Are you ready to unlock the full potential of your laser cutter software? Just like a skilled conductor leading an orchestra, mastering the art of optimizing your workflow with laser cutter software can result in a symphony of efficiency and precision.

In this article, we will reveal eight secrets that will transform you from a novice into a virtuoso in no time. By familiarizing yourself with the software interface, you will navigate through its intricacies with ease, like a seasoned captain steering a ship through turbulent waters.

Time-saving shortcuts will become your secret weapon, allowing you to accomplish tasks in a fraction of the time. Mastering the design tools will be your brush, allowing you to create intricate and flawless designs.

Templates will be your guiding light, streamlining your workflow and ensuring consistent results. And by exploring advanced features and techniques, you will push the boundaries of what is possible with laser cutting.

So, join us on this journey as we uncover the hidden gems that will revolutionize your laser cutter workflow. Prepare to elevate your creations to new heights and unleash your full potential.

Key Takeaways

- Laser cutter software optimization can lead to increased efficiency and precision in cutting.

- Familiarizing oneself with the software interface is crucial for navigating through its intricacies.

- Efficient file organization and streamlined material selection are essential for maximizing productivity.

- Mastering design tools such as vector editing, raster editing, and text editing is necessary for achieving desired results.

Familiarize Yourself with the Software Interface

Get ready to dive into the software interface and familiarize yourself with all its features to optimize your workflow with the laser cutter. To begin, take the time to learn the basic functions and navigate the software efficiently.

Start by understanding how to open and save files, as well as how to import and export designs. Familiarize yourself with the various tools available, such as the selection tool, drawing tools, and text tool. Learn how to manipulate objects, resize them, and arrange them on the work area.

Additionally, explore the options for adjusting cutting parameters and setting up the laser cutter. By becoming proficient in these aspects of the software, you will be able to work more efficiently and effectively.

Now, let’s move on to the next section about taking advantage of time-saving shortcuts.

Take Advantage of Time-Saving Shortcuts

Maximizing productivity in the laser cutting process involves utilizing various time-saving shortcuts, which can significantly enhance efficiency and streamline operations.

Efficient file organization is crucial in optimizing your workflow. By creating a logical system for storing and naming your design files, you can easily locate and access the files you need, saving valuable time.

Additionally, streamlining material selection is another important aspect. Familiarize yourself with the materials available and their respective settings in the software. This knowledge will allow you to quickly choose the appropriate material for your project and adjust the settings accordingly, eliminating the need for trial and error.

By efficiently organizing your files and streamlining material selection, you can maximize your productivity with the laser cutter software.

Now, let’s transition into the subsequent section about mastering the design tools.

Master the Design Tools

Once you’ve got the hang of it, mastering the design tools will take your laser cutting projects to the next level. To optimize your workflow and create stunning designs, it’s crucial to understand design principles and utilize troubleshooting techniques effectively.

Here are three design tools that will revolutionize your laser cutting experience:

-

Vector Editing: Use vector editing software to create precise and scalable designs. Manipulate nodes, curves, and lines to achieve intricate details and smooth contours. Learn to use tools like the Pen Tool, Bezier Curve, and Boolean Operations to enhance your designs.

-

Raster Editing: Raster editing tools allow you to work with bitmap images. Adjust the brightness, contrast, and color of your images to achieve the desired visual effect. Use techniques like dithering and halftoning to create stunning grayscale or color designs.

-

Text Editing: Mastering text editing tools will enable you to add captivating typography to your laser cutting projects. Experiment with different fonts, sizes, and spacing to create visually appealing and readable text.

By understanding these design tools and their capabilities, you can optimize your workflow and create exceptional laser cutting projects.

Transitioning seamlessly into the next section, let’s explore how templates can further enhance your efficiency.

Optimize Your Workflow with Templates

To optimize your workflow with laser cutter software, you should create and save templates for common designs. These templates can be customized to suit your needs, enabling you to speed up your workflow by avoiding repetitive tasks.

By utilizing templates, you can efficiently produce consistent and professional designs while saving valuable time and effort.

Create and save templates for common designs

Start by developing a repertoire of go-to designs, like building a toolbox of templates that you can easily pull out whenever you need. Efficient design organization is key to streamlining your production process.

Here are five steps to create and save templates for common designs:

-

Identify frequently used designs: Analyze your past projects and identify designs that you use repeatedly.

-

Standardize dimensions and settings: Set standard dimensions and engraving/cutting settings for each template to ensure consistency.

-

Create and save templates: Use your laser cutter software to create templates for each design, saving them with descriptive names.

-

Organize templates in folders: Create folders to categorize your templates based on design types or project themes.

-

Apply templates to new projects: When starting a new project, simply open the appropriate template, make any necessary adjustments, and start cutting or engraving.

By customizing templates to speed up your workflow, you can further optimize your laser cutter software usage.

Customize templates to speed up your workflow

When you personalize templates, you can turbocharge your creative process and get projects done in a flash. Customizing settings in laser cutter software allows you to optimize your workflow and improve efficiency. By tailoring templates to your specific needs, you can save time and effort in every project.

