software involve checking for updates, reinstalling the software, or adjusting settings.

Hardware issues may include misalignment of the laser beam, overheating, or worn-out parts. To resolve these problems, solutions may involve realigning the laser beam, ensuring proper ventilation, or replacing damaged components.

Troubleshooting is crucial in addressing these issues and ensuring optimal performance of your laser cutter.

How can I prevent costly repairs and downtime with my laser cutter?

To prevent costly repairs and downtime with your laser cutter, it’s crucial to implement preventive maintenance and employ effective troubleshooting techniques.

By regularly inspecting and cleaning the machine, checking for loose connections, and ensuring proper ventilation, you can identify potential issues before they escalate.

Additionally, familiarizing yourself with troubleshooting techniques such as diagnosing error messages, adjusting settings, and replacing worn-out parts will help resolve minor problems promptly. This will minimize downtime and save you money in the long run.

What are some tips for optimizing cutting performance with a laser cutter?

To maximize cutting efficiency with your laser cutter, follow these tips and techniques.

First, make sure your laser’s focus is properly calibrated for precise cuts.

Additionally, optimize your cutting speed and power settings based on the material being cut.

Use high-quality optics and regularly clean and maintain them to maintain accuracy.

Finally, consider using nesting software to minimize material waste and maximize productivity.

These strategies will help you achieve optimal cutting performance with your laser cutter.

What safety measures should I take to ensure compliance with laser cutter operation?

To ensure compliance with laser cutter operation, it’s crucial to follow certain safety measures.

First and foremost, always wear appropriate laser cutter safety gear, including protective eyewear and gloves.

Additionally, undergo laser cutter operation training to understand the correct procedures and potential hazards involved. This training will equip you with the knowledge of proper machine operation, emergency shutdown protocols, and safe material handling techniques.

By adhering to these precautions, you can minimize the risk of accidents and ensure a safe working environment.

Are there any specific maintenance steps I can take to extend the lifespan of my laser cutter?

To extend the lifespan of your laser cutter, there are several maintenance steps you can take.

Regularly clean the optics and remove any debris to ensure optimal performance.

Check and replace worn-out parts, such as belts and lenses, as needed.

Keep track of usage hours and follow manufacturer-recommended maintenance schedules.

Additionally, ensure proper ventilation and temperature control in the laser cutter’s environment.

By following these steps, you can maximize the lifespan of your laser cutter and minimize the need for costly repairs.

Conclusion

In conclusion, troubleshooting is an indispensable practice for your laser cutter. By identifying and resolving technical issues promptly, you can prevent costly repairs and minimize downtime.

This will optimize cutting performance, ensuring precise and efficient operations. Furthermore, troubleshooting promotes safety and compliance, safeguarding both your equipment and personnel.

With regular troubleshooting, you can extend the lifespan of your laser cutter, maximizing your investment. Ultimately, this leads to improved efficiency and productivity, propelling your business towards success.

Don’t underestimate the power of troubleshooting; it’s the key to unlocking the full potential of your laser cutter.