Step into the world of laser cutting, where precision meets creativity and innovation. Like a conductor leading an orchestra, laser cutter software orchestrates the symphony of design and fabrication, ensuring a seamless integration between your ideas and the machine’s capabilities. To achieve a successful workflow and harness the full potential of your laser cutter, mastering the intricacies of the software is essential.

In this article, we present nine tips that will empower you to take command of your laser cutter software and elevate your creations to new heights. From organizing your files and folders to optimizing settings for different materials, each tip is a crucial note in the composition of your laser cutting masterpiece.

Prepare to dive deep into the world of laser cutter software, where precision and artistry harmonize to bring your visions to life.

Key Takeaways

- Laser cutter software is essential for a successful workflow and should be promptly troubleshooted when issues arise.

- Staying up to date with software updates and improvements is crucial for optimal performance.

- Customizable templates can greatly improve efficiency in design and fabrication processes.

- Incorporating user feedback helps in the evolution and improvement of laser cutter software.

Organize Your Files and Folders

To make your life easier, start organizing all of your files and folders like a pro. This way, you can effortlessly find the designs you need when working with laser cutter software. Proper digital file management is crucial for a smooth workflow and efficient integration with the software.

Create a clear folder structure and categorize your files based on projects or themes. Use file naming conventions that make sense to you and include relevant information in the file names, such as project names, dates, and versions. This will help you quickly locate specific designs and prevent confusion.

Additionally, consider creating a separate folder for completed projects to keep your workspace organized. By establishing a systematic approach to organizing your files and folders, you’ll save time and avoid unnecessary frustration when using the laser cutter software.

Now, let’s move on to familiarizing yourself with the software interface.

Familiarize Yourself with the Software Interface

Get acquainted with the interface of the laser cutter software to ensure smooth collaboration and efficient utilization of resources.

Understanding software compatibility is crucial for seamless integration into your workflow.

Familiarize yourself with the different menus, buttons, and tools available in the software. Take the time to explore each feature and understand its function. This will enable you to navigate the software efficiently and make the most of its capabilities.

Additionally, it’s important to familiarize yourself with common troubleshooting techniques to address any issues that may arise during the laser cutting process. By understanding the software interface and troubleshooting common issues, you can optimize your settings for different materials and achieve the best results.

Transitioning into the next section, optimizing your settings will further enhance your laser cutting workflow.

Optimize Your Settings for Different Materials

Make sure you’re maximizing your laser cutting results by optimizing your settings for different materials. Material compatibility is crucial when it comes to laser cutting. Each material has its own characteristics and requirements, so it’s essential to adjust your settings accordingly.

Start by consulting the manufacturer’s guidelines for recommended settings for specific materials. Experiment with power, speed, and frequency settings to achieve the desired outcome. Keep in mind that different materials may require different approaches, so don’t hesitate to make adjustments and fine-tune your settings.

If you encounter any issues, troubleshooting techniques can help you identify and resolve problems. For example, if you’re experiencing excessive charring or scorching, try reducing the power or increasing the speed. It’s important to remember that optimizing your settings is a continuous process and may require some trial and error.

In the next section, we’ll discuss how to test and calibrate your laser cutter for optimal performance.

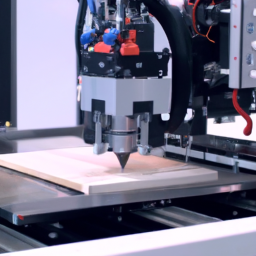

Test and Calibrate Your Laser Cutter

After optimizing your settings, it’s time to put your laser cutter to the test and fine-tune its performance for optimal results. Here are three key steps to troubleshooting issues and maintaining laser cutter performance:

-

Test different materials: Experiment with various materials to determine the ideal settings for each. This will help you understand how the laser cutter interacts with different surfaces and ensure consistent and precise cuts.

-

Calibrate laser power: Regularly calibrate the laser power to maintain accuracy and prevent issues such as under or over-cutting. Use a power meter to measure the laser output and adjust as needed.

-

Clean and maintain optics: Keep your laser cutter’s optics clean and free from debris. Regularly inspect and clean the lens, mirrors, and other components to ensure optimal performance and prevent potential damage.

By following these steps, you can troubleshoot any issues and maintain your laser cutter’s performance.

Now, let’s explore how you can utilize software features to enhance efficiency.

