Did you know that integrating laser cutter software into your workflow can increase your productivity by up to 50%?

With the right software integrations, you can streamline design and file preparation, automate material settings and job setup, improve efficiency with nesting and optimization, enhance precision and accuracy, and even monitor and control jobs remotely.

In this article, we will explore eight powerful ways to enhance your workflow with laser cutter software integrations. By implementing these strategies, you can save time, reduce errors, and maximize the potential of your laser cutter.

Whether you are a professional designer or a hobbyist, these software integrations will revolutionize the way you work with your laser cutter.

So, let’s dive in and discover how you can take your laser cutting to the next level with these innovative tools and techniques.

Key Takeaways

- Laser cutter software integrations can increase productivity by up to 50% by streamlining design and file preparation processes and automating material settings and job setup.

- Nesting and optimization techniques can improve efficiency and save time by maximizing material usage and reducing waste, as well as optimizing cutting process by arranging cutting order to minimize tool travel distance.

- Advanced calibration techniques enhance precision and accuracy by fine-tuning laser settings, ensuring accurate alignment of designs with material through camera registration, and accounting for the width of the laser beam for tighter and more accurate cuts.

- Integrating design software and plugins can streamline workflow and enhance precision by allowing seamless transfer of designs, providing access to customizable templates, and adding additional functionalities such as image editing or text manipulation through plugins.

Streamline Design and File Preparation

You can easily streamline your design process and prepare your files efficiently with laser cutter software integrations. These integrations simplify production scheduling by providing tools that allow you to organize and manage your design files seamlessly.

By utilizing laser cutter software integrations, you can minimize material waste by optimizing the placement of your designs on the material sheet, ensuring that you make the most efficient use of your materials. These integrations also provide features that allow you to automatically nest your designs, ensuring that you maximize the number of parts you can produce from a single sheet of material.

With these capabilities, you can significantly improve your workflow and reduce the time and effort required to prepare your files for laser cutting.

Transitioning into the next section, laser cutter software integrations also enable you to automate material settings and job setup, further enhancing your efficiency and productivity.

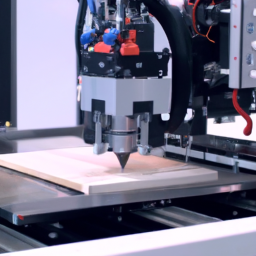

Automate Material Settings and Job Setup

Boosting your laser cutting productivity is like having a personal assistant who sets up your materials and job preferences with a single click. Laser cutter software integrations allow you to automate file organization and optimize laser settings, saving you valuable time and effort.

With automated material settings, you can easily select the type of material you’re working with, and the software will automatically adjust the laser power, speed, and other parameters accordingly. This ensures that you achieve precise and consistent results every time, without the need for manual adjustments.

Additionally, laser cutter software integrations streamline job setup by allowing you to save and recall your preferred settings for different materials and job types. With just a few clicks, you can set up your laser cutter for a new job, eliminating the need for manual recalibration.

By automating material settings and job setup, you can improve efficiency and focus more on the creative aspects of your work.

Transitioning into the next section about improving efficiency with nesting and optimization, you can further enhance your workflow by optimizing material usage and reducing waste.

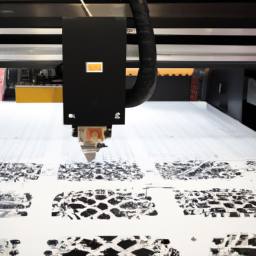

Improve Efficiency with Nesting and Optimization

Maximize your laser cutting productivity by improving efficiency and saving valuable time with nesting and optimization techniques. By utilizing nesting software, you can maximize material usage, reducing waste and ultimately saving costs.

This software intelligently arranges your designs on the material sheet, minimizing the empty spaces between each cut. By doing so, you can fit more designs onto a single sheet, maximizing material usage.

Additionally, nesting software can also help reduce production time by automatically arranging the cutting order to minimize tool travel distance, reducing unnecessary movements and optimizing the overall cutting process.

By implementing nesting and optimization techniques, you can enhance your workflow, saving time and resources. This will ultimately lead to improved efficiency and productivity.

Transitioning into the subsequent section about enhancing precision and accuracy, you can further enhance your laser cutting results by incorporating advanced calibration techniques.

Enhance Precision and Accuracy

By incorporating advanced calibration techniques, you can achieve laser cutting precision and accuracy that’s as sharp as a needle. This level of precision allows you to increase productivity and enhance your cutting capabilities. Here are some ways in which you can achieve this:

-

Fine-tune your laser settings: Adjust the power, speed, and focus of the laser beam to result in more precise and accurate cuts.

