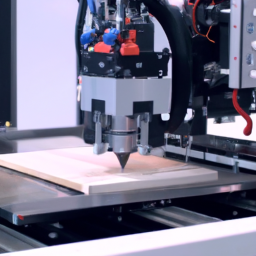

Are you tired of wasting precious time and effort on tedious manual tasks when using your laser cutter? Look no further! In this article, we will explore eight game-changing laser cutter software features that will revolutionize your workflow and save you valuable time.

Imagine a world where your machine automatically detects the material you’re working with, eliminating the need for manual input.

Picture having access to a vast library of pre-designed templates, ready to use at your fingertips.

Say goodbye to running individual jobs one by one – with batch processing, you can streamline your work and increase productivity.

And that’s not all – nesting optimization will maximize material usage, reducing waste and costs.

With efficient job queue management and seamless integration with design software, you’ll experience a seamless workflow from start to finish.

Get ready to supercharge your laser cutting process and unlock a whole new level of efficiency.

Key Takeaways

- Laser cutter software features include automatic material detection, access to pre-designed templates, batch processing, and nesting optimization.

- Job queue management and real-time progress tracking help prioritize and schedule jobs effectively, avoiding bottlenecks and ensuring a smooth workflow.

- Seamless integration with design software allows for easy file transfer and real-time design updates, improving productivity and accuracy.

- Laser cutter software saves time, enhances efficiency, and ensures optimal cutting results through features like material detection, pre-designed templates, batch processing, and nesting optimization.

Automatic Material Detection

You’ll appreciate the added efficiency and precision of the automatic material detection feature. This time-saving feature eliminates the need for manual input and ensures that your laser cutter is compatible with a wide range of materials.

By simply placing your material on the cutting bed, the laser cutter software will automatically detect its properties, such as thickness and composition, and adjust the cutting settings accordingly. This not only saves you time but also guarantees optimal cutting results every time.

Additionally, the automatic material detection feature allows you to take full advantage of advanced editing tools. With the software’s knowledge of the material, you can easily make precise adjustments to the cutting parameters, ensuring that your designs come out exactly as intended.

Now, let’s move on to the next section about pre-designed templates.

Pre-designed Templates

Get ready to effortlessly enhance your projects with our collection of pre-designed templates. These customizable designs allow you to quickly and easily create stunning laser-cut projects without the need for extensive design knowledge. Simply import external files into the software and choose from a wide variety of templates to suit your needs.

Whether you’re creating intricate patterns or simple shapes, our pre-designed templates provide a starting point that can be easily modified to fit your project requirements. Once you’ve selected a template, you can make adjustments such as resizing, rotating, or adding text to make it uniquely yours.

And now, let’s dive into the next exciting feature: batch processing, which will further streamline your workflow and save you even more time.

Batch Processing

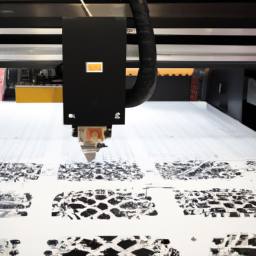

Streamline your project production with the efficient and time-saving capability of batch processing, allowing you to effortlessly handle multiple tasks simultaneously. With batch scheduling, you can easily queue up multiple files for processing, saving you time and effort.

The laser cutter software automatically organizes the files in a logical order, ensuring smooth and uninterrupted workflow.

Here are four key benefits of batch processing in laser cutter software:

-

Increased productivity: By processing multiple files at once, you can significantly speed up your production time, allowing you to complete more projects in a shorter period.

-

Simplified file organization: Batch processing enables you to keep your files organized and easily accessible, eliminating the need to manually search for each file.

-

Enhanced efficiency: The software automatically optimizes the order of files for processing, minimizing material waste and maximizing the use of the laser cutter.

-

Streamlined workflow: With batch processing, you can set up the software to automatically start processing the next file in the queue, reducing downtime and ensuring a continuous production flow.

By efficiently managing your tasks through batch processing, you can seamlessly transition into the subsequent section about ‘nesting optimization’, optimizing material usage and further improving your workflow.

Nesting Optimization

Maximize material usage and optimize your workflow with nesting optimization. This feature intelligently arranges and fits multiple design files onto a single sheet, minimizing waste and maximizing efficiency.

Nesting optimization is essential for improving material utilization and cutting efficiency in laser cutting operations. By automatically arranging designs to fit tightly together, it minimizes the amount of wasted material, reducing costs and increasing productivity.

It analyzes the dimensions and shapes of each design file and finds the best possible arrangement to maximize the use of the available space. Nesting optimization also considers factors such as material grain direction, avoiding weak spots in the sheet, and optimizing cutting paths for efficient production.

With this feature, you can significantly improve your material utilization and cutting efficiency, leading to higher productivity and reduced costs.

Transitioning into the next section, let’s explore the benefits of job queue management.

Job Queue Management

In the discussion on Job Queue Management, you’ll explore the key points of easily prioritizing and scheduling jobs, keeping track of progress, and avoiding bottlenecks.

With this feature, you can efficiently manage your workflow by assigning priorities to different jobs and scheduling them accordingly.

Additionally, you can monitor the progress of each job in real-time, ensuring that there aren’t any delays or bottlenecks in the production process.