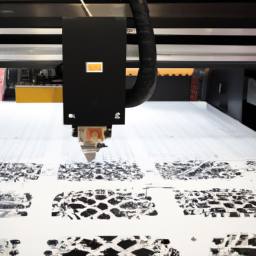

Utilize Software Features to Enhance Efficiency

Boosting productivity and streamlining operations is possible by harnessing the full potential of software features, allowing you to effortlessly optimize your laser cutting process. One way to enhance efficiency is by utilizing customizable templates offered by laser cutter software. These templates provide pre-designed settings for common materials and designs, saving you time and effort in setting up the job parameters. Additionally, troubleshooting common software issues can help prevent delays and ensure smooth workflow. Familiarize yourself with the software’s troubleshooting resources and tips, such as online forums or support documentation. By addressing software issues promptly, you can minimize downtime and maximize productivity. Transitioning into the next section, it’s crucial to stay up to date with software updates and improvements to further enhance your laser cutting experience.

Stay Up to Date with Software Updates and Improvements

To ensure a seamless and efficient workflow with your laser cutter software, it’s crucial to stay up to date with software updates and improvements.

By regularly checking for updates and installing the latest versions, you can take advantage of new features and enhancements that can greatly enhance your productivity.

One important aspect of software updates is the incorporation of user feedback in the development process. Developers rely on user input to identify bugs, suggest improvements, and address any issues that may arise. By actively participating in providing feedback, you can contribute to the evolution of the software, ensuring that it meets your specific needs and requirements.

Additionally, integrating your laser cutter software with design software can streamline your workflow even further. This integration allows you to seamlessly transfer your designs from your design software to the laser cutter software, eliminating the need for manual file conversions and reducing the risk of errors. It enables a more efficient and precise workflow, saving you valuable time and effort.

Frequently Asked Questions

How do I troubleshoot common issues with laser cutter software?

To troubleshoot common issues with laser cutter software, start by employing various troubleshooting techniques.

First, ensure that the software is up to date and compatible with your operating system.

If you encounter performance issues, check your computer’s specifications and make sure they meet the software’s requirements.

Additionally, optimize the software’s performance by closing unnecessary programs and freeing up memory.

By following these steps, you can effectively troubleshoot and optimize your laser cutter software.

What are the best practices for file naming conventions and folder organization?

When it comes to file naming conventions and organizing files and folders for laser cutter projects, there are a few best practices to follow.

Start by using clear and descriptive file names that include relevant information such as project name, version number, and material type.

Create a logical folder structure that is easy to navigate, grouping files based on project stages or categories.

Avoid using special characters or spaces in file names to ensure compatibility with laser cutter software.

By following these practices, you can enhance your workflow and ensure efficient integration with laser cutter software.

Can I use the software with different laser cutter models?

Yes, you can use the software with different laser cutter models. The software is designed to be compatible with a wide range of laser cutter models, allowing you to seamlessly integrate it into your workflow. It’s important to note that compatibility may vary depending on the specific model and its capabilities. Additionally, regular software updates ensure that you have access to the latest features and improvements for optimal performance with your laser cutter.

How can I ensure accurate and precise cuts with the laser cutter?

To ensure accurate and precise cuts with your laser cutter, start by calibrating the machine. This step is crucial for achieving consistent results.

Once calibrated, focus on optimizing the speed and power settings. Experiment with different combinations to find the sweet spot for your specific material and design.

Remember to start with lower power and increase gradually to avoid burning or charring. By fine-tuning these settings, you’ll achieve the precise cuts you desire.

Are there any safety precautions I should take when using the laser cutter software?

When using laser cutter software, it’s crucial to prioritize safety to prevent accidents. To ensure laser cutter software safety, always wear appropriate protective gear such as safety goggles and gloves.

Make sure the workspace is well-ventilated to avoid inhaling fumes. Additionally, familiarize yourself with the software’s troubleshooting features to quickly address any issues that may arise during operation.

By adhering to these safety precautions and troubleshooting effectively, you can minimize risks and ensure a safe and smooth laser cutting experience.

Conclusion

Congratulations! You’ve now unlocked the secrets to successful workflow and integration with laser cutter software. By following these 9 tips, you’ll be able to organize your files like a pro, navigate the software interface with ease, optimize settings for different materials, and even test and calibrate your laser cutter.

Don’t forget to utilize the software features to enhance efficiency and stay up to date with software updates and improvements. With these skills in your arsenal, you’ll be a laser cutting master in no time!