Adjusting parameters such as cutting speed, power, and focus can significantly impact the quality and speed of your cuts. You can also customize the layout of your templates to fit different materials and sizes, eliminating the need for manual adjustments. Take advantage of features like nesting and automatic placement to maximize material usage and reduce waste.

By customizing templates, you can streamline your workflow and achieve consistent results. Now, let’s explore advanced features and techniques to further enhance your laser cutting experience.

Explore Advanced Features and Techniques

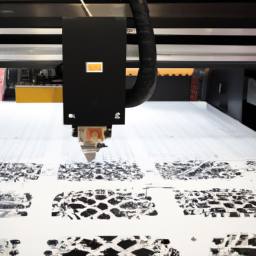

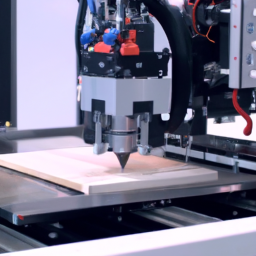

Unlock the full potential of your laser cutter software by delving into its more intricate features and techniques. This will allow your creative visions to transcend mere imagination and take shape in the tangible world. With advanced techniques, you can optimize your workflow and enhance productivity.

Take advantage of features such as nesting, which allows you to efficiently arrange multiple designs on a single sheet, minimizing material waste. Experiment with variable power settings to achieve different depths and effects on various materials. Explore the possibilities of rotary attachments to engrave cylindrical objects. Utilize the power of vector editing tools to customize intricate designs and optimize cutting paths.

By mastering these advanced features and techniques, you can elevate your laser cutting capabilities to new heights.

Transitioning into the next section, it’s crucial to stay updated with software updates and tutorials to continue expanding your knowledge and staying at the forefront of laser cutting technology.

Stay Updated with Software Updates and Tutorials

To truly elevate your laser cutting capabilities, it’s essential that you regularly stay updated with the latest software updates and tutorials. Regular software maintenance is of utmost importance as it ensures that your laser cutter software is running at its optimum performance.

These updates often include bug fixes, improved features, and enhanced compatibility with new materials and hardware. By keeping your software up to date, you can take advantage of these advancements and ensure that you’re getting the most out of your laser cutter.

Continuous learning through tutorials and online resources is also crucial for optimizing your workflow. Laser cutter software is constantly evolving, and staying informed about new techniques and features can greatly enhance your productivity and creativity.

Online tutorials provide step-by-step instructions and tips for using specific software functions, while online resources offer forums and communities where you can connect with other laser cutting enthusiasts and exchange knowledge and ideas.

By regularly updating your software and learning from tutorials and online resources, you can unlock the full potential of your laser cutter and achieve outstanding results in your projects.

Frequently Asked Questions

Can I use the laser cutter software on a Mac or is it only compatible with Windows?

Yes, the laser cutter software is compatible with both Mac and Windows operating systems. However, there are advantages to using it on a Mac.

The software is specifically designed to work seamlessly with Mac’s intuitive interface, allowing for a more user-friendly experience. Additionally, Mac’s robust hardware capabilities enhance the performance of the software, resulting in faster processing times and smoother cutting operations.

Overall, using laser cutter software on a Mac can greatly optimize your workflow.

Are there any limitations to the file size or type that can be imported into the software?

The laser cutter software does have certain limitations when it comes to file size and supported file types. In terms of file size, there’s a maximum limit that the software can handle, which may vary depending on the specific software you’re using.

As for supported file types, most laser cutter software can import common vector file formats such as SVG, DXF, and AI. It’s important to check the software’s documentation or consult with the manufacturer to ensure compatibility with your desired file size and type.

Can I save my designs in different file formats for compatibility with other software or machines?

To export designs from laser cutter software to popular file formats for compatibility with other software or machines, follow these best practices for converting laser cutter designs.

Start by selecting the desired format from the software’s export options. Common file formats include SVG, DXF, and AI. Ensure that the exported file maintains the necessary dimensions, layers, and settings for seamless integration with other software or machines.

Double-check the compatibility requirements of the recipient software or machine to achieve optimal results.

Is there a limit to the number of layers or elements I can have in a design?

Design complexity is like a puzzle with countless pieces, each representing a layer or element. The laser cutter software you use may impose certain limits on the number of layers in a design, depending on its capabilities.

Therefore, it’s crucial to understand the limitations of your chosen software. By knowing the maximum number of layers, you can plan your design accordingly and ensure its successful execution, avoiding any surprises during the cutting process.

How often are software updates released and are they free to download?

Software updates for the laser cutter software are released periodically to ensure optimal performance and address any issues or bugs. The frequency of these updates may vary, but they’re typically released on a regular basis to provide users with the latest features and improvements.

The good news is that these updates are generally free to download, allowing you to stay up-to-date with the latest advancements in the software without incurring any additional costs.

Conclusion

In conclusion, by acquainting yourself with the laser cutter software interface and utilizing its time-saving shortcuts, you can efficiently optimize your workflow.

It’s crucial to master the design tools and make use of templates to further enhance productivity.

Exploring the software’s advanced features and techniques will enable you to achieve even greater precision and efficiency.

Lastly, staying updated with software updates and tutorials ensures that you remain at the forefront of laser cutting technology.

By following these steps, you’ll be able to seamlessly execute your projects with utmost finesse.