-

Implement camera registration: By integrating a camera system into your laser cutter, you can ensure that your designs are accurately aligned with the material, minimizing errors.

-

Utilize automatic material detection: Laser cutter software that can automatically detect and adjust settings based on the material being used can greatly enhance accuracy.

-

Employ kerf compensation: By accounting for the width of the laser beam during the design process, you can achieve tighter, more accurate cuts.

With these techniques, you can significantly enhance the precision and accuracy of your laser cutting workflow, increasing productivity and expanding your cutting capabilities. Integrating with design software and plugins will further streamline your process.

Integrate with Design Software and Plugins

To make your laser cutting experience even better, why not integrate design software and plugins? By integrating your laser cutter with design software, you can streamline your workflow and enhance precision in your projects.

Collaborative workflows become easier as you can seamlessly transfer designs from your preferred design software directly to the laser cutter software. This integration also allows you to access customizable templates, which can save you time and effort by providing pre-designed patterns and shapes. With design software integration, you can easily modify and adjust designs according to your preferences, ensuring a more personalized end product.

Furthermore, plugins can add additional functionalities to your laser cutter software, such as image editing or text manipulation. By incorporating these integrations, you can maximize efficiency and creativity in your laser cutting projects.

Transitioning to the subsequent section, you can also monitor and control jobs remotely for added convenience and flexibility.

Monitor and Control Jobs Remotely

Now that you’ve learned about integrating your laser cutter software with design software and plugins, let’s explore another way to enhance your workflow: remote monitoring and control of jobs. With remote monitoring, you can keep an eye on your laser cutter from anywhere, ensuring that your jobs are running smoothly and without interruptions. This feature allows you to schedule and prioritize jobs, giving you the flexibility to manage your workload efficiently. To help you visualize the benefits of remote monitoring, here’s a table that showcases the advantages it brings to your workflow:

| Remote Monitoring Benefits |

|---|

| Real-time job status updates |

| Ability to monitor multiple machines simultaneously |

| Remote job scheduling and prioritization |

By leveraging remote monitoring, you can increase productivity and optimize your laser cutter usage.

Frequently Asked Questions

Can laser cutter software integrate with third-party design software?

By integrating laser cutter software with third-party design software, you can unleash a world of possibilities. Design compatibility is crucial, and fortunately, most laser cutter software can seamlessly integrate with popular design programs like Adobe Illustrator and CorelDRAW.

This ensures that your designs can be easily transferred and executed on the laser cutter. This integration enhances workflow efficiency by eliminating the need for manual file conversions and streamlining the production process, allowing for a more seamless and efficient workflow.

How can laser cutter software improve material utilization?

To increase efficiency and reduce waste, laser cutter software can greatly improve material utilization. By offering features like nesting and optimization algorithms, the software can intelligently arrange your designs to fit as many pieces as possible onto a single sheet of material. This minimizes the amount of wasted material and maximizes the number of pieces that can be produced.

Additionally, the software can suggest adjustments to your designs to further enhance material utilization and overall productivity.

Is it possible to monitor and control laser cutting jobs remotely?

Yes, you can easily monitor and control laser cutting jobs remotely with the right software integration. Remote monitoring and control of laser cutting jobs allows you to stay updated on job progress, adjust settings and parameters, and troubleshoot issues from anywhere.

This offers several benefits, including increased productivity, reduced downtime, and the ability to manage multiple machines simultaneously. With remote laser cutter management, you have the flexibility and convenience to optimize your workflow and ensure efficient operations.

Does laser cutter software provide real-time job status updates?

Yes, laser cutter software does provide real-time job status updates. With real-time job monitoring, you can easily track the progress of your laser cutting jobs. The software notifies you with job status notifications, giving you instant updates on whether the job is completed, in progress, or if any errors have occurred.

This feature allows you to stay informed and make timely decisions, ensuring efficient workflow and optimal productivity.

Can laser cutter software automatically adjust settings based on material type and thickness?

Do you want to effortlessly adjust your laser cutter settings based on the material type and thickness?

Laser cutter software can automate cutting parameters, optimizing efficiency by automatically adapting to different materials.

With this feature, you can achieve precise and accurate cuts without the need for manual adjustments.

By eliminating the guesswork, you can save time and enhance your workflow, focusing on other important tasks.

Conclusion

In conclusion, integrating laser cutter software into your workflow can greatly enhance your efficiency and precision. By streamlining design and file preparation and automating material settings and job setup, you can save valuable time and resources.

Additionally, optimizing nesting allows for seamless collaboration and increased creativity when integrating with design software and plugins.

With the ability to monitor and control jobs remotely, you can ensure smooth operations even when you’re not physically present.

So don’t hesitate to embrace these integrations and take your laser cutting capabilities to new heights!