Easily prioritize and schedule jobs

Boost your productivity and effortlessly manage your laser cutting jobs by easily prioritizing and scheduling them with our innovative software features. Our time-saving laser cutter software allows you to optimize your workflow by implementing effective time management techniques.

Here are three key ways our software helps streamline your production workflow:

-

Prioritization: With our software, you can assign priority levels to different jobs, ensuring that urgent projects are completed first.

-

Scheduling: Our software enables you to schedule jobs based on their complexity and available resources, allowing for efficient allocation of time and materials.

-

Automated Queuing: Our software automatically queues jobs based on their priority and scheduled time, eliminating the need for manual intervention.

By utilizing these features, you can keep track of progress and avoid bottlenecks in your production process. This seamless transition ensures a smooth workflow and maximizes your efficiency.

Keep track of progress and avoid bottlenecks

To ensure a seamless production process, our innovative software helps you effortlessly track progress and avoid any potential bottlenecks. With our time-saving laser cutter software, you can improve efficiency by monitoring job progress in real time. This allows you to identify any issues or delays that may arise during the production process, enabling you to take immediate action and keep your workflow running smoothly. Our software provides a comprehensive overview of each job, including the current status, estimated completion time, and any pending tasks. By having this information readily available, you can effectively manage your workload and avoid bottlenecks that could otherwise impede your productivity. This real-time monitoring feature ensures that you stay on track and meet your deadlines. By seamlessly integrating with your design software, you can easily transfer files and streamline your entire production process.

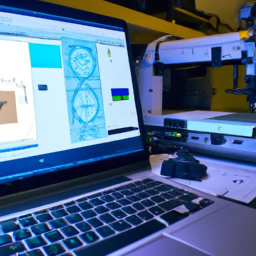

Integration with Design Software

With its seamless integration with design software, the laser cutter software streamlines your workflow, making it easier than ever to bring your creative visions to life. By streamlining file transfer, the software eliminates the need for manual file conversions or adjustments, saving you valuable time and ensuring that your designs are accurately translated from your design software to the laser cutter.

Additionally, the software provides real-time design updates, allowing you to see any changes or modifications to your design as they happen. This feature ensures that you have complete control over your project and can make necessary adjustments on the fly.

With the laser cutter software’s integration with design software, you can confidently create intricate and precise designs with ease, knowing that the software will seamlessly translate your vision to the laser cutter.

Frequently Asked Questions

What types of materials can be automatically detected by the laser cutter software?

The laser cutter software has an impressive capability to automatically detect a wide range of materials, providing convenience and efficiency in your workflow. This feature eliminates the need for manual input and reduces the chances of errors during the cutting process.

However, it’s important to be aware of common troubleshooting issues that may arise with the software, such as calibration problems or compatibility issues. To optimize your laser cutter settings for different materials, consider adjusting the power, speed, and focus settings according to the material’s properties for precise and clean cutting results.

Are there any limitations on the pre-designed templates available in the software?

When it comes to pre-designed templates in laser cutter software, there are certain limitations to be aware of. These templates offer convenience and time-saving benefits, but they may not cater to every specific design requirement. The limitations include a fixed range of available designs, limited customization options, and potential restrictions on resizing or modifying the template.

Despite these limitations, using pre-designed templates can still greatly improve workflow efficiency by providing a starting point for your laser cutting projects.

How does the batch processing feature in the software improve workflow efficiency?

With the batch processing feature in the laser cutter software, you’ll be able to streamline your workflow like never before. It’s like having a well-oiled assembly line, effortlessly processing multiple files at once.

This efficient feature allows you to send a whole batch of designs to the laser cutter, saving you valuable time and effort. No longer will you have to tediously load and process each file individually.

Let the software do the heavy lifting and watch your productivity soar.

Can the nesting optimization feature be customized to fit specific project requirements?

Yes, the nesting optimization feature in the laser cutter software can be customized to meet your specific project requirements. The software offers various customization options that allow you to adjust the nesting algorithm, define cutting priorities, and set project-specific settings. By tailoring the nesting optimization feature, you can optimize material usage, reduce waste, and improve overall productivity. This level of customization ensures that the software adapts to your unique project needs, resulting in a more efficient workflow.

Does the job queue management feature allow for prioritization or scheduling of different jobs?

Yes, the job queue management feature of our laser cutter software allows for both prioritization and scheduling of different jobs.

With this feature, you can easily set the order in which jobs are processed based on their importance or deadline.

Additionally, you can schedule jobs to be executed at specific times, ensuring efficient workflow and optimal use of resources.

This prioritization feature and scheduling feature greatly enhance productivity and streamline your laser cutting process.

Conclusion

In conclusion, laser cutter software is a powerful tool for enhancing workflow efficiency. By incorporating time-saving features like Automatic Material Detection, Pre-designed Templates, and Batch Processing, you can streamline your laser cutting process.

Additionally, Nesting Optimization and Job Queue Management allow for optimal material usage and smooth job scheduling. Integration with Design Software further simplifies the design-to-cut workflow.

With these advanced features at your disposal, you can achieve precise, detailed laser cuts with minimal effort, maximizing productivity and unleashing the potential of your laser cutter.